Pipeline welding journal vsn 478 86. Information on welded joints

Departmental building codes

Production documentation

for the installation of technological

equipment and technological

pipelines

VSN 478 - 86

Minmontazhspetsstroy USSR

Developed by institutes of the USSR Ministry of Montazhspetsstroy

Giprokhimmontazh (leading organization) - I. P. Petrukhin, M. L. Elyash (theme leader and executive in charge); VNIIMontazhspetsstroy - B.V. Popovsky, V. Ya. Eidelman.

Submitted Glavkhimmontazh of the USSR Ministry of Montazhspetsstroy

Chief engineer A. V. Anokhin.

Prepared for approval The main technical department of the USSR Ministry of Montazhspetsstroy.

Deputy chief G.A. Sukalsky.

Approved By the Ministry of Assembly and Special Construction Works of the USSR.

Deputy Minister K. K. Lipodat.

Agreed with the USSR State Construction Committee (letter dated March 4, 1986 No. DC - 1125 - 1 ).

|

Ministry of Assembly |

Departmental building codes |

VSN 478 - 86 Minmontazhspetsstroy USSR |

|

and special construction works of the USSR (Minmontazhspetsstroy USSR) |

Production documentation on installation technological equipment and technological pipelines |

For the first time |

These departmental building codes (VSN) establish the content of production documentation for the installation of process equipment and process pipelines.

1. General Provisions

1.1. The types and content of production documentation must comply with SNiP 3.01.01- 85, SNiP 3.05.05 - 84 and SNiP III - 3 - 81.

Production documentation for equipment and pipelines subject to inspection by state supervision authorities must be drawn up in accordance with the rules and regulations of these authorities.

1.2. When filling out the production documentation forms, the requirements of state, industry standards, technical conditions for the manufacture and supply of technological equipment and pipelines, as well as the requirements agreed by the customer with the involvement of the installation organization in this part of the firms must be reflected - suppliers of complete technological equipment and pipelines purchased by import.

1.3. Production documentation by type of work is completed according to technological units, and for objects in whose projects technological units are not highlighted, - on the object as a whole.

2.1. The installation organization transfers to the general contractor for presentation to the working commission the documentation provided for in SNiP III- 3 - 81, SNiP 3.01.01 - 85, SNiP 3.05.05 - 84 and real BCH (Form 1 - 10).

2.2. Before the heading of each form (except for 9 - 13) post the following information:

________________________________ ________________________

(place of construction of the enterprise) (name of the general contractor and construction organization and its departmental affiliation)

_______________________________ ________________________

(Business name - customer) (name of the installation

_______________________________organizations indicating the trust (name of the facility under construction) and departmental affiliation)

19__

(name of the technological unit) (date)

2.3. Data provided in forms (excluding forms 5 - 14), are certified by the signatures of persons responsible for maintaining production documentation in the following form:

|

Name |

Representative |

||

|

organization |

Position |

Surname, initials |

Signature |

|

Enterprise - customer |

|||

|

General contracting organization |

|||

|

Installation organization |

|||

If necessary, representatives of the company can participate in drawing up the forms. - manufacturer of technological equipment and pipelines, commissioning, design and component organizations.

2.4. Checking the installation of equipment on the foundation (base) is carried out in accordance with the working documentation for the construction of the facility and operational documentation (installation instructions) of enterprises - manufacturers. The results of the check are recorded on the equipment that is part of the technological unit (form 1) *.

* See clause 1.3.

2.5. The test results of vessels and apparatuses are recorded in Form 2. The following are indicated as the main technical characteristics of the vessels and apparatuses: overall dimensions, working pressure MPa (kgf / cm 2), weight (inoperative), serial number of the enterprise- the manufacturer.

2.6. Machines and mechanisms are tested in accordance with clause 5.3 of SNiP 3.05.05 - 84, the requirements of technical conditions and operational documentation (installation instructions) of the enterprise - manufacturer. The test results are recorded in Form 3.

2.7. Testing of technological pipelines is carried out in accordance with paragraphs. 5.4- 5.16 SNiP 3.05.05 - 84 and the requirements of working documentation. The test results are recorded in form 4 for each line of pipelines.

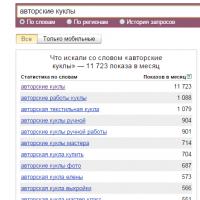

2.8. The welding work log is compiled in form 5, a list of welders and thermists- operators - according to form 6, journal of accounting and quality control of control (test) welded joints - according to form 7, journal of heat treatment of welded joints - according to form 8, certificate of survey of hidden works- according to the form 9.

2.9. The certificate of acceptance of equipment after individual tests is drawn up in form 10.

2.10. The readiness of supporting structures, including foundations for the installation of technological equipment and pipelines, is recorded in the act of intermediate acceptance of critical structures (Form 11).

2.11. The transfer by the customer to the installation of technological equipment and pipelines, as well as other products to be installed, is recorded in the form of the Central Statistical Administration of the USSR M - 25 (form 12 of the present VSN). Defects and deviations from the working drawings and regulatory - technical documents are reflected in the form of the Central Statistical Office of the USSR M - 27 (form 13 of this BCH).

Acceptance of equipment and pipelines for installation should be carried out in accordance with paragraphs. 2.5- 2.8 SNiP 3.05.05 - 84. At the same time, they check their factory readiness, assembly adaptability and completeness in accordance with GOST 24414 - 80 and other regulatory - technical documents.

2.12. When accepting working documentation for the installation of technological equipment and pipelines (form 14), it is necessary to check its compliance with the requirements of the current building codes and regulations, SPDS standards and other regulatory - technical documents.

2.13. As executive drawings of technological pipelines (if they are provided for by regulatory documents), as a rule, detail (axonometric) drawings of these pipelines should be used with the introduction of actual data into them, from which they put the stamp "Executive drawing", certified by the signature of the person responsible for the installation of pipelines and the authorized sign production documentation forms. The stamp must indicate the date of drawing up the executive drawing.

On the basis of the lists, acts, passports, certificates and other documents presented by the customer to the as-built drawing, data is entered containing information in the required volume about the parts, materials and products used during the installation of pipelines (for pipes and parts of the pipelines supplied by the contractor, similar information is indicated according to the documents enterprises - manufacturers or suppliers).

2.14. Form 1 production documentation - 14 reflects the entire range of works on the installation of process equipment and process pipelines.

2.15. The procedure for maintaining production documentation is given in the recommended Appendix 4.

Form 1

Information on clause 2.2 VSN

Act

checking the installation of equipment on the foundation

This act is drawn up in that the installation on the foundation (base) of the following equipment was checked:

|

№ p / p |

Name and number for workers drawings |

Number and the name of the workers drawings and operational documentation (installation instructions) manufacturer |

Conclusion about the results checks and anchoring fundamental bolted |

On the basis of the above, it is allowed to pour the listed equipment (except for the equipment of clauses _________, which is installed in the design position without gravy).

Note. The act, if provided for in the operational documentation (installation instructions), is accompanied by a form indicating the measurements made during installation, in the form established by the company - the equipment manufacturer.

Signatures according to clause 2.3 VSN.

Form 2

Information on clause 2.2 VSN.

Act

testing of vessels and apparatus

This act was drawn up in the fact that an external examination was performed (internal in accessible places), after which a hydraulic, pneumatic ______________________________

(cross out unnecessary)

test pressure test (delete unnecessary):

housing MPa (kgf / cm 2);

shirts MPa (kgf / cm 2).

(name of the vessel, apparatus, number according to the working documentation,

brief technical characteristics)

During the test, the equipment was under test pressure for ____ minutes (or under water filling), after which the pressure was gradually reduced to working pressure, which was maintained for ____ minutes.

Upon inspection of the equipment, it was found that _________________

Conclusion

The equipment has passed the hydraulic, pneumatic (unnecessary cross out) test pressure test and is operational at operating pressure:

housing MPa (kgf / cm 2);

pipe part MPa (kgf / cm 2);

shirts MPa (kgf / cm 2).

Signatures according to clause 2.3 VSN.

Form 3

Information on clause 2.2 VSN

Act

testing of machines and mechanisms

This act is drawn up in the fact that an individual test was carried out at idle speed of the following machines and mechanisms:

Signatures according to clause 2.3 VSN.

Form 4

Information on clause 2.2 VSN

Act

pipeline testing

This act is drawn up in what is produced by _____________

(type of test)

testing of pipeline lines _______________________________ (name and line number,

its boundaries, working pressure, MPa (kgf / cm 2)

The test was carried out in accordance with SNiP 3.05.05 - 84 ______

(name and code of other normative - technical documents, numbers

drawings of working documentation)

strength by pressure MPa (kgf / cm 2);

for tightness by pressure of MPa (kgf / cm 2).

Test duration h

During the test, no leaks or other defects were found in the pipeline.

The pipeline lines specified in this act are considered to have passed the test.

Signatures according to clause 2.3 VSN.

Information on clause 2.2 VSN

Welding log

Line No. Pipeline

(name, working pressure, temperature, product)

Site manager Welding work manager __________________________

(signature, decryption) (signature, decryption)

"___" _________________ 19__ "___" _________________ 19__

Form 6

Information on clause 2.2 VSN

List

welders and thermists- operators

|

№ p / p |

Surname, name, patronymic |

Specialty (welder, thermist - operator) |

Stigma |

Discharge |

Identity number and validity period |

Signature example |

Note |

Site manager

(signature, transcript)

Welding supervisor

(heat treatment) (signature, transcript)

Form 8

Information on clause 2.2 VSN

Magazine

heat treatment of welded joints

Line number ____________ Piping ______________________________________

(name, pressure, temperature, product)

Site manager _______________________

(signature, transcript)

"___" ___________ 19____

Welding (heat treatment) manager _____________________

(signature, transcript)

"___" ____________ 19___

Form 9 (according to SNiP 3.01.01 - 86)

Act

survey of hidden works

(Name of works)

"____" ____________ 19 ___

Commission consisting of:

representative of construction -

______________________________________________________

(surname, initials, position)

inspected the work performed by ______________________

______________________________________________________

(Name

______________________________________________________

construction - installation organization)

1. The following works have been presented for examination and acceptance _____________________________________________________

(name of hidden works)

- estimate documentation _____

______________________________________________________

(name of the design organization, drawing numbers and date

______________________________________________________

their compilation)

3. When performing work, ________________________

(name of materials,

______________________________________________________

______________________________________________________

other documents confirming the quality)

4. When performing work, there are no (or allowed) deviations from the design - estimate documentation ___________________________

(in the presence of

deviations indicate who agreed, numbers

_______________________________________________________

drawings and date of agreement)

5. Date: start of work ___________________________

Completion of work ________________________

Commission decision

- estimate documentation, standards, building codes and regulations and meet the requirements of their acceptance.

(name of work and

constructions)

Technical representative _______________________________

customer supervision (signature)

Representative _______________________________

construction - editing room (signature)

organization

Form 10

(according to SNiP III - 3 - 81)

Act

on the acceptance of equipment after individual testing

mountains. ________________ "___" _______________ 19__

Working committee appointed by _____________________________

(Name

_______________________________________________________

organizations - customer (developer),

_______________________________________________________

which appointed the working commission)

decision of "___" ______________ 19__ No. __________ as part of

chairman - customer representative ______________________

(surname, acting, position)

commission members - representatives

general contractor __________________________________

(surname, acting, position)

subcontractors (installation organizations) ____________________

_______________________________________________________

operating organization _____________________________

general designer _____________________________

bodies of state fire supervision ________________

______________________________________________________

technical labor inspectorate of the Central Committee or the Council of Trade Unions ______

______________________________________________________

the customer's trade union or operational

organizations ____________________________________________

_______________________________________________________

_______________________________________________________

other interested supervisors and organizations ________

_______________________________________________________

_______________________________________________________

Installed:

1. General contractor ______________________________

_______________________________________________________

(indicate the name and departmental subordination)

the following equipment, completed by installation, was presented for acceptance:

_______________________________________________________

(list of installed equipment and its brief

_______________________________________________________

technical characteristics (if necessary, specify in

_______________________________________________________

annex)

mounted in ________________________________________

(name of the building, structure, workshop)

included in ______________________________________

(Business name,

_______________________________________________________

its sequence, launch complex)

2. Installation work completed __________________________

(indicate the name

_______________________________________________________

installation organizations and their departmental subordination)

3. The design documentation is developed by _____________________

(indicate the name

_______________________________________________________

design organization and its departmental subordination,

_______________________________________________________

number of drawings and date of their preparation)

4. Date of commencement of installation work ___________________________

(year and month)

5. Date of completion of installation work ________________________

(year and month)

6. The existing deficiencies in the equipment presented for acceptance do not interfere with comprehensive testing and must be eliminated within the time limits specified in Appendix No. ____ to this act.

The working commission carried out the following additional tests of the equipment (except for the tests recorded in the executive documentation presented by the general contractor):

_______________________________________________________

Decision of the working committee

The installation works of the presented equipment were carried out in accordance with the project, standards, building codes and regulations, technical conditions and meet the requirements of its acceptance for comprehensive testing.

The equipment presented for acceptance, specified in clause 1 of this act, shall be considered accepted since __________________19___ for comprehensive testing with an assessment of the quality of the work performed ______________________________________________________

(excellent, good, satisfactory)

List of receptions - delivery documentation attached to the act:

1. _________________________________________________

2. _________________________________________________

3. _________________________________________________

etc.

Chairman of the working committee ______________________

(signature)

Members of the working commission ____________________________

(signatures)

Handed over:

General contractor representatives

and subcontractors

_______________________________________________________

(signatures)

Accepted:

Representatives of the customer (developer)

_______________________________________________________

(signatures)

Form 11

(according to SNiP 3.01.01 - 85)

Act

intermediate acceptance of critical structures

_______________________________________________________

(design name)

executed in __________________________________________

(name and location of the object)

"___" _____________ 19 ___

Commission consisting of:

representative of construction - installation organization __________

_______________________________________________________

(surname, initials, position)

technical supervision representative of the customer _______________

______________________________________________________

(surname, initials, position)

representative of the design organization _______________________

_______________________________________________________

(surname, initials, position)

inspected the structures and checked the quality of work,

completed by ___________________________________________

(name of construction - installation organization)

and drew up this act on the following:

1. The following constructions were presented for acceptance ____________

_______________________________________________________

(list and brief description of structures)

2. The work was carried out according to the design - estimate documentation _____

_______________________________________________________

(name of the design organization, drawing numbers and

_______________________________________________________

date of their compilation)

3. When performing work, there are no (or allowed) deviations from the design - estimate documentation ____________________________

(in the presence of

_______________________________________________________

deviations indicate who agreed, the numbers of the drawings and

_______________________________________________________

date of agreement)

4. Date: start of work ________________________________

Completion of work _____________________________

Commission decision

The work was carried out in accordance with the design - estimate documentation, standards, building codes and regulations.

Based on the foregoing, subsequent work on the device (installation) is allowed ___________________

_______________________________________________________

(name of works and structures)

construction - editing room (signature)

organization

Representative _________________________

technical supervision (signature)

customer

Representative _________________________

design organization (signature)

Form 12

Approved by order of the Central Statistical Administration of the USSR dated November 27, 1985 No. 628

![]()

Customer _____________________

Act No. ______

acceptance - transfer of equipment for installation

"___" _______________ 19___

The act was drawn up by ________________________________________________

(place of drawing up the act)

Submitted by ____________________________________________________

(name of the installer)

the following equipment for installation in ___________________

(Name

____________________________________________________________

buildings, structures, workshops)

|

Naimenova |

The code (nomen |

Plant |

Factory - Izoto |

Position number |

Arrival at the customer's warehouse |

||||

|

equipment |

clature number) |

Type, brand |

number or marking |

driver |

according to the technological scheme |

date |

acceptance certificate number |

Quantity |

Price |

Reverse side of form No. M - 25

When accepting the equipment for installation, the following was established:

1. The equipment meets \ does not correspond to the design specification or to the drawing (if it does not correspond, indicate in what) _________________________________________________________

2. The equipment was delivered complete \ incomplete (indicate the composition of the set and technical documentation, according to which the acceptance was made and what completeness) ___________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

3. Defects during external examination of the equipment were not found / found (if found, then list them in detail) ______________________________________________

_________________________________________________________

_________________________________________________________

Note. Defects discovered during inspection, installation and testing of equipment are subject to special activation.

4. Conclusion on suitability for installation _____________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

Passed by the customer's representative

Accepted by a representative of the installation organization

________________ ______________ __________________

(position) (signature) (acting, surname)

The specified equipment is accepted for storage.

Financially responsible person

Form 13

Model interdepartmental norm No. M - 27

Approved by order of the Central Statistical Administration of the USSR dated 11/27/85

№ 628

Act No. ______

on detected equipment defects

"___" _____________ 19___

_______________________________________________________

Location: city, town, etc.

Enterprise (customer) ___________________________________

(Name)

Building (structure), workshop _________________________________

This act is drawn up in the fact that in the process of revision, installation, testing (underline the stage) of the equipment listed below, manufactured by ________________________________

(plant name- manufacturer)

the following defects were found:

|

Factory |

Design organization |

date |

Discovered |

||||

|

Name |

Type, brand |

number or marking |

drawing number |

Name |

equipment manufacturing |

defects |

|

Reverse side of form No. M - 27

|

Factory |

Design organization |

date |

Discovered |

||||

|

Name |

Type, brand |

number or marking |

drawing number |

Name |

equipment manufacturing |

receipt of equipment at the warehouse |

defects |

To eliminate the identified defects, it is necessary:

_______________________________________________________

(activities or works for

_______________________________________________________

elimination of identified defects, performers and deadlines

_______________________________________________________

execution)

_______________________________________________________

_______________________________________________________

_______________________________________________________

Customer representative

(position) (signature) (acting, surname)

Contractor representative

________________ __________________ __________________

(position) (signature) (acting, surname)

Factory representative- manufacturer

________________ __________________ __________________

(position) (signature) (acting, surname)

Form 14

Information on clause 2.2 VSN

Act

transfer of working documentation for the production of work

For the production of work ___________________________________

(customer)

transferred to ______________ ________________________________

(date) (installer)

in ______ copies.

1. Working drawings according to the list of the main set No. ______

2. Attached documents according to the list of reference and

attached documents No. __________________________ including:

drawings of general views of blocks;

drawings of general types of technological structures;

drawings of general types of non-standardized equipment;

working drawings of pipelines (including special ones) *;

list of volumes of installation work in accordance with GOST 21.111 - 84;

material requirement lists according to GOST 21.109 - 82;

equipment specification in accordance with GOST 21.110 - 82;

object estimates;

local estimates;

working documentation;

documentation according to GOST 24444 - 80.

3. When checking the documentation, it was established:

the drawings of the main set comply with the requirements of clause 1.4 of SNiP 3.05.05 - 84;

drawings of general views comply with the requirements of SNiP 1.02.01 - 85;

the statements comply with the requirements of GOST;

estimates correspond to SNiP 1.02.01 - 85;

on each drawing of the main set and the attached documents there is a stamp "for production", signed by the responsible representative of the customer with the date;

availability of the conclusion of the installation organizations on the project (in accordance with clause 1.5 of SNiP 3.05.05 - 84);

4. Conclusion on the documentation

The working documentation for the construction of the facility is suitable for the preparation and production of works on the installation of technological equipment and technological pipelines.

Signatures according to clause 2.3 VSN.

* "Special" include pipelines assembled from prefabricated straight and shaped elements - gummed, lined with all types of coatings, made of non-metallic materials, as well as metal for operation at Р у ³ 10 MPa (100 kgf / cm 2), to which assembly (axonometric) drawings are transferred. For facilities built on imported equipment, axonometric drawings must be transferred to all pipelines D y ³ 50 mm.

Departmental building codes

Production documentation for the installation of process equipment and process pipelines

VSN 478 - 86

Minmontazhspetsstroy USSR

Ministry of Installation and Special Construction Works of the USSR

MOSCOW 1986

Developed by institutes of the USSR Ministry of Montazhspetsstroy

Giprokhimmontazh (leading organization) - I.P. Petrukhin, M.L. Elyash (theme leader and executive in charge);

VNIIMontazhspetsstroy - B.V. Popovsky, V. Ya. Eidelman.

Submitted Glavkhimmontazh of the USSR Ministry of Montazhspetsstroy

Chief engineer A.V. Anokhin.

Prepared for approval The main technical department of the USSR Ministry of Montazhspetsstroy.

Deputy chief G.A. Sukalsky.

Approved By the Ministry of Assembly and Special Construction Works of the USSR.

Deputy Minister K.K. Lipodat.

Agreed with the USSR State Construction Committee (letter dated March 4, 1986 No. DC- 1125 - 1 ).

These departmental building codes (VSN) establish the content of production documentation for the installation of process equipment and process pipelines.

1. General Provisions

Form 1 Certificate of verification of equipment installation on the foundation

Form 2 Certificate testing of vessels and apparatus

Form 3 Certificate of testing of machines and mechanisms

Form 4 Acceptance testing of pipelines

Form 5 Welding log

Form 6 List of welders and thermal operators

Form 7 JOURNAL of accounting and quality control of control (test) welded joints

Form 8 Log of heat treatment of welded joints

Form 9 Certificate of hidden works

Form 10 Certificate of acceptance of equipment after individual testing

Form 11 Act of intermediate acceptance of critical structures

Form 12 Act No. ______ acceptance and transfer of equipment for installation

Form 13Act No. ______ on identified equipment defects

Form 14 Act of transfer of working documentation for the production of work

3. Operational documentation drawn up during the installation of technological equipment and pipelines

4. Documentation presented or transferred to the installation organization by the customer (general contractor) for the period of installation work

Appendix 20 Reference Documentation presented for assembly units of steel pipelines for pressure over 10 MPa

Appendix 21 Reference Terms adopted in VSN 478-86

1. General Provisions

1.1. The types and content of production documentation must comply with SNiP 3.01.01-85, SNiP 3.05.05-84 and SNiP III-3-81.

Production documentation for equipment and pipelines subject to inspection by state supervision authorities must be drawn up in accordance with the rules and regulations of these authorities.

1.2. When filling out the production documentation forms, the requirements of state, industry standards, technical conditions for the manufacture and supply of technological equipment and pipelines, as well as the requirements agreed by the customer with the involvement of the installation organization, must be reflected in this part of firms - suppliers of complete technological equipment and pipelines purchased by import ...

1.3. Production documentation by type of work is completed for technological units, and for objects in whose projects technological units are not selected, for the object as a whole.

2. Content of production documentation forms

2.1. The installation organization submits to the general contractor for presentation to the working commission the documentation provided for in SNiP III-3-81, SNiP 3.01.01-85, SNiP 3.05.05-84 and these VSN (forms 1-10).

2.2. The following information is placed before the heading of each form (except for Forms 9-13):

(place of construction of the enterprise) | (name of the general contractor and construction organization and its departmental affiliation) |

||||

(name of the customer) | (name of the installation organization with indication of the trust and departmental affiliation) |

||||

(name of the facility under construction) | |||||

(name of the technological unit) | |||||

2.3. The data provided in the forms (with the exception of forms 5-14) are certified by the signatures of the persons responsible for maintaining production documentation in the following form:

Name of company | Representative |

||

Position | Surname, initials | ||

Customer enterprise | |||

General contracting organization | |||

Installation organization | |||

If necessary, representatives of the enterprise - manufacturer of technological equipment and pipelines, commissioning, design and component organizations can participate in drawing up the forms.

2.4. Checking the installation of equipment on the foundation (base) is carried out in accordance with the working documentation for the construction of the facility and operational documentation (installation instructions) of manufacturers. The results of the check are recorded on the equipment that is part of the technological unit (form 1) *.

* See clause 1.3.

2.5. The test results of vessels and apparatuses are recorded in Form 2. The following are indicated as the main technical characteristics of the vessels and apparatuses: overall dimensions, working pressure MPa (kgf / cm 2), weight (inoperative), serial number of the manufacturer.

2.6. Machines and mechanisms are tested in accordance with clause 5.3 of SNiP 3.05.05-84, the requirements of technical conditions and operational documentation (installation instructions) of the manufacturer. The test results are recorded in Form 3.

2.7. Testing of technological pipelines is carried out in accordance with paragraphs. 5.4 - 5.16 SNiP 3.05.05-84 and the requirements of working documentation. The test results are recorded in form 4 for each line of pipelines.

2.8. The welding work log is compiled according to Form 5, the list of welders and thermist-operators - according to Form 6, the logbook for recording and quality control of control (test) welded joints - according to Form 7, the log of heat treatment of welded joints - according to Form 8, the certificate of inspection of hidden works - according to the form 9.

2.9. The certificate of acceptance of equipment after individual tests is drawn up in form 10.

2.10. The readiness of supporting structures, including foundations for the installation of technological equipment and pipelines, is recorded in the act of intermediate acceptance of critical structures (Form 11).

2.11. The transfer by the customer to the installation of technological equipment and pipelines, as well as other products to be installed, is recorded in the form of the Central Statistical Administration of the USSR M-25 (form 12 of this VSN). The defects and deviations from the working drawings and normative and technical documents identified in this case are reflected in the form of the Central Statistical Administration of the USSR M-27 (form 13 of this VSN).

Acceptance of equipment and pipelines for installation should be carried out in accordance with paragraphs. 2.5-2.8 SNiP 3.05.05-84. At the same time, they check their factory readiness, assembly adaptability and completeness in accordance with GOST 24414-80 and other regulatory and technical documents.

2.12. When accepting working documentation for the installation of technological equipment and pipelines (form 14), it is necessary to check its compliance with the requirements of the current building codes and regulations, SPDS standards and other regulatory and technical documents.

2.13. As executive drawings of technological pipelines (if they are provided for by regulatory documents), as a rule, detail (axonometric) drawings of these pipelines should be used with the introduction of actual data into them, from which they put the stamp "Executive drawing", certified by the signature of the person responsible for the installation of pipelines and the authorized sign production documentation forms. The stamp must indicate the date of drawing up the executive drawing.

On the basis of the lists, acts, passports, certificates and other documents presented by the customer to the as-built drawing, data is entered containing information in the required volume about the parts, materials and products used during the installation of pipelines (for pipes and parts of the pipelines supplied by the contractor, similar information is indicated according to the documents manufacturers or suppliers).

2.14. Production documentation in Forms 1-14 reflects the entire range of works on the installation of process equipment and process pipelines.

2.15. The procedure for maintaining production documentation is given in the recommended Appendix 4.

And SNiP III-3-81.

Production documentation for equipment and pipelines subject to inspection by state supervision authorities must be drawn up in accordance with the rules and regulations of these authorities.

1.2. When filling out the production documentation forms, the requirements of state, industry standards, technical conditions for the manufacture and supply of technological equipment and pipelines, as well as the requirements agreed by the customer with the involvement of the installation organization, must be reflected in this part of firms - suppliers of complete technological equipment and pipelines purchased by import ...

2.5. The test results of vessels and apparatus are recorded in. The following are indicated as the main technical characteristics of vessels and apparatus: overall dimensions, working pressure MPa (kgf / cm2), weight (inoperative), serial number of the manufacturer.

2.6. Machines and mechanisms are tested in accordance with clause 5.3 of SNiP 3.05.05-84, the requirements of technical conditions and operational documentation (installation instructions) of the manufacturer. The test results are recorded in.

2.7. Testing of technological pipelines is carried out in accordance with paragraphs. 5.4 - 5.16 SNiP 3.05.05-84 and the requirements of working documentation. The test results are recorded for each line of pipelines.

2.8. The log of welding works is compiled according to, the list of welders and thermal operators - according to, the log of accounting and quality control of control (test) welded joints - according to, the log of heat treatment of welded joints - according to, the certificate of inspection of hidden works - according to.

2.9. The certificate of acceptance of equipment after individual tests is drawn up according to.

2.10. The readiness of supporting structures, including foundations for the installation of technological equipment and pipelines, is recorded in the act of intermediate acceptance of critical structures ().

2.11. The transfer by the customer to the installation of technological equipment and pipelines, as well as other products to be installed, is recorded in the form of the Central Statistical Administration of the USSR M-25 (real VSN). The defects and deviations from the working drawings and normative and technical documents identified in this case are reflected in the form of the Central Statistical Administration of the USSR M-27 (real VSN).

Acceptance of equipment and pipelines for installation should be carried out in accordance with paragraphs. 2.5-2.8 SNiP 3.05.05-84. At the same time, they check their factory readiness, assembly adaptability and completeness in accordance with GOST 24414-80 and other regulatory and technical documents.

2.12. When accepting working documentation for the installation of technological equipment and pipelines (), it is necessary to check its compliance with the requirements of the current building codes and regulations, SPDS standards and other regulatory and technical documents.

2.13. As executive drawings of technological pipelines (if they are provided for by regulatory documents), as a rule, detail (axonometric) drawings of these pipelines should be used with the introduction of actual data into them, from which they put the stamp "Executive drawing", certified by the signature of the person responsible for the installation of pipelines and the authorized sign production documentation forms. The stamp must indicate the date of drawing up the executive drawing.

On the basis of the lists, acts, passports, certificates and other documents presented by the customer to the as-built drawing, data is entered containing information in the required volume about the parts, materials and products used during the installation of pipelines (for pipes and parts of the pipelines supplied by the contractor, similar information is indicated according to the documents manufacturers or suppliers).

2.14. Production documentation by forms - reflects the whole range of works on the installation of technological equipment and technological pipelines.

2.15. The procedure for maintaining production documentation is given in the recommended one.

Form 1

Act

checking the installation of equipment on the foundation

This act is drawn up in that the installation on the foundation (base) of the following equipment was checked:

On the basis of the above, it is allowed to pour the listed equipment (except for the equipment of clauses _________, which is installed in the design position without gravy).

Note. The act, if provided for in the operational documentation (installation instructions), is accompanied by a form indicating the measurements made during installation, in the form established by the equipment manufacturer.

Form 2

Act

|

Form 3

Act

testing of machines and mechanisms

This act is drawn up in the fact that an individual test was carried out at idle speed of the following machines and mechanisms:

Form 4

strength by pressure .... MPa (kgf / cm2);

for tightness by pressure of MPa (kgf / cm2).

Test duration h

During the test, no leaks or other defects were found in the pipeline.

The pipeline lines specified in this act are considered to have passed the test.

Form 5

Welding log

Line No. ____________ Pipeline _______________________________________________

(name, working pressure, temperature, product)

|

Welded joint number according to drawings (executive drawings) |

Joint characteristic, mm, D n´ S steel grades or composition of steel grades, GOST, TU, certificate number |

Welding consumables (type, brand, GOST or TU, certificate number) |

Welding consumables quality inspection log number, inspection registration numbers |

Inspector's signature on weld acceptance |

Joint position (rotary non-rotary vertical, horizontal) |

Welding date |

Welding method (tacks, root of the seam, filling the groove) |

Air temperature in the working area, ° С |

||||

|

Electrodes |

Wire |

Shielding gas |

||||||||||

Continuation of Form 5

|

Temperature of (preliminary accompanying) joint heating, ° С |

Surname, name, patronymic of the welder, mark number |

Welder's signature |

Date of heat treatment of the welded joint, number of the heat treatment log and registration number in the log |

Results of external examination and measurements, color or magnetic, powder flaw detection, protocol number and date |

Welding quality control method (radiographic, ultrasonic flaw detection) |

Date of radiographic inspection or ultrasonic flaw detection, report number, inspection log number and log registration number |

Results of measuring the content of the ferrite phase in the deposited metal, protocol number and date |

Results of measuring the content of the main flying elements or steeloscopy, protocol number and date |

Defect elimination notes |

Last name, first name, patronymic, identification number and signature of the controller |

Surname, name, patronymic of the foreman or welding foreman, signature, date |

Site manager __________________________________ Welding work manager __________________________

(signature, decryption) (signature, decryption)

"___" _________________ 19__ "___" _________________ 19__

List

welders and thermal operators

Site manager __________________________

(signature, transcript)

Welding supervisor __________________________

(heat treatment) (signature, decryption)

Form 7

MAGAZINE

accounting and quality control of control (test) welded joints

___________________________________

(welded laboratory and its affiliation)

|

Line number |

Date of the previous inspection, numbers of lines and welds of the same type made by the welder after it |

Welding date of the controlled welded joint |

Welded joint number according to drawings (executive drawings) |

Temperature conditions, ° С |

Pipe ( D n´ S), mm, steel grade, (composition of steel grades) |

Welding method |

Welding consumables |

||||

|

Electrodes |

Wire |

Shielding gas |

|||||||||

Continuation of Form 7

|

Surname and initials of the welder, brand and signature of the welder |

Heat treatment date, registration number and log |

Surname and initials of the thermist-operator, stamp and signature |

Date and number of the hardness test report |

Radiographic or ultrasound control, report number |

Mechanical properties of the welded joint of the sample cut from the control joint, protocol number, date |

Metallography, protocol number, date |

Ferrite phase, protocol number, date |

Addiction to IWC, protocol number, date |

Surname, initials of the inspector, certificate number, signature, date |

Conclusion on the quality of the inspected welded joints and the welder's admission to welding of the same type of joints |

Surname and initials of the head of the welding laboratory, signature, date |

Site manager __________________________________ Welding work manager ____________________________

(signature, decryption) (signature, decryption)

"_____" _____________ 19 _____ "_____" _____________ 19 _____

Form 8

Information on VSN

Magazine

heat treatment of welded joints

Line number ____________ Piping ____________________________________________

(name, pressure, temperature, product)

|

Welded joint number according to drawings (executive drawings) |

Pipe D n´ S, mm |

Steel grade |

Type of electrodes, brand of welding wire |

Welding date |

Heat treatment date |

Heat treatment type |

Heating method |

Temperature control method |

|

Continuation of Form 8

|

Diagram number or temperature measurement time |

Heat treatment |

Surname, first name, patronymic, brand and signature of the thermist-operator |

Hardness test report number, date |

Evaluation of the suitability of a welded joint after heat treatment |

Surname, initials and signature of the heat treatment manager |

|||

|

Heating temperature ºС |

Heating rate ºС / h |

Exposure time, h |

Cooling behavior |

|||||

Site manager ___________________________

(signature, transcript)

"___" ___________ 19____

Welding (heat treatment) manager __________________________

(signature, transcript)

"___" ____________ 19___

Act

|

|

|

Technical Representative |

Representative of the construction |

|

customer supervision _______________________ |

installation organization _________________ |

|

(signature) |

(signature) |

Form 10

(according to SNiP III-3-81)

Act

|

Form 11

Act

|

Form 12

Model interdepartmental norm No. M-25

Customer _____________________ Approved by order of the Central Statistical Administration of the USSR dated November 27, 1985 No. 628

|

OKUD CODE |

||||||||

Act No. ______

|

||||||||

|

Operation code |

||

The act was drawn up by _________________________________________________________________

(place of drawing up the act)

Submitted by _____________________________________________________________________

(name of the installer)

the following equipment for installation in _____________________________________

(name of the building, structure, workshop)

End of form 12

Reverse side of form No. M-25

When accepting the equipment for installation, the following was established:

1. Equipment design specification or drawing (if not

corresponds, indicate what) ______________________________________________________

2. Equipment transferred ![]() (indicate the composition of the kit and technical

(indicate the composition of the kit and technical

documentation for which acceptance was made and what completeness) _________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

3. Defects during external inspection of equipment ![]() (if found, then

(if found, then

list them in detail) _________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

Note. Defects discovered during inspection, installation and testing of equipment are subject to

special activation.

4. Conclusion on suitability for installation __________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

Passed by a representative

customer __________________ __________________ ___________________

(position) (signature) (acting, surname)

Accepted by a representative

installation organization

_________________ _______________ ___________________

(position) (signature) (acting, surname)

The specified equipment is accepted for storage.

Financially responsible person

Form 13

Model interdepartmental norm No. M-27

Approved by order of the Central Statistical Administration of the USSR dated 11/27/85

|

OKUD CODE |

||

Act No. ______

|

||

Form 14

Act

|

* "Special" include pipelines assembled from factory-made straight and shaped elements - gummed, lined with all types of coatings, from non-metallic materials, as well as metal for operation during R y ³ 10 MPa (100 kgf / cm2), to which assembly (axonometric) drawings are transferred. For objects built on imported equipment, axonometric drawings for all pipelines must be transferred D at ³ 50 mm.

3. Operational documentation drawn up during the installation of technological equipment and pipelines

3.1. When performing installation work, the installation organization, together with other participants in the construction, if necessary, draw up operational documentation, the content of which is given in the recommended appendices -.

3.2. For each welder in the installation department, a form must be kept in which the test results of the control (test) welded joints welded by him and the results of the acceptance of the joints welded at the installation are entered.

4. Documentation presented or transferred to the installation organization by the customer (general contractor) for the period of installation work

4.1. Prior to the commencement of installation work within the agreed time frame, the customer (general contractor) must submit to the installation organization the following documentation provided for by GOST 24444-80: form or passport; picking and packing lists; assembly drawing of equipment; installation drawing; schemes of lubrication, cooling, sealing, automation, control, etc .; working drawings, passports, certificates and other documents for pipelines, materials and parts for their manufacture and installation; equipment installation instructions; specifications for custom-made equipment.

Note... If it is necessary to develop a technology for the installation of complex equipment, the customer (general contractor) transfers to the installation organization, at its request, the relevant documents from the above list for the period of preparation and production of installation work.

4.2. For assembly units of technological pipelines with a pressure of 10 MPa or more, the customer (general contractor) presents the manufacturer's documentation according to the reference.

4.3. When installing complete imported technological equipment, the following are additionally presented: instructions for welding; norms and standards, which are referenced in the working (installation) and detailed drawings of technological pipelines.

4.4. For the rest of the products and materials supplied by the customer and the contractor used in the installation of technological equipment and pipelines, certificates, passports and other documents confirming their quality are presented.

Head of the installation site ____________________________

(signature, transcript)

Head of the installation site ____________________________

(signature, transcript)

Chief Engineer _______________________________

assembly department (signature, transcript)

Head of VET _______________________________

(signature, transcript)

Site manager _______________________________

(signature, transcript)

Before the removal of the seals, their complete safety was established, the seals were removed in accordance with the instructions of the manufacturer.

Note... For pipeline fittings in column 2 indicate the type of fittings, batch number.

Protocol

|

Protocol No. _____

|

Boss

welding laboratory

__________________________ ________________________

Protocol

|

|

Pipeline (line number) |

Diameter and thickness of joined pipes, mm |

steel grade |

Sample marking |

Location of fracture and type of defects in the fracture of the sample |

Ultimate resistance, MPa (kgf / cm2) |

Bending angle or flattening clearance, mm |

Impact strength, kJ / m2 (kgf m / cm2) |

Surname, name, patronymic of the welder, mark number |

Registration number in the log book of control (trial) joints |

Number and date of the protocol for cutting production joints |

Note |

Head of the welding laboratory

_________________________ ____________________________

(trust, management) (signature, decryption)

Test conducted by _____________________________________

Protocol

|

|

Name of company, overseeing Conclusion No. ___

|

|||||||||||||||||||||||||||||||||

|

Application number |

Drawing number, piping line number |

Welded joint number |

The number of the inspected section of the welded joint |

Radiogram number |

Defects found |

Evaluation of the welded joint area |

Note |

||||||||||||||

|

Installed |

Magazine

|

||||||||||||||||||||

|

Radiogram number |

Sensitivity, mm |

The total score of the welded joint |

Defects found |

Surname, initials, brand and signatures of the inspector |

Conclusion on the quality of the welded joint (good, bad) |

Surname, initials and signature of the person who gave the opinion |

Note: |

|

|

based on control results |

||||||||

Head of laboratory ______________________________________________

(trust, management, signature, decryption)

Head of Laboratory _________________________________________ Signature

(trust, management, surname, name, patronymic)

Ultrasonic inspection specialist (surname, name, patronymic) Signature

Notes: 1. The report number should be the serial number of the corresponding entry in the ultrasonic inspection log.

2. The control scheme is mandatory.

Extreme sensitivity (1 rejection level)

Continuation of Appendix 17

|

Abbreviated description of detected defects |

Number of detected defects per 100 mm of seam length |

Conditional length of defects per 100 mm of weld length, mm |

Assessment of the quality of the seam of the welded joint |

Retest information |

Surname of the inspector |

Inspector's signature |

Note |

||||

|

17 Layout of controlled areas with indication of their sizes |

Inspected area number |

Used flaw detection kits (paint recipes) |

Description of the detected defects with an indication of the nature, size and coordinates |

Quality control |

Date of inspection |

Signature of the inspector who performed the inspection |

Conclusion number and date of issue |

||||

|

Pipeline name and number |

D n ´ S, mm |

||||||||||

Head of the welding laboratory _____________________________________________

(trust, management, signature, decryption)

Installation specification line number _________________________________________

Characteristics of the pipeline ____________________________________________________

Workspace __________________________________________________________________

Working pressure ______________ MPa (kgf / cm2) ____________________________________

Working temperature _______________ ° С

Test pressure _____________ MPa (kgf / cm2) ____________________________________

Hydraulic ________________________________________________________________

|

2. Information about pipes and pipeline parts Continuation

|

|||||||||||||||||||||||||||||||||||||||||

3. Information about welded joints

|

|||||||||||||||||||||||||||||||||||||||||||||||

Continuation

|

Welding information |

Quality control of welded joints |

Note: |

|||||||||||

|

Test result of the control joint |

|||||||||||||

|

Ultimate resistance, MPa |

Elongation,% |

Relative narrowing,% |

Impact strength, MJ / m2 |

Brinell hardness, HB |

Bend angle, degrees |

Intergranular corrosion results |

Number of joints |

External examination |

Transillumination |

Magnetic and color flaw detection |

Microstructure |

||

Continuation of Appendix 20

5. Act

hydraulic testing of assembly units

"___" _______________ 19___

Town __________________

Factory _____________________________

Workshop _______________________________

We, the undersigned, are the representative of the plant represented by

________________________________________________________________________________

representative of Quality Control Department represented by ______________________________________________________

________________________________________________________________________________

(position, surname, name, patronymic)

made this act in that a strength test was performed ________________________________________________________________________________

(assembly unit drawing number)

Working pressure _________________ MPa (kgf / cm2).

During the test, the product was kept for _________ minutes under a test pressure of __________ MPa (kgf / cm2), after which the pressure was reduced to working _________________ MPa (kgf / cm2) and held until the end of the inspection of the product.

During the test, no defects, leaks, or pressure drop were found on the manometer.

Representatives:

factory (surname, acting)

Quality control department of the plant (surname, acting)

Note

6. Act

valve tests

Town _______________________

Factory _______________________

Workshop _________________________

We, the undersigned, are the representative of the plant represented by ______________________________

________________________________________________________________________________

(position, surname, and., about.)

The representative of the Quality Control Department of the plant represented by __________________________________________________

(position, surname, and., about.)

drew up this act in that an external examination and testing of reinforcement for strength and density were carried out _________________________________________________

________________________________________________________________________________

(valve name, serial number)

Test pressure _______________________________________

strength ______________ MPa (kgf / cm2)

for density _______________ MPa (kgf / cm2)

During inspection and testing of the reinforcement, no defects were found.

The fittings are considered to have passed the strength and tightness tests and are serviceable.

Representatives:

plant (surname, and., o.)

Quality control department of the plant (surname, I., o.)

Note... To be completed and attached in case of testing.

Continuation of Appendix 20

7. Specification

(compiled according to GOST 2.108-68)

8. Conclusion

The assembly units of the technological pipeline No. _______ are manufactured and tested in full compliance with ________________ and are recognized as fit for operation at operating parameters (operating pressure, operating temperature, operating environment).

This passport contains:

on sheets

Chief engineer of the plant

Head of Quality Control Department of the plant

M.P. Date of filling out the passport

"___" __________________ 19___

Town

Appendix 21

Reference

Terms accepted in VSN 478-86

|

Definition |

|

|

Technological unit |

|

|

Pipeline line |

A section of a pipeline with constant parameters of the transported product, connecting equipment, blocks or technological units |

|

Executive drawing of the technological pipeline |

Axonometric detailing drawing of the installed pipeline line, which contains actual data on the materials and products used during its installation. The executive drawing indicates the actual geometric dimensions of the line, elevations, the location of the supports and data on welded joints |

DEPARTMENTAL BUILDING STANDARDS

PRODUCTION DOCUMENTATION

INSTALLATION PROCESS

EQUIPMENT AND TECHNOLOGICAL

PIPELINES

VSN 478-86

MINMONTAZHSPETSSTROY USSR

MINISTRY OF INSTALLATION AND SPECIAL CONSTRUCTION WORKS OF THE USSR

MOSCOW 1986

Developed by the institutes of the USSR Minmontazhspetsstroy

Giprokhimmontazh (leading organization) - I.P. Petrukhin, M.L. Elyash (theme leader and executive in charge); VNIIMontazhspetsstroy - B.V. Popovsky, V. Ya. Eidelman.

Introduced by Glavkhimmontazh of the USSR Ministry of Montazhspetsstroy

Chief engineer A.V. Anokhin.

Prepared for approval by the Main Technical Directorate of the USSR Minmontazhspetsstroy.

Deputy chief G.A. Sukalsky.

Approved by the USSR Ministry of Assembly and Special Construction Works.

Deputy Minister K.K. Lipodat.

These departmental building codes (VSN) establish the content of production documentation for the installation of process equipment and process pipelines.

1. General Provisions

1.1. The types and content of production documentation must comply with SNiP 3.01.01-85, SNiP 3.05.05-84 and SNiP III-3-81.

Production documentation for equipment and pipelines subject to inspection by state supervision authorities must be drawn up in accordance with the rules and regulations of these authorities.

1.2. When filling out the production documentation forms, the requirements of state, industry standards, technical conditions for the manufacture and supply of technological equipment and pipelines, as well as the requirements agreed by the customer with the involvement of the installation organization, must be reflected in this part of firms - suppliers of complete technological equipment and pipelines purchased by import ...

1.3. Production documentation by type of work is completed for technological units, and for objects in whose projects technological units are not selected, for the object as a whole.

2.1. The installation organization transfers to the general contractor for presentation to the working commission the documentation provided for in SNiP III-3-81, SNiP 3.01.01-85, SNiP 3.05.05-84 and these VSN (forms 1-10).

2.2. Before the heading of each form (with the exception of Forms 9-13), the following information is placed:

2.3. The data given in the forms (with the exception of forms 5 - 14) are certified by the signatures of the persons responsible for maintaining production records in the following form:

If necessary, representatives of the enterprise - manufacturer of technological equipment and pipelines, commissioning, design and component organizations can participate in drawing up the forms.

2.4. Checking the installation of equipment on the foundation (base) is carried out in accordance with the working documentation for the construction of the facility and operational documentation (installation instructions) of manufacturers. The results of the check are recorded on the equipment that is part of the technological unit (form 1) *.

* See clause 1.3.

2.5. The test results of vessels and apparatuses are recorded in Form 2. The following are indicated as the main technical characteristics of the vessels and apparatuses: overall dimensions, working pressure MPa (kgf / cm 2), weight (inoperative), serial number of the manufacturer.

2.6. Machines and mechanisms are tested in accordance with clause 5.3 of SNiP 3.05.05-84, the requirements of technical conditions and operational documentation (installation instructions) of the manufacturer. The test results are recorded in Form 3.

2.7. Testing of technological pipelines is carried out in accordance with paragraphs. 5.4 - 5.16 SNiP 3.05.05-84 and the requirements of working documentation. The test results are recorded in form 4 for each line of pipelines.

2.8. The welding work log is compiled according to Form 5, the list of welders and thermist-operators - according to Form 6, the logbook for recording and quality control of control (test) welded joints - according to Form 7, the log of heat treatment of welded joints - according to Form 8, the certificate of inspection of hidden works - according to the form 9.

2.9. The certificate of acceptance of equipment after individual tests is drawn up in form 10.

2.10. The readiness of supporting structures, including foundations for the installation of technological equipment and pipelines, is recorded in the act of intermediate acceptance of critical structures (Form 11).

2.11. The transfer by the customer to the installation of technological equipment and pipelines, as well as other products to be installed, is recorded in the form of the Central Statistical Administration of the USSR M-25 (form 12 of this VSN). The defects and deviations from the working drawings and normative and technical documents identified in this case are reflected in the form of the Central Statistical Administration of the USSR M-27 (form 13 of this VSN).

Acceptance of equipment and pipelines for installation should be carried out in accordance with paragraphs. 2.5 - 2.8 SNiP 3.05.05-84. At the same time, they check their factory readiness, assembly adaptability and completeness in accordance with GOST 24414-80 and other regulatory and technical documents.

2.12. When accepting working documentation for the installation of technological equipment and pipelines (form 14), it is necessary to check its compliance with the requirements of the current building codes and regulations, SPDS standards and other regulatory and technical documents.

2.13. As executive drawings of technological pipelines (if they are provided for by regulatory documents), as a rule, detail (axonometric) drawings of these pipelines should be used with the introduction of actual data into them, from which they put the stamp "Executive drawing" certified by the signature of the person responsible for the installation of pipelines and the authorized sign production documentation forms. The stamp must indicate the date of drawing up the executive drawing.

On the basis of the lists, acts, passports, certificates and other documents presented by the customer to the as-built drawing, data is entered containing information in the required volume about the parts, materials and products used during the installation of pipelines (for pipes and parts of the pipelines supplied by the contractor, similar information is indicated according to the documents manufacturers or suppliers).

2.14. Production documentation in Forms 1 - 14 reflects the entire range of works on the installation of process equipment and process pipelines.

2.15. The procedure for maintaining production documentation is given in the recommended Appendix 4.

Information on clause 2.2 VSN

ACT

checking the installation of equipment on the foundation

This act is drawn up in that the installation on the foundation (base) of the following equipment was checked:

On the basis of the above, it is allowed to pour the listed equipment (except for the equipment of clauses _________, which is installed in the design position without gravy).

Note... The act, if provided for in the operational documentation (installation instructions), is accompanied by a form indicating the measurements made during installation, in the form established by the equipment manufacturer.

Signatures according to clause 2.3 VSN.

Information on clause 2.2 VSN.

ACT

testing of vessels and apparatus

| This act was drawn up in the fact that an external inspection was performed (internal in accessible places), after which a hydraulic, pneumatic ______________________________ test pressure test was carried out (cross out unnecessary): (name of vessel, apparatus, number according to working documentation, brief technical characteristics) During the test, the equipment was under test pressure for ____ minutes (or under water filling), after which the pressure was gradually reduced to working pressure, which was maintained for ____ minutes. Upon inspection of the equipment, it was found that _________________ Conclusion The equipment has passed the hydraulic, pneumatic (unnecessary cross out) test pressure test and is operational at operating pressure: body ................................................. ................. MPa (kgf / cm 2); pipe part ................................................ ....... MPa (kgf / cm 2); shirts ................................................. ............... MPa (kgf / cm 2). Signatures according to clause 2.3 VSN. |

Information on clause 2.2 VSN

ACT

testing of machines and mechanisms

This act is drawn up in the fact that an individual test was carried out at idle speed of the following machines and mechanisms:

Signatures according to clause 2.3 VSN.

Information on clause 2.2 VSN

ACT

pipeline testing

| This act is drawn up in what is produced by ________________________________ (type of test) testing of pipeline lines _______________________________________________ (name and line number, its boundaries, working pressure, MPa (kgf / cm 2) The test was carried out in accordance with SNiP 3.05.05-84 (name and code of other regulatory and technical documents, numbers drawings of working documentation) pressure strength ................................. MPa (kgf / cm 2); for tightness by pressure ......................... MPa (kgf / cm 2). Test duration .................... h During the test, no leaks or other defects were found in the pipeline. The pipeline lines specified in this act are considered to have passed the test. Signatures according to clause 2.3 VSN. |

Information on clause 2.2 VSN

Welding log

Line No. _______

Pipeline __

(name, working pressure, temperature, product)

| welded joint according to drawings (executive drawings) | Joint characteristic, mm, Steel grade or composition of steel grades, GOST, TU, N certificate | Welding consumables (type, brand, GOST or TU, certificate number) | Journal number quality checks of welding consumables, check registration numbers | Inspector's signature on weld acceptance | Joint position (swivel, non-swivel, vertical, horizontal) | Welding date |

||||

| Electrodes | Wire | Shielding gas |

||||||||

Table continuation

| Welding method (tacks, root of the seam, filling the groove) | Air temperature in the working area, ° С | Temperature of preliminary concurrent heating of the joint, ° С | Surname, name, patronymic of the welder, mark number | Welder's signature | Date of heat treatment of the welded joint, number of the heat treatment log and registration number in the log | Results of external examination and measurements, color or magnetic, powder flaw detection, protocol number and date | welding quality control (radiographic, ultrasonic flaw detection) | Date of radiographic inspection or ultrasonic flaw detection, report number, journal number control and registration number on the journal | Results of measuring the content of the ferrite phase in the deposited metal, protocol number and date | results alloying elements or tyloscopy, protocol number and date | Defect elimination notes | patronymic, identification number and signature of the controller | patronymic of the foreman or welder, signature, date |

|

Information on clause 2.2 VSN

List

welders and thermal operators

Information on clause 2.2 VSN

Magazine

accounting and quality control of control (test) welded joints

(welding laboratory and its affiliation)

Table continuation

| Surname and initials of the welder, brand and signature of the welder | Heat treatment date, registration number in the journal | Surname and initials of the thermist-operator, stamp and signature | Date and number of the hardness test report | Welding quality control results | Conclusion on the quality of the inspected welded joints and the welder's admission to welding of the same type of welded joints | Surname and initials of the head of the welding laboratory, signature, date |

||||||

| Radiographic or ultrasound control, report number | Mechanical properties of the welded joint of the sample cut from the control joint, protocol number, date | Metallography, protocol number, date | Ferrite phase, protocol number, date | Addiction to IWC, protocol number, date | Surname, initials of the inspector, certificate number, signature, date |

|||||||

Information on clause 2.2 VSN

Magazine

heat treatment of welded joints

Line number ____________________________________________

Pipeline _____

(name, pressure, temperature, product)

| Welded joint number according to drawings (executive drawings) | steel grade | Type of electrodes, brand of welding wire | Welding date | Heat treatment date | Heat treatment type | Heating method | Temperature control method | Diagram number or temperature measurement time | Heat treatment | Surname, first name, patronymic, brand and signature of the thermist-operator | Hardness test report number, date | Evaluation of the suitability of a welded joint after heat treatment | Surname, initials and signature of the heat treatment manager |

||||

| Heating temperature, ° С | Heating rate, ° С / h | Exposure time, h | Cooling behavior |

||||||||||||||