General technical conditions. Scaffolding tools. General Specifications Paving Means Log Cover Form

5. REPUBLICATION. March 2002

Reprinted (as of November 2008)

This standard applies to paving means used in the process of construction and installation work during the construction, reconstruction, repair of buildings and structures for the organization of workplaces at height.

The standard does not apply to structures that combine the functions of paving means with any other functions (formwork, conductor, etc.) or used for lifting or receiving goods (lifts, platforms for receiving goods delivered to a height, etc.), as well as on the undercarriage of self-propelled paving equipment and hydraulic drive of paving equipment.

Explanations for the terms used in this standard are given in Appendix 1.

1. Types and basic parameters

1. TYPES AND BASIC PARAMETERS

The types and main parameters of the paving means must correspond to those given in the table.

Name of means of paving | The value of the standard surface load, Pa (kgf / m) | Height work site means of paving, m, no more |

Rack attached scaffolding | ||

Free-standing forests | ||

Mobile scaffolding | ||

Suspended scaffolding | ||

Demountable scaffolds | ||

Mobile scaffolds with a movable workstation | ||

Suspended scaffolding | ||

Mobile towers | ||

Electric suspended cradles | ||

Ladder platforms | ||

Platforms hung on building structures | ||

Free-standing stairs | ||

Hinged ladders | ||

Side inclined ladders | ||

Vertical ladders | ||

Flight stairs | ||

2. Technical requirements

2.1. Paving means must be designed and manufactured in accordance with the requirements of this standard, standards for paving means of a specific type, GOST 15.001 *; according to the design documentation approved in established order... Paving equipment with a machine drive for moving workplaces in height must also meet the requirements of the "Rules for the Construction and Safe Operation of Cranes" of the USSR Gosgortekhnadzor and the "Rules for the Installation of Electrical Installations (PUE)" of the USSR Ministry of Energy.

__________________

* V Russian Federation GOST R 15.201-2000 is in force.

2.2. Specifications

2.2.1. The means of paving must be designed and manufactured in climatic version U or HL in accordance with GOST 15150.

2.2.2. When developing the design of paving means, one should be guided by SNiP 2.01.07-85, SNiP II-23-81, SNiP 2.03.06-85, SNiP II-25-80.

2.2.3. Scaffolds must be able to withstand their own weight and temporary loads from people, materials and wind.

2.2.4. When developing design documentation, you should take:

Load safety factor:

1,2 - from people and materials,

1.1 - from its own weight,

1.3 - from the wind;

Reliability factor for the purpose:

7 - when calculating steel rope suspensions,

9 - when calculating the ropes of winches intended for lifting people,

4 - when calculating rod hangers,

1.5 - when calculating the fastenings of paving means to building structures,

3.0 - when calculating the specific pressure of supports on the ground,

1.0 - when calculating other elements;

Coefficient of working conditions of structural elements:

0.9 - when calculating the stability of the racks,

1.5 - when calculating the railing of the fence;

Rollover safety factor:

1.4 - when calculating the stability of free-standing and mobile paving means.

2.2.5. The material grades of the supporting elements of the scaffolds shall be indicated in the standards or technical specifications for the scaffolds of a particular type.

2.2.6. Limit deviations of the dimensions of the paving means parts should be given in the design documentation.

2.2.7. The mass of assembly elements per worker during manual assembly of paving equipment at a construction site should not be more than:

25 kg - when installing paving means at a height;

50 kg - when installing paving equipment on the ground or overlap (with their subsequent installation in working position with assembly cranes, winches, etc.).

2.2.8. The value and direction of the standard load on the handrail should be indicated in the standards or technical specifications for specific types of scaffolding.

2.2.9. The effort on the handles during the rotation of the hand drives of the paving means should be no more than 160 N (16 kgf).

2.2.10. The excess of the mass of paving means from the design should be no more than 3%.

2.2.11. For lifting with cranes, scaffolds must have slinging devices.

2.2.12. In box and tubular structures, measures must be taken to prevent the accumulation of moisture in them.

2.2.13. Steel structures of paving means must be primed and painted at the manufacturing plant with paints and varnishes that correspond to a slightly aggressive environment in accordance with SNiP 2.03.11-85.

2.2.14. Before painting, the surface of steel elements of paving means must be cleaned to the 4th degree in accordance with GOST 9.402.

2.2.15. Steel parts in contact with structural elements made of aluminum alloys must be coated to exclude the possibility of electric steam formation between them.

2.2.16. Scaffolding equipment, the working platform of which is located at a height of 1.3 m or more from the surface of the ground or overlap, must have a railings and side rails.

2.2.17. The height of the fence is indicated in the standards for a particular type of paving. The distance between the horizontal elements of the fence should be no more than 0.45 m or the fence should have mesh, lattice, etc. filling.

2.2.18. Paving means with a machine drive for moving the workplace in height must have: a movement control device located directly at the workplace; lifting height limiters; safety devices (catchers) preventing spontaneous lowering (falling) of the workplace.

2.2.19. Designs of detachable connections must have locking devices that protect them from spontaneous disconnection.

2.2.20. The presence of sharp edges, burrs, cracks, cavities, delamination is not allowed on metal parts and elements.

2.2.21. Signal coloring of paving means must comply with GOST 12.4.026.

2.3. Completeness

2.3.1. The scope of delivery should include: a means of paving a specific type according to the picking list; passport with operating instructions.

2.4. Marking

2.4.1. Each paving device must be marked with: trademark (if any) or the name of the manufacturer; product designation (brand); product or batch number; date of manufacture.

2.4.2. The method, place of marking, etc., are indicated in the standards or technical specifications for paving means of a particular type.

2.5. Package

2.5.1. The method of packing, the transport marking of the package is indicated in the standards or technical specifications for the paving means of a particular type.

3. Acceptance

3.1. To verify the compliance of paving equipment with the requirements of this standard, the manufacturer must carry out acceptance, periodic and type tests.

3.2. The order of submission for testing, the volume of the submitted batches, the composition of the tests, the parameters and technical properties to be checked, as well as the sequence of their verification, must be specified in the standards or technical specifications for paving means of a particular type.

3.3. The manufacturer of paving means must draw up a passport for them in the form given in Appendix 2.

4. Methods of control

4.1. The quality of materials and products must be certified by certificates of manufacturers.

4.2. The geometric dimensions of the paving means and their elements are checked with a tape measure in accordance with GOST 7502, a metal ruler in accordance with GOST 427, a caliper in accordance with GOST 166, a goniometer with a vernier in accordance with GOST 5378 or other instruments that ensure measurement accuracy up to 1 mm and verified by metrological organizations of the USSR State Standard in accordance with the requirements GOST 8.002 * and GOST 8.513 **.

________________

* In the Russian Federation, PR 50.2.002-94 are in force.

** In the Russian Federation, PR 50.2.006-99 are in force.

Probably a mistake in the original. Should read: PR 50.2.006-94. - Note from the manufacturer of the database.

4.3. The weight of the paving means should be measured on a balance in accordance with GOST 29329 or with a dynamometer in accordance with GOST 13837.

4.4. The quality of welds is checked visually in accordance with GOST 3242.

4.5. The color quality is determined visually in accordance with GOST 9.032.

5. Transportation and storage

5.1. Transportation of paving means should be carried out by any type of transport that ensures their safety (from mechanical damage, paint damage, pollution, etc.).

5.2. Paving equipment should be stored in accordance with storage conditions 5 in accordance with GOST 15150.

6. Instructions for use

6.1. Scaffolds should be used in accordance with the instructions attached to the product and SNiP III-4-80.

6.2. The scaffolds must be registered in the log book in accordance with Appendix 3, which must be kept at each construction site.

Registration number must be marked in a conspicuous place on the scaffolding structural member or on a plate attached to it.

6.3. The results of the commissioning and periodic inspections means of paving must be reflected in the log in accordance with Appendix 3.

The timing of periodic inspections is indicated in the standards or specifications for a particular type of paving.

7. Manufacturer's Warranties

7.1. The manufacturer must ensure that the scrims meet the requirements of this standard, the standards or specifications for a particular screed type.

7.2. The warranty period of operation is at least 12 months from the date of commencement of operation, provided that the consumer observes the rules of operation, transportation and storage established by this standard.

Appendix 1 (reference). Terms and explanations

ANNEX 1

Reference

Term | Explanation |

Scaffolds | Devices designed to organize workplaces during construction and installation work at a height or depth of more than 1.3 m from ground level or overlap |

Free-standing scaffolds | Devices that have their own stability in the working position and do not require their attachment to the supporting structures of buildings and structures |

Attached scaffolds | Devices, the stable position of which is ensured by their fastening to the structures of buildings and structures |

Movable scaffolds | Devices moved along the work front by rearranging them with a crane or manually (including with partial or complete disassembly and subsequent assembly) |

Mobile scaffolds | Devices that move along the work front by traveling on wheels |

Suspended scaffolding | Devices attached to structures of buildings and structures by flexible suspensions |

Hinged scaffolds | Devices fixedly attached to structures of buildings and structures with special parts |

Multi-tiered structure designed to organize workplaces on different horizons |

|

Scaffold | Single-tier structure designed for performance of work requiring the movement of jobs along the work front |

Mobile structure designed for short-term work at height |

|

Cradle | Suspended structure with height-adjustable workstation |

Area | Suspended structure designed to create a workplace directly in the work area |

Stairs | Designed to move people over height and create short-term jobs |

Appendix 2 (mandatory). Passport for a specific type of paving

APPENDIX 2

Mandatory

THE PASSPORT

for a specific type of paving

(Form)

1. General data | |||||||||||||||||||||

Name | |||||||||||||||||||||

Organization-developer | |||||||||||||||||||||

Project code | |||||||||||||||||||||

Enterprise (organization) - manufacturer | |||||||||||||||||||||

Manufacturing date | |||||||||||||||||||||

Permissible ambient temperature, ° С (minimum and maximum) | |||||||||||||||||||||

Design standards (SNiP, RTM, etc.) | |||||||||||||||||||||

Manufacturing standards (GOST, SNiP, etc.) | |||||||||||||||||||||

2. Characteristics and main technical data | |||||||||||||||||||||

Maximum height (lifting, installation), m | |||||||||||||||||||||

Weight, kg | |||||||||||||||||||||

3. Data on the material of the bearing (design) elements |

|||||||||||||||||||||

Name of elements and parts | Material | Material grade | NTD designation |

||||||||||||||||||

The manufacturer certifies the following: |

|||||||||||||||||||||

corresponds to working drawings and GOST | |||||||||||||||||||||

product name | |||||||||||||||||||||

2. Static load tests have been carried out | |||||||||||||||||||||

Test duration | |||||||||||||||||||||

recognized as fit for work. |

|||||||||||||||||||||

product name | |||||||||||||||||||||

Ch. engineer | |||||||||||||||||||||

Head of Quality Control Department | |||||||||||||||||||||

Appendix 3 (mandatory). Scaffolding Cover and Page Forms

Appendix 3

Mandatory

TRAVELING LOG COVER FORM

MAGAZINE

accounting for paving

name of the construction and installation organization |

and her subordination |

Person in charge of logging |

position, surname, name, patronymic |

TRAVELING LOG PAGES FORM

Characteristics of paving agents

Type and purpose. Brand | Inventory number | Main characteristic |

Manufacturer | Minimum working | Weight, kg | Name of the design organization, numbers of working drawings |

Repair details

Inventory number | Base (drawing numbers) | Surname, name, patronymic, position of the person responsible for the repair |

||

Data on technical approvals

Registration | Type of survey | Survey results | Conclusion on suitability for use | Surname, | Painting |

|

Acceptance | Period | |||||

NOTES FGUP "STANDARTINFORM"

1 On the first page add the code: MKS 91.080.99 (index "National Standards", 2008).

2 Informational data. Reference normative and technical documents:

GOST 9.402-80 has been replaced by GOST 9.402-2004;

GOST 12.4.026-76. On the territory of the Russian Federation, GOST R 12.4.026-2001 is in force;

GOST 25670-83 was replaced by GOST 30893.1-2002.

Electronic text of the document

prepared by JSC "Kodeks" and verified by:

official publication

M .: Standartinform, 2009

The standard applies to paving means used in the process of construction and installation work during the construction, reconstruction, repair of buildings and structures for the organization of workplaces at height. The standard does not apply to structures that combine the functions of paving means with any other functions (formwork, conductor, etc.) or used for lifting or receiving goods (lifts, platforms for receiving goods delivered to a height, etc.), as well as on the undercarriage of self-propelled paving equipment and hydraulic drive of paving equipment.

| Designation: | GOST 24258-88 |

| Russian name: | Scaffolding tools. Are common technical conditions |

| Status: | acts |

| Replaces: | GOST 24258-80 “Scaffolds. Classification and general technical requirements " |

| Date of text update: | 05.05.2017 |

| Date added to the database: | 01.09.2013 |

| Effective date: | 01.07.1989 |

| Approved by: | 11/28/1988 Gosstroy of the USSR ( State Committee USSR Council of Ministers for Construction) (USSR Gosstroy 237) |

| Published: | Standards Publishing House (1989) IPK Standards Publishing House (2002) Standartinform (2009) |

| Download links: |

1. TYPES AND BASIC PARAMETERS

The types and main parameters of the paving means must correspond to those given in the table.

|

Name of means of paving |

The value of the standard surface load, Pa (kgf / m 2) |

Height of the working platform of means of paving, m, no more |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Rack attached scaffolding |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Free-standing forests |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Mobile scaffolding |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Suspended scaffolding |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Demountable scaffolds |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Mobile scaffolds with a movable workstation |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Suspended scaffolding |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Mobile towers |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Electric suspended cradles |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Ladder platforms |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Platforms hung on building structures |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Free-standing stairs |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Hinged ladders |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Side inclined ladders |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Vertical ladders |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Flight stairs |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

0.9 - when calculating the stability of the racks, 1.5 - when calculating the railing of the fence; Rollover safety factor: 1.4 - when calculating the stability of free-standing and mobile paving means. 2.2.5. The material grades of the supporting elements of the scaffolds shall be indicated in the standards or technical specifications for the scaffolds of a particular type. 2.2.7. The mass of assembly elements per worker during manual assembly of paving equipment at a construction site should not be more than: 25 kg - when installing paving means at a height; 50 kg - when installing paving equipment on the ground or overlap (with their subsequent installation in working position with assembly cranes, winches, etc.). 2.2.8. The value and direction of the standard load on the handrail should be indicated in the standards or technical specifications for specific types of scaffolding. 2.2.9. The effort on the handles during the rotation of the hand drives of the paving means should be no more than 160 N (16 kgf). 2.2.10. The excess of the mass of paving means from the design should be no more than 3%. 2.2.11. For lifting with cranes, scaffolds must have slinging devices. 2.2.12. In box and tubular structures, measures must be taken to prevent the accumulation of moisture in them. 3. ACCEPTANCE3.1. To verify the compliance of paving equipment with the requirements of this standard, the manufacturer must carry out acceptance, periodic and type tests. 3.2. The order of submission for testing, the volume of the submitted batches, the composition of the tests, the parameters and technical properties to be checked, as well as the sequence of their verification, must be specified in the standards or technical specifications for paving means of a particular type. 3.3. The manufacturer of paving means must draw up a passport for them in the form given in the appendix. 4. CONTROL METHODS4.1. The quality of materials and products must be certified by certificates of manufacturers. The timing of periodic inspections is indicated in the standards or specifications for a particular type of paving. 7. MANUFACTURER'S WARRANTIES7.1. The manufacturer must ensure that the scrims meet the requirements of this standard, the standards or specifications for a particular screed type. 7.2. The warranty period of operation is at least 12 months. from the date of commencement of operation, provided that the consumer observes the rules of operation, transportation and storage established by this standard. ANNEX 1

|

|

Explanation |

|

|

Scaffolding tools |

Devices designed to organize workplaces during construction and installation work at a height or depth of more than 1.3 m from ground level or overlap |

|

Free-standing scaffolds |

Devices that have their own stability in the working position and do not require their attachment to the supporting structures of buildings and structures |

|

Attached scaffolds |

Devices, the stable position of which is ensured by their fastening to the structures of buildings and structures |

|

Movable scaffolds |

Devices moved along the work front by rearranging them with a crane or manually (including with partial or complete disassembly and subsequent assembly) |

|

Mobile scaffolds |

Devices that move along the work front by traveling on wheels |

|

Suspended scaffolding |

Devices attached to structures of buildings and structures by flexible suspensions |

|

Hinged scaffolds |

Devices fixedly attached to structures of buildings and structures with special parts |

|

Multi-tiered structure designed to organize workplaces on different horizons |

|

|

Scaffold |

Single-tier structure designed to perform work requiring the movement of workplaces along the work front |

|

Mobile structure designed for short-term work at height |

|

|

Suspended structure with height-adjustable workstation |

|

|

Area |

Suspended structure designed to create a workplace directly in the work area |

|

Stairs |

Designed to move people over height and create short-term jobs |

APPENDIX 2

Mandatory

|

(Form) 1. General data _______________________________________________________ Name _________________________________________________________ _________________________________________________________________________ Organization-developer ________________________________________________ _________________________________________________________________________ Project code _________________________________________________________ _________________________________________________________________________ Manufacturer (organization) __________________________________ _________________________________________________________________________ Date of manufacture ______________________________________________________ _________________________________________________________________________ Permissible ambient temperature, ° C (minimum and maximum) _________________________________________________________________________ Design standards (SNiP, RTM, etc.) _________________________________ _________________________________________________________________________ Manufacturing standards (GOST, SNiP, etc.) __________________________________ _________________________________________________________________________ 2. Characteristics and main technical data __________________________ _________________________________________________________________________ Standard load, N (kgf) ____________________________________________ _________________________________________________________________________ Maximum height (lifting, installation), m ______________________________ _________________________________________________________________________ Weight, kg ______________________________________________________________ _________________________________________________________________________ 3. Data on the material of the bearing (design) elements

The manufacturer certifies the following: 1 .__________________ corresponds to working drawings and GOST _______________ product name 2. Tests with static load ________________________ kgf were carried out. Test duration ______________________________________ min. 3. _________________________________________ are recognized as fit for work. product name Ch. engineer ________________________ Head of Quality Control Department _____________________ M. P. date |

APPENDIX 3

Mandatory

TRAVELING LOG PAGES FORM

Characteristics of paving agents

|

Type and purpose. Brand |

Inventory number |

Main characteristic |

|

Manufacturer |

Minimum operating temperature of operation, ° C |

STATE STANDARD OF THE UNION OF SSR

PAVING EQUIPMENT

GENERAL TECHNICAL CONDITIONS

GOST 24258-88

STATE CONSTRUCTION COMMITTEE of the USSR

Moscow

STATE STANDARD OF THE UNION OF SSR

Date of introduction 01.07.1989

This standard applies to paving means used in the process of construction and installation work during the construction, reconstruction, repair of buildings and structures for the organization of workplaces at height.

The standard does not apply to structures that combine the functions of paving means with any other functions (formwork, conductor, etc.) or used for lifting or receiving goods (lifts, platforms for receiving goods delivered to a height, etc.), as well as on the undercarriage of self-propelled paving equipment and hydraulic drive of paving equipment.

Explanations for the terms used in this standard are given in the appendix.

1. TYPES AND BASIC PARAMETERS

The types and main parameters of the paving means must correspond to those given in the table.

|

Name of means of paving |

The value of the standard surface load, Pa (kgf / m 2) |

Height of the working platform of means of paving, m, no more |

|

Rack attached scaffolding |

1000 (100) |

100,0 |

|

2000 (200) |

||

|

2500 (250) |

||

|

3000 (300) |

||

|

5000 (500) |

||

|

Free-standing forests |

1000 (100) |

20,0 |

|

2000 (200) |

||

|

Mobile scaffolding |

1000 (100) |

20,0 |

|

2000 (200) |

||

|

Suspended scaffolding |

1000 (100) |

20,0 |

|

2000 (200) |

||

|

Demountable scaffolds |

2000 (200) |

16,0 |

|

Mobile scaffolds with a movable workstation |

2000 (200) |

120,0 |

|

3000 (300) |

||

|

5000 (500) |

||

|

Suspended scaffolding |

2000 (200) |

10,0 |

|

Mobile towers |

1000 (100) |

20,0 |

|

2000 (200) |

||

|

Electric suspended cradles |

1000 (100) |

150,0 |

|

2000 (200) |

||

|

Ladder platforms |

2000 (200) |

|

|

Platforms hung on building structures |

2000 (200) |

|

|

Free-standing ladders |

2000 (200) |

20,0 |

|

Hinged ladders |

2000 (200) |

10,0 |

|

Side inclined ladders |

2000 (200) |

22,0 |

|

Vertical ladders |

2000 (200) |

22,0 |

|

Flight stairs |

1000 (100) |

30,0 |

|

2000 (200) |

(Revised edition).

2. TECHNICAL REQUIREMENTS

2.2.3. Scaffolds must be able to withstand their own weight and temporary loads from people, materials and wind.

2.2.4. When developing design documentation, you should take:

load safety factor:

1,2 - from people and materials,

1.1 - from its own weight,

1.3 - from the wind;

reliability factor for the purpose:

7 - when calculating steel rope suspensions,

9 - when calculating the ropes of winches intended for lifting people,

4 - when calculating rod hangers,

1.5 - when calculating the fastenings of paving means to building structures,

3.0 - when calculating the specific pressure of supports on the ground,

1.0 - when calculating other elements;

coefficient of working conditions of structural elements:

0.9 - when calculating the stability of the racks,

1.5 - when calculating the railing of the fence;

rollover safety factor:

1.4 - when calculating the stability of free-standing and mobile paving means.

2.2.5. The material grades of the supporting elements of the scaffolds shall be indicated in the standards or technical specifications for the scaffolds of a particular type.

2.2.7. The mass of assembly elements per worker during manual assembly of paving equipment at a construction site should not be more than:

25 kg - when installing paving means at a height;

50 kg - when installing paving equipment on the ground or overlap (with their subsequent installation in working position with assembly cranes, winches, etc.).

2.2.8. The value and direction of the standard load on the handrail should be indicated in the standards or technical specifications for specific types of scaffolding.

2.2.9. The effort on the handles during the rotation of the hand drives of the paving means should be no more than 160 N (16 kgf).

2.2.10. The excess of the mass of paving means from the design should be no more than 3%.

2.2.11. For lifting with cranes, scaffolds must have slinging devices.

2.2.12. In box and tubular structures, measures must be taken to prevent the accumulation of moisture in them.

2.2.15. Steel parts in contact with structural elements made of aluminum alloys must be coated to exclude the possibility of electric steam formation between them.

2.2.16. Scaffolding equipment, the working platform of which is located at a height of 1.3 m or more from the surface of the ground or overlap, must have a railings and side rails.

2.2.17. The height of the fence is indicated in the standards for a particular type of paving. The distance between the horizontal elements of the fence should be no more than 0.45 m or the fence should have mesh, lattice, etc. filling.

2.2.18. Paving means with a machine drive for moving the workplace in height must have: a movement control device located directly at the workplace; lifting height limiters; safety devices (catchers) preventing spontaneous lowering (falling) of the workplace.

2.2.19. Designs of detachable connections must have locking devices that protect them from spontaneous disconnection.

2.2.20. The presence of sharp edges, burrs, cracks, cavities, delamination is not allowed on metal parts and elements.

2.3 ... Completeness

2.3.1. The scope of delivery should include: a means of paving a specific type according to the picking list; passport with operating instructions.

2.4. Marking

2.4.1. Each paving device must be marked with: trademark (if any) or the name of the manufacturer; product designation (brand); product or batch number; date of manufacture.

2.4.2. The method, place of marking, etc., are indicated in the standards or technical specifications for paving means of a particular type.

2.5. Package

2.5.1. The method of packing, the transport marking of the package is indicated in the standards or technical specifications for the paving means of a particular type.

3. ACCEPTANCE

3.1. To verify the compliance of paving equipment with the requirements of this standard, the manufacturer must carry out acceptance, periodic and type tests.

3.2. The order of submission for testing, the volume of the submitted batches, the composition of the tests, the parameters and technical properties to be checked, as well as the sequence of their verification, must be specified in the standards or technical specifications for paving means of a particular type.

3.3. The manufacturer of paving means must draw up a passport for them in the form given in the appendix.

4. CONTROL METHODS

4.1. The quality of materials and products must be certified by certificates of manufacturers.

5. TRANSPORTATION AND STORAGE

5.1. Transportation of paving means should be carried out by any type of transport that ensures their safety (from mechanical damage, paint damage, pollution, etc.).

6. INSTRUCTIONS FOR USE

6.2. Scaffolds must be recorded in a log book in accordance with the appendix, which must be kept at each construction site.

The registration number must be marked in a conspicuous place on the scaffolding structural member or on a plate attached to it.

6.3. The results of commissioning and periodic inspections of paving equipment should be reflected in the journal in accordance with the appendix.

The timing of periodic inspections is indicated in the standards or specifications for a particular type of paving.

7. MANUFACTURER'S WARRANTIES

7.1. The manufacturer must ensure that the scrims meet the requirements of this standard, the standards or specifications for the specific scrubbers.

7.2. The warranty period of operation is at least 12 months from the date of commencement of operation, provided that the consumer observes the rules of operation, transportation and storage established by this standard.

ANNEX 1

Reference

TERMS AND EXPLANATIONS

|

Term |

Explanation |

|

Scaffolding tools |

Devices designed to organize workplaces during construction and installation work at a height or depth of more than 1.3 m from ground level or overlap |

|

Free-standing scaffolds |

Devices that have their own stability in the working position and do not require their attachment to the supporting structures of buildings and structures |

|

Attached scaffolds |

Devices, the stable position of which is ensured by their fastening to the structures of buildings and structures |

|

Movable scaffolds |

Devices moved along the work front by rearranging them with a crane or manually (including with partial or complete disassembly and subsequent assembly) |

|

Mobile scaffolds |

Devices that move along the work front by traveling on wheels |

|

Suspended scaffolding |

Devices attached to structures of buildings and structures by flexible suspensions |

|

Hinged scaffolds |

Devices fixedly attached to structures of buildings and structures with special parts |

|

Forests |

Multi-tiered structure designed to organize workplaces on different horizons |

|

Scaffold |

Single-tier structure designed to perform work requiring the movement of workplaces along the work front |

|

Tower |

Mobile structure designed for short-term work at height |

|

Cradle |

Suspended structure with height-adjustable workstation |

|

Area |

Suspended structure designed to create a workplace directly in the work area |

|

Stairs |

Designed to move people over height and create short-term jobs |

APPENDIX 2

Mandatory

THE PASSPORT

for a specific type of paving

(Form)

|

1. General data _________________________________________________________ Name ___________________________________________________________ __________________________________________________________________________ Organization-developer _________________________________________________ __________________________________________________________________________ Project code ___________________________________________________________ __________________________________________________________________________ Enterprise (organization) - manufacturer ____________________________________ __________________________________________________________________________ Date of manufacture _______________________________________________________ __________________________________________________________________________ Permissible ambient temperature, ° С (minimum and maximum) _ __________________________________________________________________________ __________________________________________________________________________ Design standards (SNiP, RTM, etc.) ___________________________________ __________________________________________________________________________ Manufacturing standards (GOST, SNiP, etc.) ____________________________________ __________________________________________________________________________ 2. Characteristics and main technical data ___________________________ __________________________________________________________________________ Standard load, N (kgf) _____________________________________________ __________________________________________________________________________ Maximum height (lifting, installation), m ________________________________ __________________________________________________________________________ Weight, kg _______________________________________________________________ __________________________________________________________________________ 3. Data on the material of the bearing (design) elements

The manufacturer certifies the following: 1. ______________________ corresponds to working drawings and GOST ____________ product name 2. Tests with static load ___________________________ kgf were carried out. Test duration _________________________________________ min. 3. _______________________ are found fit for work. product name Ch. engineer ________________ signature Head of Quality Control Department ____________ signature |

APPENDIX 3

Mandatory

Scaffolding Journal Cover Form

|

MAGAZINE __________________________________________________________________________ the name of the building and assembly __________________________________________________________________________ organization and its subordination Person in charge of logging __________________________________________________________________________ position, surname, name, patronymic TRAVELING LOG PAGES FORM Characteristics of paving agents

Repair details Data on technical approvals

| |||||||||||||||||||||||||||||||||||||||

How many kilometers is the Moscow Moscow Ring Road in a circle?

How many kilometers is the Moscow Moscow Ring Road in a circle? Where did the Moscow sparrows disappear: the conclusion of ornithologists Why did the sparrows disappear?

Where did the Moscow sparrows disappear: the conclusion of ornithologists Why did the sparrows disappear? How to make money on homemade toys?

How to make money on homemade toys? Coloring polymer clay in different ways

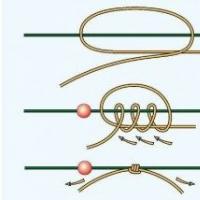

Coloring polymer clay in different ways Self-tightening knot: types, methods of knitting

Self-tightening knot: types, methods of knitting How to find clients for a beginner interior designer Where to find orders for design

How to find clients for a beginner interior designer Where to find orders for design International children's creative competition "Colorful colors of autumn. Important organizational points

International children's creative competition "Colorful colors of autumn. Important organizational points