Siemens gas turbine plant. Our goal is to launch the production of Russian gas turbines. Turbine production dynamics in the Russian Federation

There are no more than ten enterprises producing gas turbines in our country. Ground equipment manufacturers based on gas turbines and even less. Among them are ZAO Nevsky Zavod, OAO Saturn - Gas Turbines and OAO Permsky motor plant»(Part of the UEC of the Rostec corporation).

All conditions have been formed in Russia for the rapid development of the gas turbine market for ground-based applications, according to EnergyLand.info analysts. The need for distributed generation, based not on diesel fuel, but on cleaner sources, is becoming more and more urgent. There are almost no doubts about the efficiency of combined-cycle plants.

However, there are no more than ten enterprises producing gas turbines in our country. There are even fewer manufacturers of ground equipment based on gas turbines.

In the Soviet Union, the stake was placed on coal, oil and other heating sources. Therefore, the first gas turbines were not produced until the 1950s. And primarily in relation to aircraft construction.

In the 1990s, the development of power gas turbines began on the basis of engines developed by NPO Saturn for aircraft.

Today, OJSC Saturn - Gas Turbines is engaged in the production of ground power equipment based on NPO Saturn engines. Perm Motor Plant has mastered the production of gas turbine power plants based on the developments of Aviadvigatel OJSC.

At the same time, the nominal capacity of serial products of these enterprises does not exceed 25 MW on average. There are several machines with a unit capacity of 110 MW based on the NPO Saturn developments, but today they are still being fine-tuned.

Large turbines are supplied mainly foreign companies... Russian enterprises are striving to enter into cooperation with world leaders.

However, not all world leaders are interested in organizing the production of gas turbines in Russia. One of the reasons is the unstable demand for products. And he, in turn, largely depends on the level of energy consumption. Since 2010, energy consumption in Russia has grown steadily. But soon, according to experts, stagnation may come. And the increase in demand in 2013-2014 will be only about 1% per year or even less.

According to Dmitry Solovyov, Deputy Chief Designer of OJSC Saturn - Gas Turbines, similar reasons keep Russian companies from mastering the production of high-capacity gas turbines. “For the production of powerful gas turbine units(GTU) needs special equipment, large-diameter machine tools, vacuum welding installations with chambers of the order of 5 by 5 m, - he says. - To create such a production, you need to be confident in the sales market. And for this, the country should have a long-term program for the development of energy, perhaps then enterprises will start investing in the modernization of the base. "

However, the lack of predictable prospects does not mean that there is no demand at all. There is certainly a demand. Both for turbines with a capacity of more than 150 MW, and for small gas turbines that require less capital expenditures, but quite cope with the issues of increasing energy efficiency and payback.

The growth of the sales market may be due to the development of regional energy and the commissioning of generating facilities of medium capacity. And gas turbines with a capacity of 4, 8, 16, 25 MW are the segment in which they mainly operate Russian manufacturers who have already felt the market trend.

In developed countries, small cogeneration units are commonplace. In Russia, their number is still significantly lower. The main difficulty for companies supplying low-power turbines is the lack of solvency of potential customers.

Another, traditional segment of the gas turbine market is generating facilities at oil and gas fields and main gas pipelines. Gas turbine power plants make it possible to efficiently utilize associated petroleum gas, solving not only the problem of energy supply, but also the rational use of hydrocarbon resources.

According to the observations of the specialists of OAO Saturn - Gas Turbines, in the pre-crisis 2006-2008 there was a surge in oilmen's interest in domestic gas turbines. Today this demand is at a stable level.

Modern trends in the improvement of gas turbines are largely associated with innovations for the oil industry. But not only. The challenges facing the manufacturers:

- increase in efficiency,

- reduction of the number of units in the turbine,

- increased reliability,

- reduction of the volume of maintenance,

- reduction of downtime during technical condition diagnostics.

The above can solve the problem of high costs. service.

In addition, the designers of turbines strive to make them unpretentious to the gas used and the ability to work on liquid fuel.

And in the West they are also worried about the fact that, regardless of the composition of the gas, the turbine has good environmental characteristics.

A very important - promising - direction of improving GTU is associated with renewable energy sources (RES) and the prospects for the introduction of "smart grids". Initially, gas turbines were designed to provide constant power output. However, the introduction of renewable energy sources into the energy system automatically requires flexibility from other generation facilities. This flexibility makes it possible to ensure a stable level of power in the network when there is insufficient renewable energy production, for example, on calm or cloudy days.

Accordingly, a turbine for a smart power system must easily adapt to changes in the network and be designed for regular starts and stops without loss of resource. This is not possible with traditional gas turbines.

Abroad, certain successes in this direction have already been achieved. For example, the new FlexEfficiency gas turbine is capable of reducing power from 750 MW to 100 MW and then picking up baseline in 13 minutes, and when used with solar power plants will have an efficiency of up to 71%.

Nevertheless, for the foreseeable future, the most common use of gas turbines will still remain their usual combination with steam turbines as part of combined cycle plants. In our country, the market for such cogeneration facilities is by no means full and is waiting for saturation.

United Engine Corporation (UEC)- a company that includes more than 85% of the assets of Russian gas turbine equipment. An integrated structure producing engines for military and civil aviation, space programs, installations of various capacities for the production of electrical and thermal energy, gas pumping and ship gas turbine units. In total, the UEC employs over 70 thousand people. The company is headed by Vladislav Evgenievich Masalov.

A gloating article appeared in the Western press that the construction of new power plants in Crimea actually stopped due to Western sanctions - after all, we seem to have forgotten how to make turbines for power plants ourselves and bowed to Western companies, which are now forced to wind down their deliveries and thus leave Russia without turbines for energy.

"The project envisaged the installation of Siemens turbines at the power plants. However, in this case, this German engineering company risks violating the sanctions regime. Sources say that in the absence of turbines, the project faces serious delays. Officials Siemens have always said that they do not intend to implement supply of equipment.

Russia studied the possibility of acquiring turbines from Iran, making changes to the project for the installation of turbines Russian production, as well as the use of Western turbines, previously acquired by Russia and already located on its territory. Each of these alternatives poses specific challenges, which, according to sources, prevents officials and project leaders from agreeing on how to move forward.

This story demonstrates that, despite official denials, Western sanctions still have a real negative impact on the Russian economy. It also sheds light on the decision-making mechanism under Vladimir Putin. It is about the propensity of high-ranking officials, according to sources close to the Kremlin, to make grandiose political promises that are almost impossible to implement. "

"Back in October 2016, the company representatives at a briefing in Munich said that Siemens excludes the use of its gas turbines at TPPs in Crimea. We are talking about gas turbines that were produced in Russia at the Siemens gas turbine technology plant in St. Petersburg, which was put into operation in 2015.The shares of participation in this company are distributed as follows: Siemens - 65%, Power machines- beneficiary A. Mordashov, - 35%. The plant is to supply Technopromexport with 4 combined cycle gas turbines (CCGT) with a capacity of 235 MW with gas turbines of 160 MW, moreover, a TPP in Taman is indicated in the contract signed in the spring of 2016 ".

In fact, it so happened that since the times of the USSR, the production of gas turbine units for power plants was concentrated at 3 enterprises - in the then Leningrad, as well as in Nikolaev and Kharkov. Accordingly, during the collapse of the USSR, Russia was left with only one such plant - LMZ. Since 2001, this plant has been manufacturing Siemens turbines under license.

“It all started in 1991, when a joint venture was created - then LMZ and Siemens - to assemble gas turbines. An agreement was signed on the transfer of technologies to the then Leningrad Metal Plant, which is now part of OJSC Power Machines. joint venture 19 turbines were assembled in 10 years. Over the years, LMZ has accumulated production experience, so that these turbines learn not only to assemble, but also to make some components on their own. Based on this experience, in 2001 a licensing agreement was concluded with Siemens for the production, sales and after-sales service of turbines of the same type. They received the Russian marking GTE-160 ".

It is not clear where their developments, which were successfully produced there during the previous 40 years, have gone. As a result, the domestic power engineering industry (gas turbine engineering) was left behind. Now I have to begging overseas in search of turbines. Even in Iran.

"Rostec Corporation has reached an agreement with the Iranian company Mapna, which produces German gas turbines under Siemens license. Thus, gas turbines manufactured in Iran according to drawings of German Siemens can be installed on new power plants in Crimea."

Tests of the first large-capacity gas turbine in Russia have been suspended due to an accident. This will delay the start of its production and require new investments - Power Machines may join the project as an investor

Gas turbine unit GTD-110M (Photo: Russian Engineering Union)

Tests of the first large-capacity gas turbine in Russia, GTD-110M (up to 120 MW), have been stopped due to faulty mechanisms, the TASS agency reported. This was confirmed to RBC by representatives of the Gas Turbine Technologies Engineering Center, which conducted the tests, and two of its shareholders - Rusnano and the United Engine Corporation (UEC) Rostec.

“During the test tests of the GTD-110M gas turbine unit, an accident occurred, as a result of which the turbine was indeed damaged,” a representative of the Gas Turbine Technologies Research Center told RBC. The purpose of the tests was to identify design flaws in order to avoid serious incidents in the process industrial exploitation in the power system, he added. The UEC representative clarified that a number of mechanisms went out of order in December 2017, so the tests had to be stopped until the problems were eliminated.

The development of its own high-power turbine in Russia has been going on for a long time, but without much success, and in 2013 the subsidiary of UEC UEC-Saturn signed an investment agreement with Rusnano and Inter RAO to create a new generation turbine - GTD-110M, which was developed by the Gas Turbine Technologies Research Center. Inter RAO received 52.95% in this project, the Fund for Infrastructure and educational programs Rusnano - 42.34%, UEC-Saturn - 4.5%, the remaining 0.21% belongs to the non-profit partnership CIET. Rusnano was supposed to finance the project and contribute 2.5 billion rubles to the authorized capital, wrote Interfax in 2013, citing a source close to one of the parties. The corporation participated in financing the project, confirms its representative. According to SPARK, the authorized capital of the engineering center is 2.43 billion rubles. In 2016, Gas Turbine Technologies also received a subsidy from the Ministry of Industry and Trade of 328 million rubles. for partial compensation of R&D costs in priority areas, follows from the data of the system.

Sanction turbines

Russia is in dire need of a large-capacity domestic gas turbine. Last year due to lack of own technologies Despite the sanctions, Rostec's subsidiary Technopromexport was forced to install German Siemens turbines at new power plants in Crimea, which led to an international scandal. Siemens announced the suspension of work with Russian state-owned companies, and Technopromexport, as well as its head Sergei Topor-Gilka and two officials of the Ministry of Energy - Andrei Tcherezov and Yevgeny Grabchak - came under European and American sanctions.

It was planned that the tests would be completed in 2017, but then this period was postponed by six months - to the middle of 2018, for this year it was also planned to launch the equipment into serial production, recalls

In August 2012, our country became a member of the World trade organization(WTO). This circumstance will inevitably lead to increased competition in domestic market power engineering. Here, as elsewhere, the law applies: "change or die." Without revising technologies and without deep modernization, it will be almost impossible to fight the sharks of Western engineering. In this regard, the issues related to the development of modern equipment operating as part of combined cycle gas turbines (CCGT) are becoming more and more urgent.

In the past two decades, combined-cycle technology has become the most popular in the world energy sector - it accounts for up to two-thirds of all generating capacities commissioned on the planet today. This is due to the fact that in combined cycle plants the energy of the combusted fuel is used in a binary cycle - first in a gas turbine, and then in a steam one, and therefore a CCGT is more efficient than any thermal power plants (TPP) operating only in a steam cycle.

Currently, the only area in the thermal power industry in which gas turbine manufacturers from Russia are critically behind the world's leading manufacturers is high-capacity gas turbines - 200 MW and above. Moreover, foreign leaders not only mastered the production of gas turbines with a unit capacity of 340 MW, but also successfully tested and use a single-shaft CCGT unit, when a gas turbine with a capacity of 340 MW and a steam turbine with a capacity of 160 MW have a common shaft. This arrangement can significantly reduce the construction time and cost of the power unit.

The Ministry of Industry and Trade of Russia in March 2011 adopted the "Strategy for the Development of Power Engineering Russian Federation for 2010–2020 and for the future until 2030 ”, according to which this direction in the domestic power engineering industry receives solid support from the state. As a result, by 2016, the Russian power engineering industry should carry out industrial development, including full-scale tests and revision at its own test benches, improved gas turbine plants (GTU) with a capacity of 65-110 and 270-350 MW and combined-cycle plants (CCGT) at natural gas with an increase in their efficiency (efficiency) up to 60%.

Moreover, gas turbine manufacturers from Russia are able to produce all the main units of a CCGT unit - steam turbines, boilers, turbine generators, but a modern gas turbine is not yet available. Although back in the 70s, our country was a leader in this direction, when the super-supercritical parameters of steam were mastered for the first time in the world.

In general, as a result of the implementation of the Strategy, it is assumed that the share of power unit projects using foreign main power equipment should be no more than 40% by 2015, no more than 30% by 2020, and no more than 10% by 2025. ... It is believed that otherwise there may be a dangerous dependence of the stability of the unified energy system of Russia on the supply of foreign components. During the operation of power equipment, it is regularly required to replace a number of units and parts operating at high temperatures and pressures. At the same time, some of these components are not produced in Russia. For example, even for the domestic gas turbine GTE-110 and the licensed GTE-160, some of the most important units and parts (for example, discs for rotors) are purchased only abroad.

In our market, such large and advanced concerns as Siemens and General Electric are actively and very successfully operating, which often win tenders for the supply of power equipment. There are already several generating facilities in the Russian energy system, to one degree or another equipped with the main energy equipment produced by Siemens, General Electric, etc. However, their total capacity does not yet exceed 5% of the total capacity of the Russian energy system.

However, many generating companies that use domestic equipment when replacing it still prefer to contact firms with which they are accustomed to working for more than a decade. This is not just a tribute to tradition, but a justified calculation - many Russian companies have carried out a technological renovation of production and are fighting on an equal footing with the world's power machine-building giants. Today we will talk in more detail about the prospects for such large enterprises as OJSC Kaluga Turbine Plant (Kaluga), CJSC Ural Turbine Plant (Yekaterinburg), NPO Saturn (Rybinsk, Yaroslavl Region), Leningrad Metal Plant (St. Petersburg) , Perm Engine-Building Complex (Perm Territory).

How to check Internet speed - online connection test on a computer and phone, SpeedTest, Yandex and other meters

How to check Internet speed - online connection test on a computer and phone, SpeedTest, Yandex and other meters Program for the presentation of prezi in Russian

Program for the presentation of prezi in Russian From the cycle Useful garden dwellers

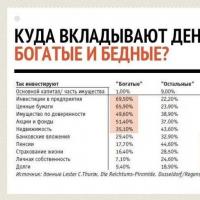

From the cycle Useful garden dwellers Striving for instant benefits

Striving for instant benefits Zebra finches - honest advice to owners

Zebra finches - honest advice to owners Borreliosis of birds (spirochetosis, treponemosis) (borreliosis)

Borreliosis of birds (spirochetosis, treponemosis) (borreliosis) What to do in case of unsuccessful attempts to find a job

What to do in case of unsuccessful attempts to find a job