Printing on various surfaces. Printing technologies. Universal technology for applying a photographic image to a wide variety of surfaces How to apply an image to any surface

Opportunities today printing technologies so expanded that images, graphics and text can be printed on a wide variety of surfaces. As a material for printing, not only ordinary paper or cardboard is no longer suitable, but also plastic film, textiles, ceramics, glass and metal. A particular material requires the selection of the most optimal printing method. In this article we will talk about how printing is carried out on a wide variety of surfaces and list the main printing technologies used to produce various printed products.

Drawing on fabric

Printing on a fabric surface is the application of drawings and inscriptions on T-shirts, bags, baseball caps and other products. Pictures and inscriptions on textiles can be applied using a variety of printing technologies, but the most popular are sublimation and direct digital printing technologies. Sublimation involves the full-color application of a variety of patterns to textiles that are resistant to sunlight, temperature fluctuations and washing.

DTX-400 Textile Printer for Printing on Textile Surfaces

It is a popular technology used to produce branded textiles. The image is applied to the fabric without loss of color quality and brightness, while it is characterized by resistance to abrasion and mechanical damage. Sublimation is the process of thermal transfer of an image or inscriptions onto a flat and easily accessible fabric surface, when, ultimately, the image is “inside” the product itself. During sublimation, the fabric surface on which the pattern is applied can withstand short-term exposure to high temperatures - up to 190 degrees, due to which the pattern is “fixed” on textile products.

Sublimation printing technology allows you to apply an image to the surface of the fabric with a wide colors and, thus, get the picture on textiles of the highest photographic quality. In addition to this, the very process of such thermal transfer does not take much time and is relatively simple. Sublimation is suitable for printing both small and large volumes. It allows not only printing on textile surfaces, but also transferring drawings to ceramics, fiberglass and even wooden surfaces, if they are previously coated with a certain composition. But as far as fabrics are concerned, sublimation printing is only suitable for textiles in which the proportion of synthetic fibers exceeds 50%.

Direct digital printing is also widely used for printing pictures and writing on fabric surfaces. This printing method provides that at first the textiles are impregnated with a special composition, which, when the image is applied, does not allow the ink to "spread" along the fibers. This ensures high-definition prints and prints at resolutions up to 720 dpi. The product made with this method is characterized by excellent resistance to light, abrasion and everyday washing. The range of colors used in direct digital printing is very wide, which makes it possible to print almost any image, logo or symbolism.

Leather, metal and wood surfaces

The so-called mesh screen printing or silk-screen printing has a wide range of possibilities. It can be used to print on metal and wood surfaces, artificial and natural leather, self-adhesive films. Silkscreen printing is nothing more than a development of the usual stencil used for decorative painting walls and textiles. The printing principle is as follows: dyes are simply squeezed through a fine-mesh mesh on a stencil, and one paint is applied per one such rental. Taking into account the peculiarities of the technology, silk-screen printing is used mainly for printing on flat surfaces of various materials. In this case, the size of the applied pattern is limited by the dimensions of the stencil mesh itself.

Kincolor UV1209C - printer for printing on metal, glass, wallpaper, leather, acrylic plastic

Kincolor UV1209C - printer for printing on metal, glass, wallpaper, leather, acrylic plastic The images printed on metal or wood by silk-screen printing are resistant to light and aggressive environments. With the help of silk-screen printing, you can print the scales of electrical appliances, apply bright drawings on the surface of leather products, fill in rough shapes with a thick layer of paint. It is possible to use a wide range of printing inks on certain binding materials. There is only one requirement for the inks used - they must not destroy the material of the stencil itself (synthetic materials or metal) and not dry quickly enough to ensure a stable printing process.

For printing on metal, leather and wood surfaces using silk-screen printing, a certain layout is initially created in vector form. Then, a special film is produced, on which the model for illumination is located. This patterned film is applied tightly to the stencil and placed under a bright light source. At the next stage, the stencil is illuminated, after which the stencil mesh becomes suitable for drawing a pattern directly on the surface of metal or natural leather.

Another common method of printing on difficult surfaces such as wood, metal or leather is with pad printing. This method first began to be used in Switzerland for marking when creating watches, but in the 20th century it became much more widespread thanks to the appearance of special pad printing presses. While silk-screen printing is more suitable for products with a flat surface, pad printing is used in the production of various products with uneven surfaces.

The swab printing method is based on the following process: ink is transferred from the printing plate to the surface by means of a special swab. This tampon is made of a sufficiently resilient, elastic material. He sinks onto the printing plate and takes with him some of the ink, while strictly observing the dimensions of the image. Then the tampon is firmly pressed against the printing surface, ensuring the transfer of the image. Here, the quality of the finished print directly depends on the quality of the form used, which is usually made from steel or photopolymerized plates.

The use of a tampon with elastic characteristics allows this technology to work with a wide variety of surfaces. Suffice it to mention that pad printing is used in radio electronics and instrumentation for marking or decorating a wide range of products. When there is a need to print a pattern on three-dimensional products with complex geometry, uneven, concave or convex surfaces, pad printing is the best option. In addition to metal, leather and wood products, pad printing allows you to apply images and inscriptions to rubber, porcelain, glass, plastic and cardboard surfaces. On top of that, is this also a very cost effective way to print? often used, for example, for decoration or personalization souvenirs... The only drawbacks of the technology are the impossibility of printing very small details of the layout and using more than five colors at a time when printing.

Polyethylene surfaces

Plastic bags are widely used today to protect or pack products, and as a practical marketing tool. Such packages often act as handout material or packing souvenirs at exhibitions and presentations. For drawing on polyethylene surfaces are actually suitable different technologies printing, however, two methods are most often used - this is the already mentioned screen printing and flexo printing. Silk-screen printing is usually used when you need to print a small number of plastic bags (up to five thousand pieces) with the ability to apply multi-color images. Moreover, it is possible to apply images and inscriptions both on one and on both sides of the package. In turn, flexo printing is used when it is necessary to print significant volumes of polyethylene products.

Matan Barak iQ 3 printer - printing on polyethylene, self-adhesive film, banner, mesh

Matan Barak iQ 3 printer - printing on polyethylene, self-adhesive film, banner, mesh Flexo printing involves the use of special relief printing forms that are distinguished by their elasticity and elasticity. With the help of such a form, covered with an ink layer, the image during the printing process is transferred directly to plastic wrap or other surface. A feature of this printing technology is the ability to apply pictures and inscriptions on non-porous surfaces, which allows flexo printing to be used in the production of plastic bags. Other equally common applications for flexo printing are gift wrapping, wallpaper, newspaper and magazine tabs.

Printing on glass and ceramic surfaces

One of the popular methods for decorating ceramic mugs, as well as other ceramic, porcelain and glass products, is decal. As you know, beautiful mugs with corporate symbols are not only a memorable gift, but at the same time effective advertising... Decoloration provides the application of a logo or pattern on ceramic, glass and porcelain surfaces as follows: first, the pattern is printed on paper, and then transferred to the desired material, followed by firing. This technology, in comparison with sublimation or pad printing, guarantees a higher stability of the applied image and makes it possible to print on surfaces of various shapes. With the help of decoloring, you can create elegant piece items from ceramics or porcelain, including the application of an original pattern in gold or silver. V last years this technology printing has gained immense popularity due to the possibility of making colorful souvenirs, After all, what modern office can do without ceramic mugs printed on them corporate logo? If certain rules are observed, a pattern printed in this way on glass and ceramic surfaces can be preserved without loss of quality for ten years.

Although glass can now be printed using a wide variety of technologies, UV printing is the most impressive in this regard, which has appeared relatively recently. Previously, to print a drawing on such a smooth, even surface as glass, it was necessary to use a special self-adhesive film, which was “rolled” by hand over the product. However, with the advent of ultraviolet printing, the need for this has completely disappeared. The fact is that devices for printing with ultraviolet inks are capable of applying an image or inscriptions directly to glass. For this, special ink is used, which polymerize or harden under the influence of ultraviolet radiation, forming a stable and durable film with an image on the glass surface.

But the advantage of UV printing on glass also lies in the fact that you can achieve truly impressive effects in the form of light haze, airiness or fancy play of colors on transparent glass. As a result, the glass products on which the images are printed begin to look like real, elegant stained glass windows. UV printing allows you to add additional volume to individual parts of the drawing or to obtain areas with different ink densities.

So, at the moment, the possibilities of printing technologies are truly endless. Via different ways prints can print colorful and crisp images on a wide variety of surfaces and materials, including plastic, glass, metal, polyethylene, ceramics, porcelain and wood. Wherein modern technologies application of the image guarantee high resistance of the press to external adverse factors and durability.

I present to you new technology applying photographic images to various surfaces (glass, metal, stone, wood, plexiglass, plastic, leather, and so on), which I simply called “Universal Technology”. With this technology, you can create a lot of options. successful business, for example, drawing images on auto glass, car bodies, furniture glass, shower cabins, mirrors, stone, tiles and so on.

Many people know about such glass processing technologies as sandblasting, chemical matting, engraving. Each of them has both advantages and major disadvantages, for example, in sandblasting, even the most primitive, it is required to build sandblasting chambers of considerable size, which need to be equipped with a system of exhaust ventilation, lighting, supply compressed air, in some cases - an abrasive recovery system. Add the mandatory use of funds here individual protection, the duration of processing the product (in the absence of a powerful compressor), the need to use special formulations to protect the image.

There are also many disadvantages in chemical matting; in some formulations for matting, formulations are used that are extremely harmful to health. The use of photomatization is also a complex multistage process. Therefore, I was constantly working on safer and simpler processing methods. The result was "Universal Technology".

An example of flat images on glass:

|

The name of the technology fully justifies itself, here it is Main advantages before other technologies:

- Drawing images of photographic quality and large size on almost any surface (glass, mirror, metal, stone, wood, plastic, plexiglass, leather, and so on).

- High quality and realism of the resulting images.

- Creation of images with a stereo effect (volume effect).

- The use of any printing devices (printers and so on) is not used.

- No sandblasting or chemical treatment of the workpiece is used.

- Photoresists and similar technologies are not used.

- For work, images of any format are used, both raster (photos, drawings, illustrations, scanned images, and so on) and vector.

- To work, you do not need to have your own workshop or workshop - images can be applied directly to the finished product (furniture, windows, shop windows, cars, and so on).

- The ability to perform the entire cycle of work by one person.

- Intuitive and simple work flow algorithm.

- Starting capital from 5-7 thousand rubles (this amount does not include the cost of technology).

- Absolute availability of all materials necessary for work.

- The work does not require any artistic skills.

- Very low cost - from 200 rubles per 1 square meter of the product.

- The images are very durable, do not fade, they can only be removed with a special compound.

These are the main features of the Universal Technology; in fact, there are many more of them.

The application of images is carried out using an airbrush for background work or a spray gun. Moreover, you do not need to draw anything, a special coloring composition is applied by continuous spraying onto a workpiece covered with a special template. After removing the template, the image is almost ready, conveying all the shadows and penumbraes, as in a photo or raster image. Thus, the minimum set of equipment that is required for this technology is the simplest airbrush or spray gun and a small compressor (for operation, a pressure of 2-3 bar is required).

|

Sample image on glass With stereo effect: |

- on any surface urgently

- We apply on ready-made packages, on flash drives, on ready-made plastic cards, on colored papers, on folders for pens, on rubber surfaces, on envelopes, on glasses, on plates, on mugs, on spoons and forks, on plastic bags, for all types of business souvenirs, for clothes, for cars (it is also possible temporary temporary car paint), walls, floors, rugs, furniture, mirrors…. On any surface!

- Free delivery of finished products in Moscow

- Free pick-up of products for application

- Execution period from 1 day

Logo application cost

The price depends on the type of product and the applied image. Send your layout and get a quick calculation of the application. The minimum order for applying a logo is 3500 rubles

Where can the logo be applied?

- on envelopes

- paper and plastic bags

- pens, lighters, key rings

- mugs

- T-shirts, corporate clothing, towels

- diaries

- umbrellas

- corner folders, paper folders

- ready-made postcards and diplomas

- for any paper products

- on plastic, glass, rubber, leather, leatherette

Possible ways to apply the logo

- silkscreen

- pad printing

- direct digital printing on finished products

- laser engraving

- application

- sublimation

- thermal transfer

- uv print

all application methods are available! depending on the type of product and the number of colors in the logo, the method of application is selected

Put a logo on a USB flash drive

Applied the logo to the finished fresnel lenses

put the logo on ready-made efalin bags by thermal transfer

applying a logo on envelopes

more package)

we put the logo on the key rings

we print on T-shirts right away

embroidery on towel

direct printing on corporate clothing

printing on pens

How many kilometers is the Moscow Moscow Ring Road in a circle?

How many kilometers is the Moscow Moscow Ring Road in a circle? Where did the Moscow sparrows disappear: the conclusion of ornithologists Why did the sparrows disappear?

Where did the Moscow sparrows disappear: the conclusion of ornithologists Why did the sparrows disappear? How to make money on homemade toys?

How to make money on homemade toys? Coloring polymer clay in different ways

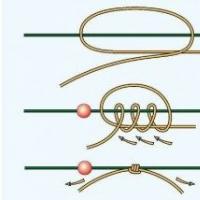

Coloring polymer clay in different ways Self-tightening knot: types, methods of knitting

Self-tightening knot: types, methods of knitting How to find clients for a beginner interior designer Where to find orders for design

How to find clients for a beginner interior designer Where to find orders for design International children's creative competition "Colorful colors of autumn. Important organizational points

International children's creative competition "Colorful colors of autumn. Important organizational points