CNC vertical milling. Vertical milling machines for metal. Models and specifications of vertical milling machines

Key Feature, which has any vertically milling machine, is the vertical orientation of the spindle. Moreover, in some modern models, it can, if necessary, shift along the axis or change the angle of inclination. Such features significantly expand the functionality of the equipment.

Another important difference from horizontal milling machines is the design of the mandrel. In this case, it is a flange with Morse cones on both sides (on one of them, an end mill is installed in the mandrel). Most vertical milling machines allow you to work with disc cutters. In this situation, a mandrel is usually used, similar to that used in horizontally oriented models, but much shorter.

Otherwise, the vertical milling machine has all the main functional elements and components

- equipment of this class:

- base plate;

- bed;

- console;

- spindle;

- sled;

- trunk;

- feed box;

- power plant.

It is important to note that some models of vertical milling machines have a consoleless design, which is best suited for processing large and / or heavy workpieces. In this case, the slide and the work table move along the guides on the frame. As a rule, the price of such devices is higher than that of console-type analogues.

Functionality

Modern vertical milling machines allow for various types of milling of workpieces made of non-ferrous metals, alloys, steel or cast iron. Most models of such equipment are suitable for the use of various types of cutting tools, which makes it possible to carry out not only milling, but also surface cutting, drilling, countersinking and boring holes.

Nowadays, it is very typical to use parts of complex configuration in various branches of mechanical engineering - the shaping surfaces of stamps, molds, gears, copiers and many others. The main methods of manufacturing such complex-shaped products are the following: casting, stamping and cutting. But only mechanical restoration milling allows you to achieve surface parameters close to the specified ones, which significantly reduces the time for finishing.

Often, a vertical milling machine acts as the optimal and even the only possible equipment for processing flat products of complex configuration. This is especially true in the current conditions of the transition of the majority engineering enterprises for small scale production.

The technological process, in which the vertical milling machine is the main unit for the manufacture of complex profile parts, is also the most economically justified in this aspect. This avoids unnecessary energy costs and production capacity. In our time, in general, there is a steady trend towards the universalization of any industrial production.

A typical technological process for processing surfaces of complex configuration consists of the following operations: blanking, milling and finishing. The latter, as a rule, is performed manually, which makes it extremely laborious. So high class surface cleanliness, which allows you to achieve a vertical milling machine, greatly facilitates the finishing operation and improves the quality of the product. Thus, this unit minimizes material costs, which is extremely important in a market economy.

The vertical milling machine is designed to perform various, mainly metalworking operations with end, cylindrical, shaped, angular and other multi-cutting tools (milling cutters). On such machines, various planes, grooves of any section, gears, die models, frames, corners and other parts made of non-ferrous metals and their alloys, various grades of steel and cast iron are processed.

The vertical milling machine is characterized by the presence of a vertically located spindle, which in many models is able to move along its own axis and rotate in a horizontal plane, which greatly expands the technological capabilities of the unit. The spindle head is located in the upper part of the bed, which also houses the gearbox. The main working movement of the machine is the rotation of the spindle.

The main structural units of a vertical milling machine include the following: gearbox, bed, slide, console, spindle and dividing heads. The latter is an extremely important element, since it is she who rotates the workpiece to the angle required for processing. In addition, the dividing head ensures continuous rotation of the workpiece when milling helical grooves.

Nowadays, the CNC vertical milling machine is increasingly being used in the industry. A distinctive feature of such modern equipment is that all types of feeds in them are controlled by signals that are recorded on magnetic tape. Arising in the windings of special coils, these signals are then fed through the traction motors to the feed screws of the machine. Such control ensures the jewelry precision of processing.

fb.ru

Application of vertical milling machine for metal

The vertical milling machine, along with the drilling machine, are the two most used machines in the industry.

Or rather, in production: where metal, wood processing is needed, the machine will always help out.

In general, the scope of this machine is akin to the area in which casting, stamping, cutting is performed.

Thanks to milling, the desired edges and shapes are obtained, which speed up the overall refinement of each detail.

In addition, the use of the machine is economically justified. Of course, the machine itself in the workshop can easily cost 1-2 million rubles, but at the same time, dozens of parts can be performed on it per day (and if the unit is equipped with a CNC, then even more), which together bring a significant income.

Milling for metal as a separate job is considered only conditionally, because the machine does not bring the part to consumer look. First comes the harvesting, then just the milling, and finally the finishing operation.

The most expensive is fine-tuning, since for the most part the experience of a person and his skillful hands decide here, as a result, more time is spent.

But the use of the machine in the first two operations allows you to generally shorten the production cycle or give more time for fine-tuning the metal, which will give a high quality part.

If you use a CNC-equipped vertical milling machine, then the accuracy and quality of the workpiece will easily surpass the result of the work of the hardened master himself: ultra-precision to fractions of a millimeter, coupled with work of any complexity, allows you to create parts from one piece of the workpiece according to the required specification.

The device of a vertical milling machine

Milling for metal, unlike drilling, requires strength in the lateral segment of the movement.

Because the drives are powerful, and the tool (cutter) is made of hard alloys.

A milling machine with or without CNC consists of the following units and mechanisms:

- bed - the supporting structure of the entire machine;

- spindle - mounted on top of the bed, rotates in a vertical projection;

- spindle axis - rotates at the right angle to the surface of the workpiece;

- a table for holding the workpiece, on which it can move along the slide;

- sled - needed to move the part along the console;

- console - a carrier beam, fixed on the frame at one end, supports and moves the table with the part along the slide;

- feed box - changes the feed rate and its direction.

It should be said separately that the console is not a mandatory part of the machine. For this reason, today there are two types of metal milling machines - consoleless and console. Additionally, the machine can be equipped with a CNC.

The console machine for metal is equipped with a spindle, which in other machines can be displaced along the axis along and rotated along the horizontal plane.

Another important difference between a vertical sample and a horizontal one is the Morse taper on the flange (ISO-40 according to international nomenclature), which includes just a cutter.

To put a disk cutter, a mandrel is placed (mandrels are sometimes interchangeable - they are placed from a horizontal machine to a vertical one and vice versa). By the way, most of the machines currently in use are console ones.

Consoleless machines for metal process vertical, horizontal surfaces, at an angle, creating grooves.

Consoleless machines for metal are not equipped with a console, and the table moves along the guides on the bed itself, which stands on the foundation.

A console CNC machine is better balanced than a consoleless one, which, however, is not significant if we are talking about an industrial machine from 200 kg in weight.

It can report greater rigidity and machining accuracy. In it, the spindle head simultaneously acts as a cutter speed box and moves vertically along the guides.

The spindle and sleeve can be moved along the axis to precisely set the cutter of the desired size. A boring machine (with or without CNC), by the way, also performs the functions of a milling machine.

Also, vice versa, you can install a boring bar, countersink, reamer on a milling machine and it will become boring. The workpiece is fixed on the machine with all kinds of grips, squares, vise and prisms.

But if we are talking about mass production, then you need to immediately fasten several blanks and process them in one batch.

To do this, collect special "canopies" in the form of a continuous row of clamps, which allow you to process several workpieces equally at once.

The dividing head, which turns the part to the desired angle, is of great help. The dividing head has a spindle and a rotary drum.

The gear wheel of the spindle is connected to the worm. The handle transmits the moment to the spindle; in one revolution, the spindle turns only 1 tooth out of all in the wheel.

There is a thread on the spindle for fastening the leash. A limbo is also attached to the spindle, dividing the parts into parts.

For limbo positioning, a folding sector is provided, the legs of which are placed under a certain number of holes.

Mill: types and purpose

The main working body of the machine for milling metal is a milling cutter made of durable steel.

The teeth of the cutter are made in the form of welding plates of durable steel.

There are compound cutters in which the plates are inserted into the body, and not welded:

- End cutter. The blade is made up of 3 parts: main, transition and auxiliary blades. The cutter tooth is located at an angle, which is formed from the projection of the main blade and the feed axis onto the plane. The auxiliary blade angle is only 10 degrees. The smaller it is, the better the smoothness of the finished plane. The angle of the adapter blade is half the angle of the main blade. The cutter can be cast or assembled, with plug-in or welded knives. It is placed to the surface of the workpiece at an angle of 90 degrees. In contrast to the cylindrical one, in which the entire cutting edge is responsible for the shape of the cutter, the end cutter profiles only with the tops of the edge. All milling work is done by the outer edges. The edge shape appears as a circle or a curved line. The smaller the size of the cutter, the better its resistance to vibration. Unlike milling by cylindering, end milling is more productive - the angle of pressure on the surface is independent of the allowance, but depends only on the width of the milling;

- Disc cutter. Disk is needed for the preparation of grooves and manholes. It is equipped with teeth on the surface of the cylinder and works on small grooves. When working, the thickness of the cutter on the outside is greater than the hub. An error of 0.05mm is allowed for the thickness. When the teeth are ground, the cutter thickness decreases, but the value is very small. The teeth in two- and three-sided cutters are placed over the entire cylindrical surface and both ends. The side edges are not significantly involved in cutting. More often, milling cutters with teeth under a slope or multidirectional are placed on the machines. In this case, all the teeth that are on the cylinder work;

- Angle cutter. It is installed for carving angled edges and slots at an angle. In a single-angle cutter, the edges are located on the end face and conical end, in a two-angle cutter - on adjacent faces. An angle cutter is mostly needed to create chip grooves. The two-angle one works more stable than the one-angle one due to the symmetry of the force along the axis during the work of adjacent tooth faces;

- End cutter. Needed for excavation of a deep groove, recesses along the contour, any ledges. Fastened with a shank. All the work on the recess is done by the leading cutting edges on the cylindrical surface, while the auxiliary ones only clean the bottom of the groove. Equipped with oblique or helical teeth;

- Key cutter. It is also the end, which works like a drill, burrowing into the material of the workpiece, then moves along the groove. When feeding along the axis, the cutting goes along the end edges;

- For T-slot. Fragile cutter with teeth directed at different angles. Due to difficult chip removal (the tooth passes 2 times per 1 revolution of the cutter), the chamfers on the teeth are often turned at an angle of 30 degrees on both ends;

- Shape cutter. Works only with shaped surfaces, can have backed or pointed teeth. The latter produce a smoother surface, more stable than a backed cutter. Both those and other types of cutters are used only in mass production.

In general, the operation of any vertical milling machine is intuitive, with the exception of CNC models - they need a specialist with a narrow profile who knows how to program.

Let's say you have a machine in front of you. On the table in front of you will be workpiece clamps. Place the workpiece, tell the gear and slowly lower the cutter down, then swipe along the line - that's the whole difficulty.

A little more knowledge is needed to understand the operation of a CNC-equipped unit.

But still, to become a master, you have to spend more than one hundred hours at the machine.

rezhemmetall.ru

Vertical milling machine - basics and principles

A vertical milling machine is a very popular technique that has found application in the engineering industry. The main feature of the equipment is that it allows the production of complex profile parts, such as stamps, copiers, and so on.

All functions assigned to a vertical milling machine can be divided into drilling, milling and boring. The accuracy of the task on such equipment is quite high. At the same time, the decent performance of the equipment is also not in doubt. Vertical type machines, as a rule, are distinguished by high drive power, which, in combination with carbide tools, create a very productive tandem.

Among design features of such units, experts note the presence of the so-called dividing head, which is used to rotate the workpiece to the required angle. In addition, the rotation of the workpiece facilitates helical grooving, which is also very important for increasing productivity.

The vertical milling machine is designed for processing metal structures with a variety of cutters and drills. The technique can be used to process any planes, various kinds of spirals, molds. At the same time, as a rule, such machines are designed for processing parts made of non-ferrous and ferrous metals, as well as alloys, which makes them multifunctional wide-profile equipment.

Vertical machine distinguishes the absence of the so-called console. The table moves along special guides of the foundation bed, which guarantees the utmost rigidity of the equipment. Of course, this is reflected in the accuracy of workpiece processing when compared with alternative types of milling machines. With details of large dimensions and mass, this technique also copes without any problems.

In the design of a vertical milling machine, the spindle head acts as a gearbox, which can be regarded as an additional feature. The head moves in a vertical direction along the rack rails. The spindle with the sleeve can also be moved along the axis.

A master who wants to acquire such equipment will undoubtedly be pleased with the fact that its functionality can be expanded with additional components, such as a vertical or universal head, a round dividing table, comb cutting devices and other options. Thus, by purchasing such a unit, if necessary, the list of tasks performed by it can be expanded.

Technical specifications

In order to clearly understand what requirements a particular machine meets, it is important to have an idea of its main parameters. To date, the range of such equipment is truly huge. Companies produce equipment in a variety of sizes and with different power ratings. The market includes both desktop units focused on domestic use and professional milling machines that can operate in harsh environments. working conditions.

The master, choosing the ideal unit for himself, should focus on such key characteristics as:

- Power is, perhaps, the main parameter that gives an idea not only about the performance of equipment, but also about the scope of its use.

- Characteristics of the workspace. This includes the dimensions of the desktop, the distance from the spindle, the spindle travel and other parameters.

- The number of spindle revolutions is a characteristic that clearly demonstrates the speed of processing a part and determines the variant of equipment.

To date, there are 3 main types of universal vertical milling machines, depending on the type of control. Manual machines are the most “ancient”, but indispensable units in small workshops. Equipment with automatic control or with numerical program management- these are already more complex designs that require the proper level of qualification for effective work on them. This is especially true for CNC machines.

Let's consider some of the popular models in order to understand what options for technology are potentially available to the master today.

prostostanok.ru

Vertical milling machine: description, characteristics, scope.

At present, mechanical engineering widely uses parts containing complex profile surfaces: shaping surfaces of stamps, molds, copiers, and many others.

The main methods for obtaining parts with such surfaces include casting, stamping, cutting. However, only machining, in particular milling, makes it possible to obtain surface parameters close to the specified ones and reduce the time for subsequent finishing. Very often this method is the only possible method, this is especially important at the moment, since most engineering enterprises have switched to mass or small-scale production. Obtaining parts by milling, with this type of production, is the most economically justified.

The main methods for obtaining parts with such surfaces include casting, stamping, cutting. However, only machining, in particular milling, makes it possible to obtain surface parameters close to the specified ones and reduce the time for subsequent finishing. Very often this method is the only possible method, this is especially important at the moment, since most engineering enterprises have switched to mass or small-scale production. Obtaining parts by milling, with this type of production, is the most economically justified.

A typical technological process for processing complex-profile surfaces includes the following operations: blanking, milling, finishing. The latter is performed manually, while the complexity of the operation is determined by the output parameters of the surface after milling. Therefore, by providing a high roughness class at the milling stage, it is possible to reduce the time for finishing, which is the most labor-intensive part. technological process. Vertical milling machine.

Designed to perform a variety of milling operations with cylindrical, angular, face, shaped and other cutters. The machines process horizontal and vertical planes, grooves, frames, corners, gears, models of stamps, molds and other parts made of steel, cast iron, non-ferrous metals, their alloys and plastics.

The power of the drives and the high rigidity of the machines allow the use of carbide tools. In the frame 1 there is a gearbox 2. The spindle head 3 is mounted in the upper part of the frame and can be rotated in a vertical plane. In this case, the axis of the spindle 4 can be rotated at an angle to the plane of the desktop 5. The main movement is the rotation of the spindle. The table on which the workpiece is fixed has a longitudinal movement along the guides of the sled 6. The sled has a transverse movement along the guides of the console 7, which moves along the vertical guides of the bed. Thus, the workpiece placed on the table 5 can be fed in three directions. A feed box 8 is mounted in the console. The following types of milling cutters are used on vertical milling machines: face (Fig. 1.1), end (Fig. 1.2), keyway (Fig. 1.3). Cutters are made in one piece (Figure 1.1, 1.2, 1.3) or prefabricated (Figure 1.4) with soldered or plug-in knives. Solid cutters are made from tool steels, brazed cutter bodies are made from structural steels; plates of high-speed steels and hard alloys are soldered to the working parts of the cutter teeth. In prefabricated milling cutters, the teeth (knives) are made of high-speed steels or equipped with hard alloy plates and fixed in the cutter body by various mechanical methods. The cutting blade of the end mill consists of the main cutting blade 8, the transition blade 9 and the auxiliary blade 10. The tooth of the end mill has a main angle in the plan j, measured between the projection of the main cutting blade on the axial plane and the feed direction. Auxiliary angle in plan j 1 is 5-10o. The smaller this angle, the lower the roughness of the machined surface. Angle a in terms of transitional cutting blade j 0=j /2. To fix workpieces on milling machines, universal and special devices are used. Universal fixtures include clamps, squares, prisms, machine vise.

When processing a large number of identical workpieces, special devices are made that are suitable only for installing and fixing these workpieces on a given machine. An important accessory of milling machines are dividing heads. They serve for periodic rotation of workpieces to the required angle and for their continuous rotation when milling helical grooves.

The dividing head consists of a housing 1, a rotary drum 2 and a spindle 4 with a center. A worm gear (usually with 40 teeth) is rigidly fixed in the housing on the spindle, which is engaged with a single-start worm. The rotation of the spindle is reported by the handle 6. Therefore, with one turn of the handle, the spindle will make 1/40 of a turn. At the front end of the spindle, a thread is cut for screwing in a cam chuck or driver. The dividing limb 5 with holes is fixed on a hollow shaft, inside which the shaft of the handle 6 is located. A limb 3 is fixed on the spindle 4 for direct division of the workpiece into parts. Helical grooves are milled with continuous rotation of the dividing head spindle, which it receives from the longitudinal feed screw of the milling machine table through replaceable wheels. The workpiece is installed in the centers of the dividing head and tailstock. During processing, the workpiece receives two movements - rotational and translational along the axis. Both movements are coordinated so that when the helical groove is moved one step, the workpiece makes one revolution. As an auxiliary tool, milling mandrels are used to secure the cutters and transmit torque from the spindle to the cutter. The base for mounting the cutter on the mandrel can be its center hole or shank (conical or cylindrical). According to the method of fastening in the first case, the cutters are called mounted, in the second - tail. Figure 1.5 shows a mandrel for mounting face mills. With a tapered shank 10, the mandrel is fixed in the spindle 1, and at the other end of the mandrel, a cutter 11 is attached with a key 12 and a screw 13. Cutters with a tapered shank 15 are fixed in the tapered bore of the spindle 1 directly or through adapter sleeves 14 (Fig. 1.6). Cutters with a cylindrical shank are fixed in a collet chuck. The taper shank of the chuck is inserted into the machine spindle and secured with a bolt. The figures show the schemes of surface milling on a vertical milling machine. The movements involved in the formation of surfaces during the cutting process are indicated by arrows in the diagrams. Horizontal planes are milled on vertical milling machines with end mills (Figure 2.1). This is more convenient due to the high rigidity of their fastening in the spindle and smoother operation, since a large number of teeth work simultaneously. Vertical planes are milled on vertical milling machines with end mills (Figure 2.2). Inclined planes and bevels are milled with end (Figure 2.3) and end (Figure 2.4) cutters on vertical milling machines, in which milling head with the spindle rotates in a vertical plane. The ledges are milled on vertical milling machines with end mills (Figure 2.5). Grooves on vertical milling machines are milled in two passes: a rectangular groove with an end mill, then bevels of the groove with an end single-angle cutter for a dovetail groove (Fig. 2.6); and for a T-shaped groove (Fig. 2.7), a rectangular profile groove is milled with an end mill, then the lower part of the groove is milled with a cutter for T-shaped grooves. Closed keyways are milled with end mills (Figure 2.8), and open ones with end or keyways (Figure 2.9). the accuracy of obtaining a keyway is an important condition for milling, since the nature of the fit on the key of the parts mating with the shaft depends on it. Milling with a key cutter provides a more accurate groove; when regrinding along the face teeth, the diameter of the cutter practically does not change. Milling of cylindrical gears on vertical milling machines is carried out with a finger cutter (Figure 2.10). Composite-profile surfaces may include convex, concave and straight sections. Moreover, a single-toothed or multi-toothed cutter can be used as a tool. In addition, the required profile can be obtained by turning or only by the translational movement of the cutter, i.e. the following methods for obtaining complex-profile surfaces can be distinguished:

- concave cylindrical surface obtained

- concave cylindrical surface obtained

A) by turning the axis of the cutter at an angle; b) due to the translational movement of the cutter; - a convex cylindrical surface obtained a) by turning the axis of the cutter at an angle; b) due to the translational movement of the cutter. In [1], the formulas for calculating the roughness for all the above methods for obtaining surfaces are given. However, the calculation according to these formulas showed that they require clarification. Refined dependencies have next view: Roughness of a concave cylindrical surface obtained by turning the cutter axis by an angle (Fig. 1.a.) angle of rotation of the cutter axis Roughness of a convex cylindrical surface obtained by rotating the cutter axis by an angle (Fig. 1.c.) From the dependences shown above, it can be seen that the roughness depends on the radius of curvature of the surface, the radius of the cutter and feed. The last two quantities have the greatest influence.

The given dependencies did not take into account random variables, such as elastic deformations, vibration of nodes technological system, temperature factor, and some others that affect the roughness model during milling to a lesser extent.

Vertical milling machines

Cantilever vertical milling machines 6K11 6K12 Cantilever vertical milling machines 6K11 6K12 are designed to perform all types of milling, drilling, countersinking and boring holes on parts made of ferrous and non-ferrous metals, their alloys and plastics in single, small-scale and serial production. The presence of a tool clamping mechanism and a number of additional devices and accessories can significantly expand the technological capabilities. Technical characteristics of vertical cantilever milling machines 6K-11 6K-12 Cantilever vertical milling machines FSS350R FSS450R - The main components of the cantilever vertical milling machines FSS350R, FSS450R are made of SCh25 cast iron, have an optimal shape and high rigidity.

The fluoroplastic coating of the table and rack guides has good anti-friction properties and anti-seize ability, which makes it possible to ensure the stability of the accuracy parameters for a long time.

The presence of automatic processing cycles (pendulum milling, milling with rapid jump, milling on a rectangular cycle in three planes) allows them to be used not only in small-scale, but also in large-scale production. Specifications of vertical console milling machines FSS-350R, FSS-450R Console milling machine ВМ127М small batch production. Powerful main drive and carefully selected gear ratios provide optimal machining conditions under various cutting conditions and full use of the capabilities of the cutting tool. Technical characteristics of the console milling machine VM-127M Vertical milling machines KM-80 KM-100 KM-150 KM-180 with CNC. (Taiwan) CNC-SITEK (Taiwan). Standard equipment: - Closed table, - Automatic lubrication system, - Coolant, - Lamp

Additional equipment: - Closed cabin, - Magazine for 16 tools, - Spindle 8000 or 10000 rpm, - TFT display, - 4 and 5 axes

Vertical milling machines

Scope of vertical type milling machines Vertically milling machines are designed to perform all types of milling work using milling cutters. Milling machines of this type are mainly used for drilling, countersinking and boring holes, processing horizontal and vertical planes, grooves, frames, corners, gears, spirals, die models, molds and other parts. Vertical type milling machines allow you to work with parts made of steel, cast iron, non-ferrous metals, their alloys and other materials. In this case, the cutter of the milling machine, together with the milling spindle, performs a rotational (main) movement, and the workpiece, fixed on the table, performs a rectilinear or curvilinear feed movement - called milling. The control of milling machines can be manual, automated or carried out using a CNC system - see CNC milling machines.

In milling machines, the main movement is the rotation of the cutter, and the feed movement is the relative movement of the workpiece and cutter.

In milling machines, the main movement is the rotation of the cutter, and the feed movement is the relative movement of the workpiece and cutter.

A vertical console milling machine, unlike a horizontal milling machine, has a vertically located spindle. Milling machines of some models allow displacement along their axis and rotation around the horizontal axis, thereby expanding the technological capabilities of the machine.

Vertically milling consoleless machines are designed for processing vertical inclined surfaces, grooves in large-sized parts. Unlike console milling machines, these machines do not have a console, and the sled and table move along the guides of the bed, installed on the foundation. This design of the machine provides its higher rigidity and processing accuracy compared to cantilever type machines, allows processing parts of large mass and size. The spindle head of milling machines of this type, which is also a gearbox, has an installation movement along the vertical guides of the rack. In addition, the spindle together with the sleeve can be shifted in the axial direction with the exact setting of the cutter to the required size.

]]>https://www.rustan.ru/stanki_2_1.htm]]>

]]>https://www.1stanok.ru/pages/stanok12.html#]]>Vertical milling machines

]]>https://www.erudition.ru/referat/printref/id.46737_1.html]]>

Vertical milling machine is designed for the manufacture of complex parts of various configurations. The spindle with the cutting tool of such milling machines is located in a vertical plane, and in the process of milling work, if necessary, rotates around its axis, milling at different angles relative to the workpiece.

Thus, vertical milling machines are characterized by a fairly high versatility, since workpieces made of carbide metals, as well as many other materials, lend themselves well to milling with such machines.

The CNC vertical milling machine is capable of leading milling work simultaneously in the longitudinal, transverse direction by moving the sled and the table, as well as in the vertical direction by moving the cutting tools.

For milling manufacturing CNC milling machines are ideally suited for high-precision single-piece products, as well as for small series production.

CNC Vertical Milling Machine

CNC vertical milling machines have a number of advantages for small and medium-sized industries:

- rigid heavy construction of milling machines allows for precise processing of workpieces;

- CNC vertical milling machine is a high-speed, reliable, accurate, powerful unit;

- quality computer program CNC provides automatic control machine;

- vertical milling machines are characterized by high productivity.

Cantilever vertical milling machines

With the help of vertical console milling machines, grooves, corners, frames, as well as inclined and horizontal surfaces can be efficiently processed. Console milling machines are distinguished by the presence of a cantilever element that moves in the vertical direction and carries the desktop. A feature of the console milling machine is that, basically, on such a milling machine, console plates with tables with workpieces rigidly fixed to them move intensively.

The spindle with the cutting tool on such a machine is in a relatively static state. CNC console milling machines are designed for serial production of curved parts and complex configurations in small and medium-sized industries.

The drive power and structural rigidity of the cantilever vertical milling machine ensures that its vertical milling tool is capable of efficiently processing carbide metals. The vertically operating spindle can be rotated with respect to the working plane of the cantilever fixed table at any angle. This makes console machines quite versatile units that are able to solve challenging tasks precise processing of workpieces from various materials.

Vertical consoleless milling machines

On vertical milling machines without a console, the cross table is mounted on a fixed bed. A feature of such machines is the movement of the table exclusively in the longitudinal and transverse directions. The advantage of vertically consoleless milling machines is the milling of large and heavy workpieces on such machines.

Work on such milling machines is carried out by a vertical spindle very smoothly due to the automatic switching of stepless gears. CNC machines without a console perform vertical machining of parts efficiently, quickly and silently.

A console milling machine, as well as a vertical milling machine, cannot be imagined without dividing heads. The vertical position of the spindle means periodic rotations of the workpiece, which are processed on a milling machine with manual control or on CNC machines. Such dividing heads provide rotation during the time when the milling tool is working.

CNC milling machines

A manual milling machine is very different from a CNC machine. CNC milling machines are characterized by a high level of automated control for production process. The use of such a CNC machine greatly accelerates the processing of workpieces, improves work efficiency and reduces the negative impact human factor. The CNC machine is capable of producing complex parts of any curvilinear configuration, moving along three axes.

A milling machine of various purposes and designs can be easily selected using the Internet in the electronic catalog of the company Laserkat LLC. Our specialists are always ready to give comprehensive information regarding any machine.

In addition, company managers will help you choose the most suitable for specific production tasks milling machine at the best price. The company "Lazerkat" offers certified high-quality machines with a guarantee, after-sales service and possible delivery.

In these specialized metalworking machines, there is no console, and the table moves along the guides of the foundation bed. This design provides high rigidity of the machine and, consequently, high machining accuracy (compared to other types of machines), which makes it possible to process parts of large mass and size. The spindle head is at the same time a gearbox, and has an installation movement along the vertical guides of the rack. In the axial direction, the spindle can also be shifted together with the sleeve.

Equipment characteristics

Manufacturers produce equipment of various sizes, capacities and, accordingly, purposes: from desktop metal milling machines to professional high-performance machines for long-term hard work. When choosing a vertical milling machine, you need to pay attention to the following characteristics:

- power, kWt

- Working area parameters, mm

- Desktop dimensions, mm

- Table movement along the X/Y/Z axis, mm

- Table rotation range, hail

- Maximum drilling diameter, mm

- Maximum end mill diameter, mm

- Maximum end mill diameter, mm

- Spindle distance, mm

- Spindle stroke, mm

- Spindle speed, rpm

- Spindle taper, ISO (DIN)

- Machine dimensions, mm

- Weight, kg

Machine control can be:

- manual;

- automatic;

- with CNC.

There are also two types of vertical milling machines for metal:

- vertical milling cantilever machine has a vertical spindle. Some models allow displacement along their axis and rotation around the horizontal axis, thereby expanding the technological capabilities of the machine.

- vertical milling non-console metal machine is designed for processing vertical inclined surfaces, grooves in large-sized parts. In these machines there is no console, and the sled and table move along the guides of the bed, installed on the foundation. This design of the machine provides its higher rigidity and processing accuracy compared to cantilever type machines, allows processing parts of large mass and size. The spindle head of milling machines of this type, which is also a gearbox, has an installation movement along the vertical guides of the rack. In addition, the spindle together with the sleeve can be shifted in the axial direction with the exact setting of the cutter to the required size.

Milling equipment is a whole class of devices that are used for processing flat surfaces, cutting slots and teeth, creating profiles and drilling holes. With the help of such equipment, you can perform work on wood or polymer material, as well as for various metals.

The installation of the cutter is carried out at a certain angle, and vertical milling machines are widely used in the industry for processing automotive parts, furniture assembly items, building products and other items. Such devices are distinguished by the convenience of design, performance and versatility of use.

The device and purpose of the vertical milling machine

Structurally, vertical milling machines are divided into two categories:

- Console machines. They are equipped with a working surface, which is rigidly fixed on the body and can move along the guides and vertical slide relative to the spindle.

- Machines without console. With their help, you can process large-sized workpieces, the process is performed at high speed. The structure adopts automatic guiding system, the spindle features high-speed structure and runs vertically.

Vertical milling machine for metal

Milling metal work requires high strength in the side of the drilling, so machines designed for such operations are distinguished by carbide parts and high electric drive power.

The basis is a frame that receives load-bearing loads; in a vertical projection, a spindle is located on the axis. Also, metalworking machines in most cases have a console, workpiece clamps and a feed box for the speed of moving the part. Some models do not have a console, a number of machines are equipped with CNC: they usually cost more.

Vertical milling machine for wood

For the processing of wooden blanks, special machines can be used, which are compact, good performance, low price and functionality.

In such devices, the spindle is mounted vertically, in some models it has a movable structure for tilting the workpiece. Replacement of a mill is carried out without the special tool. Most woodworking machines have an electric motor and require a 220 or 380 V mains connection.

Modern models may differ in the speed of milling, the maximum size of the workpiece, the quality of the processing of the wooden surface. Wood saws can also be used when working with plastic, polyamide, plastic and other light materials.

CNC vertical milling machines

Many models are equipped with a CNC - a mechanism that makes it possible to control the main processes in real time and provides the most accurate and convenient control.

Such machines have the following advantages:

- relatively small dimensions;

- high quality processing, excellent accuracy;

- productivity, the possibility of high-speed processing of materials;

- ease of setup;

- unpretentiousness in service.

Models and specifications of vertical milling machines

When choosing equipment, first of all, it is necessary to pay attention to the design, power, dimensions and additional working options of the machine. On the modern market you can find vertical milling devices of various types, including in the small and medium price segment. Vertical milling machines are produced by both domestic and foreign companies.

Machine 6r10

Machine 6p10 is a milling machine universal type, which is equipped with a rotary head and is suitable for small-scale and single production of parts. The model is distinguished by a low noise level in operation, good wear resistance of rubbing elements, and optimal accuracy indicators. The finished surface of the workpiece after processing corresponds to the roughness index V6.

Machine 6r11

In appearance, the 6r11E machine refers to cantilever structures. It is used for processing steel billets, cast iron, various types of metals, as well as hard plastics. The equipment allows you to give the workpiece a surface with a roughness up to V5, can work at different speeds at the right angle. Good power and a competent drive system ensures high performance results.

Machine 6r12

Model 6p12 is used for processing metal and cast iron blanks mainly with the help of end and face mills, creating grooves, flat edges, frames and corners. The machine is suitable for creating curved parts, processing non-standard shaped surfaces. The device is characterized by high power and rigidity, due to which high-speed steel cutters can also be used.

Machine 6r13

The 6p13 device also has a cantilever structure, is equipped with a copier for working with non-standard workpieces and a swivel spindle head. The model is suitable for the production of piece copies and small-scale production of products. Finished parts conform to accuracy class H.

Machine 6t12

Model 6t12 has a powerful electric motor, a large area of the working surface, can work in manual, inching and automatic mode. On such equipment, almost any kind of materials and workpieces can be processed.

Machine VM 127

Machine BM 127 is used to work with metal and steel parts, as well as cast iron elements. The equipment is used both in the environment of private craftsmen and professional workshops; it allows processing planes, grooves, gear, slotted products. The work cycle can be automatic or semi-automatic.

Machine 6m13p

The machine 6m13p belongs to the category of electrical devices of increased accuracy, it can work with a high-speed cutter of high rigidity. The equipment is used for small and large-scale production, allows processing parts by drilling and milling, creating gear rings and wheels.

Machine 6n11

Equipment 6n11 has a working surface of 25 by 100 cm, is equipped with a 4.5 kW main drive motor, and is used for processing non-ferrous and ferrous metals.

Distinctive features of the machine 6n11:

- high accuracy;

- performance;

- ease of maintenance.

Machine FSS 400

FSS 400 machines are suitable for individual and serial use. With their help, you can carry out along and counter milling, automatically lower the part and ensure high quality results. The control of such a machine is possible from a special pendant control.

Machine FSS 450 mr

FSS 450 mr devices manufactured in Belarus are suitable for working with cutters of various shapes and purposes. With their help it is possible to process steel, alloys and pure metals, cast iron. Most often, such machines are used in small-scale and medium-scale production.

Where and at what price to buy a vertical milling machine?

You can buy such equipment on the Internet or from direct suppliers. The cost is formed depending on the brand, functionality and purpose. So, vertical milling devices for wood cost 50-90 thousand, for metal - up to 200-250 thousand, and universal models cost up to 300 thousand rubles.

Manufacturers and suppliers of vertical milling equipment

The most popular machines on the market are HAAS, Hannsa, SMD, TAKISAWA, DMTG, Triumph, as well as Simbirsk equipment. Companies such as Abamet, kmt-stanki.ru or VseInstrumenty.ru offer favorable conditions for bulk purchases and cooperate with workshops in various cities and regions of the country.

Modern vertical milling machines are demonstrated at the annual exhibition "".

The success story of a famous tailoring magazine

The success story of a famous tailoring magazine Thesis plan abstract. How are abstracts written? What are abstracts and how not to make mistakes when writing them? Conference report

Thesis plan abstract. How are abstracts written? What are abstracts and how not to make mistakes when writing them? Conference report What is "gold" and "blue" watches in photography

What is "gold" and "blue" watches in photography How to make money with advertising on a car and what you need for this Examples of detailed, information-rich advertising

How to make money with advertising on a car and what you need for this Examples of detailed, information-rich advertising Quadratic and cubic functions

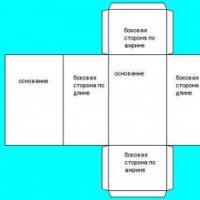

Quadratic and cubic functions How to make a paper prism

How to make a paper prism Everything you need to know about the prism for passing the exam in mathematics (2020)

Everything you need to know about the prism for passing the exam in mathematics (2020)