Independent spring unit: efficient systems for mattresses and upholstered furniture. Machines for the production of independent spring blocks (TFK) Independent spring blocks production in the urals

We are glad to welcome you to our website!

The Vinyltex company delivers upholstery materials every day! The term for forming an order is 1-3 days.

1. Delivery in Moscow and the Moscow region (MO)

- Within the Moscow Ring Road from 400 to 800 rubles;

- Outside the Moscow Ring Road 600 rubles. + 30 rubles for each km;

- Express delivery from 900 to 1500 rubles.

- Departure of the courier with samples in Moscow 500r.

Delivery is carried out to the entrance or checkpoint.

2. Delivery to regions of Russia

- Delivery to regions of Russia, cities of neighboring countries is carried out transport companies(TC) - "Business lines", "Energy", "Zheldor expedition", "PEK", "SDEK" The cost of delivery of goods to the point of departure in Moscow - 500 rubles. At the request of the client, delivery by other shopping malls is possible.

See the cost of TC services on the websites of the companies. - Delivery in the regions of Russia by cash on delivery is possible through the SDEK shopping center.

3. Delivery to foreign cities

Delivery to the cities of the far abroad is carried out only to individuals through the TC "SDEK" and EMC Mail Russia.

4. Delivery by Russian post (including cash on delivery)

- Delivery of the order to the post office in Moscow and execution of the necessary documentation - 400 rubles

- EMS delivery by Russian post. Details on the website www.emspost.ru

5. Pickup.

Four stores in Moscow work for you every day. Store addresses and opening hours can be found here.

6. Departure of the courier with samples of materials in Moscow.

Our employee will show you samples of materials, help you with their selection and ordering. The cost of the service is 500 rubles. For details, check the ones indicated on the website.

Payment

1. Cash settlement

Payment in our stores or to the courier upon receipt of the goods. In cases of making products according to your size, you need to make an advance payment in one of our stores.

2. Cashless payments

- For individuals: payment is available using the Sberbank account number.

- For legal entities: send the details of your organization by e-mail - [email protected] When requesting an invoice, indicate the taxation system - (with or without VAT)

3. Electronic money

Individuals can pay for goods through electronic system"Yandex money".

4. Cashless payments

Payment for materials can be carried out through the monetary systems of Unistream, Western Union, Blizko, etc.

For details on payment options, check with the managers by e-mail or by phone numbers indicated on the website.

A very important component of the mattress is its spring base. The service life of the product and its orthopedic properties depend on how well the block is made, what materials were used. For the manufacture of independent spring blocks, I use three components:

Almost every person who first encountered the purchase of a mattress has a number of questions regarding the spring base of the mattress. What is an independent spring block? How does he work? What are its differences? Why is it best to buy a mattress on such a block?

We will reveal the answers to all these questions in the course of a thorough analysis of the production process of spring blocks. You will see for yourself that everything is actually elementary simple and quite understandable.

So let's get started. As already mentioned above, the guarantee of a good product is in three components. The wire we use is made of hardened high-carbon steel, smooth without cracks and cavities, with a diameter of 1.8 mm. Supplied in coils, which are filled into the machine for the production of spring blocks. In the first compartment, the wire is twisted into a seven-turn, barrel-shaped spring and cut off. The finished spring enters the next compartment. It is important to note that modern technology does everything very efficiently and quickly. The output springs are one-to-one, and the production flow has a very high speed... The master can program the machine for the required number of turns and the height of the springs. Indicate what wire diameter is used and all its characteristics, thus, modern equipment can produce several types of springs that will be used in the production of mattresses. Their number in the block depends on the diameter of the spring. In the block of independent springs TFK, the diameter of the spring is 5 cm, the density of the springs per square meter is 306 pcs. In a block of independent springs Multipack spring diameter 2.5 cm, density of springs per square meter 500 pcs. In a block of independent springs Micropackage, the diameter of the spring is 1.5 cm, the density of the springs per square meter is 1000 pcs.

In the next compartment, the machine wraps the springs in a durable spunbond non-woven fabric. This material was not chosen by chance. It has high strength, is not subject to abrasion, is well ventilated, keeps its shape, and most importantly, it is absolutely safe for health. In the next compartment, the springs are separated by a special press, each spring receives its own separate "bag". At the exit, a spring tape is obtained. At this stage, it is important to note that although the springs have a common tape, they are absolutely independent of each other and do not contact each other in any way.

In the next compartment, the machine applies a thin stream of glue to the side of a row of springs and holds them together. Again, the material is connected to each other, and not the springs. A predetermined number of rows glued into a single structure is tested under the press, and is displayed on the table, from where the master takes the finished block. The glue used in production has high adhesion, strength and heat resistance.

We have covered all the stages of creating a block of independent springs. We drew your attention to the fact that in the block the springs do not interact with each other, fastening in rows occurs due to the material in which the springs are wrapped. This design of the block allows each spring to be compressed under load not to act on adjacent springs.

The mattress, based on a block of independent springs, is able to bend under each part of the body in accordance with the load as much as necessary, while maintaining the position of the body in an even state. It is such a mattress that is considered orthopedic, that is, capable of maintaining the correct position of the body during sleep.

An important point is the absence of any noise and squeaks in the mattress, because the springs do not interact with each other.

On double mattresses, two people each have their own sleeping zone, which in no way intersect and do not affect each other. Accordingly, turning over in a dream, lying down or getting out of bed, you will not disturb the other person in any way. The same cannot be said about mattresses on dependent springs, where the entire surface is uniform and the slightest vibrations are transmitted over the entire surface.

Another important feature of the block of independent springs, which affects the mattress's lifespan, is the flexibility of the springs. Thanks to it, it is not a soft layer of filler that works in the mattress, pushing under load, but a spring block. Everyone knows that metal is more durable than latex, coconut or polyurethane foam. In the Bonnel block, the springs are quite stiff and the filler in such mattresses is, as it were, in a vice - the load of a lying person presses on it from above, and an elastic spring from below. Thus, the wear of the filler in such a situation occurs much faster. In blocks on independent springs, due to the small diameter of the wire, the spring is easily fed under the load transmitted through the filler, thereby minimizing the compression of the soft layers of the mattress.

The mattress on a block of independent springs will last a long time and will delight its owner with a high level of comfort!

Bonnel spring mattresses

Bonnel spring blocks The history of the production of orthopedic mattresses began with the production of mattresses on the basis of Bonnel spring blocks. Let's see what is their basis? The spring blocks are dependent, that is, the cone springs are connected to each other by special nodes for additional rigidity. This design has both advantages and disadvantages. As for the merits:

Orthopedic mattresses based on the Bonnel spring block are suitable for people with a large body weight, since, due to their rigidity, they are able to withstand heavy loads

These mattresses are quite durable, as they retain their elastic properties for a long time due to the use of durable materials

There is an air gap between the springs, which is also important, since sufficient air exchange determines the presence of the so-called bellows effect

Orthopedic mattresses based on Bonnel spring blocks are the most economical option, since their production does not require large costs.

Unfortunately, these orthopedic mattresses are not devoid of one big drawback - due to the peculiarities of the connection of the springs, a person's weight is not distributed in the best way. As a result, the spine cannot take the most optimal position.

The basis of most modern mattresses is an independent spring block. In the production of mattresses of our company, high-quality spring blocks are used. own production, both the traditional Bonnell type and modern blocks, consisting of independent springs.

Basic Support - a classic block of dependent springs is a system of five-coil springs, held together by a spiral made of high-carbon steel spring wire. The unit is fitted with steel frames at the top and bottom for added strength.

Basic Support - a classic block of dependent springs is a system of five-coil springs, held together by a spiral made of high-carbon steel spring wire. The unit is fitted with steel frames at the top and bottom for added strength.

In an independent spring block, each spring is housed in a separate non-woven "cup", which allows for a comfortable sleep, avoiding the "wave effect" when the compression of one spring entails the compression of all other springs in the spring block. Mattresses on an independent spring block have become very popular with buyers all over the world: they provide the necessary comfortable conditions for sleeping and rest, maintaining the correct position of the spine.

Unique independent block "Revolution" For the first time in an independent block the principle of Bonnell springs is applied! In this regard, in accordance with the requirements of the equipment manufacturer Spuhl AG, special attention is paid to the insulating pocket made of nonwoven fabric, in which the spring is placed. The pocket has an even regular shape, due to which the central part of the "Revolution" spring does not have a "fitted" silhouette, unlike existing analogues. As a result, the contact of the metal with the insulating material - spunbond - is completely excluded during operation. This pocket is specially designed by Spuhl to avoid abrasion of the spunbond when maximum loads... The absence of a "fitted" pocket, in which the spring is placed, allows much more glue to be applied to the central part of the spring, evenly distributing it; as a result, the gluing area increases, and the breaking characteristics of the "Revolution" block are improved. The spring itself is conditionally divided into three parts - the middle part, due to the successive narrowing of the coils, has the greatest elasticity and works at maximum loads, the upper and lower parts have a standard coil diameter and are responsible for comfort under medium loads. The spring, due to the greater narrowing of the central turns, surpasses in its technical specifications all known types of similar springs.

Unique independent block "Revolution" For the first time in an independent block the principle of Bonnell springs is applied! In this regard, in accordance with the requirements of the equipment manufacturer Spuhl AG, special attention is paid to the insulating pocket made of nonwoven fabric, in which the spring is placed. The pocket has an even regular shape, due to which the central part of the "Revolution" spring does not have a "fitted" silhouette, unlike existing analogues. As a result, the contact of the metal with the insulating material - spunbond - is completely excluded during operation. This pocket is specially designed by Spuhl to avoid abrasion of the spunbond when maximum loads... The absence of a "fitted" pocket, in which the spring is placed, allows much more glue to be applied to the central part of the spring, evenly distributing it; as a result, the gluing area increases, and the breaking characteristics of the "Revolution" block are improved. The spring itself is conditionally divided into three parts - the middle part, due to the successive narrowing of the coils, has the greatest elasticity and works at maximum loads, the upper and lower parts have a standard coil diameter and are responsible for comfort under medium loads. The spring, due to the greater narrowing of the central turns, surpasses in its technical specifications all known types of similar springs.

Fusion Support 7 zone is a seven-zone spring system based on a block of independent springs, made of wire with a diameter of 1.8 mm, a spring height of 14 cm and a density of 256 springs per 1 m2. This system allows you to optimally distribute the load on all seven parts of the body: head, neck, shoulders, back, pelvis, knees and joints.

Fusion Support 7 zone is a seven-zone spring system based on a block of independent springs, made of wire with a diameter of 1.8 mm, a spring height of 14 cm and a density of 256 springs per 1 m2. This system allows you to optimally distribute the load on all seven parts of the body: head, neck, shoulders, back, pelvis, knees and joints.

One of the varieties of the independent spring unit is Multi Pocket, which, due to the increased number of springs, has increased orthopedicity and can withstand heavy weight loads. The wire diameter is 1.8 mm, the spring height is 13 cm, and the density is 550 springs per m2.

One of the varieties of the independent spring unit is Multi Pocket, which, due to the increased number of springs, has increased orthopedicity and can withstand heavy weight loads. The wire diameter is 1.8 mm, the spring height is 13 cm, and the density is 550 springs per m2.

Independent springs are manufactured on modern spring-winding equipment of the Swiss company Spuhl, which has been a world leader in the production of high-tech lines for creating spring blocks for more than 130 years. Also our Italian partners are Teknomac, Meca and Merello, which supply automatic lines for the production of mattresses. The Sonberry company is in constant cooperation with equipment manufacturers, carries out its regular updates, invests in training of service personnel.

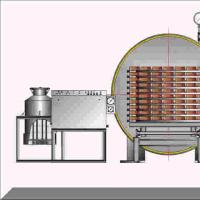

The machines are used to create springs of different sizes and then connect them into independent spring blocks. Relevant in the areas for the manufacture of mattresses at furniture enterprises with a medium and high volume of production.

Technology features

The equipment allows the production of mattresses with independent spring blocks. They are a system of free-standing springs packed in non-woven pockets. Each element of the product design is autonomous, they have an orthopedic effect, which cannot be said about bonnel.

TFK-blocks - the spring is placed in a separate section of non-woven material - spunbond. There is no strong connection between the elements; when the mattress is loaded, the pressure zone works. A foam box is placed along the perimeter of the block. And, unlike bonnel, this helps to avoid the use of additional devices - the manufacture of a metal frame. Thus, it is possible to reduce production costs for the purchase of additional equipment, and accordingly reduce the lease of industrial space and wages service personnel.

Select equipment in KAMI

In stock are presented:

- machines for winding independent springs

Equipped with 1 to 2 winding units, which allow you to work at an intensive pace, but at the same time use a gentle mode. If one of the nodes goes down, the other continues processing. The units are supplied as standard or servo-driven.

- to assemble blocks

The installation is controlled and configured using a programmer. The blocks are connected in two modes - parallel and staggered.

- automatic lines

A full-cycle complex, which produces spring blocks with springs of different diameters, heights, stiffness and shapes. The line includes installations for the production of belts and their assembly into a block, a unit for counting and cutting a spring belt. At the same time, the equipment has a compact size and low power consumption. It works stably.

One of the product categories sold by Technol is spring blocks from the manufacturer leading companies. These systems are widely used not only in the creation of mattresses, but also in the production of sofas and other types of upholstered furniture products. Here you can buy spring block for sofa at retail or order a bulk consignment of these goods for mass production various products.

The main advantages of independent type spring blocks

In favor of purchasing spring systems of an independent type, such confirmed practical use pluses like:

- Durability. The service life of the blocks of this type is higher than that of dependent analogs. A high level of wear resistance is ensured through the use of quality materials, the use of modern production technologies, as well as a special configuration of spring systems. Strong steel, a rigid fit of each element, the presence of a significant number of turns are the main factors that affect the reduction of the probability of spring deformation and ensure a long service life of the product.

- High levels of comfort and health benefits. It is no secret that most modern professions lead to a sedentary, sedentary lifestyle. As a result, the population suffers to a greater extent from various diseases of the musculoskeletal system. Spring blocks for upholstered furniture and mattresses can provide a high level of comfort, reduce the load on the spine, and produce a high anatomical effect. Thus, furniture products and other products that are created using independent type spring blocks will not only give you a comfortable rest, but can also help in solving health problems (including the prevention of diseases).

- Filler safety. If you are planning to buy in bulk latex rolls or other materials for the production of furniture or anatomical products, then you do not have to worry about preserving their integrity. Independent spring blocks placed in separate covers, so they will not damage the filler.

Types of spring blocks

Our catalog contains such systems as:

- TFK - the number of springs per square meter is 256, the diameter of the steel wire is 1.8 mm;

- Multipocket S1000 - 512 springs per square meter, wire thickness - 1.4 mm;

- Multipocket S2000 - 1000 springs per square meter, thickness from 0.9 mm.

In addition, you can purchase other products from us: buy shoe covers in bulk, order mattress and technical fabrics, fillers of all kinds, etc. To clarify the terms of cooperation and receive consulting support, call our managers: +7 495 134-2834, + 7 495 505-4620.

Best Business Books: Ranking Popular Business Literature Authors

Best Business Books: Ranking Popular Business Literature Authors Structure of a business plan point by point: learning from clear examples

Structure of a business plan point by point: learning from clear examples How to write a business plan: step-by-step instructions with examples Budget money

How to write a business plan: step-by-step instructions with examples Budget money All about pellets: production rules, standards and quality control methods

All about pellets: production rules, standards and quality control methods Chicken leg trimming conveyor

Chicken leg trimming conveyor Arrangement and construction of a drying chamber for lumber

Arrangement and construction of a drying chamber for lumber Improvement of the city, woodworking arrangement of pile foundations and pipelines Main units of machine tools

Improvement of the city, woodworking arrangement of pile foundations and pipelines Main units of machine tools