Protection against ultrasonic noise. Protection from noise and ultrasound. Personal noise protection equipment. Ultrasound protection Personal protective equipment against ultrasound

Prevention of the adverse effects of ultrasound and the accompanying noise on the body of workers should first of all be reduced to minimizing the intensity of ultrasonic radiation and the duration of action. Therefore, when choosing an ultrasound source for carrying out a particular technological operation, you should not use powers that exceed those required for their implementation; they need to be turned on only for the period of time required to complete this operation.

Ultrasound installations and their individual components (high-frequency current generators, magnetostrictive transducers, baths) must be soundproofed as much as possible by enclosing them in shelters, isolating them in separate cabins or rooms, covering them with soundproofing material, etc. If complete sound insulation is not possible, partial insulation is used, and Also

sound-absorbing screens and coatings. Due to the special danger of contact irradiation with ultrasound technological process ultrasonic treatment should completely eliminate the possibility of such an effect or, at least, reduce it to a minimum.

Baths for ultrasonic treatment should be covered with a soundproofing layer on all external surfaces and covered with soundproofing lids during operation. When opening baths to load, unload or change the position of workpieces, the ultrasonic unit must be turned off. It is advisable to block the opening of the bathtub lid with turning off the installation. If it is impossible to completely turn off the ultrasonic units, load parts into the bath in a special metal mesh or basket, and the handles of this basket should not come into contact with the walls of the bath, and especially with the liquid. To change the position of the processed products, the mesh (basket)

gets out of the bath.

Installation, rotation and removal of parts in machines for contact ultrasonic processing are also carried out when the machine is turned off. If it is impossible to turn off the installation, these operations are performed with special tongs. Metal and plastic shields are used as reflective screens to prevent the propagation of ultrasonic vibrations.

The most common personal protective equipment when working with ultrasound is noise protection and gloves. It is advisable to have the latter in two layers: rubber on the outside and cotton or wool on the inside; they absorb vibrations better and are waterproof.

If initial signs of the adverse effects of ultrasound on the body of workers are identified, it is necessary to temporarily stop working in contact with ultrasound ( another vacation, transfer to another job), which leads to the rapid disappearance of symptoms of exposure.

All newly hired ultrasound workers are subject to a mandatory preliminary medical examination, and subsequently to periodic medical examinations at least once a year.

Human exposure to electromagnetic radiation

Fields and radiation.

Electromagnetic fields(EMF) in the environment is created by power lines, electrical equipment, electrical appliances - everything technical systems, generating, transmitting and using electromagnetic energy.

The effect of EMF on the human body is determined by the frequency of radiation, its intensity, duration, individual characteristics body.

Long-term exposure to industrial frequency EMF (50 Hz) causes headaches, lethargy, memory loss, sleep disturbances, increased irritability, heart pain, etc.

It is necessary to limit the time spent in the coverage area.

Electromagnetic radiation.

Most of the non-ionizing EMR spectrum consists of radio waves, the smaller part is fluctuations in the optical range: infrared radiation(IR), visible, ultraviolet radiation(UV).

EMR radio frequencies are widely used in communications, television and radio broadcasting, medicine, radar, flaw detection, etc.

The impact of EMR radio frequencies on the body is determined by the energy flux density, radiation frequency, duration of exposure, size of the irradiated surface, individual characteristics of the body, etc.

The consequence of the absorption of EMR energy by the human body is an increase in the temperature of the organs. Exposure to EMR is especially harmful to the eyes and skin. For example, exposure to eye radiation can lead to clouding of the lens (cataracts), and possible burns to the cornea.

With prolonged exposure to EMR (above the maximum limit), disorders in the central nervous system, changes in metabolism, blood composition are possible, hair loss, brittle nails, and weight loss may occur. When emergency situations exposure to EMR is accompanied by cardiovascular disorders with fainting, increased heart rate and decreased blood pressure.

The impact of EMR of the optical range: infrared, visible (light), ultraviolet radiation on humans is not fundamentally different. The energies cause a thermal effect in the most affected organ – the skin and eyes.

In case of acute skin damage, burns and eye damage are possible.

When exposed to infrared radiation (with chronic irradiation), a sharp expansion of capillaries occurs, increased skin pigmentation - red complexion in workers: glassblowers, steelworkers, etc.

Visible (light) radiation from a nuclear explosion, for example, leads to burns of exposed skin and temporary blindness.

UV radiation is a vital factor that has a beneficial stimulating effect on the body. Optimal doses of UVR activate the activity of the heart and metabolism. The eye is most vulnerable to UV radiation. Effects on the skin: inflammation with redness, blisters, fever, chills, headache. UVR accounts for approximately 5% of solar radiation flux density. However, atmospheric pollution reduces its transparency for ultraviolet radiation.

UVR from artificial sources (for example, electric welding arcs) can cause acute and chronic prof. defeats.

Laser radiation(LI) – special kind AMY. The difference between LR and other types of EMR lies in the monochromatic nature (waves of strictly the same length) and the sharp direction of the beam.

There are direct, scattered, and specularly reflected laser radiation.

The degree of exposure to radiation on the body depends on the intensity of the radiation and the time of exposure. When the eyes are irradiated, the cornea and lens are easily damaged (heating the lens leads to the formation of cataracts). Skin damage can range from redness to charring.

According to the degree of radiation danger, lasers are divided into completely safe and dangerous. Lasers are used in communication systems, metal processing technology, medicine, control and measuring technology, military equipment and other areas.

Related information.

Ultrasound - acoustic vibrations of air or other elastic medium with a frequency above 20,000 Hz, inaudible to the human ear. Low-frequency ultrasound (up to 100 kHz), propagating by air and contact, is used in mechanical engineering and metallurgical industry for cleaning, disinfection, crushing and processing of materials; in medicine for cutting tissue, pain relief, sterilization of instruments, medical personnel’s hands and various objects; high-frequency ultrasound (from 100 kHz to 100 MHz and above), propagating only by contact, is used for flaw detection of castings, welds, and in medicine for the diagnosis and treatment of various diseases (spine, joints, etc.) The therapeutic and preventive stimulating effect of ultrasound occurs at ultrasound intensity levels not exceeding 80-90 dB.

Compared to high-frequency noise, ultrasound has a weaker effect on auditory function, but causes pronounced deviations on the part of the vestibular apparatus. Those working with ultrasound equipment may experience occupational pathology in the form of asthenic conditions or asthenovegetative syndrome with dysfunction of the cardiovascular system, and when hands come into contact with sound environment - disorders of the neurovascular system of the hands. With prolonged and intense (120 dB and above) exposure to ultrasound, destruction of bone tissue is observed. Destruction of the bone structure in the growth zone and especially at the tissue interface (bone - periosteum) occurs even under the influence of moderate doses of ultrasound.

The ultrasonic effect on the worker’s body is due to the thermal effect (conversion of ultrasound energy into thermal energy) and mechanical “cavitation” effect (compression and stretching of tissues, resulting in variable acoustic pressure).

Prevention: application of remote control of ultrasound sources; use of sound-absorbing casings and screens of the generator, cable and ultrasound transducer; parts for ultrasonic cleaning should be immersed in baths in nets with handles with vibration-isolating coatings; organize two regulated breaks: 10 minutes after 1 - 1.5 hours from the start of work before and 15 minutes 1.5 - 2 hours after the lunch break; after work - hand massage, thermal (37-38°C) water procedures, ultraviolet irradiation; use of personal protective equipment - oversleeves, mittens or gloves (outer rubber and inner cotton) and noise protection; introduction to diet or intake additional quantities vitamins C and group B; conducting preliminary and annual periodic medical examinations working. Ultrasound remote control in production conditions should not exceed 110 dB

Ultrasound is assessed based on its two main parameters: vibration frequency and sound pressure level. Oscillation frequency, like noise and vibration, is measured in hertz or kilohertz (1 kHz equals 1000 Hz). The intensity of ultrasound propagated in air and gas, as well as noise, is measured in decibels. The intensity of ultrasound propagated through a liquid or solid medium is usually expressed in units of power of oscillations emitted by a magnetostrictive transducer per unit of irradiated surface - watt per square centimeter (W/cm 2).

When propagating in a liquid medium, ultrasound causes cavitation of this liquid, that is, the formation of tiny empty bubbles in it (due to its periodic compression and rarefaction under the influence of ultrasonic vibrations), immediately filled with vapors of this liquid and substances dissolved in it, and their compression (collapse). This process is accompanied by the formation of noise.

Ultrasonic vibrations directly at the source of their formation propagate directionally, but already at a short distance from the source (25 - 50 cm), these vibrations turn into concentric waves, filling the entire working room with ultrasound and high-frequency noise.

When working on ultrasonic installations of significant power, workers complain of headaches, which, as a rule, disappear after finishing work; unpleasant noise and squeaking in the ears (sometimes to the point of pain), which persist even after finishing work; fatigue, sleep disturbance (usually drowsiness during the day), sometimes weakened vision and a feeling of pressure on the eyeball, poor appetite, dry mouth and stiff tongue, abdominal pain, etc. When examining these workers, they reveal some physiological changes during work , expressed in a slight increase in body temperature (by 0.5 - 1.0 o) and skin (by 1.0 - 3.0 o), a reduction in pulse rate (by 5 - 10 beats per minute), a decrease in blood pressure - hypotension ( the maximum pressure is up to 85 - 80 mm Hg, and the minimum - up to 55 - 50 mm Hg), somewhat slow reflexes, etc. Workers with extensive experience sometimes exhibit individual health abnormalities, that is, clinical manifestations: emaciation (weight loss up to 5-8 kg), persistent appetite disorder (aversion to food up to nausea or insatiable hunger), disturbance of thermoregulation, innervation of the hands (dulling of skin sensitivity), decreased hearing and vision, disorder of glandular function internal secretion etc. All these manifestations should be regarded as the result of the combined action of ultrasound and the accompanying high-frequency noise. At the same time, contact irradiation with ultrasound causes faster and more pronounced changes in the body of workers than exposure through the air. As the experience of working with ultrasound increases, the phenomena of its adverse effects on the body also increase. Individuals with up to 2-3 years of experience working in these conditions usually rarely show any pathological changes, even with intense doses of ultrasound exposure. In addition, the degree of adverse effects of ultrasound depends on its intensity and duration of exposure, both single and total for a work shift.

Prevention of the adverse effects of ultrasound and the accompanying noise on the body of workers should first of all be reduced to minimizing the intensity of ultrasonic radiation and the duration of action. Therefore, when choosing an ultrasound source for carrying out a particular technological operation, you should not use powers that exceed those required for their implementation; they need to be turned on only for the period of time required to complete this operation.

Ultrasound installations and their individual components (high-frequency current generators, magnetostrictive transducers, baths) must be soundproofed as much as possible by enclosing them in shelters, isolating them in separate cabins or rooms, covering them with soundproofing material, etc. If complete sound insulation is not possible, partial insulation is used, and also sound-absorbing screens and coatings.

Due to the special danger of contact irradiation with ultrasound, the technological process of ultrasonic treatment should completely eliminate the possibility of such exposure or, at least, reduce it to a minimum.

Baths for ultrasonic treatment should be covered with a soundproofing layer on all external surfaces and covered with soundproofing lids during operation. When opening baths to load, unload or change the position of workpieces, the ultrasonic unit must be turned off. It is advisable to block the opening of the bathtub lid with turning off the installation. If it is impossible to completely turn off the ultrasonic units, load parts into the bath in a special metal mesh or basket, and the handles of this basket should not come into contact with the walls of the bath, and especially with the liquid. To change the position of the processed products, the mesh (basket) is removed from the bath.

Installation, rotation and removal of parts in machines for contact ultrasonic processing are also carried out when the machine is turned off. If it is impossible to turn off the installation, these operations are performed with special tongs. Metal and plastic shields are used as reflective screens to prevent the propagation of ultrasonic vibrations.

The most common personal protective equipment when working with ultrasound is noise protection and gloves. It is advisable to have the latter in two layers: rubber on the outside and cotton or wool on the inside; they absorb vibrations better and are waterproof.

If initial signs of the adverse effects of ultrasound on the body of workers are identified, it is necessary to temporarily stop working in contact with ultrasound (another vacation, transfer to another job), which leads to the rapid disappearance of symptoms of exposure.

All newly hired ultrasound workers are subject to a mandatory preliminary medical examination, and subsequently to periodic medical examinations at least once a year.

Ultrasonic vibrations are vibrations with f = 20 kHz. Ultrasound has the same nature as sound.

Ultrasound sources: equipment that generates ultrasonic vibrations to perform technological operations(cleaning and neutralization of parts, flaw detection, welding, drying, technical control) and equipment where ultrasound occurs as a contributing factor.

Ultrasonic vibrations are divided into:

1) low-frequency f 100 kHz (propagation by air and contact) pronounced changes in the state of the nervous, cardiovascular, endocrine systems, metabolism and thermoregulation;

2) high frequency 100 kHz f 1000000 kHz

Ultrasound with a frequency of 1000 MHz propagates by contact. Here there is a local effect on the human body upon contact with media in which ultrasonic vibrations propagate (ultrasonic vibrations).

Exposure to ultrasonic energy of 6 7 W/cm2 can lead to damage to the peripheral nervous and vascular apparatus at the site of contact (for example, exposure to hands when loading and unloading parts from an ultrasonic bath).

A characteristic of ultrasonic vibrations is the sound pressure level Ly in third-octave bands.

For ultrasound transmitted by contact, the peak value of vibration velocity is normalized.

Ultrasound protection. Apply the following types Ultrasound protection: 1) remote control, 2) automatic blocking when performing auxiliary operations (loading and unloading parts, etc.), source shielding.

Mittens and gloves are used as PPE (for hands).

Ultrasound level control: Measurements are carried out at control points at a height of 1.5 m from the floor, at a distance of 0.5 m from the equipment contour and at least 2 m from the circumferential surfaces. Measurements are carried out at no less than 4 control points along the equipment contour, and the distance between the points is no more than 1 m.

To measure L (sound pressure levels) in air, equipment is used, consisting of a measuring microphone, an electrical circuit with a linear characteristic, a third-octave filter and a measuring device with standard time characteristics.

In the zone of contact with the solid medium, there is a measuring path consisting of a sensor, a laser interferometer, an amplifier, and a signal processing circuit.

Measurements are carried out in the zone of maximum vibration amplitudes.

According to GOST 12.1.001-75, permissible sound pressure levels at workplaces are established: (GOST 12.1.001-75. Ultrasound. General requirements security. 1982).

For frequency bands with a geometric mean frequency of 12500 Hz, the sound pressure level is 75 dB; for 16000 Hz - 85, for 20000 and above - 110 dB.

Hygienic standardization of air and contact ultrasound. When developing effective preventive measures aimed at optimizing and improving the working conditions of ultrasonic workers, the issues of hygienic standardization of ultrasound as an unfavorable physical factor in the working environment and habitat are put in the first place.

Materials conducted at the State Research Institute of Occupational Medicine of the Russian Academy of Medical Sciences comprehensive research served as the basis for the development new system hygienic regulation of ultrasound, which is reflected in sanitary norms and rules " Hygienic requirements when working with sources of airborne and contact ultrasound for industrial, medical and household purposes.”

Sanitary norms and rules establish the hygienic classification of ultrasound affecting the human operator; standardized parameters and maximum permissible levels of ultrasound for workers and the population; requirements for control of air and contact ultrasound, preventive measures. It should be noted that these rules and regulations do not apply to persons (patients) exposed to ultrasound for diagnostic and treatment purposes.

Table 12.3. The likelihood of developing polyneuropathy of the hands working with sources of contact ultrasound propagating in liquid and solid media

Standardized parameters air ultrasound are the sound pressure levels in decibels in one-third octave bands with geometric mean frequencies of 12.5; 16; 20; 25; 31.5; 40; 50; 63; 80; 100 kHz.

Standardized parameters contact ultrasound are the peak values of vibration velocity or its logarithmic levels in dB in octave bands with geometric mean frequencies 16; 31.5; 63; 125; 250; 500; 1000; 2000; 4000; 8000; 16,000; 31,500 kHz, determined by the formula:

L v = 20 logV/V0,

V - peak value of vibration velocity, m/s;

V0 is the reference value of vibration velocity, equal to 5?10 -8 m/s.

IN table 12.4 The maximum permissible levels of airborne ultrasound in workplaces and contact ultrasound in areas of contact of hands or other parts of the body working with sources of ultrasonic vibrations or the media in which they propagate are presented.

The new standards are based on the spectral principle, taking into account the combined effects of contact and airborne ultrasound by establishing a reduction correction equal to 5 dB to the MPL of contact ultrasound, which has higher biological activity.

When using ultrasonic sources for household purposes (washing machines, devices for repelling insects, rodents, dogs, security alarm etc.), usually operating at frequencies below 100 kHz, the standard levels of airborne and contact ultrasound affecting humans should not exceed 75 dB at the operating frequency.

In addition to sanitary rules and regulations, a number of normative and methodological documents have been developed, regulating, in particular, the working conditions of health workers using ultrasonic sources in the form of equipment, equipment or instruments.

Table 12.4. Maximum permissible levels of ultrasound in workplaces

Note. 1 The maximum permissible levels of contact ultrasound should be taken 5 dB below the tabulated data when workers are exposed to air and contact ultrasound together.

ultrasound diagnostics, organization and conduct of diagnostic studies, as well as sanitary, hygienic and medical preventive measures to limit the adverse effects of contact ultrasound on medical staff. For example, in accordance with hygienic recommendations, the area of the room for ultrasound examinations (ultrasound) should be at least 20 m2, provided that one ultrasound diagnostic unit is placed in it. The room for performing ultrasound must have a natural and artificial lighting, a sink with cold and hot water supply, a general supply and exhaust ventilation system with an air exchange rate of 1:3, installation of air conditioners is allowed. In the room, certain microclimate parameters should be maintained: air temperature - 22? C, relative humidity 40-60%, air speed no higher than 0.16 m/s.

When measuring airborne and contact ultrasound generated by household appliances and equipment, the following guidelines must be followed:

comply with the requirements set out in the current sanitary norms and rules.

Preventive actions. Measures to protect workers from the adverse effects of contact ultrasound and related factors in the working environment and labor process include:

1. Medical and biological screening when hiring, taking into account subjective (individual) and objective (occupational) risk factors.

2. Application of various labor modes (shift and rotating weekly, ten-day, monthly, quarterly, etc.) and contract system carrying out work for the period of the predicted duration of safety of work experience.

3. Hygienic, including exposure, and clinical and physiological monitoring.

4. Medical and preventive measures to improve the health of workers.

When applying for a job, it is advisable to carry out medical and biological screening in several stages:

Stage I- social selection. According to current hygienic standards and rules, the main contraindication for working under conditions of exposure to ultrasound is age under 18 years.

Stage II - medical selection, including a preliminary medical examination and functional studies, taking into account the specifics of the action of contact ultrasound and risk factors (both identified individual and specific professional-production ones established during certification or licensing of the workplace for which employment is expected).

A preliminary medical examination is carried out in accordance with the current order. When conducting preliminary medical examinations, one should take into account contraindications for work in “ultrasonic” professions, which include, along with general medical contraindications for admission to work in contact with harmful, dangerous substances and production factors include chronic diseases of the peripheral nervous system, obliterating arterial diseases and peripheral vasospasm.

In addition to medical contraindications, individual and objective risk factors that can aggravate the effects of contact ultrasound have been identified. Subjective (personal) risk factors include a hereditary burden of vascular diseases, an asthenic type of constitution, cold allergies, a history of limb injuries and frostbite, autonomic lability, mainly with a predominance of the tone of the sympathetic nervous system, long work experience in the profession, etc.

Objective or occupational risk factors are high levels of contact and airborne ultrasound, transmission of ultrasonic vibrations through a liquid medium, large area of contact with the source, contamination of hands with contact lubricants, cooling of hands, high ultrasonic index of sources, static load on the muscles of the fingers and hands, forced posture, cooling microclimate, high levels of the total index of single-digit assessment of the complex impact of factors, etc.

Of great importance in the prevention of ultrasonic exposure are rational work regimes established for a specific workplace or vibration source. When developing work regimes, you must be guided by the following principles:

Reducing the total contact time and reducing exposure to ultrasonic sounding when standards are exceeded;

Carrying out work with regularly interrupted ultrasonic influences;

Organization of two regulated breaks, the first - lasting 10 minutes, the second - 15 minutes for active recreation, special complex industrial gymnastics, physio-prophylactic procedures, etc. It is rational to arrange the first break 1.5-2 hours after the start of the shift, the second - 1.5 hours after the lunch break;

Lunch break of at least 30 minutes. In addition to shift work schedules, it is advisable to introduce sliding schedules - weekly, ten-day, monthly, quarterly, etc. These modern forms of labor regimes are most suitable for medical workers, when the ultrasonic load on workers, exceeding the permissible one, can be evenly spaced over time.

Measures aimed at increasing the body's resistance, including when exposed to contact ultrasound, include various types of physioprophylactic procedures, reflexoprophylaxis, industrial gymnastics, rational balanced nutrition, vitamin supplementation, and psychophysiological unloading.

Introductory gymnastics is carried out before work and is recommended for all workers without exception. Its main task is to raise the overall tone of the body, activate the activity of organs and systems, help quickly get into the working rhythm and shorten the period of work. The complex includes 7-9 exercises and is performed for 5-7 minutes before starting work.

As a result of numerous experimental studies, the most effective ways protecting the hands of workers from the effects of low-frequency and high-frequency ultrasound propagating in solid and liquid media.

Working with low frequency sources

When vibrations propagate in a solid medium, wear two pairs of thick cotton gloves;

When vibrations propagate in a liquid medium, use two pairs of gloves: the lower ones are cotton and the upper ones are thick rubber.

Working with high frequency sources contact ultrasound is recommended to be used:

When vibrations propagate in a solid environment - one pair of cotton gloves, or cotton gloves with a waterproof palm surface (made, for example, from waterproof synthetic materials), or cotton finger pads;

When vibrations propagate in a liquid medium, use two pairs of gloves: the lower ones are cotton and the upper ones are rubber.

As a means of personal protection against the effects of noise and airborne ultrasound, workers should use noise protection - earplugs, headphones.

Among the measures to protect workers from ultrasonic exposure important place focuses on training workers in the basics of labor protection legislation and technical rules

safety and preventive measures when working with sources of contact ultrasound; health education among workers, propaganda healthy image life.

Industrial vibration. Physical characteristics. Sources of industrial vibration. Classification. Effect on the body. Rationing. Control and measurement. Protection from the harmful effects of vibration.

Industrial vibration(mechanical vibrations of solid bodies) is characterized by the frequency of vibrations per second, amplitude, speed and acceleration of the vibrating body. According to the place of application and the degree of distribution in the human body, vibration is conventionally divided into local(or local), extending limitedly to a certain part of the body, most often to the hands of the worker (working with vibrating tools of the impact-rotary type: drilling and jackhammers, vibration compactors) and general, acting on the entire body of the worker.

Vibration may be the cause occupational disease - vibration disease, the main symptom of which is spasm of small arterioles and precapillaries of the extremities, usually the hands. There are angiotrophic disorders (angioneurosis of the extremities), decreased muscle strength, hand tremors, sluggish tendon reflexes, the development of arthrosis of small joints of the hand, elbow and shoulder joints, and changes in bone tissue. Elasticity decreases and bone fragility increases. Neuromuscular conduction is weakened. With prolonged exposure to vibration, muscle atrophy and an increase in trophic disorders develop. There is an increase in muscle excitability against the background of a decrease in their mineral saturation.

Prevention:improving the design of machines and tools that create vibration in order to reduce the amplitude of vibrations; the use of shock-absorbing pads that dampen vibration; organization of two regulated breaks: 20 minutes 1-2 hours after the start of work and 30 minutes 2 hours after a lunch break of at least 40 minutes using warming; during breaks and after work - warming hydro treatments, gymnastics and hand massage for restoration of blood circulation, ultraviolet irradiation; use of personal protective equipment (mittens, shoes, special suits with vibration-absorbing shock-absorbing materials, which reduces vibration by 10 dB); introducing into the diet or taking additional quantities (50% of the daily requirement) vitamins C, B1, B12 and calcium; Conducting preliminary and annual periodic medical examinations of workers. The MPL of local vibration in industrial conditions varies depending on their frequency characteristics (Table).

Ultrasonic technological installations As a rule, they operate at low frequencies (18-22 kHz). At 20 kHz, these settings produce audible noise. Special studies on the effects of ultrasonic vibrations on humans have shown that at a frequency of 20 kHz and sound pressure up to 100 dB, ultrasound does not pose a danger to the body. The worst conditions are observed at frequencies below 20 kHz, where even at low sound pressure levels, auditory fatigue is felt after several minutes of continuous operation.

Acceptable level

The maximum permissible sound pressure level in a 1/3-octave band at a geometric mean frequency of 20 kHz is considered to be 95 dB.

To reduce noise levels, ultrasonic equipment is produced with sound-insulating casings; At the same time, a tight fit of lids, doors and other opening elements must be ensured. All holes, cracks and grooves are covered with sound-absorbing pads. However, even under these conditions, noise specific to electrosound equipment may occur. Therefore it is necessary to apply individual means protection from noise.

Means of protection

Medical studies have proven that it is possible to significantly reduce the impact of ultrasonic vibrations on the operator by using protective clothing that fits tightly to the body. So, for example, when working on an ultrasonic machine with a power of 1.6 kW, the sound pressure intensity in the operator’s abdomen with clothes tightly fitting at the waist is 110 dB outside the clothes, and 80 dB under the clothes. Therefore, the size of workwear (robes, jackets, overalls) must correspond to the size of the operator’s clothing. The sleeves of workwear must be tied or sleeves that fit the hands must be worn. In this regard, robes with ties on the back and belts deserve preference.

An effective means of personal protection against noise when working on ultrasonic installations are plugs - plugs made of ultra-thin glass wool, inserted into the operator’s ears; this reduces noise by 20 - 25 dB. A sample of glass wool weighing 0.2-0.3 g is rolled into a cone-shaped plug 30 mm long and about 15 mm in diameter at the base. Roll up and insert plugs only with clean hands; They should be stored in clean paper. If the skin of the external auditory canal is damaged, the use of such plugs is contraindicated.

Another effective means of personal protection against noise when working on ultrasonic installations with increased sound pressure levels are anti-noise headphones of the VTSNIIOT-2 type. These headphones reduce the level of perceived noise by at least 40 dB.

To reduce the harmful effects of ultrasound on the operator’s hands when the operator comes into contact with sounded workpieces, cassettes and other devices, rubber gloves are used; It’s even better to use two pairs of gloves (underwear - cotton and outer - rubber) or rubber gloves with a cotton lining. When working with liquids, do not allow cotton gloves to become wet, as this reduces vibration insulation. The type of rubber gloves is selected taking into account the working conditions, i.e., the requirements of acid resistance, heat resistance, etc.

Ultrasound- elastic vibrations with frequencies above the range of human audibility (20 kHz), propagating as a wave in gases, liquids and solids or forming standing waves in limited areas of these media.

Ultrasound sources- all types of ultrasonic technological equipment, ultrasonic devices and equipment for industrial and medical purposes.

Standardized parameters of contact ultrasound in accordance with SN 9-87 RB 98 are sound pressure levels in one-third octave bands with geometric mean frequencies of 12.5; 16.0; 20.0; 25.0; 31.5; 40.0; 50.0; 63.0; 80.0; 100.0 kHz.

Direct contact of a person with the working surface of the ultrasound source and with the contact medium during the excitation of ultrasound in it is prohibited. It is recommended to use remote control; interlocks that ensure automatic shutdown if soundproofing devices are opened.

To protect hands from the adverse effects of contact ultrasound in solid and liquid media, as well as from contact lubricants, it is necessary to use oversleeves, mittens or gloves (outer rubber and inner cotton). Anti-noise devices are used as PPE (GOST 12.4.051-87 “Personal hearing protection. General technical requirements and test methods”).

Persons at least 18 years of age who have the appropriate qualifications and have undergone training and safety instructions are allowed to work with ultrasound sources.

To localize ultrasound, it is mandatory to use sound-insulating casings, semi-casings, and screens. If these measures do not give a positive effect, then ultrasonic installations should be placed in separate rooms and booths lined with sound-absorbing materials.

Organizational and preventive measures consist of instructing workers and establishing rational work and rest schedules.

Infrasound, its effect on the body and protection from it

Infrasound- area of acoustic vibrations in the frequency range below 20 Hz. In production conditions, infrasound, as a rule, is combined with low-frequency noise, and in some cases with low-frequency vibration. In the air, infrasound is little absorbed and therefore can spread over long distances.

Many natural phenomena (earthquakes, volcanic eruptions, sea storms) are accompanied by the emission of infrasonic vibrations.

In industrial conditions, infrasound is generated mainly during the operation of low-speed, large-sized machines and mechanisms (compressors, diesel engines, electric locomotives, fans,

turbines, jet engines, etc.) performing rotational or reciprocating motion with cycle repetition less than 20 times per second (infrasound of mechanical origin).

Infrasound of aerodynamic origin occurs during turbulent processes in flows of gases or liquids.

In accordance with SanPiN 2.2.4/2.1.8.10-35-2002 normalized parameters of constant infrasound are sound pressure levels in octave frequency bands with geometric mean frequencies of 2, 4, 8, 16 Hz.

The overall sound pressure level is a value measured when the sound level meter is turned on with a “linear” frequency characteristic (from 2 Hz) or calculated by energy summation of sound pressure levels in octave frequency bands without corrective corrections; measured in dB (decibels) and denoted dB Lin.

Infrasound remote control at workplaces, differentiated for various types works, as well as permissible levels of infrasound in residential and public premises and in residential areas are established in accordance with App. 1 to SanPiN 2.2.4/2.1.8.10-35-2002.

Infrasound has an adverse effect on the entire human body, including the organ of hearing, reducing auditory sensitivity at all frequencies.

Long-term exposure to infrasonic vibrations on the human body is perceived as physical activity and leads to fatigue, headaches, vestibular disorders, sleep disorders, mental disorders, dysfunction of the central nervous system, etc.

Low-frequency vibrations with infrasonic pressure levels above 150 dB are completely intolerable to humans.

Measures to limit the adverse effects of infrasound on workers(SanPiN 11-12-94) include: weakening of infrasound at its source, eliminating the causes of impact; infrasound isolation; absorption of infrasound, installation of silencers; personal protective equipment; medical prevention.

The fight against the adverse effects of infrasound should be carried out in the same directions as the fight against noise. It is most advisable to reduce the intensity of infrasonic vibrations at the design stage of machines or units. Of primary importance in the fight against infrasound are methods that reduce its occurrence and attenuation at the source, since methods using sound insulation and sound absorption are ineffective.

Infrasound measurements are carried out using sound level meters (ShVK-1) and filters (FE-2).

Ultrasound is mechanical vibrations of an elastic medium that have the same physical nature as sound, but are distinguished by a higher frequency that exceeds the accepted upper limit of audibility - over 20 kHz, although at high intensities (120-145 dB) sounds of higher frequencies can also be audible.

The ultrasonic frequency range is divided into low frequency vibrations (from 1.12 10 4 to 1.0 10 5 Hz), propagating both by air and contact, and high frequency oscillations (from 1 10 5 to 1 10 9 Hz), propagating only by contact.

Ultrasound, like sound, is characterized by sound pressure (Pa), intensity (W/m2) and vibration frequency (Hz).

When propagating in various media, ultrasonic waves are absorbed, and the higher their frequency, the more they are absorbed. Low-frequency ultrasound propagates quite well in the air, while high-frequency ultrasound does not. In elastic media (water, metal, etc.), ultrasound is little absorbed and is able to propagate over long distances with virtually no loss of energy.

As the ultrasonic wave propagates in a given direction, the ultrasound is scattered and absorbed, i.e. its attenuation and transition of ultrasonic energy into other forms, for example thermal, mechanical, etc.

A specific feature of ultrasound, due to its high frequency and short wavelength, is the ability to propagate ultrasonic vibrations in directed beams, called ultrasonic rays. They can create significant ultrasonic pressure over a relatively small area. This property of ultrasound has led to its widespread use: for cleaning parts, machining hard materials, welding, soldering, tinning, acceleration chemical reactions, flaw detection, checking the dimensions of manufactured products, structural analysis of substances, for processing and transmitting signals from radar and computer technology, etc. Ultrasound has also found application in medicine - for the diagnosis and treatment of various diseases, cutting and joining biological tissues, sterilization of instruments.

The active effect of ultrasound on a substance, leading to irreversible changes in it, is caused in most cases by nonlinear effects. In liquids, cavitation plays the main role in the influence of ultrasound on substances and processes, i.e. the formation in a liquid of pulsating cavities, cavities filled with steam or gas, which collapse sharply when moving into an area of high pressure, causing destruction of the surfaces of solid bodies bordering the cavitating liquid.

The impact of ultrasound on biological objects varies depending on its intensity and duration of irradiation. At low intensities (up to 2-3 W/cm 2) at frequencies of 10 5 -10 6 Hz, ultrasound produces micromassage of tissue elements, promoting better exchange substances. As the intensity increases, a number of effects are observed, which determine the biological effect of ultrasound on organs and tissues of the body. These effects include:

- mechanical, caused by alternating displacement (thickening and rarefaction) of the medium and cavitation;

- thermal (heat), resulting from the release of heat when tissues absorb ultrasonic energy;

- physicochemical (photoelectrochemical), caused by the oxidizing and catalytic action of the ultrasonic field with the acceleration of diffusion processes through biological membranes and changes in the rate of biological reactions.

Giving general characteristics effects of ultrasound on the body, we can conclude that low intensities of ultrasound have a stimulating effect, medium and high intensities depress, inhibit and can completely disrupt the function and morphology of the body’s structures.

In practice, ultrasound sources are technological equipment instruments and apparatus that generate ultrasonic vibrations from 18 kHz to 100 MHz and higher, as well as equipment in which ultrasonic vibrations arise as a concomitant factor during operation.

Industrial ultrasonic installations usually consist of a generator of electrical pulses and a converter that transforms them into ultrasonic vibrations. They mainly operate in the frequency range from 18 to 30 kHz at an intensity of up to 60-70 kW/m2.

In the process of servicing these installations, workers may be exposed to ultrasound, firstly, when it propagates in the air (most often along with noise) and, secondly, during direct contact with liquid and solid bodies through which ultrasound propagates (contact exposure) . Contact impact occurs when holding the tool during soldering, welding, tinning, when loading products into baths, etc.

When working for a long time with low-frequency ultrasonic installations that generate high-frequency noise and ultrasound exceeding established standards, functional changes in the central and peripheral nervous system, cardiovascular and endocrine systems, auditory and vestibular analyzers can occur.

Workers complain of headaches that intensify toward the end of work, with a predominant localization in the orbital and temporal regions, dizziness, increased fatigue, irritability, and drowsiness. Among workers, there is an increase in the excitability thresholds of pain, auditory, vestibular and other analyzers, a decrease in blood pressure, hypertension, and the phenomenon of moderate vegetative polyneuritis of the hands (less often of the legs). In workers who, in addition to exposure through the air, are also exposed to contact exposure, the symptoms of health problems are more pronounced, especially due to the phenomena of vegetative polyneuritis.

Prolonged work with intense ultrasound when transmitted through contact to the hands can cause damage to the peripheral and vascular apparatus (vegetative polyneuritis, paresis of the fingers). At the same time, the severity of changes depends on the time of contact with ultrasound and can intensify under the influence of unfavorable accompanying factors of the production environment.

Hygienic standards for ultrasound are defined by GOST 12.1.001-89 “SSBT. Ultrasound. General safety requirements" and SanPiN 2.2.4/2.1.8.582-96 "Hygienic requirements when working with sources of airborne and contact ultrasound for industrial, medical and domestic purposes."

The hygienic characteristic of airborne ultrasound in workplaces is the sound pressure levels (dB) in one-third octave bands (fjf n = 1/2= 1.26) with geometric mean frequencies of 12.5-100 kHz. Acceptable levels high-frequency sounds and ultrasounds during the operation of ultrasonic installations are given in table. 7.3.

The normalized parameter of ultrasound propagating by contact is the peak value of vibration velocity (m/s)

Acceptable sound pressure levels in workplaces

or its logarithmic level (dB), determined by the expression

Where V- peak value of vibration velocity, m/s; V Q- reference value of vibration velocity equal to 5 10 -8 m/s.

The permissible levels of ultrasound in the areas of contact of the hands and other parts of the operator’s body with the working parts of ultrasonic devices are given in Table. 7.3.

Permissible levels of contact ultrasound should be taken 5 dB lower than the values indicated in the table. 7.4 in cases where workers are exposed to the combined effects of air and contact ultrasound.

Table 7.4

Permissible levels of vibration velocity and its peak values at workplaces

Ultrasound levels must be monitored after installation of ultrasonic equipment, its repair, and periodically during operation, at least once a year.

Requirements for ultrasonic characteristics of equipment are determined by GOST 12.2.051-80 “SSBT. Ultrasonic technological equipment. Safety requirements". The manufacturer must indicate in operational documentation production equipment ultrasonic characteristic - sound pressure levels in one-third octave bands of the accepted frequency range, measured at control points at a height of 1.5 m from the floor, at a distance of 5 m from the equipment contour and at least 2 m from reflective surfaces.

Measurements should be made at at least four control points along the equipment contour; in this case, the distance between the measurement points should not exceed 1 m. The maximum of the measured values is entered into the equipment passport.

To protect against elevated levels ultrasound can be used the following actions: reduction of harmful ultrasonic energy radiation at the source of its occurrence; localization of the action of ultrasound by design and planning solutions; carrying out organizational and preventive measures.

To reduce harmful radiation of sound energy in the source, it is recommended to increase the operating frequencies of ultrasound sources, which ensures a decrease in ultrasound intensity.

For the purpose of localization, all installations during operation of which the levels of high-frequency noise and ultrasound exceed standard values, must be equipped with sound-insulating devices (casings, screens) lined with sound-absorbing materials (technical rubber, getinaks, roofing felt, anti-noise mastic, etc.). If these measures do not have a positive effect, ultrasonic installations should be placed in separate rooms and booths lined with sound-absorbing material.

Design and planning solutions provide for the development of automatic ultrasonic equipment with its shutdown when performing auxiliary operations, as well as installations with remote control. This makes it possible to almost completely eliminate the contact effects of ultrasound on workers and reduce to a safe minimum the time possible for workers to remain exposed to ultrasound and high-frequency noise.

In cases where turning off the equipment is undesirable, to eliminate the contact effects of ultrasound, it is necessary to use a special tool with a vibration-isolating handle and protect your hands with rubber gloves with a cotton lining. For example, when loading products into cleaning baths, nets equipped with handles with a vibration-isolating coating (porous rubber, foam rubber, etc.) are used.

Organizational and preventive measures consist of instructing workers about the nature of the effects of ultrasound, measures of protection and safe maintenance of ultrasonic installations, as well as establishing rational regimes work and rest. When systematically working with sources of contact ultrasound for more than 50% of the working time, it is necessary to provide two regulated breaks - a ten-minute break 1-1.5 hours before and a fifteen-minute break 1.5-2 hours after the lunch break to carry out physioprophylactic procedures.

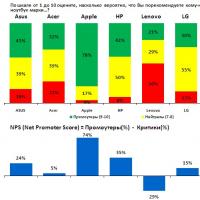

We track customer loyalty

We track customer loyalty What is the profitability threshold?

What is the profitability threshold? Where to work with a sociologist's education

Where to work with a sociologist's education Rituals to get your enemy fired from work How to get your boss fired

Rituals to get your enemy fired from work How to get your boss fired 301 83 unified technological system

301 83 unified technological system License for passenger transportation

License for passenger transportation Offers are of the following types

Offers are of the following types