Any shape memory effect. The mechanism of the shape memory effect. Shape memory metals. Memory alloy professions

Moscow State University

them. M.V. Lomonosov

Faculty of Materials Science

Topic: "Materials with shape memory".

V-year student of FNM

I. E. Kareeva

Moscow 2000

Introduction ……………………………………………………… 2

The mechanism of realizing the shape memory effect ... ... ... ... 3

Applications ……………………………………… ..7

Production of alloys with shape memory .............................................................. 9

Degradation ……………………………………………… ..10

Conclusion ………………………………………………… ..11

References ……………………………………… ..12

Introduction.

Shape memory materials (MPM) were discovered at the end of the 60s of this century. Already 10 years later (late 70s - early 80s), there are many reports in scientific journals describing the various possibilities of their application. At present, functional properties have been defined for MPF: one - and two-sided memory effect, pseudo- or superelasticity, high damping ability.

MPF has already found wide application in medicine, as long-term functioning materials implanted into the body. They exhibit high elastic properties, are able to change their shape when the temperature changes and do not collapse under conditions of alternating load. The complex nature of phase transformations of the martensitic type, which occurs in alloys based on titanium nickelide, is clearly manifested in porous structures. Phase transitions in such alloys are characterized by a wide hysteresis and a long temperature range, in which the material exhibits shape memory and superelasticity effects. In addition to alloys based on Ni-Ti, martensitic transformations exist, for example, in systems such as Pt-Ti, Pt-Ga, Pt-Al.

Shape memory alloys have a wide range of applications, depending on the temperature of martensitic transformation and mechanical properties.

The mechanism for the implementation of the shape memory effect.

Martensite.

Martensite is the structure of crystalline solids resulting from shear diffusionless polymorphic transformation upon cooling. Named after the German metallurgist Martens (1850 - 1914). As a result of the deformation of the lattice during this transformation, a relief appears on the surface of the metal; internal stresses arise in the volume, and plastic deformation occurs, which limits the growth of the crystal. The growth rate reaches 103 m / s and does not depend on temperature; therefore, the rate of martensite formation usually limits the nucleation of crystals. The counteraction of internal stresses displaces the nucleation of crystals much below the point of thermodynamic equilibrium of the phases and can stop transformations at a constant temperature; in this regard, the amount of martensite formed usually increases with an increase in hypothermia. Since the elastic energy must be minimal, martensite crystals take the form of plates. Internal stresses are also relieved by plastic deformation, so the crystal contains many dislocations (up to 10 12 cm –2), or is split into twins 100–1000 Å thick. Intragrain boundaries and dislocations strengthen martensite. Martensite is a typical product of low-temperature polymorphic transformations in pure metals (Fe, Co, Ti, Zr, Li and others), in solid solutions based on them, in intermetallic compounds (CuZn, Cu 3 Al, NiTi, V 3 Si, AuCd).

Martensitic transformations.

Intermetallic compounds Ni-Ti with a composition close to eutectic are characterized by a transition from the cubic (austenite phase) to the monoclinic (martensite) phase at room temperature. Such transformations usually occur in alloys at high stresses, but as a result of the memory effect or superelasticity, transformations can also occur at low stresses. Austenitic Ni-Ti alloys exhibit superelastic behavior under mechanical stress and tension (8%) caused by martensitic transformation. Upon unloading, martensite becomes unstable and transforms into austenite, with compensation for all macroscopic stresses ..

Martensitic transformation is a polymorphic transformation in which the change in the mutual arrangement of the atoms constituting the crystal occurs through their ordered displacement, and the relative displacements of neighboring atoms are small in comparison with the interatomic distance. The rearrangement of the crystal lattice in microregions is usually reduced to deformation of its cell, and the final phase of the martensitic transformation is a uniformly deformed initial phase. The magnitude of the deformation is small (~ 1-10%) and, accordingly, is small, in comparison with the binding energy in the crystal, the energy barrier, which prevents the homogeneous transition of the initial phase to the final one. A necessary condition for martensitic transformation, which develops through the formation and growth of regions of a more stable phase in a metastable one, is the maintenance of an ordered contact between the phases. The ordered structure of interphase boundaries with a small barrier for a homogeneous phase transition ensures their low energy and high mobility. As a consequence, the excess energy required for the nucleation of crystals of a new phase (martensite crystals) is small and, with some deviation from the equilibrium of the phases, it becomes comparable to the energy of defects present in the initial phase. Therefore, the nucleation of martensite crystals occurs at a higher rate and may not require thermal fluctuations. An essential role in the martensitic transformation is played by internal stresses arising from the elastic adaptation of crystal lattices, which are conjugated along the phase boundaries. The fields of elastic stresses lead to a shift in the equilibrium point of the interacting phases relative to the position of the true thermodynamic equilibrium for isolated, undistorted phases; accordingly, the temperature of the onset of martensitic transformation can differ significantly from the temperature of true equilibrium. The striving for a minimum of elastic stress energy determines the morphology, internal structure and mutual arrangement of martensite crystals. The new phase is formed in the form of thin plates oriented in a certain way relative to the crystallographic axes. Plates, as a rule, are not single crystals, but are packets of plane-parallel domains - regions of a new phase differing in the orientation of the crystal lattice (twins). Interference of voltage fields from different domains leads to their partial destruction. A further decrease in elastic fields is achieved by the formation of ensembles of regularly spaced plates. That is, as a result of the martensitic transformation, a polycrystalline phase is formed with a peculiar hierarchical order (ensembles - plates - domains) in the arrangement of structural components. An increase in internal stresses in the process of martensitic transformation under certain conditions leads to the establishment of a two-phase thermoelastic equilibrium, which reversibly shifts with a change in external conditions: under the action of mechanical loads or with a change in temperature, the sizes of individual crystals and their number change. Martensitic transformations are found in many crystalline materials: pure metals, numerous alloys, ionic, covalent and molecular crystals.

There are great prospects for reversible shape change during martensitic transformation (creation of superelastic alloys that restore their original shape upon heating after plastic deformation - memory effect), as well as the connection between martensitic transformation and the appearance of superconducting properties in some metals. Martensitic transformations form the basis of numerous structural transformations, due to which, with the help of thermal and mechanical treatment, a directed change in the properties of crystalline materials is carried out.

Features of porous titanium nickelide alloys.

The presence of a wide temperature range of martensitic transformation in porous titanium nickelide in comparison with cast is reflected in the temperature curves of electrical resistivity. It is shown that the martensitic transition is incomplete in porous alloys and occurs in a wider temperature range than in cast alloys. Thus, an important feature of porous titanium nickelide in comparison with a non-porous (cast) alloy of the same composition is a wide temperature range of phase transformations. It is about 250 0 C, ie, significantly exceeds the range (30-40 0 C) of transformations of the cast alloy. An increase in the temperature range of phase transformations is due to the structure of porous titanium nickelide. The size factor is also significant, since the martensitic transformation in thin bridges and massive regions manifests itself in different ways. The action of these factors leads to the fact that phase transformations in porous materials based on titanium nickelide begin in different regions at different temperatures, extending the hysteresis along the temperature axis, respectively, expanding the temperature ranges of transformations and the intervals of manifestation of shape memory and superelasticity effects in porous alloys based on nickelide titanium.

Fig.1 Temperature dependences of the effect of reversible memory and the yield point in porous (1) and cast (2) alloys based on titanium nickelide.

Figure 1 shows the shape memory effect in porous and cast alloys. In a porous alloy, the shape memory effect manifests itself in a wider temperature range than in a cast one, and the residual plastic deformation in a porous material is more significant (in Fig. 1) than in a cast one. In cast titanium nickelide, almost complete (up to 100%) shape recovery occurs after deformation by 6 - 8% and subsequent heating above the temperature range of MT (Fig. 1). With an increase in the degree of deformation of cast titanium nickelide, dislocation defects are formed, which, in contrast to martensitic transformations, are irreversible. The stage of reversible deformation by the martensitic mechanism is replaced by the stage of irreversible plastic deformation. Even at low loads, areas appear in which the magnitude of elastic deformation exceeds the limiting value. In contrast, in porous alloys, even with minimal deformations, the degree of shape recovery does not exceed 85%. The degree of shape recovery depends on porosity, pore size distribution, and the level of martensitic shear stresses, i.e. associated with the features of the deformation of porous bodies. Analysis of the deformation dependences of titanium nickelide with different porosities shows that the yield stress of the alloy decreases with an increase in porosity.

Areas of use.

Non-medical use.

The first shape memory alloy was used in the F-14 aircraft in 1971, it was Ni-Ti-Fe. The use of Ni-Ti-Nb alloys was a great achievement, but Fe-Mn-Si alloys have also received a lot of attention despite their lower recoverable stress.

There are potential uses of nitinol in the production of consumer goods. For example, an interesting invention: a device - an ashtray holder, which lowers a burning cigarette into the ashtray, preventing it from falling, say, on the tablecloth.

The reliability of shape memory devices depends on their lifespan. Important external parameters for controlling the operating cycles of the system are - time, temperature. Important internal parameters that determine the physical and mechanical properties are: alloy system, alloy composition, type of transformation and lattice defects. These parameters control the thermomechanical history of the alloy. As a consequence, the maximum memory effect will be limited depending on the number of cycles required.

Space payloads such as solar panels or satellite antennas are now mostly deployed pyrotechnics, which pose many problems. The use of materials with shape memory will eliminate all these problems, and will also provide an opportunity to repeatedly check the performance of the system while still on the ground.

Recent research on Ni-Ti alloys has shown that super elastic behavior results in improved wear resistance. The pseudo-elastic behavior reduces the elastic contact area during sliding. Reducing the elastic contact area between the two sliding parts increases the wear resistance of the material. A special type of wear is cavitation erosion, which creates specific problems in hydraulic machines, ship propellers, and water turbines. Comparative studies of various materials have shown that Ni-Ti alloys have a higher resistance to cavitation erosion than conventional alloys. In the martensitic state, the Ni-Ti alloy has very good resistance to cavitation erosion. But the manufacture of working parts subject to corrosion entirely from Ni-Ti alloy is too expensive, so the best way is to use Ni-Ti alloy combined with steel.

Medical applications.

In medicine, a new class of composite materials “bioceramic – titanium nickelide” is used. In such composites, one component (titanium nickelide) has superelasticity and shape memory, while the other retains the properties of bioceramics.

The ceramic component can be porcelain, which is widely used in orthopedic dentistry and is a fragile material. The high fragility of porcelain is due to the fact that contact stresses appear at the boundaries of various phases and grains, which significantly exceed the level of average applied stresses. Relaxation of contact stresses in a ceramic material is possible if energy dissipation occurs in the zone of these stresses due to phase transformation in titanium nickelide. A change in temperature or application of a load causes a martensitic transformation in titanium nickelide, which leads to effective relaxation of stresses in the matrix when the composite material is loaded, allowing the solid component to carry the applied load. It is known that the elastic restoration of the volume of porous compacts from a powder of superelastic titanium nickelide is associated with the rupture of interparticle contacts and is determined by the strength of the briquette, which depends on the porosity and the magnitude of the contact adhesion forces. The weakening of these forces by adding other components to the titanium nickelide powder, for example, finely dispersed tungsten or silicon carbide, significantly increases the elastic effect, since strong titanium – nickel contacts of the same name are replaced by opposite ones. Since the magnitude of the elastic effect decreases with decreasing titanium nickelide content in the compact, the concentration dependence of the elastic volume recovery is usually extreme. In the “porcelain – titanium nickelide” composite material, the components interact weakly and, after sintering, the contacts between the ceramic and metal components are weakened. When loaded, they break first and the elastic volume recovery increases. As a result, the deformation is reversible and the composite exhibits properties similar to superelasticity. The biocompatibility of the dental porcelain – titanium nickelide composite material was studied by the histological method, evaluating the tissue response in rats to implantation of composite and porcelain specimens under the skin of the anterior abdominal wall. The nature of tissue reactions, their prevalence and characteristics of cellular changes in both cases were unambiguous. Thus, composite materials “bioceramic – titanium nickelide” are biocompatible.

Obtaining shape memory alloys.

Shape memory alloys are produced by fusing individual components. The melt is quickly cooled and high-temperature processing is carried out.

A whole class of composite materials "bioceramics - titanium nickelide" for medicine has been proposed. In such materials, one component (titanium nickelide) possesses shape memory and superelasticity, while the other retains the properties of bioceramics. The most commonly used ceramic component is porcelain, which is widely used in orthopedic dentistry and is a fragile material. For the manufacture of such samples, powders of titanium nickelide and porcelain mass are used, which, after mixing and drying, are sintered in a vacuum.

Degradation

Martensitic transformation in alloys based on NiTi is an athermal process, the rate of which is entirely determined by the rate of temperature change near the thermodynamic equilibrium of the phases. Therefore, all specific mechanical effects in NiTi accompanying the martensitic transformation, such as shape memory, transformation plasticity, can be realized in very short times with appropriate heating and cooling modes. In high-speed devices, to accelerate the exchange of heat with a heat agent (liquid or gaseous), thin-sized tape, wire and pipes with micron-sized linear dimensions in cross-section are used. In this case, the state of the free surface of the alloy is of great importance. Since even small variations in the composition lead to a change in the temperature kinetics and completeness of the transformation, the segregation of elements and surface oxidation also significantly change the special properties of the material. This circumstance is of particular importance due to the need for preliminary thermal or thermomechanical treatment of the material.

Studies have shown the tendency of titanium nickelide on the free surface under thermal influences. In an oxygen-containing atmosphere, the alloy oxidizes to form an oxide layer containing mainly TiO 2 oxide. It can be assumed that since titanium is chemically very active, titanium atoms will form compounds with any non-inert gas in an oxygen-free environment, for example, nitrides in a nitrogen atmosphere. The formation of oxides along grain boundaries and on the surface can be avoided only by heat treatment of samples in vacuum or in an inert atmosphere.

Conclusion

For a long time, inelastic deformation was considered completely irreversible. In the early 1960s. a vast class of metallic materials was discovered in which the elementary act of inelastic deformation is carried out due to structural transformation. Such materials possess the reversibility of inelastic deformation. The phenomenon of spontaneous restoration of shape - shape memory effect(SME) - can be observed both under isothermal conditions and with temperature changes. During heat exchanges, such metallic materials can be reversibly deformed many times over.

The deformation recovery ability cannot be suppressed even under high force. The level of reactive stresses of some materials with SME can be 1,000 ... 1,300 MPa.

Metals with SME are among the most prominent representatives of materials with special properties. The increased interest in this metallurgical phenomenon is due to the unique combination of high conventional mechanical characteristics, fatigue resistance, corrosion resistance and unusual properties such as thermomechanical memory, reactive stress, based on thermoelastic martensitic transformation. A feature of alloys with SME is the pronounced dependence of most properties on the structure. The values of physical and mechanical characteristics change several times during the reversible phase transition austenite-martensite for different alloys, usually in the temperature range -150 ... + 150 ° C.

Of the large number of alloys with SMEs, the most promising for practical application are Ti-Ni alloys of equi- atomic composition (equal number of atoms), usually called titanium nickelide or nitinol. Less commonly used are cheaper copper-based alloys Cu-AI-Ni and Cu-A1-Zn.

The shape memory effect is that a specimen having a certain shape in the austenitic state at an elevated temperature is deformed at a lower martensitic transformation temperature. After overheating, accompanied by the reverse transformation, the original characteristic form is restored. The shape memory effect manifests itself in alloys characterized by thermoelastic martensitic transformation, lattice coherence of the initial austenite and martensite phases, relatively small transformation hysteresis, and also small volume changes during transformations. In titanium nickelide, volumetric changes are about 0.34%, which is an order of magnitude less than in steels (about 4%).

SME alloys are often referred to as the so-called intelligent materials that make it possible to create fundamentally new designs and technologies in various fields of mechanical engineering, aerospace and rocket technology, instrumentation, energy, medicine, etc. Let us consider some objects of application of SME alloys.

The development of near and deep space is associated with the creation of orbital stations and large-scale space construction. It is necessary to build such bulky objects as solar panels and space antennas. In fig. 1.1 shows a diagram of a spacecraft with self-deploying elements. The antennas consist of a Ti-Ni alloy sheet and rod, which are coiled and placed in a recess in an artificial satellite. After launching the satellite and putting it into orbit, the antenna is heated with the help of a special heater or the heat of solar radiation, as a result of which it goes out into space.

To accommodate various technical objects, residential and industrial modules, it is necessary to build large platforms in open space. Delivery of bulky units into open space is technically possible only in parts with subsequent installation work. Methods of joining parts used in mass production, such as welding, brazing, gluing, riveting and others, non-

Rice. 1.1.

/ - antenna; 2 - solar battery; 3 - energy emitter; 4 - mechanical stabilizer

Rice. 1.2. Connecting tubular parts (/) with a shape memory metal sleeve (2):O - before assembly;b - after heating

suitable in space conditions. Special requirements are imposed on the provision of extremely high security.

Taking these features into account, our country has created a unique technology for connecting elements in open space using a coupling made of TN-1 alloy. This technology was successfully used in the assembly of a truss structure made of aluminum alloys with a total length of 14.5 m and a square cross-section with a side of 0.5 m.

The truss consisted of separate tubular parts / 28 mm in diameter, which were connected to each other using a coupling 2 made of metal with shape memory (fig. 1.2). The sleeve was deformed with a mandrel at a low temperature so that its inner diameter was greater than the outer diameter of the elements to be joined. After heating above the temperature of the reverse martensitic transformation, the inner diameter of the sleeve was restored to the same diameter that the sleeve had before expansion. At the same time, significant compressive reactive forces were generated, the connected elements were plastically deformed, which ensured their strong connection. The assembly of the truss and its installation on the astrophysical module "Kvant" of the orbital complex "Mir" was carried out in 1991 in just four spacewalks and took about a day in total.

The same construction principles can be used for the installation of large-sized subsea structures at great depths.

Couplings for thermomechanical connection of pipes are used in many designs (Fig. 1.3). They are used to connect the pipelines of the hydraulic systems of the F-14 jet fighter, and there have been no accidents involving oil leaks. The advantage of couplings made of shape memory alloys, in addition to their high reliability, is the absence of high-temperature heating (as opposed to welding). Therefore, the properties of materials in the vicinity of the joint do not deteriorate. Couplings of such

Rice. 1.3. Connecting pipes using shape memory effect:

a - introduction of pipes after expansion of the coupling; b- heating

types are used for pipelines of nuclear submarines and surface ships, for the repair of pipelines for pumping oil from the seabed, and for these purposes they use large-diameter couplings - about 150 mm. In some cases, the Cu-Zn-A1 alloy is also used for the manufacture of couplings.

For fixed connection of parts, rivets and bolts are usually used. However, if it is impossible to perform any action on the opposite side of the fastened parts (for example, in a sealed hollow structure), performing the fastening operations is difficult.

The shape memory alloy stops allow in these cases the fixing using spatial shape restoration. Stoppers are made of an alloy with a shape memory effect, and in the initial state the stopper has an open end (Fig. 1.4, a). Before carrying out the fastening operation, the stopper is immersed in dry ice or liquid air and cooled sufficiently, after which the ends of the stopper are straightened (Fig. 1.4, b). The stopper is inserted into a fixed hole for fastening (Fig. 1.4, v), when the temperature rises to room temperature, the shape is restored, the ends of the pin diverge (Fig. 1.4, d), and the fastening operation is completed.

The use of shape memory alloys in medicine is of particular interest. Their application opens up wide possibilities

Rice. 1.4. The principle of operation of the stopper with the shape memory effect of the possibility of creating new effective methods of treatment. Alloys used in medicine must have more than just high mechanical properties. They should not corrode in a biological environment, should have biological compatibility with the tissues of the human body, ensure the absence of toxicity, carcinogenicity, resist the formation of blood clots, maintaining these properties for a long time. If the implanted organ, made of metal, is active relative to the biological structure, then there is a degeneration (mutation) of biological cells of the peripheral structure, inflammatory blood flow, impaired blood circulation, then the death of the biological structure. If the implanted organ is inert, then a fibrous structure arises around it, caused by collagen fibers formed from fibrous germ cells. The implanted organ is covered with a thin layer of this fibrous structure and can exist stably in biological organisms.

Special experiments carried out on animals have shown that alloys based on the Ti-Ni system have biological compatibility at a level or even higher than the commonly used corrosion-resistant steels and cobalt-chromium alloys and can be used as functional materials in biological organisms. The use of alloys with SME for treatment has shown their good compatibility with tissues and the absence of rejection reactions by the biological structures of the human body.

Spine correction. Various curvatures of the spine, both congenital and due to habit or a painful condition, lead to severe deformity when walking. This not only causes severe pain, but also has a harmful effect on the internal organs. In orthopedic surgery, the spine is usually corrected using a Harinton rod made of corrosion-resistant steel. The disadvantage of this method is the reduction in time of the initial corrective effort. In 20 minutes after installation, the corrective force decreases by 20%, and after 10-15 days - up to 30% of the original. Additional correction of effort requires repeated painful operations and does not always achieve the goal. If an SME alloy is used for the Harinton rod, then the rod can be installed 1 time, and there is no need for a repeated operation. If, after the operation, the Harinton rod is heated to a temperature slightly higher than the body temperature, then the necessary corrective force can be created. Effective for this purpose are alloys based on Ti-Ni with additions of Cu, Fe and Mo, exhibiting high elasticity in the temperature range after restoration

Corrective devices with such alloys create a constant stress on the spine during the entire treatment period, regardless of the displacement of the support points of the device.

Plate for bone connection. Methods of medical care in the case of bone fractures are to fix the fracture zone in such a state when the compression force acts on the bone with the help of plates made of corrosion-resistant steel or Co-Cr alloys.

If a shape memory alloy is used for the connecting plate, then it becomes possible to firmly fix the fracture zone by external heating of the plate to a temperature slightly higher than the body temperature after the operation, while there is no need to carry out longitudinal compression of the bone during the operation.

Intraosseous hairpins. Such pins are used in the provision of medical care for fractures of the tibia. Moreover, the pins, mainly made of stainless steel, are inserted up to the bone marrow, thereby fixing the bone. With this method, the bone is fixed due to the elastic properties of the corrosion-resistant steel, so it is necessary to insert a pin with a larger diameter than the hole diameter to create a large degree of deformation. In this regard, there is a risk of damaging the tissue in the area into which the hairpin is inserted.

The surgical procedure is simplified by using Ti-Ni based shape memory alloys for the studs. The pre-cooled stiletto heels restore their original shape at body temperature, which increases the degree of fixation.

Skeletal traction devices. The property of the material is used when restoring the shape to create significant stresses in a given temperature range.

The devices are used to effectively treat bone fractures by both permanent and discrete skeletal traction.

Wire for correcting the position of the teeth. To correct the position of the teeth, for example, a malocclusion, a wire made of corrosion-resistant steel is used, which creates an elastic force.

The disadvantage of the correcting wire is low elastic elongation and, as a result, plastic deformation. When making a wire from a Ti-Ni alloy, even with an elastic deformation of 10%, plastic deformation does not occur, and the optimal corrective force is maintained.

Technological progress is associated with the continuous growth of electricity consumption. The limited reserves of fossil fuels, the overcoming of the energy crisis and the acceptable cost of electricity production made it necessary to use atomic energy and large-scale construction of nuclear power plants (NPPs) in all developed countries of the world. Nuclear energy is the energy of the future.

By the principle of operation, nuclear power plants and thermal power plants (TPPs) differ little from each other. At nuclear power plants and thermal power plants, water is brought to a boil and the resulting steam is fed to the blades of a high-speed turbine, forcing it to rotate. The turbine shaft is connected to the generator shaft, which generates electrical energy when rotating. The difference between nuclear power plants and thermal power plants is in the way water is heated to boiling. If coal or fuel oil is burned in a thermal power plant to heat water, then in a nuclear power plant for this purpose, the thermal energy of a controlled chain reaction of uranium fission is used.

Most countries currently use light water reactors (LWRs) for power generation. Reactors of this type have two modifications: pressurized water reactors (PWR) and boiling water reactors (BWR), of which pressurized water reactors are more common.

In fig. 1.5 shows a diagram of a nuclear power plant equipped with a light water reactor (with water under pressure). The reactor vessel 9 contains the core 10 and the first circuit. In the first circuit, water circulates, which is a heat carrier and slows down

Rice. 1.5. Scheme transmission warmth between elements of the PWR station:

1 - concrete shell; 2 - shell made of corrosion-resistant steel; 3 - turbine; 4 - generator; 5 - cooling tower; 6 - capacitor; 7 - steam generator; 8 - circulation pump; 9 - reactor vessel; 10 - active zone; 11 - pressure compensator; 12 - a container with a sprinkler. Water removes heat from the core to the heat exchange (steam generator 7), where heat is transferred to the second loop, in which steam is generated. Energy conversion takes place in the generator 4, where steam is used to generate electricity. The primary circuit with all piping and components is enclosed in a specially designed container 12. Thus, any radioactive fission products that can escape from the fuel into the primary water are isolated from the environment.

In the first circuit, water is under a pressure of 15.5 MPa and at a maximum temperature of 315 ° C. These conditions prevent water from boiling, since the boiling point of water at a pressure of 15.5 MPa is much higher than 315 ° C.

In each reactor 16-25 cells (depending on design) are left free for control rods. They are moved by a control rod through the reactor vessel lid. Steam leaving the turbine 3, condenses in a water-cooled condenser 6, in which the remaining heat energy is discharged. Some cooling systems use cooling towers.

The cost of plant equipment that generates and transmits energy (reactor vessel, heat exchangers, pumps, tanks, pipelines) is about 90% of the cost of the plant. Equipment must be properly designed and manufactured from economical but guaranteed reliable materials.

Nuclear energy places high demands on the construction materials used, their production technology and performance monitoring. Structural transformations under the influence of irradiation of structural materials have a negative effect primarily on the mechanical properties and corrosion resistance. Of all types of radiation (neutrons, a- and p-particles, y-radiation) the strongest effect is exerted by neutron irradiation.

Radiation resistant materials called materials that retain the stability of the structure and properties under neutron irradiation (Table 1.11).

The corrosion rate of aluminum-based alloys in an aqueous medium under irradiation conditions increases 2-3 times. Austenitic chromium-nickel steels in wet steam are susceptible to intergranular corrosion and stress corrosion cracking.

The most dangerous consequence of radiation exposure is radiation swelling. In fig. 1.6 presents the characteristics of radiation swelling of a number of grades of steels and alloys. Swelling can be suppressed by structural-forced recombin Table 1.11

Effects of neutron irradiation on various materials

|

Integral flux of fast neutrons, neutron / cm 2 |

Material |

Exposure to radiation |

|

Polytetrafluoroethylene, floor and methyl methacrylate and cellulose |

||

|

Decreased elasticity |

||

|

Organic liquids |

Gas emission |

|

|

Increase in yield strength |

||

|

Polystyrene |

Decreased tensile strength |

|

|

Ceramic materials |

Decrease in thermal conductivity, density, crystallinity |

|

|

Plastics |

Unsuitable for use as a material of construction |

|

|

Carbonaceous |

Significant reduction in ductility, doubling of the yield stress, increased transition from ductile to brittle fracture |

|

|

Corrosion resistant steels |

Threefold increase in yield strength |

|

|

Aluminum |

Reduced ductility without complete embrittlement |

metals due to continuous decomposition of the solid solution with a certain dilatation at the interface of the matrix with the resulting secondary phase. Strong fields of structural stresses arising during decay promote the recombination of radiation-induced defects and significantly reduce swelling. Developed precipitation hardening is a way to suppress radiation swelling.

The radiation resistance of reactor materials can be achieved when a set of conditions are met. These include

Rice. 1.6.

V - volume; DR - volume change

optimal chemical composition and structure of materials, conditions of their operation: levels of operating temperature, neutron flux and properties of a corrosive medium.

There are a number of metallic materials (metal alloys) that can return to their original shape after preliminary deformation - the so-called. shape memory metals.

Description:

One of the basic perceptions by people of the phenomena of the external world is the durability and reliability of metal products and structures that stably retain their functional form for a long time, unless, of course, they are subjected to supercritical influences. However, there are a number of metallic materials (metal alloys) that can return to their original shape after preliminary deformation - the so-called. metals with shape memory.

The shape memory effect is a phenomenon of returning to its original shape upon heating, which is observed in some metallic materials after preliminary deformation.

To understand the shape memory effect, it is enough to see its manifestation once:

1. There is a metal wire;

2. This wire is bent;

3. We begin to heat the wire;

4. When heated, the wire straightens, restoring its original shape.

The shape memory effect depends on the grade of the alloy with a strictly consistent chemical composition. The temperature of martensitic transformations depends on this. The shape memory effect manifests itself only during thermoelastic martensitic transformations and can manifest itself in several million cycles.

The shape memory effect of the alloy can be enhanced by preliminary heat treatments. Reverse shape memory effects are possible, when a shape memory metal at one temperature "remembers" one shape, and at a different temperature - another.

The following metals and their alloys possess shape memory to varying degrees: Ni - Ti, Ni - Al, Ni - Co; Ti - Nb; Au - Cd; Fe - Ni, Fe - Mn - Si; Cu - Al, Cu - Mn, Cu - Al - Ni, Cu - Zn - Al, etc.

Fe - Mn - Si is the cheapest alloy.

The mechanism for implementing the shape memory effect:

1. In the initial state, there is a certain structure in the material (indicated by regular squares in the figure).

2. During deformation, the outer layers of the material are stretched, and the inner ones are compressed. In materials with shape memory, martensite is thermoelastic.

3. When heated, the thermoelasticity of martensite plates begins to manifest itself, that is, internal stresses arise in them, which tend to return the structure to its original state.

4. Since the outer elongated plates are compressed, and the inner flattened ones are stretched, the material as a whole carries out auto-deformation in the opposite direction and restores its original structure, and with it its shape.

In the process of manifestation of the shape memory effect, direct and reverse martensitic transformations are involved. Martensitic transformation is a polymorphic transformation in which a change in the mutual arrangement of atoms constituting a crystal occurs by their ordered displacement, and the relative displacements of neighboring atoms are small compared to the interatomic distance.

Direct martensitic transformation is understood as the transformation from a high-temperature face-centered cubic phase (austenite) to a low-temperature body-centered cubic phase (α-martensite). The reverse transformation is from the body-centered cubic phase to the face-centered cubic phase.

Titanium nickelide:

Titanium nickelide is a leader among shape memory materials in terms of application and study.

Nickelide titanium is an intermetallic compound of equiatomic composition with 55 wt. % Ni. Melting point 1240-1310˚C, density 6.45 g / cm3. The initial structure of titanium nickelide, a stable body-centered cubic lattice, undergoes a thermoelastic martensitic transformation upon deformation.

Nickelide titanium possesses:

– excellent corrosion resistance,

– high strength,

– good shape memory characteristics,

– good compatibility with live organisms,

– high damping (absorption of noise and vibration) material ability.

Superelastic Ni-Ti shape memory alloys - in science, technology and medicine.

The first information on the use of shape memory alloys dates back to about the 15th-13th centuries. BC e: “... God asked what he was holding in his hand. Moses replied, "The Rod." “Throw him on the ground,” God said, and the rod suddenly turned into a snake, but when Moses took it in his hands, he again became a rod ... ”. This is a classic example of the application of a shape memory alloy with a reversible memory.

Today biblical legends are becoming reality. The modern history of shape memory alloys begins in the late forties of the 20th century, when G.V. and Handorson L.G. noticed that the alloy studied by them has a shape memory effect. Later, this effect was recognized as a discovery and received the name of Kurdyumov. The unique shape memory effect quickly became known around the world and to date, more than 120 self-healing alloys have been developed. These are alloys based on the metal systems Au-Cd, Cu-Zn-Al, Cu-Al-Ni, Fe-Mn-S, Fe-Ni, Cu-Al, Cu-Mn, Co-Ni, Ni-Ti, Ni- Al and others.

The effects of shape memory, reversible shape memory, and superelasticity in the aforementioned alloys are due to the macroscopic reflection of micro- and nanostructural transformations of the crystal lattice during a polymorphic austenite-martensitic phase transformation of the first kind, and therefore these properties are retained for almost the entire life of a particular product. In life, the implementation of physical processes in metal is implemented approximately as follows.

If a small mechanical force is applied, an article made of such an alloy in a cooled martensitic state can be given any configuration and even stretch by 7-8%, in some cases up to 12%, relative length, like a rubber band. This configuration will persist until the object is heated to the temperature of the onset of austenitic transformation, and during heating to the temperature of the completion of austenitic transformation, the alloy does not pass into the austenite phase, completely restoring its previous shape and realizing the shape memory effect.

If the external influence on a specially treated element made of a shape memory alloy is limited only by heating and cooling in the temperature range of completed austenite-martensitic transformations, then the element will spontaneously bend, both upon heating and upon cooling, realizing the effect of reversible shape memory. At the same time, like the optimally loaded load-bearing elements of any metal structures, this element can be in the form of a thin rectilinear wire working in tension, which is capable of almost infinitely spontaneous deformation during heating and cooling by 2% of the relative length, generating, when heated, hundreds of times greater than bimetallic elements of the same force mass.

The effect of superelasticity is realized in a shape memory alloy product located in the temperature zone of a stable austenitic state. If, at the same time, a product made of a shape memory alloy is deformed, thereby stimulating a martensitic transformation at a constant temperature by means of a forced force, then after the elimination of this effect, the element, like a spring, will completely return to its original shape. The only difference is that, unlike the best springs, it will have an almost inexhaustible resource, and, having the shape of a straight string, it can be superelastically deformed by 7-8% of its relative length, storing ten times more energy than a traditional spring.

The shape memory effect in alloys, for example, based on Ni-Ti, is so clearly expressed that the temperature range can be adjusted with great accuracy from several to tens of degrees by introducing various additional alloying elements into the alloy. In addition, alloys based on Ni-Ti, which received the accepted name throughout the world as the name of nitinol, are quite technologically advanced in processing, resistant to corrosion and have excellent physical and mechanical characteristics: for example, the ultimate strength of nitinol ranges from 770-1100 MPa, which corresponds to similar characteristics of most steels, and the damping capacity is higher than that of cast iron, high ductility and the ability to remember the shape up to a million times. The surface of nitinol elements, like those of many titanium alloys, is coated with titanium dioxide, which determines their highest corrosion resistance to sea water, brines, most acids and alkalis. Nitinol semi-finished products are produced in the form of rods, wires, pipes and sheets  (Fig. 1) The only drawback of nitnol is its very high cost of production of semi-finished products, associated with the very high oxidizability of titanium, which is part of its composition.

(Fig. 1) The only drawback of nitnol is its very high cost of production of semi-finished products, associated with the very high oxidizability of titanium, which is part of its composition.

A unique combination of physical and mechanical properties made it possible to use shape memory alloys in almost all areas where metallic materials can be used, including medicine, space, mining, the production of all kinds of temperature sensors and actuators, robotics in the creation of thermal mechanical devices and the development of unique technologies, etc.

The medicine:

- Gloves used in the rehabilitation process and designed to reactivate groups of active muscles with functional impairment (inter-wrist, elbow, shoulder, ankle and knee joints).

- Contraceptive coils, which, after insertion, acquire a functional form under the influence of body temperature.

- Filters for introduction into the vessels of the circulatory system. They are introduced in the form of a straight wire using a catheter, after which they take the form of filters with a given location.

- Clamps for pinching weak veins.

- Artificial muscles that are powered by an electric current.

-

Anchoring pins and dynamic anchors designed to fix prostheses to the bones (Fig. 2).

- Artificial extension device for the so-called growing prostheses in children.

- Replacement of the cartilage of the femoral head. The replacement material becomes self-clamping under the action of a spherical shape (femoral head).

- Rods for spine correction in scoliosis.

- Temporary clamping fixing elements for the implantation of an artificial lens.

- Spectacle frame (lower part). Due to the superelasticity effect, glass and plastic lenses do not slip out when cooled. The frame does not stretch when the lenses are wiped or used for a long time.

- Orthopedic implants.

- Wire for correcting the dentition.

- Sutures for suturing.

- Porous nitinol constructs for replacing bone defects and treating infected wounds.

- Nets for hernia removal in humans and animals.

- A new class of composite materials "bioceramic-titanium nickelide" for orthopedic dentistry (briquettes). In such composites, one component (titanium nickelide) has superelasticity and shape memory, while the other retains the properties of bioceramics, as a result of which the deformation is reversible.

Heat sensors and alarms:

- Fire alarm (Fig. 3), fire dampers.

- Bath alarm devices.

- Mains fuse (protection of electrical circuits).

- Device for automatic opening and closing of windows in greenhouses.

- Heat recovery boiler tanks.

- Electronic contactor.

- System for preventing the exhaust of gases containing fuel vapors (in cars).

- A device for removing heat from a radiator.

- Device for turning on fog lights.

- Incubator temperature regulator.

- Control valves for cooling and heating devices, heat engines. Room air conditioner sensing valve (adjusts the wind direction in the air conditioner purge port).

- Coffee maker. Determination of the evaporating temperature, as well as for on / off valves and switches.

- Electro-magnetic food processor. Heating is carried out by eddy currents arising at the bottom of the pan under the influence of magnetic force fields. Heating is warned by a signal caused by the action of a titanium nickelide thermocouple.

- Sealing of cases of microcircuits.

- Convection type electronic cooker. A titanium nickelide sensor is used to switch ventilation during microwave heating and heating with circulating hot air.

- Manufacturing of various clamping tools.

Space:

- Antennas of earth satellites.

- Couplings that form vacuum-tight joints for work in open space. Couplings are also used in aviation and automotive engineering.

Robotics. Creation of robots with a shoulder support, an elbow joint, a wrist and a grip that have five degrees of freedom. Flexion of the wrist, clenching and unclenching of the grip are provided by spirals made of Ti-Ni alloy, and the action of the hinge and shoulder support is provided by lengthening or contracting a wire of the same alloy. The position of the hand and the speed of action are regulated by direct current flow with a modulated pulse width. The smoothness of the action of the robot is due to the fact that the given value of the force (force of restoring the shape memory) corresponds to the value of the controlled parameter (current). The actions of the robot are close to the action of the muscular mechanism.

Extractive industry. Manufacturing of a fully automated intelligent downhole system. At the existing production facilities, the production of high-tech and high-performance downhole devices based on structures made of nitinol nanostructured devices and films, reliable in extreme conditions of pressure and temperature drops, compact, easy to manufacture and operate, is being mastered. The use of these smart wells will make it profitable to develop new hard-to-reach fields with complex geology, revive oil production at suspended wells, which will ultimately reduce the operating costs of oil companies, expand their resource base and increase budget revenues.

Other uses. Nitinol is used in recorder drives. The input signal of the recorder is converted into electrical current, which heats the nitinol wire. By lengthening and shortening the wire, the pen of the recorder is set in motion. Since the drive mechanism is very simple, breakdowns are extremely rare.

The property of superelasticity of shape memory alloys is used to create highly efficient springs and accumulators of mechanical energy, to create superelastic spherical segments that operate at specified temperatures, antennas for transceiver equipment (Fig. 4).

The first widespread use of nitinol wire was in the textile industry (brassieres). By 1986, more than 1.5 million of such items were produced.

An amazing, high-tech, easy-to-manufacture and use material with shape memory is gradually taking an increasing place in our life. The range of application of these materials is increasing day by day and promises many more interesting and important things. And we can say with confidence that this is the material of the future.

For the manufacture of all of the above devices, and not only them, we use rods, tubes, wires, sheets of nitinol, successfully produced by LLC "NiTiMet Company" (www.site), the only manufacturer of nitinol in the Russian Federation today.

1. Old Testament. Egyptian executions. Rod of Moses and rod of God's wrath (Book of Exodus, chap. 4-11)

2. Likhachev V.A. and others. Shape memory effect. L., Publishing House LSU. 1987. 216 s.

3. Tikhonov A.S. and others. Application of the shape memory effect in modern mechanical engineering. M., mechanical engineering. 1981.81 s.

4. Khachin V.N. Shape memory. M., Knowledge. 1984. 62 s.

5. Ootsuka K., Shimizu K., Suzuki Yu. Shape memory alloys: Trans. with jap. / Ed. H. Funakubo. M., Metallurgy. 1990.224 s.

6. Shishkin S.V., Makhutov N.A. Calculation and design of load-bearing structures based on shape memory alloys. Izhevsk: Scientific Publishing Center "Regular and Chaotic Dynamics". 2007.412 s.

7. Shape memory alloys in medicine. / V.E. Gunther, V.V. Kotenko, M.Z. Mirgazizov, V.K. Polenichkin, I.A. Vitiugov and V.I. Itin, R.V. Ziganshin, F.T. Temerkhanov. Tomsk: Publishing house of Tomsk University. 1986.208 p.

8. Superelastic shape memory alloys in science, technology and medicine. Reference and bibliographic edition. / S. A. Muslov, V.A. Andreev, A.B. Bondarev, P. Yu. Sukhochev. M., "Folium" publishing house. 2010.456 p.

9. Website of LLC "NiTiMet Company". [Electronic resource] NiTiMET COMPANY. URL: http: //www..php (date of access: 12.02.2013).

Shape memory alloys [Electronic resource] // Vkipediya. 2013. URL: http://ru.wikipedia.org/ (date of access: 12.02.2013).

Send your good work in the knowledge base is simple. Use the form below

Students, graduate students, young scientists who use the knowledge base in their studies and work will be very grateful to you.

Posted on http: //www.site/

FEDERAL AGENCY FOR EDUCATION OF THE RUSSIAN FEDERATION

STATE EDUCATIONAL INSTITUTION

HIGHER PROFESSIONAL EDUCATION

"LIPETSK STATE TECHNICAL UNIVERSITY"

Department of Physical Metallurgy

abstract

on the topic of: "Mparts with shape memory "

Lipetsk 2010

The shape memory effect (SME) in metals, the discovery of which is rightfully considered one of the most significant achievements in materials science, is currently being intensively studied and successfully applied in a number of cases in technology.

Scientific interest in this phenomenon is determined by the desire to understand the physical nature and mechanism of the SME, which expands the fundamental concepts of the inelastic behavior of solids. From a practical point of view, these studies are stimulated by the fact that SMEs in metals are already opening up broad prospects for application in technology, making it possible to create elements and devices with fundamentally new functional properties.

Until recently, inelastic deformation was considered plastic and considered irreversible. Plastic deformation of crystals occurs due to the motion of crystal lattice defects - elementary deformation carriers, which are point defects and (or) dislocations. It is important to emphasize that, in the general case, the arrangement of dislocations and (or) point defects in new positions after deformation after removal of the load may turn out to be stable, i.e. not preferable to the original ones. The consequence of this is the almost complete irreversibility of inelastic deformation. The mechanical aftereffect observed in practice, associated with some reverse movement of defects after unloading, does not exceed 10-4-10-3 relative deformation and can be neglected.

Along with the above mechanisms, plastic deformation can be caused by mechanical twinning of the crystal.

Studies of recent decades have established that there is a wide class of materials (alloys based on titanium nickelide TiNi, brass and bronze of complex composition, etc.), in which the elementary act of plasticity is carried out due to reversible martensitic transformation, elastic twinning and a number of other processes that radically change regularities of inelastic deformation. In these alloys, in particular, complete or partial reversibility of inelastic deformation, called the shape memory effect, can be observed.

The SME of most alloys is based on the so-called thermoelastic martensitic transformations (TUMT). The theory of martensitic transformations is based on the fundamental concepts of the regular nature of the rearrangement of the crystal lattice and the coherence of the coexisting phases of austenite (A) and martensite (M), formulated by G.V. Kurdyumov (the high-temperature phase is usually called austenite, and the low-temperature - martensite).

For alloys with TUMP, the temperature dependence of the phase composition is shown in Fig. one.

When the material is cooled from the austenitic state, martensite begins to form at a certain temperature Mn. With further cooling, the amount of the martensite phase increases, and the complete transformation of austenite into martensite ends at a certain temperature Mk. Below this temperature, only the martensite phase remains thermodynamically stable. Upon heating, the transformation of martensite into austenite begins at a certain temperature An and ends completely at a temperature of Ak. Full thermal cycling results in a hysteresis loop. The width of the hysteresis loop on the temperature scale Ak-Mn or An-Mk can be different for different materials: wide or narrow (Fig. 1, a and b). In the presence of mechanical stresses, the temperatures Mn, Mk, An and Ak can shift towards higher temperatures, and in this case they are denoted as, and.

Rice. 1 - Dependence of the phase composition of the alloy on temperature: a) wide hysteresis; b) narrow hysteresis

It is important to note that at TUMT (in contrast to conventional martensitic transformations, for example, in steels), the interfaces between A and M remain coherent and are easily mobile. Upon cooling (direct transformation) in the temperature range (Mn-Mk), martensite crystals nucleate and grow, and upon heating (reverse transformation) in the temperature range (An-Ak), martensite crystals disappear (transform into austenite) in the reverse sequence (Fig. 2 ).

Rice. 2 - Growth and disappearance of martensite crystals upon cooling and heating (Cu-Al-Mn alloy)

For an isotropic material in the absence of external stresses, martensite plates formed during direct transformation do not have a preferred orientation, and local shear deformations are compensated on average over the volume. In the process of the reverse transformation (M ® A), the rearrangement of the lattice into the original one proceeds strictly in the reverse sequence. In this case, no macroscopic change in the shape of the material is observed, with the exception of a slight change in volume (for example, for an alloy based on TiNi, the change in volume is about 0.34%, which is an order of magnitude less than for steels (»4%)).

In the case of the presence of oriented stresses in the material (for example, the action of an external load), the martensite plates acquire a predominant orientation, and local shear deformations lead to a macroscopic change in the shape of the sample (Le Chatelier-Brown principle). In the process of the reverse transformation (M ® A), the lattice rearrangement occurs according to the "exactly backward" principle, while local shear deformations disappear and, therefore, the macroscopic shape change is eliminated. The external manifestation of this behavior of the material is interpreted as an SME.

For complete restoration of the shape, it is necessary that the martensitic transformation is crystallographically reversible. The crystallographic reversibility of the transformation involves not only the restoration of the crystal structure, which depends on the reverse transformation, but also the restoration of the crystallographic orientation of the initial phase before the transformation. In addition, it is necessary that the deformation is carried out without the participation of sliding, since sliding is an irreversible process, and when heated, the deformation is not eliminated.

Martensitic transformation can be initiated not only by a change in temperature, but also generated by mechanical forces. In accordance with the above, thermomartensite and mechano-martensite are distinguished, and when analyzing phase diagrams (Fig. 1), three more characteristic temperatures are usually introduced: T0, Md, Ad, where T0 is the temperature of thermodynamic equilibrium; Md is the temperature below which martensite can arise not only as a result of a decrease in temperature, but also under the action of mechanical stress; Hell is the temperature above which austenite can appear not only as a result of heating, but also under the influence of mechanical stresses.

The location of these temperatures relative to the hysteresis loop affects the behavior of the material under thermal and force action. In the case of a narrow hysteresis (Fig. 1, b), the Md temperature may turn out to be to the right of the temperature of the end of the austenitic transformation Ak, and with a wide hysteresis - to the left of this temperature (Fig. 25.1, a).

In alloys with narrow hysteresis, induced mechano-martensite, i.e., martensite formed under the action of an external load at temperatures below Md (but above Ak), will be thermodynamically unstable and should disappear upon unloading. In fig. 1, the austenite-martensite transformations are conventionally indicated by vertical arrows. In such materials, the so-called pseudoelasticity effect is observed, which is obviously associated with these phenomena.

With a wide hysteresis, the induced mechano-martensite will be thermodynamically stable and retained during unloading. In this case, deformations will disappear only after heating, i.e. after completion of the reaction M A.

Main effects of thermomechanical behavior of materials with SME

The deformation diagram of SME materials undergoing reversible phase transformations (Fig. 3) differs significantly from that for conventional materials. After elastic deformation (section 0A), the material undergoes significant plastic deformation with very little strain hardening (section AB), where plasticity is due to phase transformation. Further deformation of the material proceeds as usual (section BCD). The stress corresponding to the onset of plastic deformation (point A) associated with phase transformations is usually called the phase yield stress, in contrast to the usual yield point s t.

The phase yield stress depends on the test temperature (Fig. 3, b) and has a minimum value at a temperature close to Mn.

The occurrence of reversible phase transformations in alloys with SME is accompanied by a number of unusual thermomechanical effects, the main of which are considered below.

Transformation plasticity effect (EPP)

This effect can be illustrated as follows. A sample of an alloy with an SME at a temperature higher (in the austenitic state) is loaded with a force P (Fig. 4) and then cooled. In the temperature range, an intense accumulation of deformation e pp is observed as a result of the direct martensitic reaction. After removing the load, the deformation e pp remains. Upon subsequent heating of the deformed sample in the temperature range, the deformation e pp is eliminated, which is a demonstration of the SME. There is a linear relationship between e pp and applied stresses up to certain values, above which deviations of a different nature are observed.

Rice. 3 - Scheme of the deformation diagram (a) and the dependence of the phase yield stress on the test temperature (b) of the material with SME

metal memory shape alloy

Rice. 4 - Accumulation of deformation under load during cooling (solid line) and its elimination during heating without load (dashed lines)

Shape memory effect

The phenomenology of the SME can be illustrated as follows. The sample is deformed (for example, by stretching) at a temperature below Md (Fig. 5, a). When the stress is reached, the sample is deformed plastically (section AB), and this deformation is called phase (e f), since it is caused by phase transformations "austenite-martensite", or "martensite-martensite", or their combinations. In some cases, phase plastic deformation can proceed in several stages, which is determined by the multistage phase transformations.

Rice. 5 - Scheme of the implementation of the SME (a) and the dependence of the degree of restoration of the shape on the preliminary deformation (b)

After unloading (section BC), phase deformation (e f) is retained in the sample. When the sample is heated, as a result of the reverse martensitic transformation in the temperature range (An-Ak), the phase deformation is restored (section SD). This, in fact, is the shape memory effect.

In the case when the restored deformation e< e ф, в образце сохраняется некоторая остаточная деформация e ост, накапливаемая в результате инициализации необратимых каналов пластичности, например, дислокационных.

The dependence of the degree of recovery of deformation h, defined as h = (e vos / e f), is shown in Fig. 5 B. The maximum phase deformation, which is fully restored (h = 1) during the implementation of the SME, depends on the material, its thermomechanical treatment and deformation conditions (for example, for TiNi-based alloys = 6-12%, for Cu-Al-Mn = 4- 10 %).

The most effective deformation method is deformation in the regime of the transformation plasticity effect, when the deformation possibilities of phase transformations are most fully realized. However, technologically such a method is difficult to implement. In reality, in practice, a scheme of active deformation is used at a temperature close to Mn, at which the deforming loads are minimal (Fig. 3, b).

Posted on the site

Similar documents

Regularities and kinetics of martensitic transformation. Nucleation and growth of martensite crystals. Thermoelastic phase equilibrium. Powder structure after nitriding. Study of the microstructure and phase composition of the samples after quenching from different temperatures.

term paper, added 10/11/2015

Functional properties in an equiatomic composition NiTi alloy after quasi-static loading at different temperatures. Single shape memory effect. Study of the dependence of the coefficient of thermal expansion of the alloy on the percentage of nickel.

test, added 04/27/2015

Graphical representation of the dependence of the phase state of the alloy on temperature and composition. General view of the cooling curve of pure metal. Equilibrium in a one-component system. The main experimental and theoretical methods for constructing state diagrams.

lecture added 09/29/2013

Plastic deformation and mechanical properties of alloys. Temporary and internal residual stresses. Two mechanisms of plastic deformation, structural changes. General concept of work hardening. Scheme of displacement of atoms during sliding. Rest and polygonization.

lecture added 09/29/2013

Study of the crystallization process of metal melts. Influence of temperature on the free energy of the liquid and solid phases of the crystallization process. Melt cooling and crystal formation. Regulation of the grain size of crystals. Overview of the structure of the ingot.

abstract added 12/16/2014

Effect of cold plastic deformation and recrystallization on the microstructure and mechanical properties of low carbon steel. Plastic deformation and its effect on the properties of metallic materials. Influence of heating temperature on microstructure.

test, added 06/12/2012

Deformation - a change in the shape and size of a solid under the influence of loads applied to it. Elastic deformation is called the one in which the body restores its original shape, while plastic deformation does not restore the body.

abstract, added 01/18/2009

Critical points in steel, the dependence of their position on the carbon content. State diagram of iron-carbon alloys, phases and structural components: lines, concentration points, temperatures; analysis of phase transformations during cooling of steel and cast iron.

abstract, added 03/30/2011

Study of the regularities of changes in the electrical properties of two-component alloys, depending on their composition. Appearance and installation diagram. A value that estimates the increase in the resistance of a material (conductor) when the temperature changes by one degree.

laboratory work, added 04/11/2015

Influence of time on deformation. Elastic aftereffect, the effect of temperature on the properties of materials. Mechanical properties of materials. Features of compression tests. Dependence of the ultimate strength of plastics on temperature, heterogeneity of materials.

How many kilometers is the Moscow Moscow Ring Road in a circle?

How many kilometers is the Moscow Moscow Ring Road in a circle? Where did the Moscow sparrows disappear: the conclusion of ornithologists Why did the sparrows disappear?

Where did the Moscow sparrows disappear: the conclusion of ornithologists Why did the sparrows disappear? How to make money on homemade toys?

How to make money on homemade toys? Coloring polymer clay in different ways

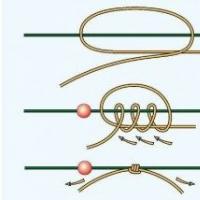

Coloring polymer clay in different ways Self-tightening knot: types, methods of knitting

Self-tightening knot: types, methods of knitting How to find clients for a beginner interior designer Where to find orders for design

How to find clients for a beginner interior designer Where to find orders for design International children's creative competition "Colorful colors of autumn. Important organizational points

International children's creative competition "Colorful colors of autumn. Important organizational points