Printing 3d photography technology. Inkjet technology

Given the increased interest in 3D photography, making these products can be very lucrative. However, in order for the business to develop, it is necessary to master the technology of making such photos.

- How do three-dimensional photos differ from ordinary ones?

- 3D photography technology

- Additional services

- 3D photography technology

One of the most important components of any business is a product or service that can interest consumers. In our time, people are offered so many interesting things that it is very difficult to surprise them. But still, there are unusual novelties for attracting customers. An entrepreneur should choose a suitable option for himself and beat it correctly, because everything new rather quickly becomes commonplace.

Sometimes it is not at all necessary to take the latest technology for work. In some cases, you can use modern advances, but in a new format. This will allow you to use already proven and successful options, but earn more on them. 3D photography is a prime example of this type of business. Three-dimensional images in a new and interesting form will be in demand, since nowadays such technologies are popular and have many fans.

How do three-dimensional photos differ from ordinary ones?

Modern technologies and special equipment make it possible to create interesting and high-quality photographs, which, with special devices, come to life and become three-dimensional.

Such products will be in demand, since so far there are few offers in this niche, but customers are interested in similar technologies. Three-dimensional photos are ordered for themselves either as a gift, they will be a good surprise for the holiday or just a decoration.

The first creation of live photos was started by the specialists of the Dance heads company several years ago. The project began working not so long ago and its followers are currently quite small. Therefore, entrepreneurs who plan to profitably invest in an interesting business have every chance to firmly gain a foothold in this niche.

There will be many clients, because everyone is tired of ordinary two-dimensional images, and three-dimensional is something new and interesting.

3D photography technology

As for 3D photographs, the production of these products will require the master to master a certain technology. To do this, you need to be at least a confident PC user, and it is better if the businessman has a special technical education. And yet, even in the absence of special skills, they can be acquired if the entrepreneur is really interested in this process.

The procedure for creating a 3D photo begins with the fact that a client contacts the salon. The master offers him various backgrounds, which will then be used in the image. The photographer takes a picture of the customer himself or uses a ready-made one if the customer plans to make a surprise for a gift.

There can be a lot of options for designing a photo. For children, a cartoon image can be used, men prefer cars and yachts, and women like to feel like queens. It all depends on the wishes of the client. The photo should correspond to the chosen background and the general idea. It should be done after the client has decided on the background image.

Next, you need to connect 2 images as it was originally intended. For this, the master must have creative potential and certain skills in working with computer programs. After that, the finished image is printed on a printer with high quality printing.

We get a picture with a slightly blurry image. A similar procedure can be carried out independently by any person at home, if he has a special program and a good printer. But here the main secret will be a special frame. It is she who allows you to see the image in three-dimensional format. That is, it will act like 3D glasses in a movie theater. Frames are made using a special technology.

The finished product is handed over to the client, and the master receives money for this. The effect of such a photo is difficult to convey. Even on a phone or computer screen, it is impossible to understand how interesting three-dimensional photos actually look.

Moreover, if you look at the image through a special application on your smartphone, the picture will come to life. This is a unique technology, but it exists and works well. Therefore, 3D photos are in great demand.

Additional services

In addition to making three-dimensional images, you can offer customers other interesting services and products. For example, you can make a three-dimensional image from photographs.

It is printed out on a special printer. In a few hours, you can get a finished figurine 20 centimeters high, which will be an accurate, but only three-dimensional copy of the photograph. That is, the client can get his own figurine, which will be created on the printer.

This technology is new, but very interesting. However, it is designed only for wealthy customers. The thing is that the equipment and materials for the work are very expensive, so the price of one figure will be about $ 300. But now they are in demand among a certain category of the population, as this is something original and impressive.

To work on the manufacture of three-dimensional products, including photos, you will need high-quality equipment and software. All this is not cheap, so the business of making 3D photos will require a lot of investment. However, all this will quickly pay off, since such products are in demand, especially among families with children who are ready to spend decent amounts on memorabilia.

3D photography technology

3D photography technology is based on binocular vision and the ability to see the world around us with two eyes, that is, from two angles. In this case, the obtained images and objects on them are displaced relative to each other, and the brain processes them and a three-dimensional picture comes out.

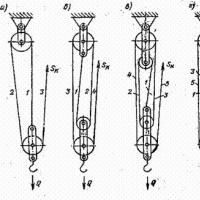

Stereo shooting involves shooting an object from two points, the distance between which is called a stereo base, and its value depends on the distance to the subject. For photography from two points, you can use two cameras installed in the desired positions, or use only one that is available, moving it to the desired distance for repeated photography. It is recommended to use a tripod, which will help prevent skewing and simplify further processing of photographs. One camera is enough for the process of shooting high-quality 3D photos. It is impossible to shoot only those subjects that are in motion.

After receiving two photographs of the same object from different angles, you need to align and combine them into a single 3D photo. Two formats of stereo photography are used: stereo pair and anaglyph. You can align photos in different graphic editors, and to merge the angles, you need to acquire special software that will allow you to make a high-quality image with a minimum of distortion and smooth viewing angles.

When the photo is ready, you need to print it. Printing must be done on high quality printers. Viewing this kind of photos is possible with the use of 3D glasses, both in cinemas, and with the installation of a photo in a special frame, the front part of which is made of special embossed glass. The best effect can be obtained on a smartphone screen using a special program.

Volumetric 3D printing of a material object based on its three-dimensional computer model is a unique technology of our time, which has great prospects in the future. Until recently, devices using it seemed like science fiction, but today they have become reality, and have already become available even for home use. Although the cost of 3D printers is still high, and exceeds the price of other computer devices, they are finding increasing practical use not only for applied creativity, but also for various areas of business. Continuous development and improvement of this technology has already led to the creation of industrial devices. Which one should you choose?

What is a 3D printer, its purpose

A peripheral computer device that, according to a digital volumetric model, creates a material object by layer-by-layer application of a rapidly solidifying material, is called a 3D printer. For the operation of such a device, a computer three-dimensional model is required, made in any of the 3D-editors or obtained on a 3D-scanner. Today there are several varieties, depending on the technology used:

- FDM and DIW 3D printers using the extrusion method based on forcing molten material through a thin hole in a special device called an extruder (in printers of the first type, a thermoplastic heated to the melting limit is applied layer-by-layer to the cooled surface of the platform, and in the second - ceramic sludge, which called ink, thick ceramic slurry can be used in large architectural models);

Extrusion technology (FDM) 3D printers make a layout by stacking molten plastic layer by layer, extruded through an extruder. The print head moves in the X and Y axes and the print bed moves down the Z axis

- printers of the SLA-DLP type, using the photopolymerization method, in which a liquid photopolymer is used, and the hardening of each of its layers is carried out by means of exposure to an ultraviolet laser;

In 3D printers based on SLA technology, the product is formed in a tray filled with photopolymer resin. Under the action of UV laser radiation acting on a thin layer of resin, it hardens and the base goes down to the thickness of the next layer

- printers in which an aligned layer of powder is used to create a three-dimensional material object, which is bonded in layers by different methods, by applying glue using inkjet printing (3DP printers) or melting it with an electron beam in a vacuum (EBM), laser radiation (SLS or DMLS, depending on powder type) and heating head (SHS);

- EBF 3D printers, which use a wire that melts under the influence of electron radiation to obtain a material model;

- printers based on the principle of lamination, or layer-by-layer application of film, in each layer of which, the contour of the part is cut out with a special cutter or laser;

- printers with a point supply of powder melted by laser or electronic radiation;

- devices working using the method of multi-jet modeling (MJM), when the method of inkjet printing is applied to a rapidly solidifying material;

- bioprinters are innovative peripheral computer devices that are just beginning to be introduced, they use cells of a living organism to form internal organs, and in the future will be able to create a full-fledged material for transplantology (there are already cases of successful manufacture and transplantation of a jaw for humans and a thyroid gland for a laboratory mouse) ...

Video: how the mechanism works

The possibilities of such a unique peripheral computer device are practically unlimited. Today it is already used for the following purposes:

- quick creation of accurate models in architectural design, design of various mechanisms and machines, as well as in interior and landscape design in order to finalize the project and present it to the customer;

- manufacturing of any complex-shaped parts for single or small-scale production, as well as spare parts for the repair of various devices;

- making models and molds for casting, including when creating jewelry;

- construction of buildings and structures of any complexity, for which they use special devices resembling a tower crane, instead of cables, which have highways for supplying liquid concrete (such a device allows you to erect 1 floor in 10 hours, which significantly reduces the construction time);

- creation of prostheses and internal organs for transplantation in medicine;

- making models of complex devices for educational aids;

- creation of geographic information systems, which are a three-dimensional map of the area in color, with an accurate display of the relief;

- production of household items, various accessories and items for interior decoration;

- development of layouts of packages and containers for marketing purposes;

- manufacturing of housings for experimental equipment - cars, automation systems and various electronic devices;

- production of advertising and souvenir products;

- production of exclusive clothing and footwear according to the figure and size of a specific client, obtained by 3D scanning.

This list clearly demonstrates the prospects for the use of 3D printers and their relevance in various areas of human activity.

How to choose: parameters to look out for

When buying any complex device, you need to clearly define for yourself the purposes for which you are going to use it. This will determine what operating parameters it suits you best. Considering that such a peripheral device is not cheap, you should select it most carefully, taking into account all the operating parameters, so that you do not regret the purchase later.

First of all, you need to decide on the type of printer for the 3D printing technology used. The most popular and affordable models for home use or small business today are:

- FDM printers, which use various types of polymer filament as a material, and have a fairly good print quality and the lowest price;

- SLA photopolymer devices with higher print quality and price, ideal for jewelry production;

- the most expensive of the peripheral devices of this group are SLS-type devices that melt the powder with a laser; it is impractical to buy them for the home, and they can only be suitable for business, due to their high cost (up to 30 thousand dollars).

Among the main selection criteria, the following can be noted:

- The type of media used for printing. When choosing a 3D printer, you need to take into account that consumables for FMD devices will cost less than for SLA printers. For those who decide to purchase an FDM printer, there is a large selection of plastics of different colors and types (PLA, ABS, HIPS, PVA and others), but PLA plastic filament will be ideal for beginners, since this material is easier to use, and products from it are perfectly flat and smooth. Those who choose the SLA 3D printer will have to purchase more expensive material in the form of photopolymer resins. For non-professional printer models, it is best to buy a photopolymer of the Vera, Somos or Tanga series, which are distinguished by transparency, high strength, heat resistance and plastic stability.

- Accuracy of printing. It is higher for SLA printers. The accuracy of reproduction of the model in devices of the extrusion type largely depends on the thickness of the layer, which is laid by the printer during printing. This means that the thinner the hole of the extruder nozzle, the higher the clarity of the reproduction of the digital model in the material object. Today, there are models of printers with different nozzle hole diameters from 0.1 to 0.4 mm. It should be understood that the smaller the nozzle opening of the extruder, the longer it will take to make the model. Here, everyone has to choose for himself what is more important for him - the accuracy of the display of the 3D model or the speed of printing.

- Printable area, which determines the maximum size of an object that can be printed with this printer. There is, of course, the ability to make larger objects, but only in parts, gluing them together with a special glue. To do this, using the 123D Make program, the digital model is split into separate parts. But, if you do not want to engage in gluing, then when choosing a printer, compare the desired dimensions of the manufactured layouts with the printable area of a particular model.

- Design features. Here it matters whether it is open or closed, and what materials the body and supporting elements are made of. These factors most of all affect the rigidity of the entire structure, on which the speed of movement of the print head depends, as well as the ability of the bearing parts of the device to damp vibrations and vibrations from several electric motors responsible for moving the printer head along all three axes (X, Y and Z) and its table along the Z axis. The case, made of wood, may seem too budgetary to some, but it perfectly absorbs vibrations. Bearing structures made of aluminum or steel will be stronger and more durable. It is better to buy SLA printers with a well-ventilated working chamber, which will facilitate faster curing of the photopolymer. And for FDM-type devices, especially when working with ABS plastic or nylon, which have a high degree of shrinkage during rapid cooling, it is better to purchase a 3D printer with a closed case and lining of the working area.

- The presence of auxiliary software. 3D printers are high-tech computer devices that require special software to operate. First of all, a 3D printer must recognize and be able to read all 3D editors and various data entry formats. The latter include the STL and X3D languages, as well as the VRML standard. There are many auxiliary programs that allow you to perform a wide variety of actions for preparing for printing and creating a material model. These are, for example, slicer programs that allow you to cut an object into parts for printing in parts (Kissslicer or Cura) or 123D Catch program, designed to work with a cloud service, and allows you to get a three-dimensional digital model of an object from its photographs taken from different angles. The presence of auxiliary software supplied by the printer manufacturer makes it much easier to work with such technically complex devices. And this fact should also be paid attention to when choosing them.

The most suitable 3D printers for small businesses

Bulk printing using 3D printers is the most promising direction for small businesses today. With the help of these computer devices, which do not require too large financial investments, as for industrial printers, it is possible to establish small-scale production of various goods.

Of the large variety of printers on the market for these purposes, models that meet the following criteria are most suitable:

- print quality must be high enough to create unique and realistic models that are interesting for sale, which immediately excludes relatively cheap printers from the choice, costing up to $ 1000;

- it is desirable that the printer be adapted for color printing (FDM, DIW, 3DP or EBF printers), which will save time for coloring goods in small-scale production;

- the device must support work with at least two main types of plastics (PLA and ABS), which will expand the possibilities of its use, and will make it possible to produce products for children (PLA plastic is intended specifically for children's goods);

- the price of consumables used by a 3D printer should provide an acceptable cost of finished products, sufficient for a normal level of business profitability;

- the size of the working chamber must correspond to the dimensions of the models provided for production, while it should be borne in mind that printers with a larger print area will cost more.

In any case, the choice of printer will depend on what type of business you intend to do. For the production of small crafts, devices of the extrusion type are suitable, and for the manufacture of jewelry or dentures - more expensive printers based on photopolymers. Among the most suitable for small businesses are the following models:

- Flashforge Creator Dual, with a working chamber volume of 5.2 liters and two extruders, the printer supports work with three types of plastics - ABS, PLA, PVA and has a printing accuracy of 0.1 mm;

- 3Dison pro AER from the Korean company Rokit, with a workspace volume of 15.3 liters, capable of working with 50 materials, having a high print speed (up to 1000 mm / sec) and a layer thickness of 0.025 mm;

- stereolithographic 3D printer, type SLA model

Pico 2 from Asiga, the perfect choice for jewelry or dental professionals, it is powered by a solid-state LED UV source.

Which device to choose for the home

Given the still high cost of peripheral computer devices for 3D printing, it would hardly be advisable to buy an overly expensive and sophisticated 3D printer for home use at a cost of 5-10 thousand dollars and more. A device priced from $ 500 to $ 3,000 will be quite enough. It all depends on the customer's exactingness to print quality and his financial capabilities.

It is best if your 3D printer for your home has simple and intuitive operation, user-friendly interface and ideal value for money. All printers in demand today for home use can be divided into the following price groups:

- budget models, the most affordable of this type of device at prices ranging from 300 to 1 thousand dollars;

- middle class printers ($ 1–1.5 thousand);

- a fairly high-end device at a reasonable price from 1.5 to 3 thousand dollars.

Among the most popular printers for 3D printing, the following models can be noted:

- Printrbot Simple, worth $ 300, which belongs to extrusion printers (FMD), and is sold disassembled - self-assembly of the device will help you better understand its design and understand the principle of operation of this equipment;

- Kino XYZ printing da Vinci 1.0- this is a new printer from the Taiwanese company XYZ printing, which has a high print resolution comparable to more expensive devices - 0.1 mm, its cost is about $ 500 (the technology of layering molten plastic - FDM is used in the work);

- Cubify CubeX, belonging to the middle price segment, with a cost of $ 1300, and characterized by high printing quality and the speed of creating a model with large dimensions, this printer is available in three design options - with 1, 2 and 3 extruders, which allows you to get color layouts of computer models, can be connected to a computer via USB connection or Wi-Fi module.

- Afinia H-Series H479 with high printing accuracy (0.15 - 0.4 mm), convenient software that works with inexpensive ABS filament of decent quality, such a device costs 1.5 thousand dollars.

Rating of the best 3D printers

The world's most famous expert in the field of volumetric printing is the foreign portal 3D Hubs, which regularly compiles a rating of the best models of printing peripherals in various nominations. According to the version of this Internet resource, the following models of 3D printers were named the best in 2017:

- Original Prusa i3 MK2 manufactured by the Czech company Prusa Research. This printer is intended for the electronics hobbyist who is new to 3D printing, who can assemble it from the parts by themselves, since it is sold disassembled. The device belongs to the extrusion models of the FDM type, and supports 15 types of plastic, including ABS and PLA, Carbon and Nylon, HIPS and FilaFlex, Bamboofill, Laybrick and others. This model in operation can use up to 4 different materials at the same time. It has an integrated Z-axis and a heating table with a PEI type plastic printed surface. A printer of this model has a fairly large print area with dimensions of 250 x 210 x 200 mm, a minimum thickness of a stacked plastic layer of 0.05 mm and a printing speed of 40 - 60 mm per second.

- BCN3D Sigma R17 (Release 2017)... This 3D printer model, released by the Spanish company BCN3D Technologies, is the continuation of the worldwide popular Sigma line of 3D printing devices. The new model uses an independent double extruder, which allows you to avoid deformations when changing the color of products, as well as simultaneously print two identical layouts. The upgraded device uses a new cooling system and upgrades the technology of the microchips that control the power. All this made the printer more silent. Sigma R17 has a high printing accuracy of 0.125 mm and a layout area of 297 x 210 x 210 mm. We use filament from the following polymers ABS, PLA, HIPS, PET and Exotics, which the extruder extrudes with a minimum layer thickness of 0.05 mm.

- Formlabs Form 2 - stereolithographic (SLA) 3D printer manufactured by the American company Formlabs, equipped with a powerful laser, touch screen and Wi-Fi module. The device has a printable area of 145 x 145 x 175 mm and a layer thickness of 0.025 - 0.1 mm. This printer uses liquid photopolymers and can be used with resins from other manufacturers. It is equipped with a heated platform and built-in control panel.

- PowerSpec 3D Pro. This model is made in China and belongs to the price category of budget 3D printers. Its distinctive features are durability, high print speed and a dual extruder design, which are rare for inexpensive models. 3D Pro supports three types of plastics (PLA, ABS and PVA) and has high printing precision. The thickness of the layer to be laid is 0.1 - 0.3 mm.

- OrdBot Hadron. This printer is manufactured by ORD Solutions, Canada. The model is a mechanical 3D printing platform made of aluminum. It has high rigidity, reliability and printing speed (400 mm / s). The principle of its operation is based on FDM technology. The device supports work with two types of plastics - ABS and PLA, and has a printable area of 190 x 190 x 150 mm. The design of this printer provides the ability to connect a second extruder, a servo drive, an LCD screen and other equipment, which will be able to significantly upgrade the device after its purchase.

3D printing technologies are just beginning to conquer the computer market, and the cost of printers for translating a digital model into a material object is still quite high. But these technologies are the future, and for sure 3D printers will soon appear in every home, becoming an everyday addition to the computer. Already today, many models have become available for people with an average income level, and are widely used not only in small businesses, but also in everyday life. Using the above recommendations, you can easily find the right printer for home use or small business of your own.

It is noteworthy that the concept of "3D printing" among enthusiasts and technologists did not exist until 1995. In the meantime, in the same 1986, the technology of selective laser sintering of polymers - SLS (Selective Laser Sintering) was developed.

Two years later, Scott Crump invented the FDM (Fused Deposition Modeling) technology. It is she who is the most common, because it has a relatively low cost of both materials and equipment depreciation. Today, it is FDM printers that are most often used at home. It is believed that the first such device was released in 1991.

For a decade, there has been relative calm in the 3D printing industry. The PolyJet technology was developed in 2000.

In 2005, the RepRap enthusiast community was created. The project is based on two ideas:

- any RepRap printer can print another RepRap printer;

- all developments of 3D printing devices are in the public domain.

"RepRap is an invention that will sweep away global capitalism, start a second industrial revolution and save the environment ..."- was written on the front page of The Guardian. We will not delve into the details of why we are talking about the second industrial revolution. It all depends on what foundation to start from when synthesizing certain definitions.

Four generations of RepRap 3D printers have been developed in eight years. However, even now, the task of playing one RepRap device to another has not been completed. It's one thing to print plastic parts; another is to create microelectronics and metal elements of the extruder structure.

In 2010, scientists managed to print an artificial 3D vessel. Now development is underway to create full-fledged human organs. Stem cells are used as "material".

At the same time, engineers were able to develop simple food-grade 3D printers that can print, for example, candy or pizza.

It is already known that, starting this year, the largest IT companies will begin their full-scale expansion in the 3D printing market. For example, Epson announced its intention to produce industrial 3D printers on a large scale. But HP wants to lead the FDM printing industry.

Basic 3D printing technologies

Today, there are many technologies for volumetric printing, but they are all somehow divided into several methods.

In 3D printing (for better understanding), a drawing is usually called a model, and the resulting object is called a mock-up.

Printing methods

Interestingly, 3D printing methods are somewhat similar to conventional (read 2D) printing methods on paper.

- Sintering SLS (Selective Laser Sintering). The material in powder form is applied in a thin layer and then sintered with a laser. So, layer by layer, the layout is created.

- Extrusion, or deposition of thermoplastics (FDM - Fused Deposition Modeling). The printer nozzle (extruder) melts the material to a liquid state and applies it in a thin layer. As it cools, the plastic re-crystallizes.

- Photopolymerization. The nozzle of the printer applies a thin layer of liquid photopolymer, which hardens under the influence of ultraviolet radiation.

- Stereolithography SLA (Stereo Lithography). The area of the liquid photopolymer is illuminated with a laser and hardened. Then the formed solidified layer is again placed in a liquid polymer and illuminated with a laser. This is how the second layer appears.

Depending on the 3D printing method, the device can be either monochrome or color. Extrusion FDM printers print layouts in only one color. Although there are models with multiple printheads, each of which can be loaded with a different color of filament.

American Dave White, owner of a small photo studio DTW, has found an interesting application for 3D printing. He offers his clients Topografics - personalized 3D printed volumetric photographs.

These images are obtained from ordinary two-dimensional photographs, their surface is textured, and when the image is illuminated with diffused light, an unusual effect appears - the photographs appear three-dimensional.

Dave says:

To print them, we experiment with technologies, and Polyjet. With such photos, you can not only see memorable moments again, but also feel them by touch and watch them wake up to life, over and over again. We also design frames for our volumetric photographs with a built-in artificial light source.

The photographer adds:

I plan to continue developing and perfecting the process, trying to reduce the cost without sacrificing quality, and make Topografics available to everyone. As 3D printing becomes more prevalent, I expect the market for such photographs to expand steadily as well.

Dave White is not the first person to have this idea. Previously, Instructables' Amanda Gassea 3D printed several of these images in a simple way. First, digital photographs are converted into a black-and-white image, then, based on it, a computer program compiles a height map of the layers of the future object.

Further, the resulting models are printed on a 3D printer in high resolution: in the darker areas of the image, the layer of material is thicker, in the light areas - the layer is thinner, so they are more transparent. With the background lighting of the photo printed in this way, the illusion of its three-dimensionality is created.

The 3D printer in our office (Objet Connex500) prints with a hard, translucent, white material that can be used to create these unique black and white prints. These prints may be incomprehensible when viewed from the outside, but when viewed backlit, they recreate images with surprising fidelity and even add some subtle dimension and texture to the "scene."

By varying the thickness of this translucent material, you can control the amount of light transmitted, thereby controlling brightness (thin areas of the material will appear brighter and thick areas darker). In this project, I converted the different colors to weights, which allows me to accurately reproduce any shades of gray in the image. I typed on this 3D machine tool photographs of Teddy's cat (Fig. 4), Saturn and its satellite Titan (Fig. 5 and 6), Williamson Mountains by Ansel Adams (Fig. 1, 2 and 3).

All these 3D models were obtained using algorithmic processing using the library ModelBuilder... This library allows you to save 3D geometry in STL and STL format, which can then be printed on a 3D printer.

To start using this library at home, you need to download the latest version of the library ModelBuilder and install to the folder you need. If you have installed the predecessor of the ModelBuilder library (the so-called Unlekker library), then you will need to uninstall it and reload the projects.

Copy your project and save it. The library will automatically place this file in the folder with the same name.

To complete the sketch, replace the part with quotation marks on the following line:

String name = "YOUR_FILE_NAME.jpg";

I think it will work with GIF ,. Jpg ,. TGA, and. PNG files but I only checked, but I only checked Jpg... The sketch will take a couple of minutes to process, but eventually he will tell you that it will be finished. The resulting file will be located in the thumbnail folder named "NAME_OF_ORIGINAL_FILE.stl"

You can open the STL file with various programs, I like MeshLab (it's free and open source).

By default my artwork will be scaled to 8 in width, with a base thickness of 0.01 to 0.02, you can change these settings.

The general director of dace group llc smbat harutyunyan, the prison trade house

The general director of dace group llc smbat harutyunyan, the prison trade house Yakunin left, Rabinovich stayed

Yakunin left, Rabinovich stayed Rabinovich mikhail daniilovich

Rabinovich mikhail daniilovich Lifting loads without special equipment - how to calculate and make a chain hoist with your own hands

Lifting loads without special equipment - how to calculate and make a chain hoist with your own hands New details about Dimona's "charity" empire

New details about Dimona's "charity" empire Principal Buyer

Principal Buyer Edward cypherin biography. New Russian. How Eduard Shifrin, having earned $ 1 billion from Ukrainian steel, got involved in development in Russia. Eduard Shifrin and withdrawal of money

Edward cypherin biography. New Russian. How Eduard Shifrin, having earned $ 1 billion from Ukrainian steel, got involved in development in Russia. Eduard Shifrin and withdrawal of money