GOST 6456 82 abrasive paper

UDC 621.921.67.02 1: 006.354 Group G25

UNION STATE STANDARD S S R

SKINS GRINDING PAPER Specifications

Ata \ e paper Specifications

Validity from 01/01/83 to 01/01/93

This standard applies to paper grinding skins intended for abrasive processing of various materials without cooling or using cutting fluids based on oil, kerosene, white spirit.

1. TYPES AND SIZES

1 1. Abrasive paper should be made of types:

1 - aphids for machine and manual processing of non-metallic materials (wood, leather, rubber, plastic, etc.);

2 - for machine and manual processing of metals, alloys.

1 2. The abrasive paper should be produced in rolls, the dimensions of which are indicated in table. one.

Table 1

Reprinting prohibited

Official edition ★

|

Continued, l 7 y. / |

||||||||||||||||

|

||||||||||||||||

Note. According to the customer's order, additional production of rolls with a length of more than 100 m is possible

1.3. The abrasive paper must be made with the following types of working layer:

C - solid;

P - embossed.

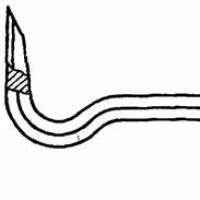

1.4. The designs and dimensions of the embossed working layer must correspond to those indicated in the drawing and in table. 2.

APPENDIX 2

METHOD FOR DETERMINING THE CUTTING ABILITY OF THE GRINDING

K The essence of the method

The ram-t method on the determination of the mass of organic glass polished with a sample of the abrasive skin during the test.

2. Equipment and materials

2.1. Diagram and description of the MI-2 type device according to GOST 426-77.

2.2. Samples of abrasive paper with an outer diameter (1742 = 5) mm and a hole diameter (55 ± 3) mm

2.3. Plates made of organic glass of the TOSN brand - in accordance with GOST 17622-72.

2.4. Rubber pads 60-80 Shore.

INFORMATION DATA

1. DEVELOPED AND INTRODUCED by the Ministry of Machine-Tool and Tool Industry of the USSR

DEVELOPERS

E. I. Ardashev; E. S. Viksman; V. T. Ivashinnikov; N. A. Ilyina; V. A. Kvitko; L.A. Kogan; O. F. Kotlyarov; I. F. Korchmar; V. A. Morozov; E. B. Petrosyan; A. A. Pylnee; S. K. Rozin; V. A. Rybakov; N. V. Syreishchikova; V. D. Tunikov; V. N. Tyrkov

2. APPROVED AND PUT INTO EFFECT by the Decree of the USSR State Committee for Standards dated 02/18/82 No. 735

3. The term of the first inspection is 1992.

Inspection period - 5 years

5. REFERENCE REGULATORY AND TECHNICAL DOCUMENTS

|

About nachenis NTD'a |

’Omsr p \ n ~ | |||

|

given by lcli I a |

|

Pr yugenio |

||

|

Prnc / K ^ pie |

||

6. The validity period was extended until 01.01.93 by the Resolution of the State Standard of the USSR dated 04.23.87 No. 1374

7. REPUBLICATION (April 1990) with Amendments No. 1, 2 G 3, approved in June 1984, April 1987, July 1989 (NUS 9-84, 8-87 11-89J

The angle of inclination of the relief a should be 5 ° -85 °.

1.5. The deviation from parallelism of the forming lines of the relief should be within the tolerance for the relief step.

An example of a symbol for a paper abrasive cloth of type 1, with a continuous working layer C, 1000 mm wide. length 50 m, on paper grade 0-200, from normal electrocorundum grade 15A, grain size 25-N, on skin glue:

2. TECHNICAL REQUIREMENTS

2.1. Abrasive paper shall be manufactured in accordance with the requirements of this standard.

2.2. The abrasive paper should be made from the abrasive materials specified in table. 3.

Note. At the request of the consumer, it is allowed to manufacture a grinding wheel and other grades of grinding materials or their mixtures.

GOST € 456-82 S. 4

2 3. For the manufacture of abrasive skins, paper should be used as a basis in accordance with GOST 18277-72, GOST 10127-75 and industry regulatory and technical segmentation for 6) magician in accordance with table. 4.

|

T a 5 1 p l a 4 |

|||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||

|

(Modified edition, Amendment No. 2). 2.4. The abrasive paper should be made from the grinding materials of the grain sizes indicated in table. 5. |

|||||||||||||||||||||||||||||||||||||||||||||

Note According to the spraying icon, it is baked about g t n g ech to 1 itch

(Modified edition, Amendment No. 3).

2.5. Grinding material must be bonded to the base of the flesh with glue in accordance with GOST 3252-80 or other bonds in accordance with industry regulatory and technical documentation.

Note It is allowed to enter in the bundle ipau.L i km lr. c ie niii cops

2.6. Grain composition of grinding materials - according to GOST 3647-89.

2 7. (Deleted, Amendment No. 3).

2 7 1. On the working surface of the grinding skin t with a cured working layer, the total area of wrinkles, folds,

coils without abrasive grains, filled with a binder, should not exceed 0.5% of the roll area.

Note By alignment with the consumer, the total area of the indicated defects is not more than 1% of the roll area.

2.7.2. On the working surface of the abrasive paper with a relief working layer, the total area of defects (merging and non-printing) of the relief layer per 1 m 2 should not exceed 5% of the area of the roll with the applied abrasive material.

(Modified edition, Amendment No. 3).

2.7.3. In a roll of sanding paper with a width of up to 1250 mm, edges with a width of more than 10 mm with defects are not allowed, with a width of more than 1250 mm - more than 15 mm.

Application Pa of the working surface of silicon carbide and electrocorundum in abrasive skins of legal status 6-M40, point glue formations or blotches protruding above the working surface are not allowed.

(Modified edition, Amendments No. 1, 2, 3).

2.8. The unevenness of the thickness of the sanding paper should correspond to the values indicated in table. 6.

Table b

|

Per (uniformity then go no mm, no bote |

|

2.9 The tensile strength of the abrasive paper, depending on the grade of paper, must correspond to the values specified in table. 7.

|

Table 7 |

||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||

2.10. Coefficient of application of grinding g 1 serial on the base Df for grinding sandpaper with a relief working layer should be 0.40-0.75.

2.11. The moisture content of the sanding paper should be 3-7%.

2.12. The reduced wear of electrocorundum and glass grinding skins should correspond to the values indicated in table. eight.

Table 8

|

Grain |

Reduced j |

SHOS FOR T "WHATS |

il 1 and f. Prvsdeapyp (nchis carbidkrem.ch "7 evoy srg ...

(Modified edition, Amendment No. 2).

2.13. The cutting ability of the abrasive paper under the test conditions specified in the mandatory annex 2 must correspond to the values specified in table. 8a.

Table 8a

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

(Modified edition, Amendments No. 2, 3). 3. RULES OF ACCEPTANCE 3.1. Acceptance inspections and periodic tests should be carried out to check that the abrasive paper meets the requirements of this certificate. 3.2. Acceptance control for compliance with the requirements of Ш7. 1.2, 2.7.1, 2.7.2 and 2 73 should be exposed to at least 1% of rolls of abrasive paper from the batch, but not less than 3 pieces, per g, 1.4; 1.5; 2.12 and 2.13 - 0.1%, but not less than 3 pcs. 3.1. 3.2. (Modified edition, Amendment No. 2). 3 2.1. The batch must consist of abrasive skins:> one-Ein. Characteristics, issued in one shift and at the same time submitted for acceptance on one document. 3.3. If, during the acceptance control, it is established that the sewing requirements of the standard are more than about 1 in a controlled manner, then the batch is not accepted. (Modified edition, Amendment No. 2). 33 1 If the charters of the youth are not in accordance with the requirements of the standard for one of the monitored indicators, then a second control is carried out on a doubled number of rolls of skin If there are defects in the resampling, the lot is not accepted. (Introduced additionally, Amendment No. 2). 3.4. Products (one of the roll sizes) that have passed acceptance control (according to clause 3 2) for compliance with the requirements of clauses 2 8 and 2 10 0.5%, but not less than 3 pieces, clauses 2 9 and 2 11 0 , 5% rupes of thin section young skin, grain size 40; 8, 5 and> 140, but not less than 3 pcs., Item 2 9- on all types of bases. (Modified edition, Amendment No. 2). 3.5. Periodic testing should not be carried out [hedgehog, once a year. (Modified edition, Amendment No. 3). 4. METHODS OF CONTROL AND TESTING 4.1-4.1.2. (Excluded, Amendment No. 2). 4.2. The dimensions and external defects of the working surface of the skin are measured with a measuring metal stick according to EOST 427-75 or a measuring metal roll to l according to GOST 7502-89. 4.2.1. The angle of inclination of the relief is measured with universal measuring instruments or a special template. 4.3. The unevenness of the thickness of the skin is measured with a micrometer type MK (with a tolerance limit of ± 0.01 mm) at a distance of at least 10 mm from the roll edge. (Modified edition, Amendment No. 2). 4 4. Calculation of the coefficient of application of the grinder ia on the base Lee is given in the mandatory Appendix 1. 4.5. To determine the moisture content of the grinding sheet, three samples are taken with dimensions of 100XYO0 mm, weighed on a technical balance with a tolerance limit of ± 0.01 g. Samples of the grinding sheet are placed in an oven and dried at a temperature of (100 ± 5) ° C until until the difference between two successive weighings does not exceed 0.02 g. The moisture content of the abrasive paper is determined by the difference in masses before and after drying and is calculated as a percentage of the initial mass. 4.6. The reduced wear of the abrasive paper (the ratio of the grain size of the sanding paper to its crumbling) is determined on the K3IJI VNIIASH device by abrasion of the sandpaper on the sandpaper for 2 minutes at a load of 29.4 N. Two samples of abrasive paper with dimensions 396X50 mm and 520X50 mm are subjected to testing. The samples are weighed on a technical balance with a tolerance limit of ± 0.05 g. Note: 1. Crumbling: l of the sanding paper is equal to the mass of the crumbling working layer at a given time interval under given conditions 2. When combing? reduced wear for grain sizes M63; M50 and M40 in the numerator, taking the numbers 5, respectively; 4 and 3. (Modified edition, Amendment No. 2). 4.7. The method for determining the cutting ability of the abrasive paper is given in the mandatory Appendix 2. 4.8. The determination of the tensile strength of the abrasive paper is carried out in accordance with GOST 13525.1-79, except for paragraphs. 3.1 and 4.1 at ambient temperature. Limit deviations in the size of test specimens should be ± 1.0 mm. (Modified edition, Amendment No. 2). 4.9. Samples for koshrol according to PP. 4.1-4.8 is taken from any place on the roll, at least 10 mm from the end of the roll or edges. The value of indicators for PP. 4.3 and 4.5-4.8 are taken as the arithmetic mean of the three definitions. 5. MARKING, PACKAGING, TRANSPORTATION AND STORAGE 5.1. On the non-working surface of the sandpaper roll, every (235 D 20) mm in the longitudinal direction and every (200 ± 20) mm in the transverse directions should be applied: manufacturer's trademark; conventional designation (except for the type and indication of the type of the working layer); batch number. Notes: 1. When using a mixture of grinding materials - in the conventional designation, mark the brand of the main grinding material, when using a mixture of zsrnist.shech - mark the main grain size. 2. By agreement with the consumer, the dimensions of the roll are allowed n: apply (Modified edition, Amendments No. 2, 3). 5.2. Ligament marking: skin glue M; combined ligament - K. 5.3. Winding the sanding paper into rolls should be even and dense, with the working layer outward, not allowing the formation of wrinkles, folds and creases. The end surface should be flat, the projections of the roll edges up to 1250 mm wide should not exceed 5 mm, over 1250 mm wide - 10 mm. (Modified edition, Amendment No. 3). 5.4. Each roll of sanding paper should be wrapped with a double layer of paper in accordance with GOST 18277-72, GOST 2228-81 or GOST 10127-75. " The roll must be sealed at the binder. Layers of wrapping paper should cover the ends of the roll and ensure its safety during transportation. 5.5. (Deleted, Amendment No. 3). 5.6. Each packaged roll must be labeled or stamped with the following information: manufacturer's trademark; symbol; date of issue and batch number; technical control stamp; the image of the State Quality Mark according to NTD for the abrasive skin, which has been appropriated with the State Quality Mark in accordance with the established procedure. 5.7-5.16. (Excluded, Amendment No. 3). 5.17. Other requirements for labeling and packaging, as well as transportation and storage - in accordance with GOST 27595-88. (Introduced additionally, Amendment No. 3). Sec. 6. (Deleted, Amendment No. 2). GOST 6456-82 С 10 PRNYUZHENPE / 05 ". Back CALCULATION OF THE APPLICATION RATIO OF GRINDING MATERIAL ON THE BASE Coefficient of application of grinding material on the base (K *, is the ratio of the area of the base with the applied grinding material to its total area) for: versions 1 and 3 is calculated by the formula where a is the width of the relief, mm, t is the step of the relief, mm; version 2 is calculated by the formula execution 4 is crumbled according to the formula a (2t-u \ K H = ^ (Modified edition, Amendment No. 1). |

Approved and put into effect

By the decree of the USSR State Standard

STATE STANDARD OF THE UNION OF SSR

SKINS GRINDING PAPER

TECHNICAL CONDITIONS

Abrasive paper. Specifications

GOST 6456-82

Group G25

OKP 39 8600

Validity

INFORMATION DATA

1. Developed and introduced by the USSR Ministry of Machine-Tool and Tool Industry.

Developers: E.I. Ardashev; E.S. Wicksman; V.T. Ivashinnikov; ON THE. Ilyin; V.A. Kvitko; L.A. Kogan; O.F. Kotlyarov; I.F. Tavern; V.A. Morozov; E. B. Petrosyan; A.A. Pylnev; S.K. Rosin; V.A. Rybakov; N.V. Syreishchikova; V.D. Tunics; V.N. Tyrkov.

2. Approved and put into effect by the Resolution of the USSR State Committee for Standards dated 02/18/1982 N 735.

3. The term of the first inspection is 1992.

Inspection period - 5 years.

4. Instead of GOST 6456-75.

5. Reference normative and technical documents

────────────────────────────────────┬─────────────────────────────

Designation of NTD, │Number of paragraph, subparagraph,

────────────────────────────────────┼─────────────────────────────

GOST 426-77 Appendix 2

GOST 427-75│4.2

GOST 2228-81│5.4

GOST 3252-80│2.5

GOST 3647-80│2.6

GOST 7502-89│4.2

GOST 10127-75-2.3; 5.4

GOST 12172-74 Appendix 2

GOST 13525.1-79│4.8

GOST 17622-72 Appendix 2

GOST 18277-72-2.3; 5.4

GOST 27595-88│5.17

6. The validity period was extended until 01.01.1993 by the Decree of the State Standard of the USSR dated 04.23.1987 N 1374.

7. Reissue (April 1990) with Amendments N 1, 2, 3, approved in June 1984, April 1987, July 1989 (IUS 9-84, 8-87, 11-89).

This standard applies to abrasive paper intended for abrasive processing of various materials without cooling or using cutting fluids based on oil, kerosene, white spirit.

1. TYPES AND SIZES

1.1. Sandpaper should be made of types:

1 - for machine and manual processing of non-metallic materials (wood, leather, rubber, plastic, etc.);

2 - for machine and manual processing of metals, alloys.

1.2. Sandpaper should be produced in rolls, the dimensions of which are indicated in table. one.

Table 1

───────────┬────────────────────────────────┬─────────────────────

Granularity Width, mm (pre-dev. +/- 3.0) │ Length, m (pre-dev.

│ 720; 750; 800; 850; 900; 1000│30

40 - 16│1250; 1350; 1400│

───────────┼────────────────────────────────┤

40; 32│1000│

───────────┼────────────────────────────────┼─────────────────────

40 - 16│720; 750; 800; 850; 900│50

───────────┼────────────────────────────────┤

25 - 10│1000│

───────────┼────────────────────────────────┤

───────────┼────────────────────────────────┤

12 - M40 │1250; 1350; 1400│

├────────────────────────────────┼─────────────────────

│720; 750; 800; 850; 900│100

───────────┼────────────────────────────────┤

8 - M40 │1000│

Note. At the request of the consumer, it is allowed to manufacture rolls with a length of more than 100 m.

1.3. The abrasive paper must be made with the following types of working layer:

C - solid;

P - embossed.

1.4. The designs and dimensions of the embossed working layer must correspond to those indicated in the drawing and in table. 2.

Execution 1

Execution 2

Execution 3

Execution 4

table 2

Dimensions, mm

─────────────┬────────────────────┬───────────────────────────────

Granularity │Width, a│Pitch, t

├────────────┬───────┼──────────────┬────────────────

│Interval│ Prev │Interval│Prev. off

││ off ││

50 - 40│ 3,0 - 15,0 │+/- 1,0│4,0 - 38,0│+/- 2,0

─────────────┼────────────┤├──────────────┤

32 - 25│ 1,5 - 12,0 ││3,0 - 30,0│

─────────────┼────────────┼───────┼──────────────┼────────────────

20 - 16│ 1,0 - 10,0 │+/- 0,3│2,5 - 25,0│+/- 1,0

─────────────┼────────────┤├──────────────┼────────────────

12 - M40│ 0.5 - 5.0││1.0 - 20.0│ +/- 0.5

The angle of inclination of the relief should be 5 ° - 85 °.

1.5. The deviation from parallelism of the forming lines of the relief should be within the tolerance for the relief step.

An example of a conventional designation of a paper abrasive cloth of type 1, with a continuous working layer C, 1000 mm wide, 50 m long, on paper of grade 0-200, from normal electrocorundum grade 15A, grain size 25-N, on flesh glue:

1C 1000 X 50 P2 15A 25-N M GOST 6456-82

2. TECHNICAL REQUIREMENTS

2.1. Abrasive paper shall be manufactured in accordance with the requirements of this standard.

2.2. The abrasive paper should be made from the abrasive materials specified in table. 3.

Table 3

Type of abrasive Abrasive grade

Normal electrocorundum -15A; 14A; F14A; 13A; F13A

White fused alumina 25A; 24A; 23A

Alloyed alumina-94A; 93A; 92A; 91A; 91A-M and 92A-M

Zirconium alumina -38A

Monokorund-44A; 43A

Green silicon carbide│64C; 63C

Black silicon carbide -54C; 53C; 51C

Glass│71St

Note. At the request of the consumer, it is allowed to manufacture abrasive skins from other grades of abrasives or their mixtures.

2.3. For the manufacture of abrasive skins, paper should be used as a basis in accordance with GOST 18277-72, GOST 10127-75 and industry-specific regulatory and technical documentation for paper in accordance with table. 4.

Table 4

────────────────┬─────────────────┬─────────────────┬─────────────

Paper grade│Conditional│Paper brand│Conditional

│ designation designation

────────────────┼─────────────────┼─────────────────┼─────────────

0-140│P1│BSh-140│P6

0-200│P2│BSh-200│P7

0-210│P3│BSh-240│P8

0-235│P4│BV-225│P9

0-240│P5│BVK-225│P10

││OV-200│P11

Note. If the paper does not have an established symbol, it is allowed to indicate its brand in the symbol of the abrasive paper.

(Modified edition, Amendment N 2).

2.4. The abrasive paper should be made from abrasives of the grain sizes indicated in table. 5.

Table 5

─────────────┬────────────────────────────────────────────────────

Conditional│Granularity

designation ├──────────────┬───────────┬──────────────┬────── ────

paper│electric corundum- │monocorundum│carbide│glass

│with silicon│

│ sanding materials│││

─────────────┼──────────────┼───────────┼──────────────┼──────────

P2; P3; P4; │50-M40│50 - 6│25-M40│50 - 6

P5; P7; P8; ││││

P9; P10; P11││││

─────────────┼──────────────┤├──────────────┼──────────

P1; P6│25-M40││16-M40│25 - 6

Note. At the request of the consumer, it is allowed to manufacture abrasive skins of other grain sizes or their mixtures.

(Modified edition, Amendment N 3).

2.5. Grinding material must be bonded to the base with flesh glue in accordance with GOST 3252-80 or other bonds in accordance with industry regulatory and technical documentation.

Note. It is allowed to introduce dyes or coloring pigments into the bundle.

2.6. Grain composition of grinding materials - in accordance with GOST 3647-80.

2.7. (Deleted, Amendment No. 3).

2.7.1. On the working surface of the abrasive paper with a continuous working layer, the total area of wrinkles, folds, areas without abrasive grains, filled with a binder, should not exceed 0.5% of the roll area.

Note. By agreement with the consumer, the total area of these defects is not more than 1% of the roll area.

2.7.2. On the working surface of the abrasive paper with a relief working layer, the total area of defects (merging and non-printing) of the relief layer per 1 m2 should not exceed 5% of the area of the roll with the applied abrasive.

(Modified edition, Amendment N 3).

2.7.3. In a roll of sanding paper with a width of up to 1250 mm, edges with a width of more than 10 mm with defects are not allowed, with a width of more than 1250 mm - more than 15 mm.

Note. On the working surface of silicon carbide and electrocorundum abrasive paper of grain size 6-M40, point glue formations or blotches protruding above the working surface are not allowed.

(Changed edition, Rev. N 1, 2, 3).

2.8. The unevenness of the thickness of the sanding paper should correspond to the values indicated in table. 6.

Table 6

────────────────────────────────┬─────────────────────────────────

Grit Thickness unevenness, mm, not

────────────────────────────────┼─────────────────────────────────

M63 - M40│0.06

2.9. The tensile strength of the abrasive paper, depending on the grade of paper, must correspond to the values indicated in table. 7.

Table 7

──────────┬─────────────────────┬───────────┬─────────────────────

Conditional Breaking load, │ Conditional Breaking load,

designation - │Н, not less, in│ designation Н, not less, in

Paper DirectionsPaper Directions

├──────────┬──────────┤├──────────┬──────────

│longitudinal│transverse││longitudinal│transverse

P1│196.0│107.8│P7│225.4│117.6

──────────┼──────────┼──────────┼───────────┼──────────┼──────────

P2│245.0│137.2│P8│274.4│137.2

──────────┼──────────┼──────────┼───────────┼──────────┼──────────

P3│294.0│156.8│P9│401.8│175.5

──────────┤│├───────────┼──────────┼──────────

P4│││P10│372.4│157.0

──────────┼──────────┼──────────┼───────────┼──────────┼──────────

P5│392.0│98.0│P11│225.5│117.6

──────────┼──────────┤│││

P6│176.4││││

2.10. The coefficient of application of the abrasive to the base for abrasive cloth with a relief working layer should be 0.40 - 0.75.

2.11. The moisture content of the sanding paper should be 3 - 7%.

2.12. The reduced wear of electrocorundum and glass grinding skins must correspond to the values indicated in table. eight.

Table 8

─────────────────────┬────────────────────────────────────────────

Grit│Reduced wear for types

├────────────────────┬───────────────────────

─────────────────────┼────────────────────┼───────────────────────

50 - 32│5.0 - 20.0│S. 20.0

25 - 16│4,0 - 15,0│"15,0

12 - 6│2,0 - 11,0│"11,0

5 - M40│1.5 - 9.0│ "9.0

Note. Reduced wear of silicon carbide abrasive skin with grain sizes 6 - М40 type 1 should be 1.5 - 7.0; type 2 - St. 7.0.

(Modified edition, Amendment N 2).

2.13. The cutting ability of the abrasive paper under the test conditions specified in the mandatory Appendix 2 must correspond to the values specified in table. 8a.

Table 8a

───────────────┬──────────────────────────────────────────────────

Granularity│Cutting capacity of the skin, g / min, not less

├─────────────────┬─────────────────┬──────────────

│ electrocorundum silicon carbide │ glass

50│0,422│0,450│0,300

───────────────┼─────────────────┼─────────────────┼──────────────

40│0,300│0,320│0,260

───────────────┤││

───────────────┼─────────────────┼─────────────────┼──────────────

25│0,290│0,300│0,250

───────────────┼─────────────────┼─────────────────┼──────────────

20│0,200│0,220│0,160

───────────────┼─────────────────┼─────────────────┼──────────────

16│0,195│0,210│0,110

───────────────┼─────────────────┼─────────────────┼──────────────

12│0,187│0,205│0,080

───────────────┼─────────────────┼─────────────────┼──────────────

10│0,176│0,200│0,070

───────────────┼─────────────────┼─────────────────┼──────────────

8│0,151│0,195│0,060

───────────────┼─────────────────┼─────────────────┼──────────────

6│0,100│0,192│-

5│0,079│-│

───────────────┼─────────────────┤│

───────────────┼─────────────────┼─────────────────┤

M63│0.079│0.066│

───────────────┼─────────────────┼─────────────────┤

M50│0.038│0.025│

───────────────┼─────────────────┼─────────────────┤

M40│0.014│0.021│

(Modified edition, Amendments N 2, 3).

3. RULES OF ACCEPTANCE

3.1. Acceptance inspection and periodic testing should be carried out to control the conformity of the abrasive paper with the requirements of this standard.

3.2. Acceptance control for compliance with the requirements of paragraphs. 1.2, 2.7.1, 2.7.2 and 2.7.3 should be exposed to at least 1% of rolls of sanding paper from the batch, but not less than 3 pieces, according to paragraphs. 1.4; 1.15; 2.12 and 2.13 - 0.1%, but not less than 3 pcs.

3.1, 3.2. (Modified edition, Amendment N 2).

3.2.1. A batch should consist of a sanding paper of one characteristic, made in one shift and simultaneously presented for acceptance on one document.

3.3. If, during acceptance control, non-compliance with the requirements of the standard for more than one controlled indicator is established, then the batch is not accepted.

(Modified edition, Amendment N 2).

3.3.1. If a discrepancy with the requirements of the standard for one of the monitored indicators is established, then a second control is carried out on a doubled number of rolls of skin.

If there are defects in the resampling, the lot is not accepted.

(Introduced additionally, Rev. N 2).

3.4. Products (one of the roll sizes) that have passed the acceptance control (according to clause 3.2) for compliance with the requirements of clauses must be periodically tested. 2.8 and 2.10 0.5%, but not less than 3 pcs., P. 2.9 and 2.11 0.5% rolls of 40 grit sandpaper; eight; 5 and M40, but not less than 3 pcs., P. 2.9 - on all types of bases.

(Modified edition, Amendment N 2).

3.5. Periodic tests should be carried out at least once a year.

(Modified edition, Amendment N 3).

4. METHODS OF CONTROL AND TESTING

4.1 - 4.1.2. (Excluded, Rev. N 2).

4.2. The dimensions and external defects of the working surface of the grinding skin are measured with a measuring metal ruler in accordance with GOST 427-75 or a measuring metal tape in accordance with GOST 7502-89.

4.2.1. The angle of inclination of the relief is measured with universal measuring instruments or a special template.

4.3. The unevenness of the thickness of the skin is measured with a micrometer of the MK type (with a tolerance limit of +/- 0.01 mm) at a distance of at least 10 mm from the edge of the roll.

(Modified edition, Amendment N 2).

4.4. The calculation of the coefficient of application of grinding material to the base is given in the obligatory Appendix 1.

4.5. To determine the moisture content of the sanding skin, three samples of 100 x 100 mm are taken, weighed on a technical balance with a tolerance limit of +/- 0.01 g. Samples of the sanding skin are placed in an oven and dried at a temperature of (100 +/- 5) ° С until the difference between two successive weighings does not exceed 0.02 g.

The moisture content of the abrasive paper is determined by the difference in masses before and after drying and is calculated as a percentage of the initial mass.

4.6. The reduced wear of the abrasive skin (the ratio of the grain size of the sanding skin to its crumbling) is determined on the KZSH VNIIASh device by abrasion of the skin on the skin for 2 minutes at a load of 29.4 N.

The test is carried out on two samples of abrasive paper with dimensions of 395 x 50 mm and 520 x 50 mm.

The samples are weighed on a technical balance with a tolerance limit of +/- 0.05 g.

Notes. 1. The crumbling capacity of the abrasive skin is equal to the mass of the crumbling working layer at a given time interval under given conditions.

2. When calculating the reduced wear for grain sizes M63; M50 and M40 in the numerator are taken, respectively, the numbers 5; 4 and 3.

(Modified edition, Amendment N 2).

4.7. The method for determining the cutting ability of the abrasive paper is given in the obligatory Appendix 2.

4.8. The determination of the tensile strength of the abrasive paper is carried out in accordance with GOST 13525.1-79, except for paragraphs. 3.1 and 4.1 at ambient temperature. Limit deviations of the dimensions of the test pieces shall be +/- 1.0 mm.

(Modified edition, Amendment N 2).

4.9. Samples for control according to PP. 4.1 - 4.8 is taken from any place on the roll, at least 10 mm from the end of the roll or edges. The value of indicators for PP. 4.3 and 4.5 - 4.8 is taken as the arithmetic mean of the three definitions.

5. MARKING, PACKAGING, TRANSPORTATION AND STORAGE

5.1. On the non-working surface of the sandpaper roll, every (235 +/- 20) mm in the longitudinal direction and every (200 +/- 20) mm in the transverse directions should be applied:

conventional designation (except for the type and indication of the type of the working layer);

batch number.

Notes. 1. When using a mixture of abrasives, mark the grade of the main abrasive in the conventional designation; when using a mixture of grains, mark the main grain.

2. By agreement with the consumer, the dimensions of the roll may not be applied.

(Modified edition, Amendments N 2, 3).

5.2. Bundle marking:

skin glue - M;

combined ligament - K.

5.3. Winding the sanding paper into rolls should be even and dense, with the working layer outward, not allowing the formation of wrinkles, folds and creases.

The end surface should be flat, the projections of the roll edges up to 1250 mm wide should not exceed 5 mm, over 1250 mm wide - 10 mm.

(Modified edition, Amendment N 3).

5.4. Each roll of sanding paper should be wrapped with a double layer of paper in accordance with GOST 18277-72, GOST 2228-81 or GOST 10127-75.

The roll should be glued at the seam. Layers of wrapping paper should cover the ends of the roll and ensure its safety during transportation.

5.5. (Deleted, Amendment No. 3).

5.6. Each packaged roll must be labeled or stamped with the following information:

manufacturer's trademark;

symbol;

date of issue and batch number;

technical control stamp;

the image of the State Quality Mark according to NTD for the abrasive skin, which has been appropriated with the State Quality Mark in accordance with the established procedure.

5.7 - 5.16. (Excluded, Amendment No. 3).

5.17. Other requirements for labeling and packaging, as well as transportation and storage - in accordance with GOST 27595-88.

(Introduced additionally, Amendment No. 3).

Sec. 6. (Deleted, Amendment No. 2).

Annex 1

Mandatory

CALCULATION OF THE APPLICATION RATIO OF GRINDING MATERIAL ON THE BASE

Coefficient of application of grinding material on the base (- the ratio of the area of the base with the applied grinding material to its total area) for:

versions 1 and 3 is calculated by the formula

where a is the width of the relief, mm;

t - relief step, mm;

version 2 is calculated by the formula

execution 4 is calculated by the formula

![]() .

.

(Modified edition, Amendment N 1).

Appendix 2

Mandatory

METHOD FOR DETERMINING THE CUTTING ABILITY OF A GRINDING SKIN

1. The essence of the method

The method is based on determining the mass of organic glass polished with a sample of abrasive skin during the test.

2. Equipment and materials

2.1. Diagram and description of the MI-2 type device - in accordance with GOST 426-77.

2.2. Samples of sanding paper with an outer diameter (174 +/- 5) mm and a hole diameter (55 +/- 3) mm.

2.3. Plates made of organic glass of the TOSN brand - in accordance with GOST 17622-72.

2.4. Rubber pads 60 - 80 Shore.

2.5. Adhesive grades BF-2 and BF-4 in accordance with GOST 12172-74 or other grades that ensure the strength of the connection of plexiglass plates with a rubber gasket - in accordance with regulatory and technical documentation.

(Modified edition, Amendment N 2).

3. Preparation for the test

3.1. Stick the plates onto the rubber pads.

3.2. Pre-grind new plexiglass plates under test conditions until traces of wear appear on the entire working surface of the plates, remove dust and weigh with a tolerance limit of +/- 0.01 g.

4. Carrying out the test

4.1. Set the test modes shown in the table.

───────────────┬─────────────────┬─────────────────┬──────────────

Grit Clamping force, N│ Processing time, │ Presence of blowing

││min│ during processing

───────────────┼─────────────────┼─────────────────┼──────────────

80 - 50│98.0│5│Without blowing

40 - 25│72,5│├──────────────

20 - 6│49.0││With blowing

5 - M40│25.5││

(Modified edition, Rev. N 1, 2).

4.2. Place the abrasive paper to be tested by changing the abrasive paper on the disc after lapping.

4.3. Fix the plexiglass plates in the holders in the same position as when lapping.

4.4. At the end of the test, free the plexiglass plates, remove dust and weigh with a permissible error limit of +/- 0.01 g.

5. Processing of test results

5.1. Cutting capacity (Q g / min) is determined by the formula

where m is the mass of polished organic glass, g;

5 - processing time, min.

State standard of the USSR GOST 10054-82

"WATERPROOF SANDING PAPER SKIN. TECHNICAL SPECIFICATIONS"

Waterproof abrasive paper. Specifications

Instead of GOST 10054-75

This standard applies to water resistant abrasive paper intended for abrasive processing of various materials with and without the use of cutting fluid.

1. Dimensions

1.1. Sandpaper should be produced in rolls and sanding sheets, the dimensions of which are indicated in table. one.

Table 1

Note. At the request of the consumer, it is allowed to manufacture rolls and sheets of other sizes.

An example of a symbol for a waterproof abrasive paper in a roll, 750 mm wide, 50 m long, on wet paper, made of green silicon carbide, grade 64C, grain size 16-P:

750x50 М 64С 16-P GOST 10054-82

The same, sanding sheet, 230 mm wide, 280 mm long, on wet-strength paper with polymer latex coating, made of black silicon carbide, grade 53C, grain size 16-P:

L 230x280 L1 53S 16-P GOST 10054-82

2. Technical requirements

2.1. Sandpaper must be manufactured in accordance with the requirements of this standard.

2.2. The abrasive paper must be made of grit 16-M14 from the abrasive materials specified in table. 2.

table 2

Note. At the request of the consumer, it is allowed to manufacture abrasive skins from other brands and grain sizes of abrasives.

2.3. For the manufacture of abrasive paper, wet-strength paper in accordance with GOST 10127 and industry-specific regulatory and technical documentation on paper should be used as a basis in accordance with table. 3.

2.4. Grinding material must be firmly connected to the base with varnishes of the YAN-153 and PF-587 brands or other water-resistant bonds according to industry regulatory and technical documentation.

2.5. Grain composition of grinding materials - according to GOST 3647 (grinding and grinding powders with indices P and N) and according to industry regulatory and technical documentation.

Table 3

Note. If the paper does not have an established symbol, it is allowed to indicate its brand in the symbol of the abrasive paper.

2.6. (Deleted, Amendment No. 3).

2.6.1. On the working surface of the sandpaper in rolls, the total area of wrinkles, folds, areas without abrasive grains, filled with a binder, should not exceed 0.5% of the roll area.

Note. By agreement with the consumer, the total area of these defects is not more than 1.5% of the roll area.

(Modified edition, Amendment N 3).

2.6.2. (Deleted, Amendment No. 3).

2.6.3. On the working surface of the sheets, the total area of wrinkles, folds, areas without abrasive grains, filled with a binder, and with damage to the edges should not exceed 0.5% of the sheet area.

Note. By agreement with the consumer, the total area of the indicated defects is not more than 1% of the sheet area.

(Modified edition, Amendment N 3).

2.6.4. (Deleted, Amendment No. 3).

2.7. The unevenness of the thickness of the sanding paper should not exceed the values indicated in table. 4.

Table 4

2.8. The tensile strength of the abrasive paper must correspond to the values indicated in table. 5.

Table 5

______________________________

* As agreed with the consumer.

2.9. The cutting capacity of the abrasive paper must correspond to the values given in table. 6.

Table 6

|

Grain |

Grain |

Cutting capacity, g / min, not less |

|

(Introduced additionally, Rev. N 1).

3. Acceptance rules

3.1. Acceptance inspection and periodic testing should be carried out to control the conformity of the abrasive paper with the requirements of this standard.

(Modified edition, Amendment N 1).

3.2. Acceptance control for compliance with the requirements of paragraphs. 1.1, 2.6.1 and 2.6.3 must be exposed to at least 1% of sanding paper rolls or packets of sheets from the batch, but not less than 3 pieces, clause 2.9 - 0.1%, but not less than three rolls or packets.

3.2.1. A batch should consist of a sanding paper of one characteristic, made in one shift and simultaneously presented for acceptance on one document.

3.3. If, during acceptance control, non-compliance with the requirements of the standard for more than one controlled indicator is established, then the batch is not accepted.

(Modified edition, Amendment N 2).

3.3.1. If a discrepancy with the requirements of the standard for one of the monitored indicators is established, then a repeated control is carried out on a doubled number of rolls of skin, packets of sheets.

If there are defects in the resampling, the lot is not accepted.

(Introduced additionally, Rev. N 2).

3.4. Products (one of the sizes of rolls, sheets) that have passed the acceptance control in accordance with clause 3.2, for compliance with the requirements of clauses 3.2, must be periodically tested. 2.7 and 2.8 0.5% sandpaper rolls or sheets of 16 grit; eight; 5 and M40, but not less than 3 pcs., P. 2.8 on all types of bases.

(Modified edition, Amendment N 2).

3.5. Periodic tests should be carried out at least once a year.

(Modified edition, Amendment N 3).

4. Test methods

4.1. Determination of the tensile strength of abrasive paper in a dry state according to GOST 6456.

4.1.1. The tensile strength of the abrasive cloth in a wet state is determined as follows: the prepared abrasive cloth samples are soaked before testing in water at a temperature of (20 ± 2) ° C for two hours. Excess water is removed with filter paper and the test is carried out immediately in accordance with GOST 6456.

4.2. The method for determining the cutting ability of the abrasive paper is in accordance with GOST 6456 with the additions specified in paragraphs. 4.2.1, 4.2.2.

4.2.1. Before testing, samples of abrasive skins are subjected to final drying for one hour at a temperature of (100 ± 5) ° C.

4.2.2. The cutting ability of the abrasive paper is determined when:

clamping force - 25, 5 N;

grinding time - 5 min.

Testing of abrasive paper with grain sizes 16-M40 is carried out with air blowing.

The maximum permissible error of weighing samples of organic glass plates when testing abrasive paper with grain sizes M63-M14 is ± 0.001 g.

4.3. Control of dimensions, uneven thickness, appearance of the working surface of the sandpaper - in accordance with GOST 6456.

5. Marking, packaging, transportation and storage

5.1. On the non-working surface of a roll of sanding paper, every (150 ± 15) mm in the longitudinal and transverse directions should be applied:

manufacturer's trademark;

symbol;

batch number.

Note. By agreement with the consumer, the dimensions of the roll or sheet may not be applied.

(Modified edition, Amendments N 1, 3).

5.2. The wrapping of the sanding paper into rolls should be tight and even, not allowing the formation of wrinkles, folds and wrinkled areas.

The end surface must be flat, the projections of the edges must not exceed 10 mm.

5.3. Each roll of sanding paper should be wrapped in paper in accordance with GOST 8273, GOST 18277, GOST 10127 or GOST 2228 and sealed at the joint. Layers of wrapping paper must reliably cover the ends of the roll and ensure its safety during transportation.

5.4. Sanding sheets should be packed in bundles of (50 ± 1) pcs. or (100 ± 2) pcs. Packs are sealed with paper or paper sanding tape with grain sizes of 10 and finer, at least 35 mm wide across the width of the sheets.

(Modified edition, Amendment N 1).

5.5. Packs of 5-10 pcs. stacked in bags and sealed with paper or paper sanding tape with grain sizes of 10 and finer, at least 35 mm wide or with adhesive tape of grade B in accordance with GOST 18251. The sealed package must be wrapped in paper in accordance with GOST 8273-75, GOST 18277, GOST 10127 or GOST 2228 so so that the end is on the front of the bag. The bag is tied with twine.

(Modified edition, Rev. N 1, 2).

5.6. (Deleted, Amendment No. 3).

5.7. Each packaged roll or bag must have storage instructions and a label indicating:

manufacturer's trademark;

batch numbers;

release dates;

conventional designation;

the number of sheets for the package;

images of the State Quality Mark for abrasive skins, which have been appropriated by the State Quality Mark in accordance with the established procedure;

technical control stamp.

The label should be stuck on the roll at the seam of the wrapping paper.

5.8-5.19. (Excluded, Amendment No. 3).

5.20. Other requirements for labeling and packaging, as well as transportation and storage - in accordance with GOST 27595.

(Introduced additionally, Amendment No. 3).

6. Manufacturer's Warranties

6.1. (Deleted, Rev. N 1).

6.2. (Deleted, Rev. N 2).

6.3. (Deleted, Rev. N 1).

> DK 621.921.67.021: 006.354 Group G25

STATE S I 1 N D A 5 G UNION SSR

SKINS GRINDING PAPER

Technical conditions

Awasive paper Specifications

The term of infancy is from 01.01.83

Present5 ;; | The standard applies to abrasive paper intended for abrasive processing of times -.

1. TYPES AND SIZES

1.1. Sandpaper should be made of types:

1 - for machine and manual processing of non-metallic materials (wood, leather, rubber, plastic, etc.);

2 - for machine and manual processing of metals, splaeosis.

1.2. Sandpaper should be produced in rolls, the dimensions of which are indicated in table. one.

Table I

Lerepechltha aosprvschema

gost 6 "b-3J p. 2

1.3. The abrasive paper must be made with the following types of working layer:

C - solid; t Р - embossed.

1.4. The designs and dimensions of the embossed working layer must correspond to those indicated in the drawing to in table. 2.

The angle of inclination of the relief should be 5 ° -85 °.

1 5. The deviation from parallelism of the generatrices of the relief line must be within the tolerance for the relief step.

Pokmer of the conventional designation of paper abrasive skins of type 1, with a continuous working layer C. with a width of 1000 mm. length 50 m, on 0-200 grade paper. from normal electro.corunl grade 15A, grain size 25-M. on skin glue:

S 1000X50 P2 I5A 25-I M GOST 6456-82

2. TECHNICAL REQUIREMENTS

2.1. Abrasive paper shall be manufactured in accordance with the requirements of this standard.

2.2. The abrasive paper should be made from the abrasive materials specified in table. 3.

P r and e h and r. On the order of the grave-grabber, it is allowed to n; ha? About "le> 1st grinding school> pk" III drutl mlrok iL-lchfmatsriylov OR THEIR mixture.

(Modified edition, Amendment L 1. 2, 3).

GOST 4456-82 С. t

2.3. For the manufacture of abrasive paper as an axis> you must use paper in accordance with GOST 18277 - 72. GOST 10127-75 and industry regulatory and technical :! d-gh, centesht on paper b in accordance with table. -I.

11 rimetch L1 by. Boarded C;. “^ Ia has no mustache i ^ hos.ichko: and the conditional 1" lma "chenmi. dpiusmpsia nd jo.MHiiru obidmachskki grinding tour> and ^ like her brand.

(Modified edition, Rev. As 2).

2.4. The abrasive paper should be made from the grinder-ternals granular gay, indicated in the table. 5.

Note. By. "Ika" y iioipeuiire.iH is allowed h tmge / .ee. " l-shfo-hip 111K \ rki other.irie guests or their mixtures.

(Modified edition, Amendment No. 3).

2.5. Grinding material must be connected to the base of the skin with glue but GOST 3252-80 or other bonds according to industry, regulatory and technical documentation.

Note: It is allowed to enter a bunch r.p: i 4 ".i.v. I nor * f: .cr Hire pshien-sh.

2.6. Grain composition of grinding materials - in accordance with GOST 3647-80.

2.7. (Deleted. Amendment No. 3).

2.7.1. On the working surface of the grinding skin: with a special working layer, the total area of wrinkles, folds,

S. 5 GOST 6454- ":

i.o without abrasive grains, filled with binder, should not exceed 0.5% of the roll area.

Note. By agreement with the consumer, the total amount of the indicated defects is allowed no more than 1% of the roll area.

(Changed edition, Amendments L 2, 3).

2.7.2. On the working surface of the abrasive paper with a relief working layer, the total area of defects (merging and non-printing) of the relief layer for 1 m2 should not exceed 5% of the area of the roll with the applied abrasive material.

(Modified edition, Amendment No. 3).

2.7.3. In a roll of sanding paper with a width of up to 1250 mm, edges with a width of more than 10 mm with defects, with a width of more than 1250 mm - more than 15 mm are not allowed.

Note Pa working surface of kzrbidkremisao n elekhtroko- | "> d- * g * g" th in-squall skins eerinstosts 6-M40 point * .lee "are not allowed.

(Modified edition, Amendment L I, 2, 3).

2.8. The unevenness of the thickness of the sanding paper should correspond to the values indicated in table. 6.

Table 6

2.9. Strengthen the tearing of the abrasive skin depending on: "! paper grade must correspond to the values specified in table. 7.

GOST 6456-82 p. 6

2.10. Coefficient of application of the abrasive base L "* for abrasive cloth with a relief working layer should be 0.40-0.75.

2.11. The moisture content of the sanding paper should be 3-7%.

2.12. The reduced wear of electrocorundum and glass polished l / o skins must correspond to the values indicated * in the table. eight.

Table 8

il shis "-. shas Bringingii iwroc karOnlcrchmshch" voO sh.shfi ^ myi "sh niKvp-h: ktocioO and type I should be 1.5 7.0: tpna 2" ■ *. 7.0.

(Modified edition. Rev. L & 2).

2.13. The cutting ability of the abrasive paper under the test conditions specified in the mandatory Appendix 2. must be c-clear to the values specified in table. 8a.

T a 6 L I! n l 8a

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (Changed edition. Amendments No. 2, 3). |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

P. 7 GOST 6456 - "2

J. RULES OF ACCEPTANCE

3.1. To control the conformity of the grinding grinder to the requirements of this standard, it should be carried out; control and periodic testing.

3.2. Acceptance control for compliance with the requirements of paragraphs. 1.2, 2.7.1. 2.7.2 l 2.7.3 should be exposed to at least 1% of the rolls of abrasive cloth from the batch, but not less than 3 pieces, logs.:. 1.4; 1.5; 2.12 and 2.13 - 0.1%. but not msnse 3 pcs.

3.1. 3.2. (Changed edition. Change.> To 2).

3.2.1. The batch should consist of abrasive skins ::. ", Od-Mil.charaKTtpifctiki, made in one shift and at the same time presented for acceptance but one document.

3.3. During acceptance control, gels were found to meet the requirements of the standard for more than one controlled indicator. then the batch is not accepted.

(Changed rslakinya, Amendment No. 2).

3.3.1. If there is a discrepancy between the fsbovanikm standard for one of the monitored indicators, then a second control is carried out on a doubled number of rolls of skin.

If there are defects in the resampling, the batch is not green-mzyug.

(Introduced additionally, Amendment No. 2).

3.4. Periodic tests should be carried out on the product (one of the roll sizes) that has passed the acceptance control (according to clause 3.2), for compliance with the requirements of clauses. 2.J and 2 10 0.5%. but not less than 3 pcs. pp. 2.9 and 2.11 0.5% rolls of 40 grit sandpaper; S; 3 and 440, but not less than 3 pcs., P. 2.9 - not zee.h types of bases.

(Modified edition, Amendment L "2).

3.5. Periodic tests should be performed once a year.

(Modified edition, Amendment No. 3).

4. METHODS OF CONTROL AND TESTING

4.1-4.1.2. (Excluded, Amendment M 2).

4.2. The dimensions and external defects of the working surface of the grinding skin are measured with a measuring metal ruler in accordance with GOST 427-75 or a measuring metal pwieuv.i g, "/ GOST 7502-89.

4.2 1. The angle of inclination of the relief is measured by universal similarities of intention or by a special template.

4.3. Uneven skin thickness is measured with a micrometer

GOST L> L- 82 C. 3

of the LAC type (i with a permissible error limit of 0.01 im) at a distance of at least 10 mm from the roll edge.

(Modified edition, Amendment No. 2).

4 4. Calculation of the coefficient of application of the grinding material a ia as the basis A. is given in the obligatory Appendix 1.

4.5. To determine the moisture content of the grinding grinder, three samples with dimensions of 100XY0 mm are taken. vgveshnvayug on technical scales with a tolerance limit of ± 0.01 g. Samples of abrasive skins are placed in a drying oven and dried at a temperature of (100g5) ° C until then. until the difference between two successive weighings does not exceed 0.02 g.

The moisture content of the abrasive paper is determined from the difference in masses before k after drying and is calculated as a percentage of the initial mass.

4.6. The reduced wear of the abrasive skin (the ratio of the grain size of the sanding skin to its crumbling) is determined on a K3UJ VNIPASH device by rubbing the skin against the skin for 2 minutes tip and a load of 29.4 I.

The test is carried out on two shaped abrasive skins with dimensions &> ""> "o0 mm and 520X50 mm.

The samples are weighed on a technical balance with a tolerance limit of ^ 0.05 g.

Note e<| П Н II Я:

1. Olschmsms * I "of the sanding paper is equal to the mass of the sagging working milking and i-i.iiiui-u." I time interval under given conditions

2. When rnechs-k-prnvelsiiogo wear and tear blunder yurn.utostsi MVZ; M50 and M40 are in the numerator B. "The rudder is 5; A and 3.

(Modified edition, Amendment No. 2).

4.7. Meto! determination of the cutting ability of the abrasive paper is given in the mandatory Appendix 2.

4.8. The determination of the tensile strength of the abrasive paper is carried out in accordance with GOST 13525.1-79, except for paragraphs. 3.1 and 4.1 at ambient temperature. Limit deviations of the sizes of samples for w "lpyannya should be ± 1.0 mm.

(Modified edition. Amendment L6 2).

4.9. Samples for control by PP. 4.1-4.8 are taken from any place of the roll, at a distance from the end of the roll or edges not less. than 10 mm. The value is indicative but nn. 4.3 and 4.5-4.8 are taken as the arithmetic mean of the three definitions.

S. MARKING. PACKAGE. TRANSPORTATION AND STORAGE

5.1. On the non-working surface of the sandpaper roll, every (235: 20j mm in the longitudinal direction and every (200 ± 20) mm in the numbered directions) should be applied:

With 9 roc; MS * -SJ

manufacturer's trademark;

conventional designation (except for the type and indication of the type of layer);

batch number.

Notes;

". When using cvecn abrasives - in a conditional shell, mark the brand of the main abrasives, when using a mixture ^ csnns "" .-; goy-mark the main jopHiicrocrb.

2. As agreed with the consumer. "®" * roll dimensions to tolerances * "to: - mow.

(Changed edition. Amendments No. 2, 3).

5.2. Ligament marking: skin glue M; combined ligament - K.

5.3. Winding the sanding paper into rolls should be even and dense, with the working layer outward, not allowing the formation of wrinkles, folds and creases.

The end surface should be flat, the protrusions of the roll edges with a width of up to 1250 mm should not exceed 5 mm, with a width over 1250 mm - 10 mm.

(Changed edition. Amendment L 3).

5.4. Each roll of sanding paper should be wrapped in a double layer of b \ magi but GOST 18277-72, GOST 2228-81 or GOST 10127-75. "

The roll must be glued on the C1yk. Layers of wrapping paper should cover the ends of the roll and ensure its safety during transportation.

5.5. (Deleted, Amendment No. 3).

5.6. Each packaged roll must be labeled or stamped with the following information:

manufacturer's trademark; symbol: lata of issue and batch number: stamp of technical control;

the image of the State Quality Mark according to NTD for the abrasive skin, which has been appropriated with the State Quality Mark in accordance with the established procedure.

5.7-5.16. (Excluded, Amendment No. 3).

5.17. Other requirements for labeling and packaging, as well as transportation :: storage - in accordance with GOST 27595-88,

(Introduced additionally, Amendment No. 3).

Sec. 6. (Deleted. Amendment No. 2).

GOST 6456 - 82 p. 10

APPENDIX I O "/: gslchos

CALCULATION OF APPLICATION RATES UIL AND FMAT F P IL J1A BASED ON

Coefficient of application of shlnfmaterial sludge base (/ C, is the ratio of n.! "

where a is the width of the relief, mm; t - relief step, mm; execution 2 is calculated according to the formula

execution -J is calculated by the formula

(Modified edition, I ”m. L I).

attach 2

METHOD FOR DETERMINING CUTTING ABILITY BY GRINDING

Essence of Metol

The om-m-t method for the determined grinding mass of the surface of the plexiglass abrasive skin during the tests.

2. Equipment and materials

2.1. Diagram 'and description of the MI-2 type device according to GOST 42G- 77.

2.S. Samples of abrasive paper with an outer diameter (! 74-fc5> mm and a hole diameter (55 ± 3> mm

2-3. Plates made of organic glass brand TOSN ~ according to GOST I7622-72.

2.4. Lining made of rubber of hardness but Shore GO-80.

2.5. Glue grades VF-2 and BF 4 in accordance with GOST 12172-74 or other brands, which ensured the spice of joining the plates of organic glass with a reshnoy gasket.

(Amended rglction, Rev. JA 2).

3. II o d I- o a k a k and s g v a k and k>

3 I. Stick the plates onto the rubber pads.

3 2. Pre-grind new plexiglass plates during testing until signs of wear appear on the entire working surface and clean *, from dust and weigh; errors ± 0.0! G.

4. Carrying out the test

4.1. Set the test modes indicated in the table

1Ln “n.- ochp

Gr »iVip-iCmrbr

| Usg.-yas pvnzhimp. II |

||

. <. wax во*

(Modified edition, Rev. fft I. 2).

4.2. Install msgtyvasmyl oPramch "g .:: kf vi -y., ■ i ^ walkie. replacing the sanding paper and "after lapping".

4.3. Fix the plexiglass plates m in the holders in the same 1> burn as when lapping.

4 4. At the end of the tests, free the plates and plexiglass glass, "clean it from dust and dry it with a limit of permissible g> gsiaist ± 0.01 g.

5. Processing result!) About experienced *

5.1. The cutting ability (0 g. "Mii) is determined by the formula

where m is the mass of polished organic glass, g; 5- processing time, mime.

gost t456-aj p. one?

INFORMATION DATA

1. DEVELOPED AND INTRODUCED by the Ministry of Machine-Tool and Tool Industry of the USSR

DEVELOPERS

E. I. Ardashev; E. S. Viksman; V. T. Ivashinnikov; N. A. Ilyina; V. A. Kvitko; L.A. Kogan; O. F. Kotlyarov; I. F. Korchmar; V. A. Morozov; E. B. Petrosyan; A. A. Pylnee; S. K. Rozin; V. A. Rybakov; N. V. Syreishchikova; V. D. Tunikov; V. N. Tyrkov

2. APPROVED AND INTRODUCED INTO EFFECT by the Decree of the USSR State Committee for Standards dated 18.02.E2 No. 735

3. The term of the first inspection is 1992.

Inspection period - 5 years

4. REPLACE GOST 6456-75

5. REFERENCE REGULATORY AND TECHNICAL DOCUMENTS

* 'Nwp U4I.T.1. "" Y * ". ™, irc. I.

Oss: quality<«;1? !**Д. !а 2*112 CCI-LI".a

42Ya-77 427-75 2238- "I 3252 PO 3W7-" L 7502 ei 10127-75 1-2172-74 13925.1- 79 17S22-72 18277- 72 27595-88

i 3: 5 i Appendix 2

Appendix 2 i.3; 5.4 0.17

6. The validity period was extended until 01.01.93 by the Resolution of the State Standard of the USSR dated 04.23.87 No. 1374

7.REVISED (April 1990) with Amendments M2 1, 2, 3, approved in June 1984, April 1987, July 1989 | IUS 9-84, 8-87, 11-89)

State standard of the USSR GOST 6456-82

"Pelt PAPER GRINDING. TECHNICAL SPECIFICATIONS"

Abrasive paper. Specifications

Instead of GOST 6456-75

This standard applies to abrasive paper intended for abrasive processing of various materials without cooling or using cutting fluids based on oil, kerosene, white spirit.

1. Types and sizes

1.1. Sandpaper should be made of types:

1 - for machine and manual processing of non-metallic materials (wood, leather, rubber, plastic, etc.);

2 - for machine and manual processing of metals, alloys.

1.2. Sandpaper should be produced in rolls, the dimensions of which are indicated in table. one.

Table 1

|

Grain |

Width, mm (pre-dev. ± 3.0) |

Length, m (pre-dev. ± 0.5) |

|

720; 750; 800; 850; 900; 1000 | ||

|

1250; 1350; 1400 |

||

|

720; 750; 800; 850; 900 | ||

|

1250; 1350; 1400 |

||

|

720; 750; 800; 850; 900 | ||

Note. At the request of the consumer, it is allowed to manufacture rolls with a length of more than 100 m.

1.3. The abrasive paper must be made with the following types of working layer:

C - solid;

P - embossed.

1.4. The designs and dimensions of the embossed working layer must correspond to those indicated in the drawing and in table. 2.

table 2

Dimensions, mm

|

Grain |

Width, a | |||

|

Interval |

Prev off |

Interval |

Prev off |

|

The angle of inclination of the relief alpha should be 5 ° -85 °.

1.5. The deviation from parallelism of the forming lines of the relief should be within the tolerance for the relief step.

An example of a conventional designation of a paper abrasive cloth of type 1, with a continuous working layer C, 1000 mm wide, 50 m long, on paper of grade 0-200, made of normal fused alumina grade 15A, grain size 25-N, on flesh glue:

1C 1000X50 P2 15A 25-N M GOST 6456-82

2. Technical requirements

2.1. Abrasive paper shall be manufactured in accordance with the requirements of this standard.

2.2. The abrasive paper should be made from the abrasive materials specified in table. 3.

Table 3

|

Type of abrasive |

Grinding material grade |

|

Normal fused alumina |

15A; 14A; F14A; 13A; F13A |

|

White fused alumina |

25A; 24A; 23A |

|

Alloy electrocorundum |

94A; 93A; 92A; 91A; 91A-M and 92A-M |

|

Zirconium alumina | |

|

Monocorundum | |

|

Green Silicon Carbide | |

|

Black silicon carbide |

54C; 53C; 51C |

Note. At the request of the consumer, it is allowed to manufacture abrasive skins from other grades of abrasives or their mixtures.

2.3. For the manufacture of abrasive skins, paper should be used as a basis in accordance with GOST 18277, GOST 10127 and industry regulatory and technical documentation for paper in accordance with table. 4.

Table 4

|

Paper stamp |

Symbol |

Paper stamp |

Symbol |

Note. If the paper does not have an established symbol, it is allowed to indicate its brand in the symbol of the abrasive paper.

(Modified edition, Amendment N 2).

2.4. The abrasive paper should be made from abrasives of the grain sizes indicated in table. 5.

Table 5

Note. At the request of the consumer, it is allowed to manufacture abrasive skins of other grain sizes or their mixtures.

(Modified edition, Amendment N 3).

2.5. Grinding material should be bonded to the base with flesh glue in accordance with GOST 3252 or other bonds in accordance with industry regulatory and technical documentation.

Note. It is allowed to introduce dyes or coloring pigments into the bundle.

2.6. The grain size composition of the grinding materials is in accordance with GOST 3647.

2.7. (Deleted, Amendment No. 3).

2.7.1. On the working surface of the abrasive cloth with a continuous working layer, the total area of wrinkles, folds, areas without abrasive grains, filled with a binder, should not exceed 0.5% of the roll area.

Note. By agreement with the consumer, the total area of these defects is not more than 1% of the roll area.

2.7.2. On the working surface of the abrasive paper with a relief working layer, the total area of defects (merging and non-printing) of the relief layer per 1 m 2 should not exceed 5% of the area of the roll with the applied abrasive material.

(Modified edition, Amendment N 3).

2.7.3. In a roll of sanding paper with a width of up to 1250 mm, edges with a width of more than 10 mm with defects are not allowed, with a width of more than 1250 mm - more than 15 mm.

Note. On the working surface of silicon carbide and electrocorundum abrasive paper of grain size 6-M40, point glue formations or blotches protruding above the working surface are not allowed.

(Changed edition, Rev. N 1, 2, 3).

2.8. The unevenness of the thickness of the sanding paper should correspond to the values indicated in table. 6.

Table 6

2.9. The tensile strength of the abrasive paper, depending on the grade of paper, must correspond to the values indicated in table. 7.

Table 7

|

Symbol of paper |

Symbol of paper |

||||

|

longitudinal |

transverse |

longitudinal |

transverse |

||

2.10. Coefficient of application of abrasive to the base K n for abrasive cloth with a relief working layer should be 0, 40-0, 75.

2.11. The moisture content of the sanding paper should be 3-7%.

2.12. The reduced wear of electrocorundum and glass grinding skins must correspond to the values indicated in table. eight.

Table 8

|

Grain |

Reduced wear for types |

||

Note. The reduced wear of silicon carbide abrasive paper with grit size 6-M40 type 1 should be 1, 5-7, 0; type 2 - St. 7, 0.

(Modified edition, Amendment N 2).

2.13. The cutting ability of the abrasive paper under the test conditions specified in the mandatory annex 2 must correspond to the values specified in table. 8a.

Table 8a

|

Grain |

Cutting capacity of the skin, g / min, not less |

||

|

electrocorundum |

silicon carbide |

glass |

|

(Modified edition, Amendments N 2, 3).

3. Acceptance rules

3.1. Acceptance inspection and periodic testing should be carried out to control the conformity of the abrasive paper with the requirements of this standard.

3.2. Acceptance control for compliance with the requirements of paragraphs. 1.2, 2.7.1, 2.7.2 and 2.7.3 should be exposed to at least 1% of rolls of sanding paper from the batch, but not less than 3 pieces, according to paragraphs. 1.4; 1.15; 2.12 and 2.13 - 0.1%, but not less than 3 pcs.

3.1, 3.2. (Modified edition, Amendment N 2).

3.2.1. A batch should consist of a sanding paper of one characteristic, made in one shift and simultaneously presented for acceptance on one document.

3.3. If, during acceptance control, non-compliance with the requirements of the standard for more than one controlled indicator is established, then the batch is not accepted.

(Modified edition, Amendment N 2).

3.3.1. If a discrepancy with the requirements of the standard for one of the monitored indicators is established, then a second control is carried out on a doubled number of rolls of skin.

If there are defects in the resampling, the lot is not accepted.

(Introduced additionally, Rev. N 2).

3.4. Products (one of the roll sizes) that have passed the acceptance control (according to clause 3.2) for compliance with the requirements of clauses must be periodically tested. 2.8 and 2.10 0.5%, but not less than 3 pcs., P. 2.9 and 2.11 0.5% rolls of 40 grit sandpaper; eight; 5 and M40, but not less than 3 pcs., P. 2.9 - on all types of bases.

(Modified edition, Amendment N 2).

3.5. Periodic tests should be carried out at least once a year.

(Modified edition, Amendment N 3).

4. Methods of control and testing

4.1-4.1.2. (Excluded, Rev. N 2).

4.2. The dimensions and external defects of the working surface of the grinding skin are measured with a measuring metal ruler in accordance with GOST 427 or a measuring metal tape in accordance with GOST 7502.

4.2.1. The angle of inclination of the relief is measured with universal measuring instruments or a special template.

4.3. The unevenness of the thickness of the skin is measured with a micrometer of the MK type (with a tolerance limit of ± 0.01 mm) at a distance of at least 10 mm from the edge of the roll.

(Modified edition, Amendment N 2).

4.4. The calculation of the coefficient of applying thin section material to the base K n is given in the mandatory Appendix 1.

4.5. To determine the moisture content of the sanding paper, three samples of 100x100 mm are taken, weighed on a technical balance with a tolerance limit of ± 0.01 g. Samples of the sanding paper are placed in an oven and dried at a temperature of (100 ± 5) ° C until the difference between two consecutive weighings will not exceed 0.02 g.

The moisture content of the abrasive paper is determined by the difference in masses before and after drying and is calculated as a percentage of the initial mass.

4.6. The reduced wear of the abrasive skin (the ratio of the grain size of the abrasive skin to its crumbling) is determined on the KZSH VNIIASH device by abrasion of the skin on the skin for 2 minutes at a load of 29.4 N.

The test is carried out on two samples of abrasive paper with dimensions of 395x50 mm and 520x50 mm.

The samples are weighed on a technical balance with a tolerance limit of ± 0.05 g.

Notes:

1. The crumbling capacity of the abrasive skin is equal to the mass of the crumbling working layer at a given time interval under given conditions.

2. When calculating the reduced wear for grain sizes M63; M50 and M40 in the numerator are taken, respectively, the numbers 5; 4 and 3.

(Modified edition, Amendment N 2).

4.7. The method for determining the cutting ability of the abrasive paper is given in the mandatory Appendix 2.

4.8. The determination of the tensile strength of the abrasive paper is carried out in accordance with GOST 13525.1, except for paragraphs. 3.1 and 4.1 at ambient temperature. Limit deviations of the dimensions of the test pieces shall be ± 1.0 mm.

(Modified edition, Amendment N 2).

4.9. Samples for control according to PP. 4.1-4.8 is taken from any place on the roll, at least 10 mm from the end of the roll or edges. The value of indicators for PP. 4.3 and 4.5-4.8 are taken as the arithmetic mean of the three definitions.

5. Marking, packaging, transportation and storage

5.1. On the non-working surface of the sandpaper roll, every (235 ± 20) mm in the longitudinal direction and every (200 ± 20) mm in the transverse directions should be applied:

conventional designation (except for the type and indication of the type of the working layer);

batch number.

Notes:

1. When using a mixture of abrasives, mark the grade of the main abrasive in the conventional designation; when using a mixture of grains, mark the main grain.

2. By agreement with the consumer, the dimensions of the roll may not be applied.

(Modified edition, Amendments N 2, 3).

5.2. Bundle marking:

skin glue - M;

combined ligament - K.

5.3. Winding the sanding paper into rolls should be even and dense, with the working layer outward, not allowing the formation of wrinkles, folds and creases.

The end surface should be flat, the projections of the roll edges up to 1250 mm wide should not exceed 5 mm, over 1250 mm wide - 10 mm.

(Modified edition, Amendment N 3).

5.4. Each roll of sanding paper should be wrapped with a double layer of paper in accordance with GOST 18277, GOST 2228 or GOST 10127.

The roll should be glued at the seam. Layers of wrapping paper should cover the ends of the roll and ensure its safety during transportation.

5.5. (Deleted, Amendment No. 3).

5.6. Each packaged roll must be labeled or stamped with the following information:

manufacturer's trademark;

symbol;

date of issue and batch number;

technical control stamp;

the image of the State Quality Mark according to NTD for the abrasive skin, which has been appropriated with the State Quality Mark in accordance with the established procedure.

5.7-5.16. (Excluded, Amendment No. 3).

1. The essence of the method

The method is based on determining the mass of organic glass polished with a sample of abrasive skin during the test.

2. Equipment and materials

2.1. Diagram and description of the MI-2 type device - in accordance with GOST 426.

2.2. Samples of abrasive paper with an outer diameter (174 ± 5) mm and a hole diameter (55 ± 3) mm.

2.3. Plates made of organic glass of the TOSN brand - in accordance with GOST 17622.

2.4. Rubber pads 60-80 Shore.

2.5. Adhesive grades BF-2 and BF-4 in accordance with GOST 12172 or other grades that ensure the strength of the connection of plexiglass plates with a rubber gasket - in accordance with the normative and technical documentation.

(Modified edition, Amendment N 2).

3. Preparation for the test

3.1. Stick the plates onto the rubber pads.

3.2. Pre-grind new plexiglass plates under test conditions until traces of wear appear on the entire working surface of the plates, clean from dust and weigh with a tolerance limit of ± 0.01 g.

4. Carrying out the test

4.1. Set the test modes shown in the table.

|

Grain |

Clamping force, N |

Processing time, min |

The presence of blowing during processing |

|

Without blowing |

|||

|

With blowing |

|||

(Modified edition, Rev. N 1, 2).

4.2. Place the abrasive paper to be tested by changing the abrasive paper on the disc after lapping.

4.3. Fix the plexiglass plates in the holders in the same position as when lapping.

4.4. At the end of the test, free the plexiglass plates, remove dust and weigh with a permissible error limit of ± 0.01 g.

5. Processing of test results

5.1. Cutting capacity (Q, g / min) is determined by the formula

where m is the mass of polished organic glass, g;

5 - processing time, min.

What to do in case of unsuccessful attempts to find a job

What to do in case of unsuccessful attempts to find a job Information about welded joints

Information about welded joints Gost scrap of ferrous metals (download) Scrap for construction gost 1405 83

Gost scrap of ferrous metals (download) Scrap for construction gost 1405 83 How many kilometers is the Moscow Moscow Ring Road in a circle?

How many kilometers is the Moscow Moscow Ring Road in a circle? Where did the Moscow sparrows disappear: the conclusion of ornithologists Why did the sparrows disappear?

Where did the Moscow sparrows disappear: the conclusion of ornithologists Why did the sparrows disappear? How to make money on homemade toys?

How to make money on homemade toys? Creative business: making handmade toys

Creative business: making handmade toys