Sapr as stands for. Sapr in construction. Bentley Systems, Incorporated - Product Series

Pro / ENGINEER

CAD / CAM / CAE system. With over 310,000 professional users working with Pro / ENGINEER, it is extremely powerful, combining unmatched speed and accuracy. More than 42,000 businesses around the world use PTC PLM products at all stages of the product lifecycle.

The new version of Pro / ENGINEER offers advanced, dramatically increasing designer productivity technologies for modeling and editing geometry, as well as an apparatus for creating photorealistic images of the highest quality. Among them - the creation of three-dimensional models in the form of a "point cloud", dynamic deformation of a three-dimensional model and many others.

Developer - Parametric Technology Corp. , USA.

CATIA

CATIA is a key brand for Dassault Systèmes and a global leader in software products that support design and innovation. Around the world, thousands of companies in various industries are using the virtual design capabilities of CATIA products to create truly successful products. CATIA solutions are targeted at all companies, from OEMs to their suppliers and small and medium-sized businesses.

CAD / CAM / CAE system CATIA (Computer Aided Three-dimensional Interactive Application) is a fully integrated universal CAD / CAM / CAE system of a high level, which allows to ensure the parallel execution of the design and production cycle of CATIA, being a universal system of computer-aided design, testing and manufacturing, It is widely used at large machine-building enterprises around the world for computer-aided design, production preparation, and reengineering. Functions supported by CATIA / CADAMSolutions: administration - planning, resource management, inspection and documentation of the project; · the most advanced modeling; · description of all mechanical connections between the components of the object and bringing them into a state of spatial mutual positioning; · automatic analysis of geometric and logical conflicts · analysis properties of complex assemblies; · developed tools for tracing communication systems in compliance with the specified restrictions; · specialized applications for technological preparation of production.

Developer - Dassault Systèmes, (France).

SolidWorks

Powerful engineering CAD package for solid parametric modeling of complex parts and assemblies. The design system of the middle class, based on the parametric geometric kernel Parasolid. Created specifically for use on personal computers under the control of Windows operating systems.

Developer - Dassault Systèmes.

NX

Siemens PLM Software's NX CAD / CAM / CAE system offers next-generation tools and technologies that are transforming product development. Brand new tools enable product development in a single, manageable environment by integrating all processes. NX tools provide more modeling capabilities, flexibility and performance. By combining parametric and tree-less modeling, and active layout technology to make assembly work easier, NX sets new standards for speed, performance and ease of use.

Unigraphics Solutions, Inc product line: Unigraphics Solutions, Parasolid, Solid Edge, Unigraphics, IMAN, ProductVision, GRIP.

CSoft.

SolidEdge

Solid Edge is a market leader in CAD systems for mechanical engineering, equipped with unique tools for creating and editing 3D digital models. With superior basic modeling and built-in workflows, industry-specific needs, and seamless integration with design controls, Solid Edge delivers accurate, error-free design solutions. Part and assembly modeling tools in Solid Edge enable engineers to easily create a wide variety of products, from single parts to assemblies of thousands of components. Industry-specific teams and structured workflows accelerate the design of common features, while creating, analyzing, and editing assemblies ensures that every part is mated accurately and functions correctly. When designing in Solid Edge, your products are assembled correctly the first time.

Developer -. Additionally - CSoft.

think3

A computer-aided design system for medium-level mechanical engineering; provides two-dimensional design, three-dimensional surface and solid modeling, design of products from sheet materials, associativity of a two-dimensional drawing with a three-dimensional model, photorealistic presentation of the project.

Developer - think3, Inc, USA.

Product family for design and project data management: CAD 3D and 2D CAD, Integrated Product Data Management (PDM), and software interoperability. A wide range of add-on modules for design, CoCreate provides speed, flexibility to respond to changes for customers, short development cycles, easy design process. The main modules are CoCreate Modeling and CoCreate Drafting.

Developer - Parametric Technology Corp.

KeyCreator

KeyCreator ™ is full-featured software that provides professional designers with state-of-the-art tools to tackle complex design work. KeyCreator allows full editing of both native and imported geometry and supports the creation of complex surface models. Easy to use and create 2D drawings and 3D models.

Developer - Kubotek Corporation, USA.

T-FLEX

The T-FLEX CAD / CAM / CAE / CAPP / PDM software package unites programs for three-dimensional design, modules for preparing control programs for CNC machines and engineering calculations. All systems of the T-FLEX CAD / CAM / CAE / CAPP / PDM complex operate on a single information platform of the T-FLEX DOCs PDM system. The Russian software complex T-FLEX CAD / CAM / CAE / CAPP / PDM is a set of modern software tools for solving problems of automation of three-dimensional design, design and technological preparation of production of any complexity in various industries.

CAD T-FLEX CAD is a professional design program. CAD T-FLEX CAD combines powerful parametric capabilities of 2D and 3D-modeling with tools for creating and formatting drawings and design documentation. Technical innovations and good performance of T-FLEX CAD in combination with a convenient and intuitive interface make T-FLEX CAD a versatile and effective tool for 2D and 3D product design. With a wide range of CAD design tools, T-FLEX CAD is the best choice for solving any design problem. Designers around the world use T-FLEX CAD in a wide variety of industries: general mechanical engineering and instrumentation, in the aerospace, automotive and shipbuilding industries, as well as in design and construction organizations. CAD T-FLEX CAD is used both in the design of products of the main production, and in the creation of the entire complex of necessary equipment - stamps and molds, tools and fixtures.

Developer - Top-Systems, Moscow.

"BCAD Pro" is a software system for a full design cycle: design, construction and preparation of production for everything that can be made from sheet and profile materials. It allows you to design both various products from these materials: furniture, trade equipment, exhibition stands, pavilions, small architectural forms, and the premises in which these products are located, for which they are made: offices, clubs, bars, apartments, etc. ., as well as various elements of such premises: podiums, reception counters, bar counters and much more - are successfully designed in bCAD Pro. It is possible to work simultaneously with several projects, combining models into a single project, placing the created models in the office or apartment. BCAD Pro includes the capabilities of all other products in the line: bCAD Furniture, bCAD Showcase and bCAD Designer. Everything that is written about the capabilities of these products is in it. In it, you can perform all the same work and create libraries of materials, fasteners and components. The main differences are the ability to create products with profile parts and export information about designs in database formats.

Developer - ProPro Group, Novosibirsk.

COMPASS

One of the leading Russian products. A CAD system designed for a wide range of design and development work, easy to learn, easy to use, and at the same time has a cost that is acceptable for the complex equipment of Russian enterprises, including medium and small ones. Allows you to carry out two-dimensional design and construction, quick preparation and release of various drawing and design documentation, the creation of technical text and graphic documents. Developer - Russia.

DesignCAD Series

DesignCAD is a program that combines easy to understand and use 2D drafting with powerful and accurate 3D modeling to achieve stunning results depending on your imagination and creativity. Design has never been as easy as using an easy-to-understand program interface and extensive reference library. The program allows you to quickly create the drawings you want. Also, the program has the ability to solid modeling and create animations and presentations. DesignCAD 3D Max is a versatile CAD tool for beginners and advanced users.

Developer - IMSI / Design, LLC. , USA.

TurboCAD Pro

TurboCAD Pro is a powerful all-in-one tool for professional CAD design. Combined 2D and 3D design is able to satisfy the most discerning users. The full power of the industry standard ACIS® v8 solid modeling engine coexists with powerful surface modeling to give you maximum flexibility. TurboCAD Prol supports twenty-five of the most popular file formats, including AutoCAD® DWG / DXF, MicroStation® DGN, 3DS, IGEN, STL and more. You can also export your projects to HTML, JPG, MTX. TurboCAD Professional includes realistic rendering, full 3D modeling with shells and lofting .... working with AutoCAD files, the ability to work with the Internet, tutorials. TurboCAD is fully customizable, has built-in Microsoft's VBA and is compatible with Microsoft Office. This program also includes the Software Development Kit and Visual Basic® Macro Recorder. TurboCAD Professional is the newest and most powerful 3D CAD application.

Developer - IMSI / Design, LLC. , USA

IronCAD

Computer-aided design system for mechanical engineering. Provides 2D design and 3D solid modeling.

Developer - Visionary Design Systems, Inc. , USA.

Cimatron

Cimatron is an integrated CAD / CAM system that provides a complete set of tools for product design, development of drawing and design documentation, engineering analysis, creation of control programs for CNC machines. Cimatron satisfies the requests and requirements of the widest range of users, works on various platforms, including personal computers. The system is used by about 6,000 companies worldwide.

Developer - Israel. Optional on Bee Pitron.

TEBIS

Developed CAD / CAM system. 2D design and drawing, 3D modeling.

Developer - Tebis Technische Informationssysteme AG, Germany.

VISI Series

Vero product line, advanced system: CAD / CAM / CAE Software - Molds, Tools, Wire EDM, Laser Cut. Provides two-dimensional design and drafting, three-dimensional surface and solid modeling, generation of programs for CNC machines, visualization of part processing.

Developer - Vero Software, USA. Watch on-line video.

VX CAD / CAM

Developed CAD / CAM system. Core modules: VX Innovator, VX Designer, VX Mold & Die, VX 3D Machinist, VX End-to-End.

Developer - VX Corporation, USA.

The main product - CADMAX SolidMaster - a computer-aided design system that provides 2D design, 3D surface and solid modeling.

Developer - USA.

Calculations and analysis

ANSYS

Finite element package. ANSYS, Inc. for 35 years it has been one of the leaders in the CAE market, develops and offers a wide range of software products for automated engineering analysis. Founded by Mr. John Swanson, the company was originally called Swanson Analysis Systems, and offered only the ANSYS universal finite element complex. Later, the program gave a name to the firm itself. Today the company is the market leader in settlement systems both in terms of sales volume and the number of workplaces of its software used all over the world, and the breadth of the range and applicability of software products: ANSYS, AutoDYN, CFX, Fluent, ICEM, Maxwell ... this is just a short list.

The ANSYS product line is wide and provides all the needs of a calculator at all stages of its work, from building or modifying a geometric and mesh model, then moving on to efficiently solving a problem, and ending with processing, presenting and documenting the results.

The main ones in the line of software products are the following, which are tools for solving problems:

ANSYS - strength, thermal physics, electromagnetism

AutoDYN - simulation of highly non-linear and fast-flowing processes

CFX - Fluid Dynamics

Fluent - fluid dynamics

Maxwell - electromagnetism

DesignModeler - creation and / or modification of geometric models

ICEM is a universal tool for building and modifying mesh models

Gambit is a universal tool for building and modifying mesh models for fluid dynamics problems

MSC.Software

Pre-production

IMS Software

ADEM

ADEM system is intended for automation of design and technological bureaus, workshops of the main and technological production. Having a modular structure, ADEM can be completed both for solving specific design problems and for end-to-end production preparation. The system includes modules:

ADEM CAD

ADEM CAPP / CAM

ADEM GPP

ADEM Vault

These modules combine in a single design and technological space all known methods of design and modeling, preparation of control programs for all types of racks of CNC machines. They ensure the integrity of graphic, technological and calculated information, management of the company's databases, and the generation of any reporting documents.

Developer - Omega ADEM Technologies Ltd. Additional information - Vasily Lovygin, Tomsk. ADEM in Tomsk.

CAD / CAM system, which occupies a leading position in the world in terms of the number of sales and package installations among CAD / CAM systems. Provides wireframe and surface modeling of parts, visualization and documentation of simple and complex parts and assembly units, development of control programs for turning, milling, electrical discharge machining on CNC machines.

Developer - CNC Software, Inc. , USA.

Vero Software

Manufacturing product line: CAD / CAM - Computer Aided Design / Automated Process Control.

Developer - Vero Software Plc, UK. Additionally - PF "MOLD SERVICE" Company.

OCTOPUS

The integrated complex of software products will allow: to automate all processes of preparation and production planning in a short time and with high efficiency; organize work at the enterprise in accordance with international standards; to increase the speed, quality and productivity of labor.

Developer - SPRUT-Technology CJSC, Naberezhnye Chelny, Russia.

Delcam PLC

The Delcam family of programs covers all stages of the production cycle. It combines functionality with the latest in user interface technology. As a result, a drastic reduction in the design and production preparation phase. Each Delcam product is focused on a specific aspect of the design, production and inspection of complex products and is the most optimal solution for its application:

Delcam PowerSHAPE, Delcam PowerMILL, Delcam PowerINSPECT, Delcam CopyCAD, Delcam ArtCAM, Delcam Exchange, Delcam Toolmaker, Delcam Electrode, Delcam PS-Team, Delcam FeatureCAM, Delcam

PartMaker, Delcam Crispin, Delcam DentCAD, Delcam DentMILL.

Developer - Delcam PLC.

SolidCAM

A package for generating control programs for CNC machines when machining parts with complex surface or solid geometry. Provides 2.5 and 3-axis milling, turning, visualization of the machining process.

Developer - Israel.

Conceptual design and visualization

Autodesk® AliasStudio ™

Autodesk® AliasStudio ™ is part of Autodesk's digital prototyping technology and is now known as the Autodesk Alias family of products, which includes Autodesk® Alias® Design, Autodesk® Alias® Surface and Autodesk® Alias® Automotive.

A full-featured suite of creative design tools to help companies create superior design solutions that drive business success. A program for consumer product designers that allows you to manage the entire process of working on a design: from finding ideas to handing over finished surfaces to designers. Develop and communicate concepts faster with sketches, 3D models, illustrations, photorealistic images, and animations.

Autodesk, Inc.

Helps you develop innovative designs for consumer goods faster. Autodesk Alias is part of Autodesk's digital prototyping technology. The program is used to develop the design of consumer products. It covers the entire process of working on a design - from sketching ideas to handing over finished surfaces to designers.

Autodesk, Inc.

Autodesk® Alias® Surface

Autodesk® Alias® Surface provides a complete set of dynamic 3D modeling tools that transform conceptual models and scanned data into high quality surfaces for consumer product design, as well as Class A surfaces for automotive design.

Autodesk, Inc.

Autodesk® Alias® Automotive

Autodesk® Alias® Automotive is the industry leading automotive design product, the choice of top auto design studios around the world. The product provides a complete set of visualization and analysis tools covering the entire process of modeling complex shaped products, from creating sketches to obtaining finished surfaces of class A.

Autodesk, Inc.

Form-Z

2D design and drafting system, 3D surface and solid modeling, visualization and animation for professional design, visualization and design.

Developer - Autodessys, Inc. , USA.

Applied CAD

Bentley Systems, Incorporated - Product Series

Bentley is a global leader in end-to-end software solutions for support and infrastructure throughout its lifecycle. in the design, creation and operation of buildings, bridges, transport networks, water, heat and power supply enterprises, water purification, etc.

MicroStation Platform Products and Technology:

Analysis and design of buildings

Design and construction of bridges

Land management

Cartography

Civil Engineering

Plant design and construction

Conceptual design of industrial facilities

Design and analysis of electricity and gas supply networks

Construction design and analysis

Design and analysis of water supply and sewerage networks, etc.

Developer -.

The E3.series system is modular. It consists of three main modules:

E3-schematic - a module for designing various types of schematics (technological, functional, pneumatic, electrical, single-line, etc.)

E3-cable is a module for designing cable-harness circuits, as well as external wiring diagrams. Includes the functionality of the E3-schematic module

E3-panel is a layout and tracing module. Carries out the arrangement of equipment in the cabinet (board, panels, etc.); wire routing in accordance with the schematic diagram; layout of cables through cable channels on the plan of the object.

In addition to the main modules, there are additional ones:

Interfaces for exporting data on harnesses and cables to 3D design systems and 3D cable layout by objects - Autodesk Inventor Professional, SolidWorks, Unigraphics, Catia.

E3-PDF Output - a module for exporting a project to vector PDF format. The structure of the project is preserved in such a PDF file; it is possible to search for a product by any attribute; cross-referencing of products and chains and other options.

Developer - Zuken.

CADSTAR

Advanced computer-aided design and manufacture of electronic circuits and printed circuit boards (PCB CAD). Developer - Zuken.

DEFCAR CAD / CAM

System for design and preparation of production in shipbuilding.

Developer - Defcar, S.L. , Spain.

VUTRAX

Vutrax PCB CAD is a computer-aided design system for electronic circuits and printed circuit boards (PCB CAD).

Planit

Planit CAD / CAM product line - computer-aided design for the wood, stone and metal industry: Wood CAD / CAM Software, Stone CAD / CAM Software, Wood CAD / CAM Software.

Developer - Planit, USA.

CAD-programs (computer aided design) - system complexes for design, with the help of which they automate tasks at different stages of manufacturing industrial products (design, pre-production). In the Russian-language abbreviation - CAD (computer-aided design system).

All CAD-systems, regardless of terminology, are designed to optimize the work of the engineering staff of the enterprise. If applied correctly, appropriately, they increase the productivity of individual groups of employees. And this leads to an increase in the overall performance of the staff as a whole.

CAD-systems deployed at the enterprise allow solving the following tasks:

- to reduce the labor intensity of individual operations and processes, which means to reduce the time and costs for the development and manufacture of products;

- reduce the time spent on preparing projects - with these systems, design is brought to a fundamentally different level;

- to increase the accuracy of manufacturing products without losses in speed (production efficiency even increases);

- reduce the costs that are necessary to maintain the engineering staff (which reduces the cost of the finished product);

- improve the quality of design - CAD programs bring it to a new technical and economic level;

- reduce the cost of sample modeling and testing.

CAD - complete solutions. They can be software, technical, and others. With the help of CAD, they automate the preparation of design and construction documents and other documents within the enterprise, unify design, optimize the process of making management decisions (by expanding information support), and solve other problems.

Versatility and free integration with SAP solutions

Due to their high efficiency and flexibility of products, the systems are used in various fields - from dentistry and medical prosthetics to mechanical engineering. Today CAD programs are software that is freely integrated into SAP systems, they are compatible with any of their solutions. Using special buses, you can combine CAD with PLM or CAM systems (computer aided manufacturing). The latter, designed for working with CNC machines, create numerical control algorithms, open up opportunities for the manufacture of high-quality complex-profile products in a shorter time.

CAD software solutions also support:

- top-level systems - CAD / CAM Unigraphics;

- complexes at the middle level - Solid Edge;

- lower-level systems - AutoCAD and others.

The programs integrate with Pro / Engineer, SolidWorks, TeamCenter, Inventor, and other products. They are easy to learn, they have a "user-friendly" interface, wide functionality (you can customize them so that they meet the individual requirements of the customer and the specifics of the business). CAD systems support concurrent design technologies. With them, you can freely use the methods of variant optimization, mathematical modeling. Another important plus is that the price of the product is flexible. It is determined by the functionality that is selected for a specific customer, his needs, tasks, opportunities.

ASAP Consulting offers services for the development of optimized design and manufacturing solutions that use advanced automation tools. We will select CAM, CAD solutions for a specific task, help to deploy products in the enterprise, and advise on all emerging issues.

CAD system(сomputer-aided design computer support for design) is a computer-aided design system designed to carry out design work using computer technology, and also allows you to create design and technological documentation for individual products, buildings and structures.

Usually, the abbreviation CAD considered the standardized English equivalent of the term CAD... However, the concept of CAD is not a complete equivalent of CAD as an organizational and technical system: so in GOST 15971-90 this phrase is given as a standardized English equivalent of the term "computer-aided design". The term CAD in English can also be translated as CAD system, automated design system, CAE system.

A number of foreign sources establish a certain subordination of the concepts of CAD, CAE, CAM. The term CAE is defined as the most general term to encompass any use of computer technology in engineering, including CAD and CAM. The term CAx (computer-aided technologies) is used to denote the entire spectrum of various automation technologies using a computer, including CAD tools.

The main purpose of creating CAD- increasing the efficiency of engineers' labor by automating work at the design and preparation stages. So, thanks to CAD, it is possible to achieve:

Reducing the complexity of design and planning;

- reduction of design time;

- reducing the cost of design and manufacture, reducing operating costs;

- improving the quality and technical and economic level of design results;

- reducing the cost of full-scale modeling and testing.

CAD uses the technical knowledge of specialists as input information, who introduce design requirements, refine the results, check the resulting structure, change it, etc.

The computer-aided design system is implemented in the form of a complex of applied programs that provide design, drawing, three-dimensional modeling of structures, flat or volumetric parts.

As a rule, modern CAD systems include modules for modeling a three-dimensional three-dimensional structure (details) and design of drawings and text design documentation (specifications, statements, etc.).

CAD classification according to GOST 23501.108-85:

Type / type of design object

- the complexity of the design object

- the level of design automation

- the complexity of design automation

- the nature of the issued documents

- the number of issued documents

- the number of levels in the structure of technical support

Classification of CAD (or CAD subsystems) by purpose:

CAD (computer-aided design / drafting) means computer-aided design, in the context of this classification, the term denotes CAD tools designed to automate two-dimensional and / or three-dimensional geometric design, create design and / or technological documentation, and general-purpose CAD.

- CADD (English computer-aided design and drafting) - design and creation of drawings.

- CAGD (English computer-aided geometric design) - geometric modeling.

- CAE (computer-aided engineering) - means of automation of engineering calculations, analysis and simulation of physical processes, carry out dynamic modeling, verification and optimization of products.

- CAA (computer-aided analysis) is a subclass of CAE tools used for computer analysis.

- CAM (English computer-aided manufacturing) - means of technological preparation of production of products, provide automation of programming and control of equipment with CNC or GAPS (Flexible Automated Manufacturing Systems)). The Russian analogue of the term is ASTPP - an automated system for technological preparation of production.

- CAPP (English computer-aided process planning) - automation tools for planning technological processes used at the junction of CAD and CAM systems.

Many computer-aided design systems combine the solution of tasks related to various aspects of CAD / CAM, CAD / CAE, CAD / CAE / CAM design. Such systems are called complex or integrated.

Generally accepted international classification of CAD / CAM / CAE systems:

Drawing-oriented systems, which were the first to appear in the 70s. (and are still successfully used in some cases).

Systems that allow you to create a three-dimensional electronic model of an object, which makes it possible to solve problems of its modeling up to the moment of manufacture.

Systems supporting the EPD Electronic Product Definition concept. EPD is a technology that enables the development and maintenance of an electronic information model throughout the entire life cycle of a product, including marketing, conceptual and detailed design, technological preparation, production, operation, repair and disposal.

CAD abbreviation in modern technical, educational literature and state standards stands for "Computer-aided design system", although more closely matches the abbreviation CAD decoding "Design work automation system", but it is heavier for perception and is used much less often. Misinterpretation can often be heard - "Computer-aided design system", which is inherently erroneous, since the concept of "automatic" implies the independent operation of the system, without human participation, and in CAD, some functions are performed by a person, and only individual design operations and procedures are automatic. The interpretation is also not entirely correct "Software tool for design automation" because it is too "narrow": of course, nowadays, CAD is often understood only as an application software for the implementation of design activities. However, in the domestic literature and state standards, CAD is defined as a more capacious concept that includes not only software.

Currently the largest developers of CAD / CAM systems are the companies:

Parametric Technology Corporation (PMTC) - Pro / Engineer software, Windchill;

- Dassault Systemes (DASTY) - CATIA, SolidWorks, ENOVIA CATIA, DELMIA software;

- Autodesk (ADSK);

- Unigraphics Solutions (UGS) - Unigraphics, Solid Edge, iMAN, Parasolid software;

- Structural Dynamics Research Corporation (SDRC) - I-DEAS software.

CAD systems are those that are used to perform a variety of design procedures using computer technology. Also, with the help of such software, a technological one is created for individual buildings, products or structures. Modern CAD systems are used in a wide variety of areas of modern human activity, and almost each has its own unique type of such utilities.

What it is?

Often, the abbreviation CAD is considered to be the standard English equivalent of the term CAD, but in reality this is not entirely true. CAD systems cannot be considered as a full-fledged analogue of CAD systems as an organizational and technical system, since GOST gives this phrase in the form of a standardized English equivalent of the term "computer-aided design". Thus, the term CAD is translated into English more as CAE system, but a number of foreign sources indicate that the term CAE is a generalized concept that includes the use of any computer technology in engineering work, including CAM and CAD.

Why is this needed?

CAD systems are used primarily to maximize the efficiency and productivity of engineers through full design automation and further preproduction. Thus, due to their use, the following advantages are achieved:

- the design time is significantly reduced;

- the amount of labor required for planning and design is reduced;

- the total cost of manufacturing and design is significantly reduced, which directly affects the operating costs;

- an increase in the technical and economic level, as well as the quality of the results of the design work carried out;

- reducing the costs required for testing and full-scale modeling.

As input data, modern CAD systems use various technical knowledge of experts who are engaged in clarifying the results, introducing various design requirements, checking the resulting design, changing it, and many other things.

The implementation of the computer-aided design system is carried out as a complex of applied utilities, with the help of which design is provided, as well as further drawing and three-dimensional modeling of structures or volumetric and flat parts.

In the majority of cases, CAD-systems include modules for modeling three-dimensional structures, as well as the design of drawings and various design text documentation.

They are classified mainly according to several parameters:

- the type and type of the object in question;

- the level of automation of the design procedure;

- the complexity of the object being created;

- the complexity of the automation process;

- the number of documents used;

- the nature of the documents used;

- the total number of levels that will be present in the structure of technical support.

Special purpose

Depending on what the tasks of CAD systems are being implemented, they are divided into several groups:

- Automation of three-dimensional or two-dimensional geometric design, as well as the creation of various technological or design documentation.

- Design and further creation of drawings.

- Geometric modeling.

- Automation of various engineering calculations, dynamic modeling, as well as analysis and simulation of physical processes with subsequent verification and optimization of products.

- A subclass of CAE tools used for computer analysis.

- Means intended for the technological preparation of the production process of various products, which allows for the automation of the programming procedure and further control of equipment with GAPS or CNC.

- Tools designed to automate planning processes for various technological processes used at the junction of CAM and CAD systems.

Most computer-aided design systems can combine the solution of various problems that relate to different aspects of design - this is an integrated or integrated computer-aided design (CAD) system.

Generally accepted international classification

The modern classification divides them into several categories:

- drawing-oriented systems, which first appeared in the seventies of the last century, but can still be used in some situations;

- systems that create three-dimensional electronic models of objects, due to which it becomes possible to solve various problems related to modeling up to the production procedure;

- systems that support the concept of a complete electronic description of an object.

The latter type is a technology that provides the development and subsequent support of an information electronic model throughout its entire life cycle, including conceptual and detailed design, full-fledged marketing, production, technological preparation, operation, as well as disposal and repair.

In modern technical and educational literature, as well as in various state standards, the abbreviation CAD is interpreted as "Computer-aided design system", but at the same time the concept of "Design work automation system" corresponds most closely here, but it is more difficult to perceive, therefore, it occurs an order of magnitude less often ... It often happens that, while designing in CAD systems, you may notice an incorrect interpretation of the "Automatic design system", although in fact it is inherently erroneous. Do not forget that the concept of "automatic" provides for a completely independent operation of the system without the need for any human participation, while CAD still requires the execution of some tasks by the person himself, and full automation refers only to individual procedures and operations. ...

The concept of "Computer-aided design software" is also not entirely correct, since it can be called too narrowly focused. Of course, at the moment, CAD is considered exclusively as applied software necessary for carrying out design activities, but in fact, in the domestic literature and various state standards, CAD is considered as a more voluminous concept, which includes not only software tools.

CAD in dentistry

The vast majority of modern dental clinics use CAD. CAD systems in dentistry are used for the production of high-quality dental prostheses, for more than ten years they have been used for the manufacture of abutments for implants, crowns and all kinds of prostheses, all of which are of excellent quality and high precision. The essence of this technology lies in the fact that initially a three-dimensional modeling of the created structure is carried out on a computer, and only then, using the design model, the manufacturing is carried out on the milling unit.

Thus, dentists receive many benefits through the use of CAD technology in their work. CAD systems in dentistry are most often used in the following ways:

- first, the doctor takes an impression, which is then sent to the laboratory;

- after delivery, the impression is placed in a specialized scanner that creates a model of the future product;

- the CAD system comes into play: the 3D model turns into a specialized file that will serve as a data source for the milling unit;

- using the resulting file, a frame is produced on the milling unit from a special workpiece made of zirconium oxide;

- in the end, the resulting frame is carefully covered with a ceramic mass and baked.

CAD / CAM systems in dentistry allow the production of zirconium dioxide crowns, which differ from metal-containing products in a number of advantages. By themselves, these products practically do not differ in color from natural teeth, since the choice of shade is carried out during the production of the frame. Further, the frame is carefully covered with a special ceramic mass, which has a translucent and translucent structure, and also includes a fairly wide range of colors in its palette, which makes it possible to make crowns similar to natural teeth.

By itself, it is highly biocompatible, even when compared with precious metals, and is a hypoallergenic material, which has been confirmed in the course of a number of scientific clinical studies. However, in reality, crowns based on a zirconium oxide framework are far from the only type of products for the manufacture of which CAD / CAM systems are used. A CNC machine based on these technologies allows you to make:

- various bridges;

- customized abutments.

In addition to the already mentioned zirconium dioxide, a wide variety of materials can be used in the manufacturing process, including plastic, wax, cobalt and titanium, chromium.

What are the benefits?

These technologies provide such advantages as:

- the highest possible manufacturing accuracy with minor deviations;

- full automation of production processes, which almost completely eliminates the likelihood of errors;

- the ability to use a variety of materials;

- the ability to carry out procedures for modeling and manufacturing products in different places;

- limiting productivity of any ongoing processes.

CAD in mechanical engineering

The CAD system (T-FLEX CAD and others) has found a fairly widespread use in the field of mechanical engineering, which differs in three levels - lower, middle and upper. This division appeared at the turn of the eighties and nineties of the last century.

The lower level includes CAD / CAM / CAE systems with low cost, which are mainly focused on 2D graphics, that is, they are mainly aimed at providing automation of drawing work. As light CAD systems, personal computers were used, which already at that time were significantly inferior in functionality to full-fledged workstations.

Top-level systems, or, as they are also called, heavy CAD systems, were developed in order to be used on all kinds of mainframes or workstations. Such systems turned out to be much more versatile, but at the same time had a rather high cost, focusing mainly on surface and solid modeling. The design of various drawing documentation in them is often carried out through the preliminary development of special geometric three-dimensional models. After that, systems in which the 3D modeling function was limited exclusively to solid models, that is, occupying an intermediate position between heavy and light, received their own, average level.

Today, the development of CAD has already led to the fact that in most middle-level systems, special surface modeling tools have begun to appear, and the functions available for use in personal computers have also become acceptable for modern upper-level systems. Due to this, even the principles by which the distinction between medium and heavy systems was previously carried out has changed. Modern CAD systems of a heavy level are now called CAE / CAD / CAM / PDM, that is, those that simultaneously include such features as:

- technological and design engineering;

- engineering analysis;

- project information management;

- extended set of special software modules.

In contrast, modern mid-range systems are usually called mainstream, mid-range, or simply serial.

Systems of the same level can be called approximately equivalent in functionality, since some new achievements that appear in a certain software and methodological complex will soon be implemented in new versions of others. In CAD of large companies, it is quite often customary to combine several systems of different levels at the same time. This is often due to the fact that almost all design procedures can be carried out on CAD systems of the middle and lower levels, and besides, heavy ones are too expensive. It is for this reason that enterprises buy licenses for top-level programs in a rather limited number, and the vast majority of modern client bases are provided at the expense of the lower and middle tiers.

At the same time, it often happens that CAD / CAE systems can have certain problems in terms of exchanging information with each other, but such troubles are solved by using special formats and languages adopted in CALS technologies, although to ensure undistorted transmission of geometric data through intermediate unified languages have some complexities to overcome.

Structure

Like any other complex system, CAD includes several subsystems that can be design or maintenance.

The former are directly involved in the implementation of various design work. As an example of these, one can cite subsystems for three-dimensional geometric modeling of all kinds of mechanical objects, circuit analysis, creation of design documentation, or tracing of PCB connections.

Service subsystems are intended to ensure the normal operation of the designers, and their combination is quite often called the CAD system environment among specialists. Typical maintenance subsystems are often used for project management databases, various subsystems for the development and subsequent maintenance of CASE software, as well as training ones designed to facilitate the users' mastering of technologies implemented in CAD.

Structuring in various aspects allowed the emergence of types of CAD software, of which today there are only seven:

- technical, which includes various;

- mathematical, combining all kinds of mathematical methods, algorithms and models;

- software, which is a computer CAD program;

- informational, which includes databases, management systems for these bases, as well as many other information used in the design process;

- linguistic, expressed in the form of communication languages between computers and designers, languages for data exchange between CAD hardware and programming languages;

- methodical, which includes all kinds of design technologies;

- organizational, executed in the form of job descriptions, staff schedules and other documentation, with the help of which regulation of the work of design enterprises is carried out.

It is worth noting that the entire set of information that is used in the design process is called by specialists the CAD information fund. A database is an ordered set of information, which reflects various characteristics of objects and their relationship in a certain database.Access to the database for studying, recording and subsequent data correction is carried out through the DBMS, and the set of DBMS and DB is usually called BND, that is, a data bank.

Classification

CAD / CAM design systems are classified according to a number of characteristics, such as application, purpose, scale (how comprehensively the tasks are solved), and the nature of the underlying subsystem.

In terms of applications, the following CAD groups should be distinguished among the most popular and representative ones:

- used in the field of general mechanical engineering (due to which they are usually called mechanical engineering);

- used in the field of radio electronics;

- used in the field of construction and architecture.

In addition, there is also a fairly large number of specialized systems either allocated in the listed groups, or representing a completely independent branch of the classification. As an illustrative example, we can cite CAD systems for large integrated circuits, electrical machines, aircraft, and a number of others.

In terms of scale, individual software and methodological complexes differ, including a complex for checking the strength of various mechanical products according to the finite element method or a complex for checking electronic circuits, as well as systems with a unique architecture of not only software, but also hardware.

Basic subsystem

The following types of CAD exist here:

- Based on the subsystem of geometric modeling and computer graphics. Such CAD systems are mainly focused on various applications in which design acts as the main design procedure, that is, a clear definition of spatial forms, as well as the mutual location of objects. That is why this group includes many CAD systems from the field of mechanical engineering, based on the graphics cores. Nowadays, it is quite common to use unified graphics cores.

- Based on DBMS. They are mainly guided by those applications in which it is possible, by carrying out relatively simple mathematical calculations, to process a sufficiently large amount of information. They are often found in technical and economic applications, such as the design of business plans, but they are often used in the design process of large objects like control panels in automatic systems.

In addition, there are also complex CAD systems, which include subsystems of all previous types. As typical examples of such complex systems, it is worth mentioning software that is actively used in modern mechanical engineering, or CAD LSI. The latter includes a DBMS and various subsystems for designing components, functional and logical circuits, crystal topology, as well as tests for analyzing the suitability of manufactured products. In order to ensure the normal management of such complex programs, it is customary to use specialized system environments.

The table presented in this material is an ordered list of manufacturers of ready-made software solutions in the field of design, development and industrial design systems.

Peculiarities

Along with the use of automation systems for engineering calculations and CAE analysis, at this time, as a rule, computer-aided design (CAD) systems are used. Information from CAD systems goes to CAM (Computer-aided manufacturing). It should be noted that the English term "CAD" in relation to industrial systems has a narrower interpretation than the Russian term "CAD", since the concept of "CAD" includes CAD, CAM, and CAE. Among all information technologies, design automation takes a special place. First of all, design automation is a synthetic discipline, since it includes various modern information technologies. So, for example, the technical support of CAD is based on the operation of computer networks and telecommunication technologies, and CAD also practices the use of personal computers and workstations. Speaking about the mathematical support of CAD, it should be noted the variety of methods used: computational mathematics, mathematical programming, statistics, discrete mathematics, artificial intelligence. CAD software systems can be compared with some of the most complex modern software systems, which are based on such operating systems as Windows, Unix, and programming languages such as C ++ and Java, as well as modern CASE technologies. Almost every development engineer should have knowledge of the basics of design automation and be able to work with CAD tools. Since all design departments, offices and design bureaus are equipped with computers, the work of a designer with such a tool as an ordinary drawing board or calculations using a slide rule have become irrelevant. Consequently, enterprises that work without CAD or use it to a small extent become uncompetitive, since they spend much more time and money on design.

CAD types

- CAD software (MO) - this type implies the combination of mathematical methods, models and algorithms in order to perform design)

- Linguistic support of CAD (LO) - this support is an expression of communication languages between designers and computers, data exchange languages and programming languages between CAD technical means;

- CAD technical support (TO) - this includes peripheral devices, computers, communication lines, data processing and output, etc .;

- CAD information support (IO) - consists of databases (DB), database management systems (DBMS) and other data that are used in the design;

- CAD software (SW) is, first of all, CAD computer programs;

- Methodological support (MetO) - includes various kinds of design techniques;

- Organizational support (OO) - is represented by staffing tables, job descriptions and other documents that determine the work of the project enterprise.

CAD structure

As one of the complex systems, CAD consists of two subsystems: design and maintenance. Design procedures are performed by design subsystems. Subsystems for geometric three-dimensional modeling of mechanical objects are a prime example of designing subsystems. With the help of servicing subsystems, the functioning of the designing subsystems is carried out, their unity is usually called the system environment or the CAD shell. Typical service subsystems are considered to be design process management (DesPM - Design Process Management), design data management (PDM - Product Data Management). Dialogue subsystem (DP); DBMS; instrumental subsystem; monitor - providing interaction of all subsystems and control of their execution - these are the service subsystems of the software. The dialog subsystem of the software enables the interactive interaction of the CAD user with the control and design subsystems of the software, as well as the preparation and correction of the initial data, familiarization with the results of the design subsystems operating in batch mode.

The structure of a CAD software is determined by the following factors:

- aspects and level of descriptions created with the help of software, designed objects and subject area;

- the degree of automation of specific project operations and procedures;

- resources provided for software development;

- architecture and composition of technical means, mode of operation.

CAD classification

CAD is classified according to the following principles: purpose, application, scale and nature of the underlying subsystem. For their intended purpose, CAD or CAD subsystems are distinguished, which provide various aspects of design. Thus, CAE / CAD / CAM systems appear as part of MCAD:

- CAD-F or CAE (Computer Aided Engineering) systems. This refers to CAD of functional design.

- CAD-K - design CAD systems for general mechanical engineering, most often they are called simply CAD systems;

- CAD-T - technological CAD of general mechanical engineering - ASTPP (automated systems for technological preparation of production) or CAM systems (Computer Aided Manufacturing).

By applications, the most important and widely used are the following CAD groups:

- Mechanical CAD or MCAD (Mechanical CAD) systems are CAD systems for applications in the general mechanical engineering industries.

- ECAD (Electronic CAD) or EDA (Electronic Design Automation) systems - CAD for radio electronics.

- CAD in the field of architecture and construction.

In addition, there are a large number of more specialized CAD systems, either allocated in certain groups, or being an independent branch in the classification. These are such systems as: BIS -SAPR (large integrated circuits); CAD of aircraft and CAD of electrical machines. By scale, independent software-methodical complexes (PMK) CAD are determined:

- Complex for the analysis of the strength of mechanical products in accordance with the finite element method (FEM)

- Electronic circuit analysis complex;

- PMK systems;

- Systems with unique software and hardware architectures.

Classification by the nature of the basic subsystem

- CAD systems that are aimed at applications where the main design procedure is design, that is, the definition of spatial forms and the relative position of objects. It is a CAD system based on computer graphics and mathematical modeling. This group of systems includes most of the CAD graphics cores in the field of mechanical engineering.

- CAD systems focused on applications in which large amounts of data are processed with fairly simple mathematical calculations. It is a DBMS-based CAD system. CAD data are mainly found in technical and economic applications, for example, in the process of designing business plans, objects like control panels in automation systems.

- Complex (integrated) CAD systems, which include a set of previous types of subsystems. Typical examples of complex CAD systems are CAE / CAD / CAM systems in mechanical engineering or CAD LSI systems. Thus, the DBMS and subsystems for the design of components, schematic, logical and functional diagrams, topology of crystals, tests for verifying the suitability of products are an integral part of the LSI CAD. In order to manage such complex systems, specialized system environments are used.

- CAD based on a specific application package. In fact, these are freely used software and methodological complexes, such as a complex for simulation of production processes, a complex for the synthesis and analysis of automatic control systems, a complex for calculating strength by the finite element method, etc. As a rule, CAD data are related to CAE systems. For example, logic design programs based on the VHDL language, mathematical packages such as MathCAD.

CAD development

One of the key themes of CAD development is "cloud" computing: remote work with data located on remote servers from various devices with Internet access. Today, clouds have made very significant progress in the segment of lightweight applications and services - mainly in the consumer sector. There are two possible integration options. In the first case, the entire infrastructure of engineering services is transferred to the cloud, and, accordingly, the need for engineering software installed at the workplace disappears altogether. In the second case, the designer still has a graphic workstation with a CAD system installed, but at the same time he gets access from it to various cloud services, thanks to which it is possible to solve problems that require very significant resources (for example, to carry out strength analysis). It is possible to carry out cloud interaction in two ways: publicly, when access to the server located at the provider is open via the Internet, and privately, when the server is located in the enterprise and calls to it occur over a closed local network. In Russia, the development of clouds in the field of CAD is constrained by the need to maintain excessive secrecy in many projects. Therefore, it is most likely that private clouds will become the main driver of the market in the near future. The clouds are not only about new technologies, but also the opportunity to experiment with new business models.

The next major trend is alternative operating systems. Five years ago, when there was talk of an alternative to Microsoft Windows, it was usually Linux. This topic is still relevant today: the domestic national software platform, most likely, will be based on the Linux kernel; there is a growing interest in this OS in the field of education and in government agencies (there are examples of a successful transition). However, now we can already talk about the significant potential of the operating system Google Chrome OS. And here the mentioned trend merges with the cloud trend - Google OS, as you know, does not imply the installation of applications on a local computer.

An important role in the promotion of this OS is played by the trend towards a decrease in the market share of the PC. Obviously, if you move most of the cumbersome and complex computing to the clouds, the hardware requirements will be reduced and you will be able to work on any device. For example, on tablets. As a result, CAD developers will have to either develop platform-independent solutions (cloud version), or make them multi-platform.

The next topic is hardware. Here again, everything is determined by the dissatisfaction of the market with the decision of the monopolist - the classic architecture of Intel (the pace of its development). In this regard, there is a clear trend towards the development of the ARM architecture. It is now supported by several manufacturers, among which one of the most active is Nvidia (Nvidia). So far, this architecture is actively used only in mobile devices, but in the near future, apparently, it will go to stationary PCs. This is indirectly evidenced by the fact that the future Microsoft Windows 8 OS will be able to work on the ARM architecture too (for the first time not only on Intel).

The second trend is the transfer of a significant part of computing from the central processor to the graphics core. This topic belongs rather to the field of parallel computing.

Another trend is the growth of the mobile device market. It got the biggest boost last year with the iPad. At first, however, it seemed that this device was purely consumer and in the corporate sector it would not be applicable. However, it turned out that it is quite suitable for solving many problems.

In the CAD sector today, many employees are mobile - working on the road, at remote construction sites, moving around the country, working from home. (All this requires a handy mobile device.)

One way or another, abroad that every employee of the engineering service will soon have a tablet, today they speak of it as a fait accompli. Mobile platforms IOS Apple and Android Google, attractive for developers, have already appeared, as well as a significant number of CAD applications for them.

Now it is very difficult to say whether the keyboard and mouse will leave our arsenal in ten years. But the fact is that multi-touch (finger-oriented) interfaces are clearly gaining popularity. In mobile devices, they have almost become the standard. Today it is quite clear that this interface is more than suitable for consuming information. Whether it is just as good for its creation, for working with CAD, it is still difficult to say. The technological base is still lacking for a massive transition to such interfaces. There are simply no large enough multi-touch panels on the market today with the resolution required for CAD.

The CAD market is very conservative. Even replacing one such system with another within the framework of work on one project is a rather difficult task. What can we say about a serious change in the paradigm, interfaces, generations of CAD. Therefore, this market is clearly not among the leaders in the technological race - there is development, but obviously not as fast as we would like. However, in the next decade, engineers who have grown up in the era of the Internet, new technologies and mobile devices will come to enterprises, and one way or another they will actively bring elements of their culture to the market.

CAD in construction

Business digitalization has affected all its industries. In the last decade, solutions for the design, engineering and construction of industrial facilities have been booming. From Soviet drawing boards, the designers came to 3D modeling. Alexey Lebedev, CEO of AVEVA, helped to understand what digitalization means for this segment, how to help the team work in a single space and why it has not yet been possible to finally get rid of paper media.

Scenario "March 8" junior group

Scenario "March 8" junior group Scenario of a game program for junior schoolchildren

Scenario of a game program for junior schoolchildren Flowers from Zhostovo: painting on metal

Flowers from Zhostovo: painting on metal Why does the router not distribute the Internet via WiFi and how to fix it?

Why does the router not distribute the Internet via WiFi and how to fix it? SAP program what is it

SAP program what is it Electronic money and payment systems

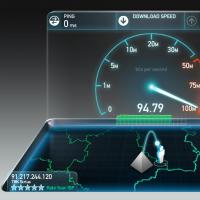

Electronic money and payment systems What is internet speed and how to check it online

What is internet speed and how to check it online