Development of measures to improve working conditions at the battery operator's workplace. Occupation - Battery Operator List of Documentation at the Battery Operator's Workplace

What kind of workplaces are subject to certification? This question arose among the majority after the introduction of amendments to the procedure for the certification of workplaces (AWP. - Ed.) - Order of the Ministry of Health and Social Development of the Russian Federation No. 342n. Previously, all workplaces were subject to certification, without exception. According to the Order of the Ministry of Labor No. 590n, only those on which a number of conditions are fulfilled are subject to certification. Office workplaces are not subject to certification. But many, nevertheless, still have questions about how to correctly identify jobs that require mandatory certification.

Specialists of the Center for Certification and Licensing "Unified Standard" prepared a number of clarifying answers to the readers' most exciting questions about whether the workplaces of a courier, homeworker, builder, librarian, seamstress, battery operator, dispatcher are subject to mandatory certification and explanations were given on how to properly certify them ...

How to certify a courier's workplace?

Certification of the courier's workplace is carried out in accordance with the Order of the Ministry of Health and Social Development of the Russian Federation No. 342n. The representative of this profession does not have a strictly fixed workplace. His workplace is non-stationary in all respects, because he has a traveling nature of work. Non-stationary work places are places with geographically changing work areas. The check is carried out on the basis of preliminary expert assessments... The certification committee determines a typical set of factors specific to the courier (for example, vibration, changeable air temperature, static load). The basis for the assessment is undoubtedly local regulations, but certifying commission can also use the method of interviewing workers and employers.

By the way, certification of a courier's workplace is considered one of the most economical. Evaluation does not require it special efforts from the side of the certifying organization, and the workplace usually has a standard set of factors. There can also be savings when highlighting a similarity feature, if the organization has several employees filling this position.

How to certify a builder's workplace?

Workplace the builder poses a great risk of threat to health and life. In terms of danger, this profession ranks second, second only to miners. 50% of accidents in their activities are due to falls from a height. The reason is the insufficient organization of the safety of their working conditions. Therefore, the fight against injuries in this environment is one of the most urgent.

One of the most effective methods for monitoring and checking working conditions is the certification of workplaces for working conditions. Due to the fact that in the course of its implementation, violations are identified and eliminated, the likelihood of accidents is noticeably reduced.

The effectiveness of certification work is achieved more through knowledge of the specifics of the organization of labor of builders, so that certification can rightfully be called effective and high-quality.

Electroplating workstation

Electric welder's workplace (welding under a layer of flux)

| P / p No. | Job options | ||||||

| Air of the working area: - chromium oxide, mg / M³ - carbon oxide, mg / m³ - manganese, mg / m³ - nitrogen oxides, mg / m³ - iron oxide, mg / m³ | 0,1 0,5 | 0,5 0,5 | 1,2 | 0,2 | 1,3 0,2 | 0,5 0,3 | |

| - infrasound, dB | |||||||

| 0,2 | 0,3 | 0,4 | 0,2 | 0,4 | 0,4 | ||

| Industrial lighting: natural, artificial KEO, Lk category of visual work | 0,4 | 0,5 | 0,5 | 0,6 | 0,4 | 0,5 | |

| Non-ionizing radiation: - ESP (level), kV / m - IF EMF (intensity), kV / m | |||||||

| Yes Yes 3/60 | Yes Yes 4/80 | Yes Yes 5/100 | Yes Yes 3/30 | Yes Yes 6/120 | Yes Yes 4/85 |

| P / p No. | Name production factor | Job options | |||||

| Air of the working area: - sulfuric acid, mg / M³ - hydrochloric acid, mg / m³ - nitric acid, mg / m³ | 0,5 - | 1,2 - | 2,5 - | - 2,5 | - | - 1,5 | |

| Vibroacoustic indicators: - noise (equivalent level), dBA | |||||||

| Microclimate: temperature, С air flow velocity, m / s relative air humidity,% | 23,8 0.3 | 0,35 | 23,8 0,2 | 0,.3 | 0,2 | 0,4 | |

| 0,6 | 0,5 | 0,5 | 0,6 | 0,4 | 0,4 | ||

| Severity labor process: - the mass of the part, kg - the mass of the transported load per shift on the working surface, kg - the mass of the transported load when lifting from the floor, kg | |||||||

| The tension of the labor process: - work on those. process - responsibility for final result- number of elements / operation time, s | Yes No 2/40 | Yes No 2/50 | Yes No 3/100 | Yes No 3/100 | No Yes 4/80 | No Yes 3/90 |

| P / p No. | Production factor | Job options | |||||

| Air of the working area: - carbon oxide, mg / M³ - nitrogen oxides, mg / m³ - sulfuric acid, mg / m³ | 2,5 | 1,5 | - | - 1,5 | |||

| Vibroacoustic indicators: - noise (equivalent level), dBA | |||||||

| Microclimate: temperature, С air flow velocity, m / s relative air humidity,% | 0,2 | 0,2 | 0,3 | 0,4 | 0,3 | 0,4 | |

| Industrial lighting: natural, artificial KEO, Lk category view. works | 0,4 | 0,5 | 0,5 | 0,6 | 0,4 | 0,5 | |

| Non-ionizing radiation: - PMP (total), kA / m - ESP (level), kV / m - IF EMF (intensity), kV / m | |||||||

| The severity of the labor process: - the mass of the part, kg - the mass of the transported load per shift on the working surface, kg - the mass of the transported load when lifting from the floor, kg | |||||||

| The tension of the labor process: - work on those. process - responsibility for the final result - number of elements / time of operation, s | No Yes 5/500 | No Yes 5/500 | No Yes 5/500 | No Yes 5/500 | No Yes 5/500 | No Yes 5/500 |

A. 2. Variants of individual tasks for practical training(manual arc welding)

| P / p No. | Production factor | Job options | |||||||||

| Air of the working area: - chromium oxide, mg / m³ - carbon oxide, mg / m³ - manganese, mg / m³ - nitrogen oxides, mg / m³ - iron oxide, mg / m³ - silicon dioxide, mg / m³ | 0,1 10,0 0,6 5,0 1,0 1,4 | 0,5 20,0 0,8 2,0 5,0 1,0 | 1,0 30,0 1,2 5,0 2,0 0,8 | 15,0 10,0 0,3 4,0 1,0 1,2 | 1,3 20,0 0,4 3,0 2,0 1,3 | 0,5 30,0 0,8 5,0 1,0 1,2 | 1,0 1,4 | 0,7 1,5 | 0,5 1,2 | 0,3 1,1 | |

| Vibroacoustic indicators: - noise (equivalent level), dBA - infrasound (general level), dB | |||||||||||

| Microclimate: - temperature, С - air flow velocity, m / s - relative air humidity,% | 0,2 | 0,3 | 0,4 | 0,3 | 0,3 | 0,4 | 0,2 | 0,2 | 0,3 | 0,3 | |

| Industrial lighting: - natural, KEO - artificial, Lk - the category of visual work | 0,4 | 0,5 | 0,5 | 0,6 | 0,4 | 0,5 | 0,7 | 0,8 | 0,7 | 0,8 | |

| Non-ionizing radiation: - ESP (intensity), kV / m - PCh EMF (PDU), kV / m - UV-A (DII) W / m2 | 7,5 | ||||||||||

| The severity of the labor process: - the mass of the part, kg - the mass of the transported load per shift on the working surface, kg - the mass of the transported load when lifting from the floor, kg | |||||||||||

| The tension of the labor process: - work on those. process - responsibility for the final result - number of elements / operation time, s - operation time, s | Yes Yes | Yes Yes | Yes Yes | Yes Yes | Yes Yes | Yes Yes | No Yes | No Yes | No Yes | No Yes |

Note:

1. welding is carried out using PPE (including eyes);

2. The weight of parts includes the weight of all parts to be welded.

A. 3. Maximum permissible concentration (MPC) of harmful substances in the air of the working area and their hazard classes

| № | Substance | MPC mg / m³ | Hazard Class |

| Nitrogen oxides | |||

| Acetone | |||

| Iron oxide | |||

| Silica | 1,0 | ||

| Cadmium oxide | 0,1 | ||

| Nitric acid | |||

| Sulfuric acid | |||

| Hydrochloric acid | |||

| Manganese | 0,3 | ||

| Dust (sanded) | |||

| Lead | 0,01 | ||

| Amyl alcohol | |||

| Butyl alcohol | |||

| Hydrocarbons | |||

| Carbon oxide | |||

| Chromium oxide |

Appendix B

The main functions of the battery are: preparation of electrolyte, testing, charging and repairing batteries.

Workplace equipment table 1.

Table 1. Technological equipment

|

Name |

Type or model |

dimensions in plan, mm |

Quantity |

|

Battery tester |

|||

|

Rectifier |

|||

|

Battery charging cabinet or rack |

|||

|

Battery Parts Welding Tool |

Kiev plant of medical equipment |

||

|

Electrolyte filler |

|||

|

Electric crucible for lead smelting |

|||

|

Electric crucible for melting mastic |

|||

|

Electric distiller |

Leningrad plant EMO |

Table 2. Technological equipment

|

Name |

Model or GOST |

Quantity |

|

Bath for washing battery parts |

Giproavtotrans |

|

|

Puller for removing lugs and terminals |

||

|

Template for welding output terminals |

||

|

Electrolyte level tube |

||

|

Stirring stick " |

||

|

Battery cap wrench |

||

|

Battery carrier |

||

|

Load fork |

||

|

Acid meter |

GOST 895 - 66 |

|

|

Thermometer |

GOST 2045 - 71 |

|

|

Electric soldering iron |

GOST 7219 - 69 |

|

|

Funnel for filling electrolyte |

||

|

Beaker for measuring the amount of electrolyte |

||

|

Rubber bulb for electrolyte suction |

||

|

Electric stove |

||

|

Tank for warming up mastic |

GOST 306 - 69 |

|

|

Ceramic mug |

||

|

Double pliers for removing plate blocks |

||

|

Lead filling bucket |

||

|

Battery cap remover |

||

|

Displacer of plus and minus signs |

||

|

Carbon electrode holder |

||

|

Lead cutter |

||

|

Form for casting inter-element compounds |

||

|

Template for soldering lugs to plates |

||

|

Form for casting lead rods |

||

|

Drying cabinet |

||

|

Separator cutter |

||

|

Hand drill |

GOST 2310 - 70 |

|

|

Bench hammer |

GOST 2310 - 70 |

|

|

Blowtorch or gas torch |

Repair of batteries is carried out in the amount of capital on the basis of ready-made main parts (plates, separators, storage tanks) with the production of castings of inter-cell connections of batteries, terminals and lead pins.

In the above layout, the battery operator's workplace is located in two adjacent isolated rooms. In one room there are the charging and acid compartments, and in the other there are the repair and equipment compartments.

The area of the battery operator's workplace is determined by the actual area occupied by the equipment and inventory, taking into account the density coefficient of the equipment arrangement, equal to 3.5.

To carry out the total amount of work, three accumulators are required. The project adopted: one accumulator of the 4th grade and two accumulators of the 3rd grade, one of which operates on the lines TO - 1 and TO - 2. The work of the battery compartment is organized in two shifts.

In accordance with current Model Norms the battery operator is given the following overalls, footwear and safety devices: a cotton suit with acid-resistant impregnation, rubber ankle boots, goggles and goggles, a rubber apron and rubber gloves.

The accumulator is a highly qualified specialist who identifies problems and malfunctions in the operation of the power supply and in equipment powered by it. To cope with this task, you need a sufficient amount of knowledge. A person who owns this profession will not be satisfied with what has already been achieved, since the development of modernized technologies requires renewal of knowledge and skills.

PROFESSION HISTORY

In fact, it all started simply, with the development of the prototype of the battery 200 years ago by Johann Wilhelm Ritter. Each of the inventions is capable of transforming and renewing. And now, different types of transport, loading equipment, and various mobile devices are working on different types of battery. Battery power supplies are increasingly being used as uninterruptible power supplies.

A large number of equipment operating on multiple-charging batteries require maintenance, and therefore special knowledge. Therefore, being a battery pack is essential for many industries.

WHAT YOU NEED TO KNOW ABOUT THE BATTERY PROFESSION

The work of the accumulator provides for:

- knowledge of the basics of electrical engineering;

- knowledge of safety rules for the operation of acids and alkalis

- knowledge of devices, purpose and types of power supplies

- knowledge of the rules for the use and maintenance of batteries

The profession is needed in the engineering industry, in the field of machine maintenance services, construction equipment, mobile devices. With each new year, the scope of using power sources is expanding, which means that the number of jobs where battery specialists will be needed is increasing.

WHAT THE BATTERY SHOULD DO

The profession has to introduce a specialist at the workplace, where the necessary procedures will be carried out:

- assembly and disassembly of batteries different types, filtration is made, vessels are degreased, distilled water is prepared;

- cleaning and flushing of battery vessels;

- preparing the battery for charging;

- voltage measurement of battery power supplies;

- battery charging;

- determination of the level and density of electrolyte;

- solder the battery connections;

- preparation of an alkali solution;

- identification of damage and their elimination on the battery cells;

- sludge removal, casting lead lugs and connecting strips;

- determination of the quality of the electrolyte;

- maintenance of technical documentation.

Such an incomplete list of responsibilities that can be further divided in accordance with the category of a specialist.

REQUIREMENTS FOR THIS PROFESSION

The battery is an electrical installation, so the worker who becomes the battery operator is obliged to protect qualification group approval (II-V) for electrical safety.

HOW TO BECOME A BATTERY

You can get knowledge in any center vocational training by taking standard courses. Forms and methods of training can be: full-time, intramural-distance, with the departure of a professional to the customer's site.

After the exams, you are given a diploma and a certificate of the profession with the described qualification rank and an electrical safety certificate, where the admission group will be recorded.

The main functions of the battery are: preparation of electrolyte, testing, charging and repairing batteries.

Workplace equipment (tab. 50 - 53)

Table 50 Process equipment

|

Name |

Type or model |

Overall dimensions in plan, mm |

Quantity |

|

Battery tester | |||

|

Rectifier | |||

|

Battery charging cabinet or rack | |||

|

Battery Parts Welding Tool |

Kiev plant of medical equipment | ||

|

Electrolyte filler | |||

|

Electric crucible for lead smelting | |||

|

Electric crucible for melting mastic | |||

|

Electric distiller |

Leningrad plant EMO |

Table 51 Technological equipment

|

Name |

Model or GOST |

Quantity |

|

Bath for washing battery parts |

Giproavtotrans | |

|

Puller for removing lugs and terminals | ||

|

Template for welding output terminals | ||

|

Electrolyte level tube | ||

|

Stirring stick " | ||

|

Battery cap wrench | ||

|

Battery carrier | ||

|

Load fork | ||

|

Acid meter |

GOST 895 - 66 | |

|

Thermometer |

GOST 2045 - 71 | |

|

Electric soldering iron |

GOST 7219 - 69 | |

|

Funnel for filling electrolyte | ||

|

Beaker for measuring the amount of electrolyte | ||

|

Rubber bulb for electrolyte suction | ||

|

Electric stove | ||

|

Tank for warming up mastic |

GOST 306 - 69 | |

|

Ceramic mug | ||

|

Double pliers for removing plate blocks | ||

|

Lead filling bucket | ||

|

Battery cap remover | ||

|

Displacer of plus and minus signs | ||

|

Carbon electrode holder | ||

|

Lead cutter | ||

|

Form for casting inter-element compounds | ||

|

Template for soldering lugs to plates | ||

|

Form for casting lead rods | ||

|

Drying cabinet | ||

|

Separator cutter | ||

|

Hand drill |

GOST 2310 - 70 | |

|

Bench hammer |

GOST 2310 - 70 | |

|

Blowtorch or gas torch |

Table 52 Organizational rigging

|

Name |

Type or model |

Overall dimensions, mm |

Quantity |

|

Battery disassembly table | |||

|

Cabinet for devices and fixtures | |||

|

Battery storage rack |

2000 х380х 600 | ||

|

Fume hood for melting lead and mastic |

1280x825xX800 | ||

|

Equipment stand | |||

|

Stand for bottles for acid |

NIIAT - AR - 2 | ||

|

Sand box | |||

|

Chest for cleaning materials |

Table 53 Production containers and handling equipment

|

Name |

Type or model |

Overall dimensions, mm |

Quantity |

|

Electrolyte drain bath |

Giproavtotrans, MV - 029 | ||

|

Electrolyte dilution bath |

740 X304 X X500 | ||

|

Sulfuric acid bottle |

NIIAT - AR - 2 | ||

|

Distilled water tank | |||

|

Bottle for ammonia | |||

|

Battery trolley |

Repair of batteries is carried out in the amount of capital on the basis of ready-made main parts (plates, separators, storage tanks) with the production of castings of inter-cell connections of batteries, terminals and lead pins.

In the above layout, the battery operator's workplace is located in two adjacent isolated rooms. In one room there are the charging and acid compartments, and in the other - the repair and equipment compartments (Fig. 30).

The area of the battery operator's workplace is determined by the actual area occupied by the equipment and inventory, taking into account the density coefficient of the equipment arrangement, equal to 3.5.

To carry out the total amount of work, three accumulators are required. The project adopted: one accumulator of the 4th category and two accumulators of the 3rd category, one of which operates on the lines TO - 1 and TO - 2. The work of the battery compartment is organized in two shifts.

In accordance with the current Standard Regulations, the battery operator is given the following overalls, safety footwear and safety devices: a cotton suit with acid-resistant impregnation, rubber ankle boots, goggles and goggles, a rubber apron and rubber gloves.

How many kilometers is the Moscow Moscow Ring Road in a circle?

How many kilometers is the Moscow Moscow Ring Road in a circle? Where did the Moscow sparrows disappear: the conclusion of ornithologists Why did the sparrows disappear?

Where did the Moscow sparrows disappear: the conclusion of ornithologists Why did the sparrows disappear? How to make money on homemade toys?

How to make money on homemade toys? Coloring polymer clay in different ways

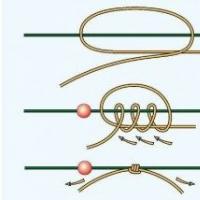

Coloring polymer clay in different ways Self-tightening knot: types, methods of knitting

Self-tightening knot: types, methods of knitting How to find clients for a beginner interior designer Where to find orders for design

How to find clients for a beginner interior designer Where to find orders for design International children's creative competition "Colorful colors of autumn. Important organizational points

International children's creative competition "Colorful colors of autumn. Important organizational points