Automation of management processes at the enterprise. Automation of enterprise management processes. Automation of personnel management processes

MINISTRY OF EDUCATION AND SCIENCE

RUSSIAN FEDERATION

Federal Agency for Education

Pacific State Economic University

branch in Arsenyev

Department of Economics

COURSE PROJECT

discipline: "Informatics"

"Automated enterprise management systems"

Student F-83 gr.

Istomina T.V.

Supervisor

Ishkova S.V.

Arseniev - 2009

Introduction

1. General information of the automated control system

1.1 The composition of the automated control system and the basic principles of their creation

1.2 The main problems and tasks of the automated control system

2. Automated enterprise management systems of the ERP / MRP standard

3. Decentralized control system from LIPro

Conclusion

List of sources used

Appendix

Introduction

At the current stage of computerization of all spheres of human life, the issue of enterprise management automation is very acute. Currently, Russian enterprises use the world-renowned MRP and ERP methodologies.

The first automated planning systems - planning systems material resources, MRP systems - appeared in the USA in the 60s, and have not lost their relevance to this day. At this time, the leadership of American industry was unconditional. However, the emergence of strong competition from Europe and Japan required appropriate solutions.

APCS - an automated enterprise management system or an enterprise management information system, what is now called ERP in English.

The implementation of an enterprise management information system, like any major transformation in an enterprise, is a complex and often painful process. Nevertheless, some of the problems that arise during the implementation of the system are well studied, formalized and have effective solution methodologies. Early study of these problems and preparation for them greatly facilitate the implementation process and increase the efficiency of further use of the system.

The problem of having the necessary materials and components at the right time, in the right place and in the right quantity is especially relevant for mass assembly plants, where conveyor downtime is unacceptable. It was for such productions that the MRP methodology and the corresponding software solutions were developed.

The MRP methodology serves to achieve the following goals:

Minimize inventories in warehouses of raw materials and finished products;

· Optimize the flow of materials and components into production and eliminate equipment downtime due to materials and components that did not arrive on time.

It should be understood that MRP is a methodology that in practice is computer program.

The purpose of this course project is to consider theoretical aspect APCS and one of the enterprise management systems.

1. Consider general information APCS, composition and principles of construction.

2. Consider the main tasks and problems of the automated control system.

3. Consider the practical implementation of MRP and ERP systems for automated control systems.

4. Consider one of the decentralized management systems.

1. General information

Automated enterprise management system (APMS) is a complex of software, technical, informational, linguistic, organizational and technological tools and actions of qualified personnel, designed to solve the problems of planning and managing various types of enterprise activities.

Automated enterprise management systems are necessary to optimize and increase the efficiency of the work of managers and some other personnel departments of the enterprise. Experts argue that enterprise management with the help of automated systems contributes to the growth of the competitiveness of any company. Automated enterprise management systems are especially important for managers. According to statistics, an ordinary manager spends about 60% of his precious time on reporting and compiling documentary tasks for staff. Effective base employee data, which is part of enterprise management, allows the manager to get quick access to the necessary information and perform actions for the reception and movement of personnel. In addition to everything, enterprise management with the help of modern systems allows you to perform automated payroll calculations based on a variety of parameters. In particular, it provides for a position, individual benefits, sick leave, travel allowance, and more. The available information contributes to the prompt calculation and accounting of wage data in financial statements.

Depending on the functional equipment, the following automated enterprise management systems are distinguished:

1) Multifunctional systems that allow you to perform the entire range of tasks related to the management of the enterprise.

2) Systems of expert analysis, which are aimed at discovering the main trends and directions of development of the enterprise.

3) Calculation systems wages.

4) Comprehensive personnel management programs. They allow you to solve a huge list of tasks in the field of personnel management: contact information of employees, work schedules, enrollments and dismissals, salaries, and much more.

The main task of expert programs is to store and compare the various characteristics of the applicant with similar characteristics of the best employees of the company. This approach allows you to find promising employees for a particular department. Due to the high cost of such solutions, it is advisable to use them only within the framework of large enterprises. Automated enterprise management systems, which are designed to solve complex problems, are recommended to be integrated with accounting systems. This feature is due to the fact that the manager will be able to make an adequate decision only if there is up-to-date data on the state of the enterprise. The introduction of enterprise management systems contributes to the adoption effective solutions within a whole range of tasks.

Automated enterprise management systems (ACS) are usually integrated systems. APCS according to the nature of production is divided into the following types: continuous, discrete (single, small-scale, medium-scale production) and continuous-discrete type (mass-flow and large-scale production). APCS manufacturing enterprise, as a rule, includes control subsystems:

warehouses

supplies

personnel

Finance

design and technological preparation of production

production nomenclature

equipment

· operational planning production needs

1.1 The composition of the automated control system and the basic principles of their creation

The practice of creating an automated control system of various classes and purposes confirmed the effectiveness of using a number of methodological principles for creating an automated control system, formulated by Academician V.M. Glushkov back in the 70s, the main ones include the following:

1) The principle of new problems, but these are optimal control problems that can be solved using the capabilities of computer technology;

2) The principle of complex, or systems approach in the development of automated control systems, in accordance with which it is necessary to comprehensively address issues of a technical, economic and organizational nature;

3) The principle of the first manager assumes that the development of an automated control system should be carried out with the participation and under the guidance of the director of the enterprise (for the entire automated control system) or heads of functional services (for subsystems of the automated control system);

4) The principle of continuous development of the system, according to which the number of tasks to be solved is continuously increasing, and new tasks do not replace those already implemented;

5) The principle of modularity and typification, which consists in the selection and development of independent parts of the system and their use in various subsystems;

6) The principle of consistency in the throughput of individual parts of the system, to ensure maximum performance of the system as a whole;

7) The principle of workflow automation and a single information base.

1.2 The main problems and tasks of the automated control system

The main problems and tasks that arise in most cases in the implementation of enterprise management information systems and recommendations for their solution.

1) Lack of setting the task of management at the enterprise

This point is probably the most significant and difficult. At first glance, its theme echoes the content of the second paragraph, devoted to the reorganization of the structure of the enterprise. However, in fact, it is more global and includes not only management methodologies, but also philosophical and psychological aspects. The fact is that most managers manage their enterprise only on the basis of their experience, their intuition, their vision, and very unstructured data about its state and dynamics. As a rule, if a manager is asked to describe in some form the structure of his enterprise or a set of provisions on the basis of which he makes managerial decisions, the matter quickly comes to a standstill.

Competent setting of management tasks is the most important factor influencing both the success of the enterprise as a whole and the success of the automation project. For example, it is completely useless to engage in the introduction of an automated budgeting system if the budgeting itself is not properly set up at the enterprise, as a certain sequential process.

Unfortunately, at the moment in Russia it has not fully developed national approach to management, and currently Russian administration represents an explosive mixture of Western management theory (which in many respects is not adequate to the current situation) and the Soviet-Russian experience, which, although in many respects in harmony with general life principles, no longer meets the strict requirements of market competition.

- Content

- Introduction

- Problem analysis (main part)

- Ways to improve (rationalize or develop) the problem under study

- Bibliography

Introduction

Recently, more and more enterprises are faced with the problem of improving the manageability of the company: improving control and speeding up business processes, improving the ability to track them and the possibility of obtaining metrics that characterize the quality of business processes. The only way to implement such tasks is to introduce an automated system that performs the above functions. However, at present, an attempt to solve the problem of introducing such a system encounters significant difficulties associated with the lack of an adequate supply on the market.

V modern organization the manager is faced with the need to solve many problems in the face of a shortage of working time. Among the main sources of problems in the work of a modern manager are the following:

- A large number of processes in which the manager is involved, while performing different roles: initiator, responsible executor, controller.

- Great amount documents that require approval, clarification, response, tracking, execution.

- The need to control the timely execution of tasks and tracking the obligations assumed.

- Constantly growing volumes additional information necessary for making managerial decisions .

Every day everything greater value acquires efficiency in decision-making, control over the execution of decisions, rational use of accumulated information and previous experience.

Many applications in one workplace

In common applications (accounting software, systems warehouse accounting etc.) the user works with information within one workstation, and rarely goes beyond it. Workflow applications automate the basic management processes in an organization that cover the majority of employees. In this regard, each employee is forced to use the entire range of applications at his workplace and, accordingly, master the interface of each application.

Infrequent use of apps

The user interacts with application functions aperiodically as needed to perform a specific function in a business process. He can perform a certain function very rarely, for example, to participate in the approval of the text of the annual report. All this requires, firstly, a certain activity of the application in relation to the user, the application must tell him what and when he should do; secondly, to provide a unified interface for various functions in various .

The need to organize a common information space

The provisions of this class accumulate information about the main aspects of the activities of the employees of the organization. In this regard, it is necessary to pay special attention to the generality of the mechanisms for searching, extracting knowledge, accumulating statistical information and analyzing processes. At the same time, it is important to have access to information about the employment of employees in various business processes. The presence of such integrated mechanisms will provide qualitatively new information about the work of the organization.

The need for flexible application modification tools

Complexity of application complex management

With the successive implementation of a large number of applications that automate individual document processing tasks that are not integrated into single system, significantly complicates and increases the cost of their maintenance. This can ultimately negate the effect of automation and requires the implementation of applications within a single administration and maintenance system.

All this makes it impossible to effectively implement a set of workflow automation applications in the absence of their close integration and the creation of a unified infrastructure for the implementation of these tasks.

Thus, we understand that the introduction of infrastructure for the integrated automation of workflow processes, necessary condition successful implementation of the system.

With this approach, the task is developed in two stages, namely, the introduction of an infrastructure for automating tasks of this class and the implementation of a complex of integrated applications on its basis.

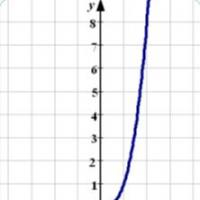

However, the implementation of such a platform is not always appropriate. The graph illustrates the feasibility of implementing a workflow automation platform. When implementing a set of non-integrated applications, the first implementations are relatively inexpensive, however, when implementing a large number of applications, on the one hand, the cost of their maintenance and staff training increases significantly, on the other hand, the need to integrate them (for example, the need to build reports that include information from multiple sources), which leads to additional costs. In addition, as the system develops, users are forced to use many applications with a heterogeneous interface, which also reduces their efficiency.

Rice. 1 Dependence of the total implementation costs and the number of implemented applications when using different strategies.

All of them have both their pros and cons. Let's dwell on the DocsVision system. It includes both an application development platform and business process automation tools.

- Support for the process approach in the organization of management;

- Automation of the processes of coordination and approval of documents;

- Routing and delivery of documents to users' workstations;

- Organization of interaction with contractors and customers;

The DocsVision 3.0 platform allows you to implement a wide variety of applications in your organization, such as:

- Creation of electronic archives of documents with distributed access

- Design and project documentation management system

- Creation of knowledge bases about products, processes (corporate repository of regulations and procedures)

Universal Client workplace should provide navigation through the tree of application folders, search facilities for system objects, initialization of object processing, as well as dynamic management of tabular data and reports.

Support overall structure reference books.

Today, there are two alternative approaches to automating management tasks in an organization. The first is the sequential implementation of individual applications that automate individual control processes. The second - in the implementation of a platform for the implementation of an integrated system for automating process management and the creation of applications based on it, integrated into a single complex.

Implementation of complex applications that implement "fixed" functionality.

Examples of such applications are office automation systems, execution control automation tools, and project documentation management systems. The main advantage of this approach is the relatively low cost and fairly quick effect from the implementation of applications. Applications of this group are ideal for automating specialized workstations focused on performing routine operations isolated from other areas of enterprise automation, for example, such as a clerk's workplace in a large organization or an archival filing system.

However, in a modern organization, there is an increasing need for complex management automation. To meet this challenge, applications need to span multiple jobs. Moreover, one user can participate in different document processing processes in different roles. For example, a user can play the role of an approving person in the system for approving administrative documents, be responsible for the formation project documentation in the project management system, control the execution of tasks in the execution control system.

Successfully solving isolated tasks, end applications do not allow combining all functions into a single document and process management system in a company, which significantly limits the effectiveness of implementing such applications and limits the potential for its use in the future. An alternative to this approach is the implementation of an integrated management automation system based on a single software platform.

Because of this, the cost of implementing the system and using applications increases significantly. In addition, to organize optimal interaction of applications, system scalability, the ability to integrate into the infrastructure of the organization's information system, maximum flexibility and extensibility of the system and the ability to create distributed solutions

Each document can be associated with a set of tasks for its execution.

- The structure of the job associated with the document. The system supports five job routing methods:

- off-line task DocsVision

- common task in Microsoft Outlook

- regular email message

- a message with a URL link to the DocsVision task card by e-mail

- placing a shortcut on the DocsVision task card in the user's personal folder DocsVision .

- Tools for automatic distribution and collection of performance information. In the event that the task has several executors, the system determines the routing method:

- The parallel routing method implies the simultaneous distribution of the task to all executors,

- Serial - serial,

- Alternative - mailing to all executors with automatic withdrawal of the task when it is accepted by the first executor.

- User time management.

- Consolidated performance discipline control. Consolidated control of performance discipline is reduced to the formation of reporting on the status of tasks. Examples of reports can be the following:

- All overdue documents to date

- All documents not completed on time by a specific employee for a certain period

- Tasks in an incomplete state under the control of a specific user

8. Organization of procedures for periodic processing of documents and broadcasting of documents.

Need help learning a topic?

Our experts will advise or provide tutoring services on topics of interest to you.

Submit an application indicating the topic right now to find out about the possibility of obtaining a consultation.

The creation of a productively functioning management system of an economic entity involves the following activities:

Identify factors that significantly affect the activities of the unit and prioritize them;

1. Determine the direction of the vertical processes due to the collection and provision of information;

2. Select or design a typical organizational chart for each structural unit according to the role principle (personnel information, product data, financial flow data, etc.);

3. Determine the focus of horizontal processes (HP) that complement the priority focus of vertical processes;

4. Design horizontal processes taking into account the role approach;

5. For employees who successfully cope with the assigned functions for the implementation of the GP, provide formal and informal ways to enhance their activities.

Consider in detail formal ways that ensure the maintenance of the productive functioning of an economic entity.

* Documentation procedures and business processes. The main goal is to increase the efficiency of employees' work by regulating their role responsibilities and decentralizing decision-making. This approach makes it possible to develop “internal” standards for each employee and legitimize the procedure for interaction between structural divisions, fixing it with the relevant regulatory documents.

* Optimization business processes and key decision-making procedures in order to increase the “controllability” of all links in the hierarchical organizational structure, starting from an individual performer and ending with an economic entity as a whole. This is achieved by balancing key corporate business processes and increase the stability of their functioning.

* Creation intellectual groups within the framework of defining activities in order to generate proposals for their promising areas.

* Organization a team of employees to implement a specific project within a particular area of subject activity. This activity is the most responsible, since the team is obliged to strictly monitor the expenditure financial resources and meet the deadlines, realizing the tasks set. In addition, the activities of the team itself in the implementation of the project must be carried out in accordance with the planned stages.

Consider the most characteristic stages of project implementation. Such stages can be the following: determination of the main parameters, planning of work, formation of a development team, organization of work on the implementation of the project, control of the progress of implementation, completion.

The stage “determining the main parameters” involves: setting a goal; allocation of human, financial and material resources; terms of implementation; possible risks. At the "work planning" stage, the sequence of work performed, their interaction, the results of each of the work are determined, a schedule for their implementation is drawn up, possible deviations from the deadlines and measures to eliminate them, the resource availability of each work is specified. The stage "formation of a group of developers" involves the selection of specialists in each area provided for in the project, the distribution of responsibility between them. At the stage of "organization of work on the implementation of the project" organizational measures are worked out for the effective implementation of each work and for the creation of the project as a whole. The "implementation progress control" stage provides for constant monitoring, recording and tracking of all types of work and stages; identification of "bottlenecks" in the implementation and their elimination. The stage "finishing" involves summing up the results of the project; development of measures to ensure the elimination of recorded miscalculations in the first cycle of the project.

Control automation

When a question is raised in an organization and a decision is made to automate management, many questions arise. We list the most significant of them. What motivates this decision? What does "automate control" mean? Where to begin? What are the main stages of development? How to approach the problem of choice? What should be the evaluation criteria? What are the preferences for one or another design methodology and tool environment? What does that require?

We will try to answer these and other questions that inevitably arise in the course of creating an organization's management automation system, the main stages of which are shown in a generalized schematic diagram (Fig. 2.4).

Fig 2.4. Generalized scheme of organization management automation

methodical approach. The functioning of any organization is aimed at the productive solution of a certain set of tasks. These include the following: hiring an employee, firing an employee, tracking career growth, staffing, payroll, concluding various contracts, transferring money, providing the necessary amount of production resources, successful behavior in the product market, etc. When setting each of the tasks, the initial state of affairs, available resources, tools, and requirements for performers are described. In addition, the goals that are expected to be achieved as a result of the implementation of certain tasks are determined.

Solution in general view a particular task involves the implementation of a certain set of actions that form a certain process. Schematically, this can be represented as follows: performers sequentially perform actions according to a predetermined process, attracting the appropriate tools and spending the necessary resources. The specialist in such processes acts as an executor. In other words, the functioning of the organization is considered as the implementation of a certain set of tasks, each of which has corresponding processes.

Summarizing the above, we conclude: for the productive functioning of an organization (in the general case of an economic entity), it is necessary to have statements of all tasks expected to be developed and descriptions of the processes for their implementation.

On the other hand, any organization should be considered as a system that should adequately respond to changes in the internal and external environment and effectively adapt to the new conditions of its functioning. At the same time, it is necessary to take into account issues related to the reorganization of the economic entity itself, which leads to a possible transformation of the organizational structure, which, in turn, involves changes in the list of tasks to be solved, their formulations, sequence, as well as the processes for their implementation.

A change in problem solving processes, in turn, may lead to qualitative and quantitative changes in resources, redefinition of tools, modification of the composition of performers and / or redistribution functional duties between performers, as well as improving their professional level.

We will proceed from the fact that in an organization for any task a process for its solution is defined, provided that it is provided with the necessary resources, tools and trained personnel. At the same time, the joint development and solution of several problems should be coordinated among themselves in terms of time, resources, composition of performers and a set of tools.

Let's define managerial link of the organization as a set of structural divisions and employees providing: compilation of a list of tasks to be solved in the organization; their setting; implementation of processes for solving tasks; resource, instrumental and staffing support for each process; implementation of processes and coordination of their execution. At the same time, care should be taken to increase the efficiency of the functioning of the managerial link, due to an increase in the productivity of workers in solving specific tasks without prejudice to the achievements quality indicators by automating control.

Thus, the motive for making a decision on automation of management is the desire to streamline internal environment the functioning of the organization in order to increase the productivity of specialists - managers.

Further presentation of the material involves the clarification of a number of concepts.

Automation- this is a system of measures aimed at increasing the productivity of an individual through the transfer and performance of its functions by machines and / or mechanisms.

Control automation- this is the performance of the functions of an individual by software and hardware in the implementation of part or the entire process of solving a particular problem. As a rule, automation of control is identified with the availability of information necessary for these purposes. This means that you should start automating management if there are actually existing information processes supported by relevant documents.

It is known that the functioning of the organization and its management link is carried out on the basis of certain documents. The document is involved in solving production, personnel, accounting, financial or other tasks. In this way, document should be considered as a basic component of management.

Let's define office work as a process of creating forms of documents and executing management procedures on their basis in order to solve a certain set of tasks that ensure the functioning (possibly productive) of the organization. Thus, office automation is considered as a leading component of the organization's management automation system as a whole.

There are two approaches to the process of automation of the organization's management system. The first approach is designed to automate the existing management system, which is based, as a rule, on paper-based office work. The second one involves the creation of electronic office work for a new management system, which ensures maximum automation of the entire management process.

Consider the organization and management system, which is based on paper workflow. At the same time, under paperwork we will understand the process of producing a set of paper documents as the main carrier of information necessary for decision-making, and one or another specialist is assumed to be the executor. In this case, the development of an automation system should begin with the automation of the existing management process, which is usually based on a paper-based record keeping system. This decision is due to the fact that the management process exists de facto, and the organization actually functions. Recall that the current system of paperwork reflects the level of development of the management system specific organization which is understandable, familiar to its employees and corresponds to their qualifications. Therefore, a gradual transition to management automation is painless, when only the information carrier changes from paper to electronic, and the usual order of execution of management processes and procedures remains the same. In this case, it is necessary to formally describe existing system paper-based management. It is necessary to involve the employees of the organization involved in a particular process in the development of a management automation system, due to the fact that only they know all its features. It is necessary to describe a separate process for solving a specific task and the process of executing the forms of documents used in its implementation. With such a formulation of the question, the descriptive document covers only one task, and it is visible to the worker who formalizes its description. In this case, the employee must formally describe his work, which he performs daily. Descriptive documents for each task and process within the development of an automated control system are project documentation. The creation of project documentation involves the use of a formalized language, the syntax and vocabulary of which are clearly understood by all development participants. The vocabulary of such a language is based on the vocabulary subject area and / or substantive activity, as well as the vocabulary of paperwork. This approach is dictated by the fact that the exchange of information is carried out at the level of documents, their functional purpose, the types of data presented in them, as well as operations performed both on individual data and on documents as a whole. Note that along with the term "paperwork" we will use the term "paperwork".

Consider an organization and its management system, which is based on electronic office work. Under electronic office work refers to such proceedings in which an electronic document is used as the basic information carrier, and the executors are employees whose workplaces are equipped with computers, which, in turn, can be combined into a computer network. Note that along with the term "electronic record keeping" we will use the term "electronic document management".

As for paper documents, in this case they play a supporting role.

The development of an automation system based on the design documentation of paper office work is reduced to the design of an electronic office workflow. We list the main differences: the main carrier of information is an electronic document; operations are performed both on parts and on the electronic document as a whole; maintenance of meta-information of an electronic document, which is an integral part of a single information space of an organization, is assigned to a computer; maintenance of electronic documents (distribution, replication, collection, replication, copying, storage, etc.) is performed within the networked computer environment.

At the next stage of developing an automated system, an intrasystem description is implemented using the tools of the selected software platform. Consider how you can choose a software platform.

Production automation is understood as the replacement of manual labor with machine labor, whether it be robots, automatic devices or software. Automation lies in the fact that on the production line the workflow and some of its components (operations) are performed not by people, but by special equipment or information systems. Considered an innovation of the 21st century, today automated production can completely replace a person in many types of work.

Automation of operations can include the automation of a single operation or the automation of the entire manufacturing process. Automated equipment can range from simple sensors to autonomous robots and other complex equipment.

Goals of factory automation

Increasing productivity and the desire to gain a competitive advantage is usually the main reason for starting an automation project in many enterprises. Other reasons for automation may not be due to “hope for the future” but to specific reasons, such as a dangerous work environment or the high cost of human labor. Some businesses are automating processes to reduce production time, increase production flexibility, cut costs, eliminate human error, or make up for shortages. work force. Automation decisions typically involve some or all of these economic and social factors.

At the same time, one can single out the general goal of industrial automation: to replace human labor and optimize work*. In a broader sense, the goals of process automation conditionally include:

- Reduction of personnel serving production;

- Increasing the production of products;

- Expansion of the product range;

- Increase in production volumes several times;

- Improving production safety.

*However, there are some nuances here: automation in production can increase maintenance costs.

For business owners, evaluating the pros and cons of automation can be a daunting task. The speed with which technology is adopted, combined with a natural resistance to change, causes the business owner to delay the introduction of new management tools, although they themselves understand that by delaying the introduction of new and more efficient technologies, they lose their competitive advantage.

Automation types

While automation can play an important role in increasing productivity and reducing costs in the service industry, factory automation is most prevalent in manufacturing industries. V last years in the field of production, the following types of automation are used:

- Information Technology (IT);

- Computer Aided Manufacturing (CAM);

- Equipment with numerical program management(NC);

- Robots;

- Flexible manufacturing systems (FMS);

- Computer Integrated Manufacturing (CIM).

Information Technology (IT) cover a wide range computer technology used to create, store, retrieve, and distribute information. It is due to information technology that most of the automation is currently being carried out, for example,.

Computer Aided Manufacturing (CAM) refers to the use of computers in various production planning and control functions. The manufacturing process uses CNC machines, robots and other automated systems.

Numerical Control Machines (NC) are programmed versions of machines that perform operations sequentially. Machines can have their own computers for this purpose. Such tools are commonly referred to as computerized CNC machines. In other cases, many machines may share the same computer. They are called direct numerical control machines.

Robots– This type of automated equipment can perform various operations that are usually handled by a person acting as an operator. In manufacturing, robots are used for a wide range of tasks, including assembly, welding, painting, loading and unloading heavy or hazardous materials, inspection and testing, and finishing work.

Flexible Manufacturing Systems (FMS) represent complex systems, which may include machine tools with numerical control, robots and automated material processing systems, that is, these are fully automated lines for a complete production cycle.

Computer Integration System (CIM) is a system in which many production functions linked through an integrated computer network and includes production planning, quality control, automated manufacturing, computer-aided design, purchasing, marketing and other functions.

There is a large selection on the market today software products to automate business processes of production. Considering Information Technology automated production based on 1C, the following popular software products can be distinguished:

- 1C: Manufacturing Enterprise Management 8;

- 1C:ERP Enterprise Management 2;

- Additional modules in accounting configurations;

- Specialized solutions for managing the production of alcohol, meat and fish products, construction industry etc.

1C: Production plant management 8

A comprehensive application solution that covers the main control and accounting loops at a manufacturing enterprise, the production subsystem of which allows you to fully control production processes from the moment materials are transferred to production to the release of finished products. Main functionality:

- Production planning (updating, detailing and adjusting plans based on the results of completed periods);

- Calculation of the cost price (plan-fact analysis of the cost price);

- Cost management;

- Reflection of production operations in management, accounting and tax accounting.

Free

consultation

expert

Natalia Sivorina

Consultant-analyst 1C

Thank you for your feedback!

A 1C specialist will contact you within 15 minutes.

1С:ERP Enterprise Management 2

It implies the implementation of the control subsystem production processes companies at different levels.

In the system, automation of production planning processes is organized using the documents "Production plans" and "Orders for production". Functionality is provided for keeping records of services for the processing of tolling raw materials, production on the side (by a third-party organization), diagnostics of the formation of a production schedule, scheduling of a production schedule. A list of resource specifications, route sheets is maintained.

To manage tasks and production processes, the system provides the ability to maintain the following regulatory and reference information:

- Route maps;

- Brigades;

- Types of work of employees;

- Structure of work centers;

- Permission to replace materials;

- Transition options.

The functionality of the system allows you to account for labor costs and the output of employees performing production orders and general production work, as well as accounting for the output of the team with labor participation rates (KTU).

I would like to note that after the introduction of automation systems in the company, the question arises of finding qualified specialists with the proper level of knowledge. That is, another problem of automation can be considered the search for new specialists or the improvement of the skills of the existing staff of the company.

The list of problems in the use of software products can be supplemented by the emergence of threats of hacking the system, dependence on power supply and technical vulnerability. However, all these risks are offset by a large number of positive effects from the introduction of automated systems: a decrease in product defects, a decrease in the cost of a product due to a reduction in the labor intensity of work, an increase in the number of new customers due to an increase in product quality and its reduction in price.

The pace that the automation of various business areas has gained over the past 20 years can be called truly dizzying. Regardless of the scale of the business, owners are focused on automation, and the modern market offers them a huge selection of automated solutions. Under these conditions, the key to success is the careful analysis and implementation of management schemes, and not the rapid and thoughtless introduction of new technologies. Automation should be a planned, strategic move based on the real needs of the manufacturing plant to meet all the needs of the organization and bring maximum value.

The success story of a famous tailoring magazine

The success story of a famous tailoring magazine Thesis plan abstract. How are abstracts written? What are abstracts and how not to make mistakes when writing them? Conference report

Thesis plan abstract. How are abstracts written? What are abstracts and how not to make mistakes when writing them? Conference report What is "gold" and "blue" watches in photography

What is "gold" and "blue" watches in photography How to make money with advertising on a car and what you need for this Examples of detailed, information-rich advertising

How to make money with advertising on a car and what you need for this Examples of detailed, information-rich advertising Quadratic and cubic functions

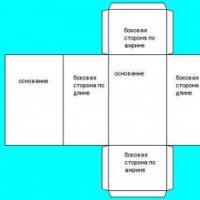

Quadratic and cubic functions How to make a paper prism

How to make a paper prism Everything you need to know about the prism for passing the exam in mathematics (2020)

Everything you need to know about the prism for passing the exam in mathematics (2020)