Make money from home cheese production. Business plan for the production of cheese: how to open a cheese dairy and where to start cheese making. In what form to open a business

Anti-Russian economic sanctions and retaliatory import restrictions have created an imbalance between supply and demand in the Russian food market. Consumers in all regions complain about the shortage of dairy products. The situation allows you to start a business with minimal risks. The production of cheese on modern equipment, if there are raw materials and materials, is not difficult. A team of several people can master the technology and reach the commercial level. They need a small start-up capital and a facility that meets health and safety standards. You will find information on all the nuances of business, as well as a detailed business plan in our article.

Is it profitable to open a cheese production: demand analysis

Food products are always in demand. Food that meets the needs of customers does not lie on store shelves. Business in this area brings guaranteed income. And the profit depends on many components. First of all, from the readiness of the manufacturer to withstand the period until stable production and sales are established. Rarely does the payback come in a year. For cheeses, it will take a longer time, because there are varieties loved by gourmets that ripen up to six months or longer.

But when the cheese maker finds his niche in the market and his reputation is reinforced by the high quality of his products, he will acquire regular customers and a stable level of sales. This is the psychology of consumers, most of whom remain loyal to those manufacturers whose products meet recognized standards.

Cheese is a product of milk processing. Any technology can be used, but commercial production needs volumes that are obtained from milking the following domesticated animals:

- cattle - cows, buffaloes, zebu;

- small ruminants - goats and sheep;

- camels.

In Russian realities, camel milk is exotic. A resourceful entrepreneur could draw attention to his brand with a small batch of camel cheese.

Milk from other animals (mares, moose, donkeys, deer, female marine mammals) is also used. But this is the lot of enthusiasts and scientists. It is not suitable for a novice businessman, although with an established production, a small part of such milk can become a component for creating new varieties or single batches.

Mini-workshop in operation

The market in Russia is far from saturation. There are many cheeses on store shelves made with soy protein and palm oil. It is enough to go to any farmer's market to see how quickly, even on a weekday, the products of small cheese dairies are sold. Their prices are comparable to those of imported cheeses, but the buyer is willing to pay for a high quality natural product. Russia is not a cheese exporter. It is unable to saturate its domestic market and will be among the main importers for many years to come.

In 2009, Russia ranked 22nd in the world in terms of cheese consumption. From 5.9 kg per capita per year, it lagged almost 2 times behind Poland, which ranks 21st, where the indicator is 10.5 kg. And no comparison is possible with the average level in the EU countries - 20 kg / person or with the absolute leader in Greece, where 31 kg is the share of each inhabitant. Since 2014, the gap has only widened. Before the imposition of sanctions against Russia, analysts predicted an annual growth of 4% in cheese production. Now this is not enough. We need a qualitative leap: all hope is for small private cheese dairies and farms.

Business plan

It is not difficult to start a cheese production. Mechanical engineering and food industry provide a wide range of technological lines from mini-cheese dairies to workshops, coupled with dozens of starter cultures and enzymes for all types of cheese products. Banks are willing to provide loans, and regional authorities - subsidies and assistance in setting up a business. The equipment does not have to be purchased: it can be rented or leased. Before investing, the future cheese maker needs to decide the following:

- Choose a registration form. Cheese production requires licensing. The legal entity must make the appropriate amendments to the constituent documents. An individual at the start may limit himself to registering an individual entrepreneur or a farm with the prospect of re-registering in an LLC, if the business begins to expand and goes beyond the sole sole proprietor.

SP provides a sparing tax regime. The choice of a businessman is 6% of the imputed income, 15% of the profit or a one-time purchase of an annual patent. - Find wholesale suppliers of raw materials. Cheese is a milk-consuming product. From 1 liter of milk, he receives 100–120 g of cheese. To start at a mini-cheese factory, you need 25 liters of milk daily to produce 2.5–3.0 kg per day of young cheese, which still needs ripening.

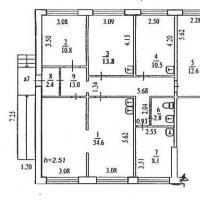

- Prepare two rooms. The first is production, it must meet the requirements of Rospotrebnadzor for food production and Rostekhnadzor in terms of fire safety and labor protection. And the second room with a microclimate favorable for storing and ripening cheese. A basement or cellar will do. Young cheeses sell quickly, but do not generate significant profits. Aged cheese with a spicy taste is more expensive. Ripe heads will give a good financial result.

- Organize sales. Delicious cheese does not stagnate, but the buyer himself will not come. You can sell it by paying for a place in specialized markets or negotiate with retail chains and catering. While the cheese ripens, you will have to run around with samples to attract future buyers.

The entrepreneur who has solved these four problems is ready to go. What kind of cheese to cook?

Cheese varieties

Despite all the variety, the classification of cheeses is quite simple.

Table: classification of cheeses

True, if you dig deeper, then in each category their subcategories, species, subspecies, types and individual or regional varieties will begin to branch. It is impossible to grasp the immensity, it is better for a cheese maker to concentrate on 2-4 types and adjust his production as he moves on the market.

Soft, hard, pickled, moldy - they may all be made from the same batch of milk

Interesting observation from entrepreneurs working on Italian hardware. Russian consumers were reluctant to buy up cheeses popular in Italy. But when changes were made to the recipe, making the cheeses saltier and harder, the problem with implementation disappeared. Affected by the taste preferences of the Russians, which do not coincide with the Italian ones.

- "Parmesan";

- "Feta" and similar feta cheese;

- "Mozzarella";

- Roquefort, Dorblu, Gorgonzolla and Danable;

- Camembert and Brie;

- Ricotta;

- Emmental;

- Gouda and Edam;

- Mascarpone;

- "Cheddar".

Any of these cheeses can be made in Russia subject to technology, but it should be remembered that a number of names are patented trademarks. This means that you will need to choose your own name for your cheese.

The most demanded and popular cheeses are made from goat and sheep milk. They are almost guaranteed 100% sales. They are not enough on the shelves of Russian stores. But, unfortunately, in agriculture there is still a bias towards meat and wool breeds of small ruminants. Breeding goats and sheep for dairy production is the lot of small farms or specialized enterprises that are themselves sharpened for the production of cheeses.

A cheesemaker must definitely plan the release of products from goat and sheep milk, but it is better to start a business and conquer the market with cow milk. In recent years, there has been a steady increase in dairy livestock, and with it wholesale offers for the supply of milk.

Financial component

The case requires an initial investment. Depending on the scale of production and own funds for the production of cheese, additional funding will need to be attracted. The profit will not come immediately, and the operating costs are increasing every day.

Table: calculation of start-up investments

| Expenditure | Enterprise type | |||

| Homemade production (rub.) | Farming farm (rub.) | Mini-workshop (rub.) | Factory (rub.) | |

| Registration, licensing | 5 000 | 5 000 | 15 000 | 30 000 |

| Annual rental of premises | - | - | 120 000 | 250 000 |

| Equipment and materials | 20 000 | 40 000 | 100 000 | 150 000 |

| Salary fund | 0 | 30 000 | 100 000 | 150 000 |

| 20 000 | 20 000 | 40 000 | 60 000 | |

| Logistics and procurement of raw materials (starting) | 5 000 | 5 000 | 50 000 | 150 000 |

| Advance payments | - | - | 10 000 | 20 000 |

| Unexpected expenses | 5 000 | 5 000 | 10 000 | 20 000 |

| Total | 55 000 | 105 000 | 445 000 | 830 000 |

Minimum sets of equipment were taken for the mini-shop and plant.

Not that much money. Home and farm cheese production can be started at your own expense. It is assumed that the farm uses its own premises with minimal recruitment of outside workers. To open a mini-workshop or a factory, you need funds comparable to a consumer loan. A favorable condition is that modern production lines do not require a large number of personnel. In the mini-shop 2-3 people will handle it, in the plant 5-6, the rest will be done by the automatics.

Compact and convenient: production room and pantry for storing and ripening cheeses

The most difficult for business will be the first months when sales are limited, cheeses continue to ripen, and regular payments are inevitable. In no case should production be idle. Milk is needed every day to load the capacity. Its cost is not the same by region; in the calculations, an average of 40 rubles / l was taken for direct purchases from manufacturers. For the farm, the assumption is made that some of the raw materials will be from their backyard, but with the hiring of workers.

Table: monthly expenses

| Monthly expenses | Enterprise type | |||

| Homemade production (rub.) | Farming farm (rub.) | Mini-workshop (rub.) | Factory (rub.) | |

| Logistics and milk procurement | 25 000 | 25 000 | 130 000 | 260 000 |

| Utilities | 5 000 | 5 000 | 20 000 | 50 000 |

| Salary fund | - | 30 000 | 100 000 | 150 000 |

| Mandatory payments to PF and social insurance | 20 000 | 20 000 | 40 000 | 60 000 |

| Maintenance and repair equipment | 1 000 | 1 000 | 5 000 | 10 000 |

| Loan payments | - | - | 15 000 | 35 000 |

| Unexpected expenses | 5 000 | 5 000 | 10 000 | 20 000 |

| Total | 56 000 | 86 000 | 320 000 | 585 000 |

The table gives an idea of how much you need to sell products to cover monthly costs and partially offset the initial investment. You need revenue at least 10-15% more than monthly expenses. That is, as a first approximation:

- Home production - 63,000 rubles;

- Farm - 97,000 rubles;

- Mini-workshop - 360,000 rubles;

- Plant - 660,000 rubles.

These numbers, like beacons, will help to calculate in reverse how much milk needs to be processed in order to reach the given parameters. The first sales of young and pickled cheeses will start from the second week. Whey will be an additional income. It is a valuable drink, as well as a raw material for culinary and production of "Ricotta" type cheeses. From the third month, the sale of soft and semi-hard cheeses will begin. In six months, the hard ones will ripen and the enterprise will reach the planned capacity.

Let us take the average price at which an entrepreneur will hand over his products to retail chains and catering, 600 rubles / kg, and determine how much milk needs to be processed monthly. For the calculation, we use the proportion of 10 liters of milk = 1 kg of cheese. In fact, more will be released, but losses of finished products are inevitable and some part will not be sold.

- Home production (63,000: 600) x 10 = 1,050 l / m or 35 l / day;

- Farm (97,000: 600) x 10 = 1,620 l / m or 54 l / day;

- Mini-workshop (360,000: 600) x 10 = 6,000 l / m or 200 l / day;

- Plant (660,000 rubles: 600) x 10 = 11,000 l / m or 370 l / day.

Milk is often measured in 20 liter aluminum jars. As you can see, home and farm production will need 2 and 3 flasks, respectively. The mini-workshop and the plant will have to order a tanker.

When income exceeds expense

The food industry is not producing quick returns. But well-established production guarantees a stable income. The cheese factory does not exist on its own, it provides a steady supply to milk producers who are equally interested in the continued development of cheese production. It is a difficult task for a cheese maker until he returns the initial investment and comes out on a net profit. He depends on an uninterrupted supply of milk, which must be paid for immediately, and he needs to maximize the sale of his products to avoid overstocking. The very existence of the business depends on the success of sales. The entrepreneur should feel the preferences of the buyers, but not blindly follow them.

A few hours ago, these cheeses were milk: now they are ready to be transferred to the pantry for ripening.

10 liters of milk will make 1 kg of cheese. It can be sold immediately to the young, immature, but relatively cheap. Or leave it for 3–6 months of ripening and the price will increase, but will it be sold at that price? If there are no long-term contracts for the supply of cheese to a specific consumer, you need to be flexible and expand the product line. Part of the milk for young and pickled cheeses, part for hard and the rest for small elite lots, which can be stored for a long time and wait for their buyer.

The main components of the guaranteed profitability of cheese production:

- The effective demand of the population.

- Supply of the cheese dairy with quality raw materials and materials.

- Personnel qualifications.

- Products that meet the tastes of the region.

- Organization of sales on a long-term basis.

- A room with a microclimate for storing and ripening cheeses.

Cheese making does not bring millions in either the first or the second year. According to analytical research from open sources, starting a business, a conscientious cheese maker can calculate a payback in time:

- Home production - 1.0–1.5 years;

- Farming - from 1.5 to 2.5 years;

- Mini-workshop - 2-3 years;

- Plant - 2.5-3.5 years and longer.

To some, the wait will seem long, but the number of cheese makers in Russia is constantly growing. Perhaps they are inspired by the example of their Italian colleagues, who employ up to 100 cheese dairies in a city of 10,000 inhabitants. One per 1000 people. With such a density of production, everyone finds their buyer. Someone directly at the place of residence, someone delivers to other regions and countries. Good cheese will definitely be in demand.

How hard and soft cheeses are made

The modern technological process is designed to the smallest detail and is almost completely automated.

Continuous chain from raw milk to ripening cheese heads

Fresh milk that has passed pasteurization is poured into a bath at a temperature of + 35 ° C, where, while stirring, a sourdough (rennet or mushroom enzyme) and a 10% solution of calcium chloride (optional, at the rate of 1 g CaCL 2 per 5 liters of milk) are added to it. Calcium chloride is optional, but its microscopic presence accelerates the clotting of the cheese ball, which becomes denser and more whey-free. After about 40–60 minutes, the mass is compacted, it is cut into small lumps and stirred, accelerating the curdling process (coagulation). An hour later, the cheese mass starts to sink in the whey, which means it's time to separate. The whey is partially scooped out, the remaining mixture is transferred to a settling tank or immediately transferred to sieve molds. Salting occurs at the same time. Salt directs fermentation in the desired direction for the cheese-maker and stimulates subsequent maturation. The remaining whey is quickly removed, the mass is constantly compacted. A curd substance accumulates in the molds, which, after being pressed, turns into young cheese, very young and not yet ready for sale. Although there are lovers of this.

Video: Swiss cheese production technology

The next stage is ripening. The process is technologically controlled. Even at the stage of laying under the press, ingredients are added to the cheese according to the recipes or, after removing from the molds, they are subjected to special processing, as a result of which one head will be used to make feta cheese, the other will remain ripe and become hard cheese, the third will be filled with mold, and it will become Roquefort ...

A cheese maker is like a creator and, at his request, a head of young cheese, which a few hours ago was milk, can become either a mass popular product, or a rare specimen, a gourmet or collector's dream.

Home and farm production can be done with the efforts of one family. The mini-workshop and the plant will require qualified personnel. If there are enough raw materials, then a round-the-clock production should be organized so that the equipment does not stand idle. In this case, each shift must have a foreman (foreman) and 2–4 workers who ensure the full cycle from milk intake and processing to putting the cheese mass into molds and then transferring it to the room where ripening takes place. In addition to them, additional staff is needed:

- Milk Purchasing and Cheese Sales Manager.

- Accountant.

- Cleaners of premises.

The latter are very important. A dirty room is a huge risk for production. Cheeses, like living organisms, are sensitive to external influences. Alien mold, pathogenic bacteria, foreign bodies and strong odors can spoil the entire batch, causing colossal losses to production.

Sales organization

The success of the entire enterprise depends on the sale of products. Even at the stage of registration and purchase of equipment, this issue should be addressed. The best option is long-term supply contracts for shops and catering facilities. It is difficult to implement it without support, because the consumer does not see the finished product and is often not inclined to trust promises, but it is worth trying.

From the moment of launching production, you need to immediately actively enter the market. Including through advertising, presentations and promotions. The cheesemaker has many opportunities at his disposal along the way.

- Lease of a trading place in the market.

- Opening an online store.

- Participation in weekend fairs, when free points of sale are allocated for consumer goods.

- Organization of tastings.

- Presentation of samples at exhibitions.

- Direct contacts with retail chains and catering.

- Participation in clubs and forums of cheese makers.

- Registration of pages in social networks and the creation of support groups on their basis.

The main thing is the consumer properties of the cheese, its taste, smell, color, structure. For this he is loved by millions. With high quality, sales will increase every day until the maximum capacity of the cheese dairy is reached. Hard varieties have one more wonderful property: they can wait for the buyer, and during the waiting time their taste will only improve. With proper storage, of course.

Cheese production has an additional income item - whey. It may not be possible to use it at first, and most of it will go to waste irrevocably. But from the very beginning, you need to plan for its processing for subsequent marketing. Whey is used to obtain:

- soft cheeses like "Ricotta";

- raw materials for cooking and bakeries;

- the drinks;

- feed raw materials;

- milk protein powder;

- raw materials for the development of biologically active additives.

This will require additional investment, but as a result - increased production, less waste and increased profitability.

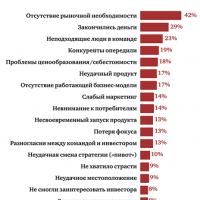

Risks and prospects

Any production is fraught with problems and risks. If it cannot be avoided, then you need to prepare in advance.

Table: Potential Problems and Solutions

| Situation | Solution options |

| Disruption of supplies. Poor quality raw materials. | Choice of several suppliers. Screening out the unscrupulous. Quality control at the place of production of raw materials. |

| Equipment breakdown. | Warranty service agreements. |

| Unlawful actions of inspectors of Rospotrebnadzor and Rostekhnadzor. | Legal business conduct. Publicity, openness. Legal protection in state and judicial authorities. |

| Poor product quality. | Careful adherence to technology, recipes, sanitary standards, storage rules and delivery to consumers. |

| Failure to pay for the delivered goods. | Delivery on credit or with deferred payment only under completed contracts. Protection of your rights in court and in arbitration. |

| Low production discipline. | Personal personnel work. Recruiting employees through agencies with a good reputation. |

| Force majeure circumstances. | It never happens suddenly. Monitor the market situation and control our own production. |

| Unsold products. | What can be stored is sent for subsequent ripening. The rest is for processing. |

| Seasonal fluctuations in supply and demand. | Market research. Gaining experience. Communication with business colleagues. Participation in community work. |

In addition, one should not forget about such a reliable tool as insurance. It is impossible to compensate for any losses at the expense of an insurance policy, but minimizing losses is the direct responsibility of a business person.

Development forecast

The prospects for the cheese business in Russia are excellent. Even the lifting of sanctions and the resumption of imports will not make up for the cheese deficit on the market. The excess of demand over supply is forecasted for many years to come, until the average per capita consumption approaches the European one. This means that the cheese market will grow and expand following the rise in the welfare of the population. The state import substitution program creates good starting preconditions for any business in the processing of livestock products, including the production of cheeses and related products.

The cheese market in Russia is not saturated: supply is lower than demand. The success of the production depends on the raw material base in the immediate vicinity of the cheese dairy and a reliable sales organization. To reduce the risks, contracts with several suppliers should be concluded and the quality control of raw materials should be carried out at the production site. And loss insurance will save you from ruin and bankruptcy.

Cheese is the most valuable food product. And making cheese at home (like) is also a profitable business. This product is always relevant, because it is included in the diet of most Russians. DIY cheese is much healthier, tastier, and cheaper than one bought at the grocery store. Moreover, it contains absolutely no preservatives and other chemical components. To start your own business, you need to purchase raw materials and equipment. It will be much easier to start entrepreneurs dealing with goats or cows. After all, they can process milk from these animals and, as a result, receive the final product without additional financial costs.

Making cheese at home

Cheese making is a stable source of income that does not require large capital investments. This fact is due to numerous factors. The main ones are:

- low cost of equipment necessary for running a home business;

- the ability to produce a wide variety of cheese varieties at home using the same equipment;

- high demand for all types and varieties of products;

- even a novice entrepreneur can set up a sales market.

Any entrepreneur can learn how to make cheese at home. There is nothing extremely difficult about this. With the advent of experience, a homemade cheese maker will be able to produce elite varieties of such a useful product.

Home-made cheese types

Any cheese, regardless of what type it belongs to, will always be in great demand. Cheese making, as well as, is a stable business. Taking into account the methods of curdling milk, then all cheeses can be divided into two main categories.

Each category can be divided into several more subcategories and subspecies. Over time, any homemade cheese maker will be able to become an expert in the cheese industry and learn to understand all types of cheese.

Three kinds of cheese - three kinds of profit

In the functioning of the "cheese business" all varieties of this product have their own purpose and strengths. At home, you can produce three types of cheese:

- Solid. It does not require special storage conditions and is expensive. Such cheeses are stored for several months, and some for several years. The only condition is that the room must be well ventilated with an air temperature of + 12 ° C.

- Cottage cheese. It is a perishable product, but quick to prepare. It can be put on sale the next day after production. To extend the shelf life, it is enough to put the cheese in the refrigerator.

- Semi-solid. This product combines the features and benefits of the above two types. The production of semi-hard cheeses, in contrast to hard varieties, takes less time, while the product itself is stored much longer than cottage cheese. In addition, these cheeses increase the assortment, which contributes to an increase in the percentage of sales and profit from the sale of finished products.

Features of different varieties allow a business to quickly respond to all kinds of market changes, come up with short and medium-term strategies for the development of home entrepreneurship. The basement, where special conditions are created, complete with hard cheese, is a bank with deposits, a source of stable profit.

Advice: you should not start producing several varieties at once, it is better to limit yourself to 1-3 types. In the future, having evaluated the dynamics and rates of sales, it will be possible to make a decision to increase the range.

It should be noted that for the production of different varieties, one main product is needed - milk. In addition, the equipment is used the same (the only exceptions are some types of cheese). Only the recipes and production technologies differ.

Raw material requirements

For the production of cheese, you will need milk, sourdough or rennet. Some manufacturers use dyes to give the finished product a more beautiful color.

The main raw material used to manufacture the product is milk. It can be either goat or cow. It is better to use milk immediately "from under the cow", then the fat content of the cheese will be higher. Although partially filmed will do. After all, the main condition is the quality of the product, and it depends on the health of the animals.

In order for the mini-workshop to function without interruption, an agreement should be concluded for the supply of milk with the farm. The document must indicate the quantity of products supplied, payment options and quality requirements.

Sourdough is essential for acid formation. In the future, the taste of the cheese will depend on it. Some of its types are sold in stores, others can be prepared at home:

Recipe number 1... To make a starter culture with your own hands, you need to take 0.5 liters of fresh whole milk and place it in a dark place for a day (+ 30 ° C). This raw material is added to milk when making homemade cheeses that do not need a press.

Recipe number 2... You can also prepare sourdough with yeast. To do this, add 120 g of the product to a glass of warm milk. Then remove the mixture in a warm place and leave to ferment for 24 hours. Then you need to drain half of the milk and add fresh milk. The procedure should be repeated six more times over the course of one week. During the specified time, the raw material will mature and be ready for use.

Another main component is abomasum (a product obtained from the stomachs of young animals). Milk begins to curdle within an hour after the addition of enzyme preparations. In stores, they are more often found in the form of tablets and extracts. In addition, you can also see “vegetable” rennet on sale, because most cheese lovers are vegetarians.

Equipment for cheese dairy - price

For the production of homemade cheeses, as well as for the production, you need special equipment. Part of the inventory is always at hand for any hostess, some items can be made by hand. For home production, you may need:

- cheese dairy;

- forms of various volumes;

- Press;

- containers for milk (bottles, buckets and cans);

- thermometer;

- funnels;

- table scales;

- measuring spoons for dispensing bulk ingredients.

The cheese dairy is necessary for curdling milk and separating whey. This process implies the exact observance of the temperature regime for a specific period of time. In modern automatic cheese dairies, curdling takes place without human intervention. The only thing that is required is to set the time and temperature. This equipment is more suitable for small farms. For cheese making at home, small cheese dairies without a timer with the function of maintaining a constant temperature are more appropriate. The price of a cheese making machine depends on several criteria and ranges from 130,000 to 400,000 rubles:

- from power;

- from capacity;

- from the presence of additional regulating devices.

The mini-cheese dairy can process 100 liters of milk per day. And since the goods will be produced in limited volumes, there is no need to create special conditions for the ripening and preservation of the cheese. This means that there is no need to purchase additional equipment.

DIY mini cheese dairy

Some time ago, prices for mini-cheese dairies were sky-high, but with the advent of domestically produced models on the market, prices have dropped significantly. Today they cost a little more than the same usual multicooker or bread machine.

The main advantage of mobile cheese factories is that they can be used to prepare not only homemade cheese, but also cottage cheese, sour cream, and yogurt. In addition to everything else, such a device is compact, takes up little space, does not require complex maintenance and consumes little energy. The cheese dairy requires an ordinary socket and water. Processing 18 liters of milk takes approximately two hours. The output is 2 kg of hard cheese.

If desired, a cheese dairy can be made by hand. For living conditions, a 1.5 kW heating element is quite enough. The dairy must be able to connect to running water. For accurate compliance with temperature conditions, the device should be equipped with a special thermostat.

Molds for cheese at home

Each type of cheese has a special shape that has developed historically. Ripening, ease of handling, as well as transportation - all this strongly depends on the shape and size of the product. For example, a soft cheese like Camembert ripens from end to center. And if the product is too thick, then it simply does not have time to ripen to the end, and mold will begin to appear on its surface. If you make hard cheese too small, then it dries faster than ripens.

The purchase of special forms is advisable only when the skills of cheese making have already been acquired. Moreover, they are more appropriate for mass production. For cheese making at home, there is no fundamental difference in which form to lay the cheese mass. It can be either rectangular or cylindrical.

In the learning process, you can use homemade equipment. To make a mold for cheese, you need to take a 0.5 liter bucket of mayonnaise and pierce it with a heated knitting needle. Then cut the lid so that when immersed it reaches the middle of the bucket. That's all - the cheese mold is ready.

If the household has a 1 liter tin can, then you can use it to make the mold. The bottom of the container should be pierced with a nail so that the torn edges of the holes "look" outward. This will prevent deformation of the cheese. The inside of the jar should be lined with a cloth, and then filled with cheese mass and closed on top with a cloth. The mass is ready for spinning. Excess liquid will flow out through the hole.

Russian cheese production technology

A wide variety of cheeses can be produced at home. The manufacturing technology of each type is different, although the process uses the same equipment.

The process of making Russian cheese consists of the following operations:

- milk pasteurization;

- adding a special starter culture;

- curd formation;

- molding curd;

- pressing;

- salting;

- ripening.

Russian cheese is made from thermally processed milk with a fat content of at least 50% in dry matter, moisture - 40%, salt - 1.4-1.8%. Cheese weight 11-13 kg. A suitable shape is a cylinder 16-18 cm high and 34-36 cm in diameter. The finished product has a distinct cheesy, slightly sour taste and smell, a dense texture, a pattern of flattened, slit-like eyes. The surface is smooth and without subcrustal layer.

In thermally processed milk add 15-30 grams of calcium chloride per 100 kg of milk and 0.8-1% bacterial starter culture containing aroma and lactic acid streptococci, which play an important role in the maturation of this type of cheese.

Coagulation of the mixture is 20-30 minutes at t 30-32 ° C. The curd should be dense, so that sharp edges are obtained at the break. Next, it should be cut into cubes of 8-10 mm (cheese grain). By the end of the aging process for 10-15 minutes and kneading (30-40 minutes), the size of the cubes will decrease to 6-7 mm. During this time, up to 30% of the serum is removed,

Reheating is carried out at a temperature of 40-42 ° C and lasts no more than 20 minutes. Then the curd is kneaded for 30-50 minutes. This is done to dry the mass, partially lose the stickiness and increase the acidity. Then another 40% of the whey is separated, after which the curd is sent to molds lined with damp serpyanka (reinforcing material). The mass is compacted and then pressed.

Advice: do not throw away whey after boiling. If you take it back to the cheese dairy, add two liters of milk, a little apple cider vinegar and heat it to t + 92 ° C, then you can get delicious and appetizing cottage cheese, which means the first profit.

Before pressing, it is better to replace the serpyanka with a damp cloth, so the cheese will turn out to be more beautiful. During the first hour, the cheese is pressed under a pressure of 10-15 kPa, after which it is increased to 20 kPa, and then to 30-40 kPa. After eight hours, the pressure is reduced to 20-25 kPa. The total pressing time is 8-12 hours.

The next stage is salting in a 20-22% solution. The process time depends on the acidity, temperature of the product and the brine itself and increases depending on the weight of the cheese. For example, a 1 kg head takes 10-12 hours. The final step is drying and maturing. Shelf life is 4 months in film or paraffin at 2-4 ° C.

Save the article in 2 clicks:

Making cheese, like, is a profitable and promising business that can be organized by anyone without experience and special education. It is more profitable to open this business in a village or village near a large settlement, in a more remote area it is more difficult to translate this idea into reality, since good sales channels are needed.

In contact with

Photo from the sites turystycni-marky_com_ua.jpg, superski.ru, lady.ru

Dear readers, today we present to you an unusual article. This is a story that recently came to our mail. What is he talking about? In short, about how a person left a good position for the sake of cheese, and what in the end he got out of it.

Hello! Let me introduce myself - Andrey. I am a little over 30, until recently I worked as a commercial director of a large trading company in Moscow, I didn’t deny myself anything and lived happily ever after. But the moment came when I got sick of everything. Then the crisis struck ...

In general, I'm tired. There was a desire to quit work, house, car and rush for six months somewhere in Bali or Goa, or somewhere else, where the sea and warmth, no work and headache. Fortunately, finances allowed me to do this, and my friends, who had settled in warm lands a few months ago, invited me to visit. And I almost made up my mind, I was even going to sell the car.

But then something skipped a beat inside. “Hey, wake up! Why do you need it? Hang out on sandy beaches for six months, and then? Back to Moscow, to the glass office and again to the work you are running from now? " But it’s true! Six months of happiness and carelessness, and then ... No, I don't want that. But what to do? “Andrey, turn on your brain,” the inner advisor whispers to me. - Why don't you put the money into action. To their own business. " Here it dawned on me - I need to open a business, work for myself and for my own pleasure, then I will be happy.

But I faced a difficult choice. One acquaintance, having learned about my plans, immediately offered to become a co-owner of a new nightclub, another to become a restaurateur, a third campaigned to invest in a newfangled Internet project, and so on. In short, there were more than enough offers, but I felt that all this was not mine.

And then one day when I was buying my beloved italian cheese, the inspiration came. I will study cheese business! All is decided. And don't just sell someone else's made cheese, I will make this product myself, adored from childhood.

And then one day when I was buying my beloved italian cheese, the inspiration came. I will study cheese business! All is decided. And don't just sell someone else's made cheese, I will make this product myself, adored from childhood.

From that moment my business history began. The first thing I did was to buy some land adjacent to the land plot with a house in a village near Moscow that I had acquired a year ago. The next step was the selection of equipment for my mini cheese dairy and search for a technologist.

Here the choice turned out to be rather difficult. But, after talking on the relevant forums on the Internet, as well as visiting several farms with cheese dairies in Italy, having looked at the equipment produced by large and small firms (Pietrobiazi, Marican, Sfoggi) - thanks to friends who organized the excursions - I stopped at the equipment of a small Italian company Sfoggi. For half a century of its existence, she learned to produce a universal and inexpensive milk processing equipment... Especially - cheese dairies, on which you can make hard and soft cheeses, cottage cheese, pasteurize milk. The equipment of this company won over me with an ideal combination of manual labor and automation, modern technologies.

It is also important for me that the cost of equipment is not transcendental, while the equipment must be reliable, durable, well-proven. Another important factor is the post-sale service of the equipment by the supplier (as the latter, I chose the Impulse Group company). Having analyzed everything, I stopped, in my opinion, on the best option. Although it is possible that someone will find my choice strange, but, as they say, there are no comrades in taste and color.

So, I will continue. Everything about everything took me a little over fifty thousand euros. And this is a significant part of my savings. At that moment I was still working at the same place, so I did not feel any particular constraint in money, but I wanted to start mine as soon as possible, so that I could quit my job as soon as possible and plunge headlong into what I loved.

So, I will continue. Everything about everything took me a little over fifty thousand euros. And this is a significant part of my savings. At that moment I was still working at the same place, so I did not feel any particular constraint in money, but I wanted to start mine as soon as possible, so that I could quit my job as soon as possible and plunge headlong into what I loved.

And now the day has come. The equipment is installed and ready to work, a technologist and a couple of service personnel have been hired, an agreement has been reached on the daily supply of 1800 liters of milk with a neighboring farm. In short, everything is ready to go. Accordingly, I left the company where I had been working for many years, got into the car and rushed to the village to start production.

Now I will tell you a little about how my mini cheese dairy and the magical process of turning ordinary milk into wonderful cheese. But I will not reveal all the secrets, do not blame me.

First of all, we divide all the resulting milk into two parts. 600 liters are immediately sent to the cheese maker, and 1200 go to a special container, where they are cooled to plus four degrees Celsius. The milk that gets into the cheese maker is first pasteurized at a temperature of 65-72 degrees, and then cooled to 38 degrees.

We add enzyme and rennet to the cooled milk, mixing everything thoroughly. Soon the milk curdles into a curd mass. It breaks to pieces. If we're going to make it soft quick ripening cheese, then the pieces should be large, about the size of a walnut. If we are talking about ordinary cheese, conditional type "Russian", then the pieces are needed smaller, close in size to hazelnuts.

Then the broken mass is distributed by an automatic machine according to the forms, placed on a special heated pallet. In this case, the whey, in which the cheese mass floats, flows into a special container.

Then the broken mass is distributed by an automatic machine according to the forms, placed on a special heated pallet. In this case, the whey, in which the cheese mass floats, flows into a special container.

Here comes the first pause in the production process. After all, the future cheese in the forms should be compacted. This can be done using a special press, or it can be done in a multifunctional tub, where the cheese mass flows from the cheese dairy, filling in the forms. When all the forms are filled, the bath lid is closed, the heating turns on. Due to the high humidity and temperature, self-pressing of the cheese circles occurs, which after a couple of hours can be placed in a saline solution for salting.

Remember the whey that dripped when molding the cheese mass? So, I do not pour it into the sewer, but put it into business, earning extra money on this seemingly waste. Ask how? It's simple, we make diet cottage cheese out of it. To do this, the whey is pumped back into the cheese maker, mixed with two liters of milk and a small amount of apple cider vinegar. All this heats up to 92 degrees, and, voila, we get the freshest and tastiest cottage cheese.

And here mini cheese dairy brings me the first money. This, as you probably already guessed, is the sale of cottage cheese. Interestingly, I didn't have to look for consumers of this by-product for a long time. First, a confectionery shop in a neighboring town buys it in large quantities. Secondly, I deliver ecologically clean and natural cottage cheese, which is stored for just a couple of days, to a Moscow store of eco-products, where it goes with a bang. And this alone brings a good income.

But back to cheese. Depending on what kind of cheese we want to get, the blanks are either immersed in a brine bath for several hours or a day, or they are sprinkled with coarse salt on all sides. After the salted cheese is sent to the refrigerator, where it is stored at a temperature of plus 4 to 12 degrees.

| Typical Italian family farm cheese dairy |

| 100-120 cows in stall housing which are looked after by one employee (feeds, cleans, milks). Husband, wife and wife are engaged in milk processing from morning till lunchtime. The cooking process takes place in an automated cheese dairy with a capacity of 600 liters and lasts from 2 to 4 hours. Every day they make 2-4 boiling of cheeses, cottage cheese, pasteurization of milk - all on one set of equipment. After dinner, the wife takes care of the house, the husband soaks the cheeses in saline, vacuum-wraps the cheese slices or small circles of cheese for sale, pours pasteurized milk into PET bottles. The farm has a small shop with a daughter behind the counter. The constant assortment includes 15-20 varieties of cheese, cottage cheese, milk in bottles. Surplus milk is sold to wholesalers. |

Perhaps the most important thing begins here. Depending on the type cheese, the heads are laid out on racks, where they will be stored from 2-4 weeks to several months. They require daily inspection, turning and, if necessary, additional salting of the surface. Currently, the bulk of my cheese ripens in about a month. But I leave some of the products for a much longer period. After all, these are my future masterpieces - cheeses that have ripened for at least a year!

The demand for such a product in the premium segment is quite high, but foreign manufacturers dominate here. I do not expect to squeeze them out yet, but I intend to win the hearts of true fans of cheese with my novelties, but for the price I can significantly beat foreigners, and this is with quite comparable quality. And I myself am not averse to eating a similar product. After all, as a matter of fact, partly for the sake of this I started this whole enterprise.

Basically, this is where my story about cheese production ends. It's time to take stock of some results. So, we produce up to three different types of cheese per day. Plus, we produce cottage cheese, which literally "off the wheels" every day.

As for the implementation of cottage cheese, it was said above. I sell cheese through three channels. Firstly, these are supplies to the same eco-shops, including online ones, as diet cottage cheese, where organic cheese from a private cheese dairy is very well sorted. Secondly, there is a small shop at the cheese dairy that sells mostly inexpensive cheese for local residents. Thirdly, I recently entered into supply contracts with several restaurants.

As you can see, the business was quite successful. Although, to be honest, it's still not worth talking about an enterprise younger than a year. But, at least, I get from my work such moral satisfaction (and financial as well), which I could not even dream of before, and I don’t want to go on vacation yet. But there is a great desire to develop their business further, and there are a lot of plans here.

For example, I decided to master a new direction. I really love the salad with mozzarella, basil, tomatoes and balsamic vinegar. But how annoying it is to buy foreign cheese for him, and not the one made at my cheese dairy. So, soon my equipment park will expand due to the appropriate machine for the production of this delicate product.

In addition, the thoughts have an expansion to the scale of a typical Italian family cheese dairies... True, for this I have to at least become the owner of a herd of hundreds of cows and get married. The latter, I hope, will happen in the near future. And finally, I dream of opening a “cheese boutique”, or maybe several, following the example of those that I saw in Switzerland. But that's a completely different story.

Dear readers, today I will present you with an unusual article. In our country, cheese enjoys well-deserved popularity and love among all segments of the population. This is a story that recently came to our mail. What is he talking about? In short, about how a person left a good position for the sake of cheese, and what in the end he got out of it.

My Kingdom for Cheese, or How I Opened a Mini Cheese Dairy

Hello! Let me introduce myself - Andrey. I am a little over 30, until recently I worked as a commercial director of a large trading company in Moscow, I didn’t deny myself anything and lived happily ever after. But the moment came when I got sick of everything. Then the crisis struck ...

In general, I'm tired. There was a desire to quit work, house, car and rush for six months somewhere in Bali or Goa, or somewhere else, where the sea and warmth, no work and headache. Fortunately, finances allowed me to do this, and my friends, who had settled in warm lands a few months ago, invited me to visit. And I almost made up my mind, I was even going to sell the car.

But then something skipped a beat inside. “Hey, wake up! Why do you need it? Hang out on sandy beaches for six months, and then? Back to Moscow, to the glass office and again to the work you are running from now? ”. But it’s true! Six months of happiness and carelessness, and then ... No, I don't want that. But what to do? “Andrey, turn on your brain,” the inner advisor whispers to me. - Why don't you put the funds into action. To your own business. " Here it dawned on me - I need to open a business, work for myself and for my own pleasure, then I will be happy.

But I faced a difficult choice. One acquaintance, having learned about my plans, immediately offered to become a co-owner of a new nightclub, another to become a restaurateur, a third campaigned to invest in a newfangled Internet project, and so on. In short, there were more than enough offers, but I felt that all this was not mine.

And then one day, when I was buying my favorite Italian cheese, an inspiration came. I'll be in the cheese business! All is decided. And not just sell cheese made by someone else, I myself will produce this product, adored since childhood.

My business story

From that moment my business history began. The first thing I did was to buy some land adjacent to the land plot with a house in a village near Moscow that I had acquired a year ago. The next step was the selection of equipment for my mini-cheese dairy and the search for a technologist.

Here the choice turned out to be rather difficult. But, after talking on the relevant forums on the Internet, as well as visiting several farms with cheese dairies in Italy, looking at the equipment produced by large and small firms (Pietrobiazi, Marican, Sfoggi) - thanks to friends who organized the excursions - I stopped at the equipment of a small Italian company Sfoggia. For half a century of its existence, it has learned to produce universal and inexpensive equipment for milk processing. Especially - cheese dairies, where you can make hard and soft cheeses, cottage cheese, pasteurize milk. The equipment of this company bribed me with an ideal combination of manual labor and automation of the technological process, modern technologies.

It is also important for me that the cost of equipment is not transcendental, while the equipment must be reliable, durable, well-proven. An important factor is the post-sale service of the equipment by the supplier (as the latter, I chose the Impulse Group company).

Having analyzed everything, I stopped, in my opinion, on the best option. Although it is possible that someone will find my choice strange, but, as they say, there are no comrades in taste and color.

So, I will continue. Everything about everything took me a little over fifty thousand euros. And this is a significant part of my savings. At that moment, I was still working at the same place, so I did not feel any particular constraint in money, but I wanted to start my mini-cheese dairy as soon as possible in order to quit my job as soon as possible and plunge headlong into my favorite business.

Equipment installed

And now the day has come. The equipment is installed and ready to work, a technologist and a couple of service personnel have been hired, an agreement has been reached on the daily supply of 1800 liters of milk with a neighboring farm. In short, everything is ready to go. Accordingly, I left the company where I had been working for many years, got into the car and rushed to the village to start production.

Now I'm going to talk a little about how my mini cheese dairy works and the magical process of turning regular milk into wonderful cheese. But I will not reveal all the secrets, do not blame me.

First of all, we divide all the resulting milk into two parts. 600 liters are immediately sent to the cheese maker, and 1200 go to a special container, where they are cooled to plus four degrees Celsius. The milk that gets into the cheese maker is first pasteurized at a temperature of 65-72 degrees, and then cooled to 38 degrees.

We add enzyme and rennet to the cooled milk, mixing everything thoroughly. Soon the milk curdles into a curd mass. It breaks to pieces. If we are going to make a quick ripening soft cheese from the mass, then the pieces should be large, approximately like a walnut. If we are talking about ordinary cheese, of the conditional type "Russian", then smaller pieces are needed, close in size to hazelnuts.

Then the broken mass is distributed by an automatic machine according to the forms, placed on a special heated pallet. In this case, the whey, in which the cheese mass floats, flows into a special container.

Here comes the first pause in the production process. After all, the future cheese in the molds should be compacted. This can be done using a special press, or it can be done in a multifunctional tub, where the cheese mass flows from the cheese dairy, filling in the forms. When all the forms are filled, the bath lid is closed, the heating turns on. Due to the high humidity and temperature, self-pressing of the cheese circles occurs, which after a couple of hours can be placed in a saline solution for salting.

Remember the whey that dripped when molding the cheese mass? So, I do not pour it into the sewer, but put it into business, earning extra money on this seemingly waste. Ask how? It's simple, we make diet cottage cheese out of it. To do this, the whey is pumped back into the cheese maker, mixed with two liters of milk and a small amount of apple cider vinegar. All this heats up to 92 degrees, and, voila, we get the freshest and tastiest cottage cheese.

And here the mini-cheese dairy brings me my first money. This, as you probably already guessed, is the sale of cottage cheese. Interestingly, I didn't have to look for consumers of this by-product for a long time. First, a confectionery shop in a neighboring town buys it in large quantities. Secondly, I deliver ecologically clean and natural cottage cheese, which is stored for just a couple of days, to a Moscow store of eco-products, where it goes with a bang. And this alone brings a good income.

But back to cheese. Depending on what kind of cheese we want to get, the blanks are either immersed in a brine bath for several hours or a day, or they are sprinkled with coarse salt on all sides. After the salted cheese is sent to the refrigerator, where it is stored at a temperature of plus 4 to 12 degrees.

Typical Italian family farm cheese dairy

100-120 cows in stall housing which are looked after by one employee (feeds, cleans, milks). Husband, wife and wife are engaged in milk processing from morning till lunchtime. The cooking process takes place in an automated cheese dairy with a capacity of 600 liters and lasts from 2 to 4 hours. Every day they make 2-4 boiling of cheeses, cottage cheese, pasteurization of milk - all on one set of equipment. After dinner, the wife takes care of the house, the husband soaks the cheeses in saline, vacuum-wraps the cheese slices or small circles of cheese for sale, pours pasteurized milk into PET bottles. The farm has a small shop with a daughter behind the counter. The constant assortment includes 15-20 varieties of cheese, cottage cheese, milk in bottles. Surplus milk is sold to wholesalers.

Perhaps the most important thing begins here. Depending on the type of cheese, the heads are laid out on racks, where they will be stored from 2-4 weeks to several months. They require daily inspection, turning and, if necessary, additional salting of the surface. Currently, the bulk of my cheese ripens in about a month. But I leave some of the products for a much longer period. After all, these are my future masterpieces - cheeses that have ripened for at least a year!

The demand for such a product in the premium segment is quite high, but foreign manufacturers dominate here. I do not expect to squeeze them out yet, but I intend to win the hearts of true fans of cheese with my novelties, but for the price I can significantly beat foreigners, and this is with quite comparable quality. And I myself am not averse to eating a similar product. After all, as a matter of fact, partly for the sake of this I started this whole enterprise.

Basically, this is where my story about cheese production ends.

Let's sum up

It's time to take stock of some results. So, we produce up to three different types of cheese per day. Plus, we produce cottage cheese, which literally “off the wheels” every day.

As for the implementation of cottage cheese, it was said above. I sell cheese through three channels. Firstly, these are supplies to the same eco-shops, including online ones, as diet cottage cheese, where organic cheese from a private cheese dairy is very well sorted. Secondly, there is a small shop at the cheese dairy that sells mostly inexpensive cheese for local residents. Thirdly, I recently entered into supply contracts with several restaurants.

As you can see, the business was quite successful. Although, to be honest, it's still not worth talking about an enterprise younger than a year. But, at least, I get from my work such moral satisfaction (and financial as well), which I could not even dream of before, and I don’t want to go on vacation yet. But there is a great desire to develop their business further, and there are a lot of plans here.

For example, I decided to master a new direction. I really love the salad with mozzarella, basil, tomatoes and balsamic vinegar. But how annoying it is to buy foreign cheese for him, and not the one made at my cheese dairy. So, soon my equipment park will expand due to the appropriate machine for the production of this delicate product.

In addition, the idea is to expand to the scale of a typical Italian family cheese dairy. True, for this I have to at least become the owner of a herd of hundreds of cows and get married. The latter, I hope, will happen in the near future. And finally, I dream of opening a “cheese boutique”, or maybe several, following the example of those that I saw in Switzerland. But that's a completely different story.

//www.equipnet.ru/articles/power-industry/power-industry_693.html

Cheese production

One of the promising lines of business in food production is cheese production. Where to start, what costs and income - read on.

Today, for the production of dairy products, it is not necessary to open a huge factory that is served by a huge number of personnel. Such a business can even be opened at home. Cheese production as a business does not require huge investments and generates a stable income.

Types of cheese

The cheese sold in Russia is divided into types:

- hard (hard texture since it has been pressed, it cuts well, goes well into the grater; examples are cheddar, parmesan, gouda, etc.)

- soft (soft co-essence, most often with mold; famous examples are Camembert, brie)

- semi-hard (a cross between soft and hard, a famous example is edam ball)

- brine (what is sold in brine or containing salt are types of feta cheese and suluguni, various "Adyghe", domestic mozzarella, etc.)

The most popular varieties on sale are hard.

There is also a whole processed cheese industry. remember cheese in trays and processed curd cheeses "Druzhba", famous in their time.

Speaking about a small cheese production, you can start from another division into products by type:

- solid;

- soft;

- home.

Hard cheese

It can be obtained from curd, which must be pre-washed and separated from the whey. The curd should be pressed until it starts to taste. Sometimes it is pressed for one month. The resulting product can be eaten almost immediately. Aged cheese, however, tastes much better. In order to get the most solid product possible, it is necessary to use whole milk. This cheese is in great demand. Therefore, the production of hard cheeses is the most profitable.

Soft cheese

Its production technology is the same as that of hard cheese. The only major difference is that you need to keep it under pressure a lot less. One week is enough to get the finished product. The production of soft cheeses is carried out using skimmed or whole milk.

Homemade cheese

Homemade cheese is called soft cheese, which is made from special cottage cheese containing a large% of water. Quite often it is made from skim milk. However, the production of homemade cheese can also be carried out with whole milk. This technology is the simplest.

The cheese factory is a stable business, as this dairy product will always be in demand. However, be prepared for the fact that this is not the kind of business that you can start with a minimum investment.

Get ready for the costs. Even a small production will require a decent investment.

A room of 300 square meters or more, ceilings of 3.5 m, water supply and sewerage, a good access road, compliance with sanitary norms and rules (SanPiN 2.3.4.551-96).

All this will draw 5-7 million, and in the case of production of hard varieties - 12-13 million, with a capacity of 1400 kg per day. A plus will go to the costs of installation, equipment for storing the finished product, rent, salary, taxes and other costs.

Please note that this is food production, which means you need permits, certificates for products.

Experienced entrepreneurs say that getting into this business cannot have less than 30 million rubles in heart. And expect a payback in less than 3-4 years.

If you open it in a completely mini-format, then the investments will still be significant:

- line purchase 300 thousand rubles

- repair of the premises under the requirements of SanPin 200 thousand rubles

- registration, permits, documentation 100 thousand rubles

- personnel training 30 thousand rubles

As a result, the amount of investments was about 630 thousand rubles.

Plus monthly expenses, which will be a big burden until production and distribution are established. For example (not in the capital) - rent, electricity, water supply - 40-60 thousand, advertising - 20, salary - 45 (4 people), other -30-40 thousand.

If you are not intimidated by the input data, then let's turn to the details.

Cheese production as a business

Economically, making cheese at home has many advantages. It is quite easy to calculate the profitability of such a production. For example, we can assume that the cost of one liter of milk will cost 25 cents. From one hundred liters of milk, about ten kilograms of hard cheese is obtained. Its approximate cost is eight dollars per kilogram. Thus, you can get 55 dollars in profit from the sale of ten kilograms of finished products.

Business profitability can be viewed in more detail in numbers

During production, the yield of finished products directly depends on what kind of cheese is produced. The yield of soft cheeses is 20%, hard - 10%, semi-hard - 15%. The indicators can be significantly increased if you use a special container for receiving milk.

It takes about 3-4 hours to cook. This has a positive effect on work productivity. Indeed, within one day, you can make 3 brews.

You can use the same equipment in the production of almost any grade. Exceptions include aesthetic varieties that are not very popular.

For storing products, you need a room equipped with good ventilation. Also, it is necessary to maintain the temperature at +10 degrees. You don't have to look for a very large room. For such purposes, at first, an area of 15 square meters is enough.

When opening the production of cheese, one cannot do without special equipment - a cheese maker. Its cost depends on the model. For home production, a device with a volume of 10 liters is suitable. Its price is about $ 500. There are also more voluminous models. Their price reaches thousands of dollars.

Equipment

For starters, a cheese line may include the most basic equipment. However, you can buy the rest later. Homemade cheese making technology may include the following equipment:

Cheese maker

It must be equipped with a heating element with a power of about 1.5 kW. It would be nice if it could be connected to running water. In order to independently regulate and control the operating temperature, you need to use models with a built-in thermostat.

- milk sterilizer;

- molds made of special food grade plastic;

- strainer colander;

- special container for salting;

it is made of stainless steel; - weights for pressing cheese.

Their weight should be about five kilograms. You can use a press instead.

Auxiliary equipment

Ancillary equipment includes:

- container for a set of whey;

- container required to drain the product;

- milk cooler.

The above equipment is quite enough for the organization of production. The advantages include the fact that it does not need careful maintenance and does not require any special conditions during its operation. There is no need to look for additional finances for preventive maintenance or repair.

Equipment manufacturers

First of all, it is worth considering domestic manufacturers.

For example, PC Molekspert LLC, Barnaul. Mini cheese making tub with a loading volume of 70 liters. costs from 200 thousand rubles, and is suitable for the production of cheese, cottage cheese, drinking pasteurized milk. Here you can also buy a vertical pneumatic cheese press (for 24 cells at a price of 520 thousand rubles) and a molding apparatus for forming a cheese bed and subsequent pressing at a price of about 1 million 220 thousand rubles.

Equipment made in Italy is also in demand.

The multifunctional cheese dairy Sfoggia Sfoggiatech with a capacity of 120 liters allows the production of several types of cheese, cottage cheese, pasteurized milk. Production is carried out with a maximum heating of milk up to 100 degrees. The price tag for a set of cheese-making equipment from this company starts from 99 thousand euros.

Quality certification

Home manufacturing is a real business. If you plan to sell the resulting product, you will have to issue a special certificate for cheese.

Since 2014, the certification of cheese has been carried out on the basis of the regulatory document TR 033/2013 "On the safety of milk and dairy products", and is carried out in the so-called form of declaration. You can correct certificates for the cyclical production of cheese, or you can - for individual lots of cheese. The documentation provides for both of these options.

For example, if you need to organize the production of processed cheese, then for its production you need to receive a declaration OKP 92 2511. It can be issued for a contract, or for the manufacturer himself.

To obtain a certificate, you will have to prepare the following documents:

- cheese research protocols;

- previous certificates, if any;

- description of raw materials, production equipment and production processes;

- regulatory documents (technical regulations, GOSTs), on the basis of which the production process is conducted;

- contracts for raw materials and the supply of cheese (if cyclical production is certified);

- other documents that would indicate the quality of the products received.

The validity period of certificates for individual batches is equal to the shelf life of this product. If the certificate was rectified for cyclical production - no more than 5 years.

Cheese production requires compliance with standards (67.100.30 Cheese), or GOSTs (27568–87, 52685–2006, 52686–2006, 52972–2008, 53379–2009, etc.)

Cheese business prospects and income

Mini-business 20-24 kg

Take the smallest business as an example. Mini-workshop with a daily production volume of about 20-24 kg.

According to those who are already on their own experience in the subject, such a workshop will require about 200 liters of milk per day, and in monetary terms, the cost of such production per month is about 1.7-2 million rubles. This includes milk as raw materials, enzymes and additives in milk, salaries, taxes, electricity, transportation, rental of premises and other necessary expenses.

100 kg of cheese per day

If we move to the next level and start producing 100 kg of cheese per day, the situation looks like this:

- 2200 kg approximate sales of finished products per month;

- revenue of 440 rubles per month (at a selling price - 200 rubles per 1 kg);

- net profit 50-70 thousand rubles per month.

Here, the payback is possible in a year, but this is when calculating 100% of the sales of the product.

Problems and solutions

It should be remembered that the purchase of cheeses in chain stores starts at 200-250 rubles. per kg. According to the calculations of those who have already opened production, with the purchase price of milk from 20 rubles per liter and higher, production in such small volumes is unprofitable.

Income can be obtained only by raising purchase prices to 300 rubles per kg of production, and lowering the cost of milk to 10 rubles per liter. And this, in turn, is possible with your own herd. In this case, the line for the production of your own cheese should pay off in 3-4 years.

What can you do if you don't have your own herd?

Give up the idea of attaching your product to networkers. In small shops, products are ready to take in small volumes, while there are many such shops.

It makes sense to rent a tent at a market that sells farm food. Customers will quickly get used to your tent and products, and this will be a cheese marketing coup.

Also, be sure to work on your milk supply. We need a stable supply of quality milk at a cheap price. Look for farms in the area that can provide you with the right amount of starting product. And then there will be a chance to promote your business on cheese.

Rules for products to be loved by consumers

In order for the products to meet all taste requirements, it is recommended to adhere to important rules:

- use only high-quality milk from healthy cows during production;

- do not add antibiotics to products;

- monitor the level of active acidity. It should not exceed 6.8;

- the acceptance temperature should be within 12 degrees, and the fat content should be about 3.5;

- all of the above indicators must be indicated in the contract concluded with the supplier of raw materials.

Consumers have recently been very good at natural products, “homemade” products made without the use of chemical additives, flavors, thickeners, etc., and are willing to pay more for them than their “fair price” based on costs and industry-specific margins.

https://rabota-na-sebja.ru/proizvodstvo-syra/

Cheese is one of the most popular dishes, known since ancient times. Its preparation can truly be considered an art, as it is quite complex. In addition to the basic recipes, you should experiment during the preparation process. The best option would be to create your own brand, your brand. Therefore, the production of cheese as a business in the form of a mini-workshop is quite a profitable and interesting business.

Advantages

They lie in the demand for the product and high profitability. This business is pretty simple and scalable. There is a possibility of introducing various types of cheese, both regular and premium. In addition, it is worth considering the large number of markets for these products. In Russia, due to import substitution, this niche is more than relevant.

What should you pay attention to?

First of all, it is worth analyzing the market and the most demanded positions of competitors among buyers. It is important for an entrepreneur to find out the taste of the most popular types and to do it even better, or at least in the same way. Take a closer look at the demand for cheese products in general. All of this can be done through market research and consumer surveys. When your product hits the market, it's important to remember to take taste feedback from customers.

Where to open?

If there is no purpose of opening a store near a production facility, then there is not much difference in the location. The place can be a warehouse or a workshop. But it is important that the premises meet all the requirements of the SES. Interior finishing, flooring and a high level of hygiene must be carried out. Based on the fulfillment of these requirements, the epidemiological authority issues its conclusion and permission to work.

How much to invest?

The amount of investment depends on what production volumes are planned. For starters, it is recommended to start with the simplest production line. If there are no funds at all, you can start with making cheese at home. This product is quite cost-effective, which will allow organizing systemic production in a short time.

How to advertise?

In the case when the production is at home, then the promotion must be done through the Internet and social networks. If possible, a product site will be a good channel of attraction. You can also use outdoor advertisements, flyers and advertisements. If the production is registered and organized professionally, you need to register a trademark. Under it, produce different flavors, organize tastings and promotions in retail outlets.

Difficulties

Depending on what resource you lack, there will be various difficulties. For example, where to find an investment or a company that leases equipment. If there is no idea about the technology of cheese making, you need to buy or develop it. It is important to think over the conditions of storage and transportation of the finished product. It is worth taking care of the condition of the room in which the work is done.

First, you need to write a business plan for the upcoming enterprise. It should be with all the miscalculations and a detailed description of the entire process. Based on this, you need to organize sales channels. These channels are retail outlets, other entrepreneurs, wholesale buyers. You can contact a distribution company, which will sell products for a percentage.

Where to sell:

- wholesale bases;

- resellers;

- distributors;

- markets;

- supermarkets;

- small shops;

- catering establishments.

Competition

According to market research, the niche is not particularly competitive. Despite the simplicity of the business, not everyone can do it. Therefore, having a good recipe that satisfies the tastes of customers, you can enter the market. You just need to make it a little tastier and cheaper than the competition.

Cheese production as a business, mini home workshop

During the crisis, many wondered about the production of cheese as a business. Is a mini workshop a prerequisite for this enterprise? However, before raising such global questions, let's start from scratch, let's figure out how to avoid the problems that await entrepreneurs.

Cheese is a product with an original taste that is in high demand among customers. It is included in the diet of any of us. Probably everyone knows about the beneficial properties of cheese products. This raw fermented milk product is quickly absorbed by the body, saturates it with many useful substances: proteins, fats, phosphorus and calcium salts.

A variety of types of cheese is a great opportunity to choose what suits your taste (processed cheese, hard cheese, cottage cheese). Such a great demand for finished raw fermented milk products necessarily generates competition, which will never be avoided. However, despite this, it makes sense to organize your own home production of cheese, to open a mini workshop - a business at home.

Where to start a homemade cheese making business?

There are many lucrative business ideas for making good cheese that avoid complexities. First of all, it is important to follow a sound business plan. This will make it possible to predict the demand and competition in the presented area, to determine the financial investments and the project's self-sufficiency period. In addition, you will be able to predict difficulties, troubles and avoid mistakes when implementing a business idea at home.

How to get documents and register a business?

To start making a raw fermented milk product at home, to open your own mini workshop, you need to collect documents and register in accordance with the law. There are two ways - registration as an individual entrepreneur or as a legal entity (LLC). If you are aiming to open a mini production workshop at home and sell a raw product in small batches, then it is more optimal to register as an individual entrepreneur. If you do decide to open a factory, register as a “limited liability company”.

Certification of raw fermented milk products

Since cheese is a food product, its production is subject to special certification. To obtain permission for the manufacture of raw fermented milk products, you will need to collect a number of documents:

- Contract;

- application;

- sanitary registration certificate;

- veterinary certificate;

- mock up labels

Cheese production technology at home

There are many types of cheese, but they are all conventionally divided into hard and soft varieties. Having organized your own mini home workshop, it is quite possible to produce all types of fermented milk products, as well as Italian cheese.