Manufacturers of cardboard boxes. Carton boxes

The production of cardboard boxes has been using the same technology for many years. But the equipment is constantly being improved. Our enterprise uses an automated line for the production of four valve corrugated boxes YKMB II+ and a rotary die-cutting line APSTAR HG 2 1628 with full-color printing. The process is divided into 10 stages:

Conditioning starting materials in a room with a temperature of at least 15 °C.

Unwinding of rolls and heating of materials on special rolls to increase the depth of penetration of glue into the paper layer.

Formation of a corrugated layer in a corrugated press.

Applying glue to the tops of the corrugations and gluing a flat layer of cardboard.

Applying glue in a gluing machine to the free corrugations and gluing the second flat layer (the process is repeated until the required number of layers is obtained).

Drying under strict temperature conditions.

Cooling.

Nesting, scoring and cutting into sheets of the required size.

Die-cutting blanks of the required cutting.

Assembly and gluing.

The equipment is controlled by computers and ensures the precise execution of all technological processes. We develop the design taking into account product parameters and marketing objectives. At the customer's request, we adapt standard samples from the FEFCO catalog. We add the necessary options to the already existing varieties of products - handles, windows, holders.

We produce cardboard products from three-layer and five-layer cardboard. At the same time, circulations from 500 pieces to large wholesale batches of industrial volume are possible. Delivery throughout Moscow and the region is carried out using the company’s own transport. We deliver products to the regions using transport companies. We carry out shipment strictly according to schedule.

Printing

We can apply up to 5 colors of full color printing on any box. The production of products with logos is carried out in the following several stages:

- preparation of die forms;

- production of flexographic forms;

- applying flexographic printing using a flexoform;

- cutting out the contour using a die.

Full color flexo printing will significantly increase your brand recognition. The UniTechUpak company will help you with this and will produce any corrugated cardboard product with full-color printing. The price of all our products consists of the cost of raw materials and payment for the manufacturing process.

The Central Printing House company produces cardboard boxes wholesale and offers many profitable solutions for various products. Our catalog contains models intended for clothing and shoes, souvenirs and gifts, perfumes and cosmetics, flowers, alcohol and much more. There is also a large selection of food packaging - confectionery, pizza, fish, fruit. Each buyer will definitely be able to choose the best option for the production of packaging boxes, depending on the characteristics and features of the goods, the requirements for transportation and storage.

Production of custom cardboard boxes of any complexity

When producing cardboard boxes, Central Printing House LLC uses modern equipment that allows us to create high-quality cardboard packaging in a short time. We have at our disposal specialized machines for processing corrugated cardboard, forming and gluing, applying images. We also produce self-assembled structures that do not require forming additional equipment or retaining materials.

Our production has a number of other advantages:

- Thanks to the automation of most processes, we produce large wholesale quantities of boxes in literally a week, and in some cases, in a few days. The timing depends on the complexity of the work and the need to use non-standard sizes.

- We can make custom boxes of any size and design for almost all types of products existing today.

- The corrugated cardboard we use meets the requirements of GOST, international standards and environmental regulations.

If you do not find a suitable option among the standard models offered, we will produce cardboard boxes in accordance with your individual requirements. Experienced specialists of Central Printing House will develop a design of a structure of any complexity with any number of edges.

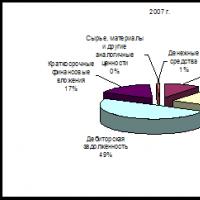

The cost of manufacturing cardboard boxes in bulk to order

A number of factors influence the formation of prices for the production of boxes. First of all, the cost depends on the raw materials and dimensions of the structures. Typically, for packaging boxes we use three-layer cardboard of two brands - T-23 and T-24, which differ in price and characteristics. Therefore, the products offered are in a wide range price range, thanks to which each buyer will be able to choose an option that suits him financially.

The production of boxes in Moscow to order is organized at the highest level, and we guarantee the highest quality of the products sold. Our packaging reliably protects goods during transportation, provides safe storage conditions and protection from external influences. If desired, you can apply almost any image, logo or name of your company to the surface to make your brand even more recognizable. To place an order, please call the numbers listed on the website, and we will do work of any complexity for you!

Advantages of TimPak-Production

- The variety of products we produce will significantly expand the scope of your choice, and the price-quality ratio will pleasantly surprise you. From us you can order regular and laminated corrugated cardboard boxes of any size and any complexity, thanks to the modern equipment that our workshops are equipped with. Making boxes to order is really convenient, since all production elements will be designed specifically for you.

- Also, having printing equipment, we are ready to offer you our services in applying images to packaging, subject to placing an order for production. We will quickly produce high quality products at affordable prices.

- We will fulfill both wholesale and small wholesale orders within the specified time frame. And our company’s specialists will help you when developing a design for printing on packaging.

- All products are subject to strict quality control and comply with technical specifications and state standards. You can also place an order with us for the production of cardboard packaging according to an individual order or according to a catalog international standards FEFCO.

Stages of production of boxes and cardboard packaging

The packaging production process consists of four stages. The first stage is design. The second stage is making the base. The third is printing on the surface of the package. And finally, the last one is the assembly of finished products.

1. Packaging design

The packaging design development stage assumes that, based on the size, weight of the product for packaging and the wishes of the customer, the designer will choose the type of cardboard, volume or dimensions boxes, shape and design features, external design, and determine the technology for assembling and manufacturing future packaging. At this stage, it is necessary to indicate the features of distribution, transportation and storage of boxes, as well as consider ways to dispose of used packaging.

Based on the type of construction, cardboard boxes are determined in various groups, such as:

Cardboard box "Lid - bottom"

A cardboard box of this design is an ideal option for packaging bed linen, expensive blankets and textile accessories. Thick cardboard is much less susceptible to deformation than plastic, which prevents the product from becoming wrinkled. Packed bed linen or a blanket in such a box acquires the status of an exclusive product. To save on packaging production, you can accentuate design elements on the lid, while it will be enough to make the bottom in a simple version.

Four valve box

This cardboard box is a classically produced box; it is used for packaging general consumer goods. This type of box can be made in almost any size.

Box type "Pack - pack"

The box has a low manufacturing cost. This includes various products and medications. Most often, packaging is intended for single use.

Box type "Tutu - dovetail"

Economical packaging for inexpensive goods. By the way, the production of such packaging is optimal in price if it is necessary to arrange the seal symmetrically. The special design of the self-assembling bottom allows the box to withstand significant weight.

2. Making the basis for the production of cardboard packaging

Packaging production standard sizes carried out on a conveyor belt. Exclusive cardboard boxes are made by hand.

Lamination is used to protect packaging from moisture. Matte and glossy films of various thicknesses are used. If it is partially necessary to demonstrate packaged products, small windows are cut out.

After the design is approved by the customer, a die form is put into production - a special tool that is used to cut out the base.

3. Printing cardboard boxes for packaging

On next stage pre-press preparation is in progress. Analyze color scheme On a specific type of cardboard, a color proof helps. Once the plotter layout is approved, production of the order begins.

Two technologies are used to print on packaging: lamination or offset printing.

For improvement appearance boxes, as well as protection from mechanical damage and moisture, use printing techniques such as embossing, varnishing, gluing and lamination.

For varnishing, depending on the budget allocated, water-dispersion, ultraviolet or offset varnish is used.

Relief protrusions on cardboard boxes are made by embossing, for which it is necessary to make a special cliche.

4. Assembling cardboard boxes

At the last stage of making boxes, die-cutting, creasing and gluing are done.

The cardboard is manually pressed along the fold lines. The die-cut is then used to automatically perform the die-cutting.

Depending on the design of the box, its gluing is done either manually or automatically.

The article will tell you how you can make it yourself and use a cardboard box. Here you will find templates and master classes on making boxes of different shapes.

A box is the easiest way to pack or hide something. The box can serve as an excellent means of storing things: jewelry, cards, small items and cosmetics. Of course, modern stores will provide you with a lot of options for boxes: large, small, curly, square, with lids, decorated and simple cardboard.

It is much more pleasant to create something with your own hands and decorate it the way you would like it and the way the product itself will correspond to the style of the holiday, room, or occasion. You can make a craft from absolutely any cardboard. The material can be purchased at a craft store (you will find a large selection of cardboard colors and textures), or you can use one that is often packaged in household appliances(refrigerators, for example, or washing machines).

For work you will need:

- Cardboard (as much as needed for your preferred size product).

- Hot glue (you can, of course, use any other glue, but hot glue is preferable due to its quick drying and strong bonding of the material).

- Template (with the help of it you can understand exactly how you should cut, bend and glue the material).

- Scissors and pencil - for marking and cutting. This is necessary to ensure that your product looks neat and aesthetically pleasing.

Flip Lid Box Template Flip Lid Box TemplateIMPORTANT: There are two main types of cardboard boxes with lids. One assumes the presence of a lid that covers the top of the box, the other - a lid that folds back, but is part of the box.

How to make a box with a lid step by step:

- Prepare all the supplies, print the template for the box on a printer or draw it in the exact proportions on cardboard.

- Cut out two elements from cardboard

- Start folding the dotted lines and gluing them carefully.

- Press the edges firmly to hold the material together.

- Let the product dry a little

- After drying, you can decorate the box to your liking.

Video: “Box: master class”

How to make a round cardboard box: diagram, template

A round cardboard box is a very beautiful and practical product that will always find its use. Having decorated it to your liking, you can store jewelry and jewelry, sewing and embroidery kits, cosmetics, clippings and much more inside.

Making a round cardboard box is a little more difficult than, for example, a square one. However, it is quite possible to “figure it out” with your own hands, without spending a lot of money on materials. Use thick cardboard and follow the template provided exactly; you can only change the size, but not the shape of the parts.

How to make a round cardboard box, templates:

Round Cardboard Box Template No. 1

Round Cardboard Box Template No. 1

What parts does a round cardboard box consist of: template No. 2

What parts does a round cardboard box consist of: template No. 2

In what order should the parts of a round box be glued together: template No. 3

In what order should the parts of a round box be glued together: template No. 3

Round cardboard box with handle: finished product

Round cardboard box with handle: finished product Video: “Gift box or casket made of cardboard: detailed master class”

How to make a heart box from cardboard?

A heart-shaped box is much more difficult to make than a round or square box. However, if you follow the tips and templates, you can easily create this beautiful piece.

A heart-shaped box is not only a storage box, it is an ideal packaging for giving a gift to a loved one. Such a box can be filled with many surprises: sweets, souvenirs, trinkets, gifts, keychains, flower petals, even butterflies can fit in it.

IMPORTANT: The heart box is in many ways similar to a round box, but here everything depends on the bottom: if it is proportional, then the whole product can look neat and even. The box has two bottoms: internal and external, the walls of the box are attached according to the principle of a round box.

Different templates for making a heart-shaped cardboard box:

Heart-shaped box template from one piece: template No. 1

Heart-shaped box template from one piece: template No. 1

Heart-shaped box template from one piece: template No. 2

Heart-shaped box template from one piece: template No. 2 Step-by-step work in photos:

Prepare identical hearts: two bottoms and a lid

Prepare identical hearts: two bottoms and a lid

Cover the bottom with the side of the box

Cover the bottom with the side of the box

Fix and wait until completely dry, make a lid

Fix and wait until completely dry, make a lid Video: “Heart-shaped box: master class”

How to make boxes from paper and cardboard?

Giving gifts in bags, cellophane wrappers and paper wrappers is no longer attractive and is considered a sign of “bad taste.” Your gift will look much more impressive in a paper or cardboard package that you glue and decorate yourself.

IMPORTANT: The size and shape of your box depends only on what exactly you will be giving. Heavier gifts require thick cardboard, but for small and light ones you can even glue a paper box together.

Boxes made of cardboard and paper, different templates:

Simple Rectangular Box: Template

Simple Rectangular Box: Template

Hinged Lid Box: Template

Hinged Lid Box: Template

Triangular box: template

Triangular box: template

Simple square box: template

Simple square box: template

Box-pouch: template

Box-pouch: template How to make a box from colored cardboard?

In a modern creativity store you will find a huge selection of cardboard:

- Kraft cardboard (solid sand-colored material)

- Colored cardboard

- Velvet cardboard

- Holographic cardboard

- Glitter cardboard

- Cardboard with prints, drawings and inscriptions

- Textured cardboard and much more

IMPORTANT: All this variety of choice allows you to create cardboard boxes of incredible beauty and use them for any purpose.

Cardboard for creativity

Cardboard for creativity Video: “How to make a cardboard box?”

How to make a cardboard box without a lid?

If you need to make a cardboard box without a lid, you should also use a template. This product is perfect for storing personal items: pencils, cosmetic brushes, hair accessories and much more.

Box template without lid

Box template without lid Video: “Do-it-yourself box without a lid using origami technique”

How to make a cardboard box for candy?

Boxes of chocolates don’t have to be bought in a store; you never know exactly what will be inside. It’s always nicer to make a box with your own hands, fill it with candy to your liking and give it to a loved one. This will not only be a “delicious” gift, but also very original and special.

Box with handles: template

Box with handles: template

Box with a butterfly: template

Box with a butterfly: template

Triangle box: pattern

Triangle box: pattern How to make a jewelry box from cardboard?

It is very convenient to store jewelry, jewelry and watches in a cardboard box. You can buy it or make it yourself, decorating it to your liking. If desired, you can make one or several sections inside the box.

A few tips and templates for making a flat cardboard box will help you make your own packaging of any size.

Template for flat box

Template for flat box Video: “DIY Flat Storage Box”

How to make a square box from cardboard?

A small square box can be used as a bomboniere or packaging for small surprises for your loved ones.

Simple square box template

Simple square box template How to make a triangular box from cardboard?

A triangular box can exist as a separate unusual package, or it can be part of a cake-shaped package.

Triangular box template

Triangular box template Do we decorate cardboard boxes with our own hands?

Decorating a homemade box depends only on how original and great your imagination is. The box should also be decorated based on the occasion (a holiday, for example, or the decor in the room).

How and with what you can decorate any cardboard box:

- Lace and fabric

- Satin ribbons

- Scoop and burlap

- Stickers and stickers

- Buttons and other accessories

- Sequins and stones

- Colored paper

- Kraft paper

- Drawings and inscriptions

Video: “5 ideas for decorating a box”

"GofroAlliance" is a manufacturer of certified packaging containers. Our company uses modern automated equipment and environmentally friendly raw materials. All products undergo multi-level quality control and meet standards. We accept orders for the supply of large and small quantities of products.

Product advantages

The production of cardboard boxes uses high demand in the field of trade. This is due to the advantages of this type of packaging.

Favorable price. The products are affordable in comparison with alternative types of packaging materials, which are made of wood, plastic, metal, etc. The use of cardboard boxes allows you to reduce the final cost of goods and make them more accessible to customers.

Ease. Packaging made from corrugated cardboard is relatively lightweight. Thanks to this, additional costs for transporting packaged goods are reduced and the process of transporting them is simplified.

Cardboard box processing technologies

When making packaging products, almost any image can be applied to the surface of cardboard, since the material is easy to process. This process is carried out using the following technologies.

Flexography.

This printing method involves the use of synthetic, quick-drying inks to create an original design for packaging products. In this case, special elastic polymer forms are used. Offset printing.

This technology is suitable for printing on thin sheet materials. The print quality will match the photo. Processing with synthetic film. If the packaging products will be used for storage or transportation food products with a high fat content, their facial or reverse sides

covered with polyethylene or a protective polymer emulsion. This helps prevent the appearance of greasy stains on the surface of the corrugated cardboard.

Varnishing.

In the process of manufacturing custom cardboard boxes, the surfaces of the products can be treated with a special varnish coating. This method allows you to enhance the gloss effect, increase the wear resistance of the packaging and improve its appearance. Our offer We produce boxes on favorable terms for you. In the catalog you can select products of the required sizes, depending on the purpose for which the packaging materials will be used. If necessary, we will produce custom-made cardboard boxes according to

individual project . Also, at the production stage, cardboard may undergo an additional reinforcement stage. This treatment will significantly increase the strength characteristics of the product and make it more resistant to external damage. For getting

additional information |

For the production of custom-made cardboard boxes in Moscow, contact our manager by phone listed on the website, or leave a request by email. |

|

Price per m 2 boxes in rubles, brown without printing

Did you like the article? Share it

Did you like the article? Share it We recommend articles on the topic

We recommend articles on the topic What does the name Victor mean for a boy?

What does the name Victor mean for a boy? Professional and personal qualities of a sales manager

Professional and personal qualities of a sales manager How to quit without working for two weeks, step-by-step instructions Why you need to work for 2 weeks when leaving

How to quit without working for two weeks, step-by-step instructions Why you need to work for 2 weeks when leaving Advances of modern natural science

Advances of modern natural science Job Description for Seller of Non-Food Products of Category I

Job Description for Seller of Non-Food Products of Category I