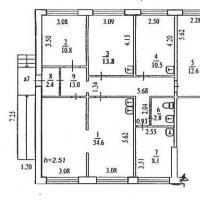

Schematic formula for calculating the usable area of the warehouse. Calculation of warehouse technological zones: efficient planning of the rented area

Warehouse premises of any enterprise should be competently divided into two functional areas. The first is for storage finished products, packing and loading. The second functional area contains technical and engineering rooms. For effective work of the entire warehouse, it is necessary to calculate the optimal parameters of both sections and determine their location.

Before planning storage areas, the designer studies the specifics of the enterprise and the specifics of commodity circulation.

Basic requirements for the layout of warehouses

Warehouse design should be based on several practical requirements:

- the area intended for storing goods should be twice the size of the premises allocated for the remaining needs of the warehouse;

- the layout of the premises should be designed for the use of warehouse equipment, loading equipment. It is required to create conditions for high-quality stacking and storage of products. This is the guarantee of the continuity of trade, the accuracy of all technological processes;

- if possible, it is recommended to arrange a single-span warehouse with a large area. The absence of partitions and sufficient width (about 24 meters) are favorable conditions for the movement of loading and unloading equipment and other special devices. To ensure the bearing capacity, columns and reinforced spans are arranged;

- the main storage areas are planned with a ceiling height sufficient for the efficient stacking of packages and the passage of special equipment.

At the design stage, specialists find out the specifics of the technological processes that will be carried out in this warehouse, the number and parameters of premises for various purposes, and their mutual arrangement. All these points will subsequently affect the efficiency of warehouse operation and the profitability of the entire enterprise.

Characteristics of the main storage areas

The most common type of storage space is warehouses. All the rest are similar to them on the principle of zoning, the differences will be only in equipment and equipment. The project provides for several technological zones, each of which has its own purpose:

- Area for manual or mechanized unloading of vehicles ... It is also here that the goods are removed from the transport packaging. The site should be designed for the possibility of short-term storage of pallets, boxes, etc., prior to their transfer to the acceptance expedition. The unloading zone is an area into which large-capacity vehicles can enter. It can be located inside a building or in the surrounding area.

- Expedition acceptance area ... The counting, reconciliation of the quantity and quality of the goods is carried out, the receipt of packages is recorded and their storage is carried out before being transferred to the main storage room. The expedition site may be isolated from other areas, but must be adjacent to the unloading area.

- Storage area... Here, racks are installed in accordance with the permissible storage height of a particular type of product, and the necessary microclimate is created. This is the largest of all storage areas. In it, a site must be allocated for the preparation of goods for storage, the formation of places. Depending on the specifics, products can come here directly from the unloading area.

- Order packing area ... Selection and picking of several commodity items ordered by the consumer into one transportation unit is carried out. The territory is directly adjacent to the storage area, and sometimes is part of it. There is a direct access to the dispatch expedition area.

- Expedition dispatch area ... Preparation of accompanying documentation, checking the quality of packaging. In this room, the goods are accepted for shipment by the forwarder or directly by the consignee. A short storage of the prepared batch is possible until the arrival of the vehicle.

- Loading area... This is an area designated for the entry of trucks. It should be located in a separate room or in an open area. On the large enterprises a railway ramp is envisaged.

All technological areas are interconnected by walkways and wide driveways.

Determination of the main parameters of the warehouse

To calculate warehouse space, designers use several formulas:

- The total area of the warehouse. Calculated by the formula:

S = S floor + S sp + S set + S pr + S sl + S pe + S oe, where

- S is the total area of the warehouse, m 2;

- S floor - the so-called usable area. This is the total value for all areas directly occupied by racks, pallets and other devices for storing products, m 2;

- S pr - the territory occupied by the acceptance expedition site, m 2;

- Ssp is the total area of technological passages and driveways, total for the entire warehouse area, m 2;

- S set - area of the area for picking and packing orders, m 2;

- S pe - site of the acceptance expedition, m 2;

- S cn - the total area occupied by workplaces. This includes all areas set aside for the direct location of warehouse personnel, m 2;

- S oe - section of the departure expedition, m 2.

If an approximate calculation of the total area is performed, it is allowed to use a simplified formula and carry out calculations through a coefficient according to the formula:

S = S floor / a, m 2.

In this formula, a = 0.3 ... 0.6 is the utilization rate of warehouse premises, in another way it is called the specific gravity of the usable area. The amount of the correction depends on the specifics of the stored products.

The formula for calculating the useful storage area

S floor = Q max / q add, m 2, where

- Q max - the maximum amount of stored products for which the warehouse is designed, t;

- q add - the maximum permissible storage load per unit area, t / m 2.

The useful area of storage facilities can be calculated using the general formula:

S gr = QZKn / (254CvKigoN), m 2,

- where Q is the forecasted annual turnover, rubles / year;

- З - the projected volume of stocks of goods, depends on the time of turnover;

- Kn - coefficient from 1.1 to 1.3. The amendment determines the unevenness of the workload of warehouses. It is calculated as the ratio of turnover in the months of peak load to the average turnover;

- Kigo is the utilization rate of the cargo volume;

- 254 - the number of working days in a calendar year;

- Cv is the approximate cost of storing one unit of product volume, rubles / m 3. It can be determined by calculation, knowing the mass of goods that occupy 1 m 3. Measurements are performed by warehouse workers directly in the storage room, then the resulting figure is simply multiplied by the cost of one cargo unit: kilogram, gram, ton, etc.

- To determine Q and Z, preliminary forecasts are used, an exact calculation is not required.

The utilization rate of the cargo volume shows the stacking height of storage units and their density. In practice, it is impossible to use the capabilities of the warehouse 100% in this regard, especially if the goods are stacked on a rack. The coefficient is calculated by the formula:

Kigo = V full / (S about × H), where

- V floor - the volume of one packed storage unit that can be stored on a specific equipment using 100% of the height, m 3;

- H - height of storage of goods, m;

- S about - the area of the projection of the outer contours of racks and other equipment intended for storing goods, transferred to a horizontal plane.

- Experienced designers know that in practice the coefficient will be 0.64 for pallets, and 0.67 for storing goods without a pallet.

If the goods are stored in bins, you will need to calculate the required number of cargo items (bins and racks). To do this, use the formula:

S floor = S st × N st, where

- S st - area of one rack, m 2;

- N st - the number of pieces of equipment (racks).

- If goods arrive at the warehouse in a non-uniform flow, the usable area is calculated based on the minimum cost:

S res × S 1 + 365PkS 2 - min, where

- S res - the area allocated for the reserve, m 2;

- S 1 - the cost of maintaining one unit of the area of the reserve section, rubles / m 2;

- Pk - coefficient taking into account the possibility of refusal to store products;

- 365 - the number of days in a calendar year;

- S 2 - probable financial losses for refusal to store, attributed to one day, rubles.

Acceptance and picking areas

To calculate the acceptance and picking zones, the calculated load indicators are used for each square meter of the area. The values are taken enlarged to create a small technological reserve. For an approximate calculation, it is allowed to assume that 1 m 3 of products will have to be placed on each unit of area. Several basic formulas are used for the calculation:

Formula for calculating the length of a rail or road ramp (gable for unloading goods):

L fr = nl + (n - 1) li, where

- l is the length of one unit of the used transport, m;

- n is the number of transport units at unloading;

- li - the gap between two transport units simultaneously unloading, m.

- The area allotted for the reception and packaging of products is calculated by the formula:

S pr = Q g × Kn × A2 × t pr / (365q add × 100) + S in, where

- Kn - coefficient of unevenness, taking into account the change in the amount of stored products in different months. The amendment is taken equal to 1.2 ... 1.5;

- t pr - the time during which the goods are in the acceptance zone, day;

- 365 - the length of the calendar year;

- A2 - the percentage of goods arriving through the warehouse acceptance area,%;

- q add - average load per unit area. In this formula, it is taken equal to ¼ of the load calculated for the warehouse, t / m 2;

- S in - the total area of sites for sorting, weighing and other technological operations. Usually this value is in the range of 5-10 m 2.

S set = Q g × Kn × A3 × t km / (254 × q add × 100), where

- 254 - the number of working days;

- A3 is the share of goods that need to be assembled in the warehouse,%;

- t km - the duration of the stay of products in the picking area, day.

With a small turnover, the acceptance and picking areas are combined and located in one room. With a large amount of work in these areas, they are separated. The acceptance area is designed with a small margin of space, so that in the future there will be no problems with more intensive processing of incoming products. In particular, this room should be designed for short-term storage of goods that accumulate during weekends and holidays.

Formula for calculating the section of the acceptance expedition:

S pe = Q g × t pe × Kn / (365q e), where

- Q g - the number of goods received during the year, t;

- t pe - time of storage of goods in this area, day;

- q e - the enlarged value of the permissible load per unit area in the acceptance zone.

- The area of the dispatch expedition is calculated by the formula:

S oe = Q g × t oe × Kn / (254q e), where

t oe is the storage time of the cargo at the given site, day.

- Passage width:

A = 2B + 3C, where

- B is the width of the warehouse equipment, cm;

- C - the necessary margin for the passage of the vehicle, usually 15-20 cm.

- When drawing up a project, the width of the main thoroughfares is usually taken as 1.5-4.5 m, the width of the side passages is 0.7-1.5 m, the height of the premises is 3.5-5.5 m, for multi-storey warehouses - 18 m.

Calculation of the auxiliary area

The parameters of the office space depend on the number of warehouse employees. If no more than 3 people work, each has 5 m 2, if more than 5 people - 3.25 m 2. For the manager, 12 m 2 are provided. Basic calculation formulas:

- Number of racks:

N st = N t / V st, where

- N t - the volume of stored goods, m 3;

- V st - capacity of one rack unit, m 3.

- Total capacity:

E = F c qm, where

- F c - the area occupied for the storage of goods;

Warehouse space efficiency indicators

Calculations are made for a specific type of equipment. Indicators determine the effectiveness of its use. Calculation formulas:

Utility factor of warehouse space:

K s = S floor / S os, where

- S floor - useful area of premises, m 2;

- S OS - total area, m 2.

Typically, the ratio is obtained in the range 0.25-0.6. The higher it is, the more efficiently the warehouse equipment is used. It can also be calculated by dividing the volume occupied by the stacks by the total storage space.

This kind of lesson will tell you about how to count warehouse space... When designing a construction plan, a decisive role is played by a clear organization of the on-site storage facilities. For storage of sand, gravel, precast concrete, lumber, I accept an open warehouse. For storage of binders, finishing materials, glass, plumbing equipment, I accept a closed warehouse.

It stores structures, semi-finished products, products and equipment.

Open area planned, is compacted and has a slope for drainage of atmospheric waters. Thus, the construction plan is a set of warehouses, change houses, engineering networks, mechanisms and the facility being built.

The number of materials to be stored in the warehouse must ensure the uninterrupted supply of the building construction with all the necessary materials, structures and products, in the right amount. The figure below shows the location on construction site warehouses of various types. Please note that only an open warehouse is located within the crane's reach, the other two are located outside the crane's border.

We calculate warehouses in the following sequence:

2. Determine the stock of material. Q warehouse = Qsk * t * K1 * K2 / Tc, where

Qsc. - the amount of material used;

n is the standard stock in days, depending on the condition of the roads, the type of vehicles;

K1-coefficient of uneven consumption of materials K1 = 1.2, taking into account high labor productivity

K2-coefficient of uneven receipt of materials to the warehouse K2 = 1.1, depending on the remoteness of the supplying plants building materials as well as the type of transport

We define warehouse area at the construction site for each material.

Fsk = Qsk / q * Ksk, where

Ksk- the utilization rate of warehouse space, taking into account aisles and driveways.

Qck - the amount of material to be stored in the warehouse

q -

standard amount of material placed on 1m2 of storage area.

The initial data and calculations for each material are summarized in a table

|

Statement of consumption of basic building materials |

|||||||||

|

name of materials |

gauge |

days of work |

days of stock |

storage rate |

warehouse area |

warehouse type |

|||

|

foundation block |

open |

||||||||

|

floor slabs |

open |

||||||||

|

open |

|||||||||

|

open |

|||||||||

|

ceramic tile |

|||||||||

|

window and door blocks |

|||||||||

|

paints, varnishes |

closed |

||||||||

|

Warehouse type |

Calculated area |

Accepted area |

warehouse dimensions |

|

open warehouse |

|||

|

indoor warehouse |

So we found areas of all types of warehouses, took their size, which will be sufficient for the temporary storage of materials, taking into account their development and the arrival of new ones.

a) Calculation of the area of warehouses. The total warehouse area includes:

useful area, i.e. area directly occupied by the stored material (racks, stacks) f floor,

area occupied by acceptance and release sites, fpr;

office space occupied by office and other office premises, fsl;

auxiliary area occupied by driveways and walkways, fwsp.

The total area will be equal to:

Determination of the usable area. The usable area of warehouses storing metals, hardware, tools, spare parts and other products is determined in two ways: by the method of loading per 1 m2 of floor area and by the method of filling the volume.

The method of loading 1 m2 of floor area is the most convenient and simple. The calculation formula is:

where is the value of the established stock of the corresponding material in the warehouse, t; - load per 1 m2 of floor area, i.e.

Using the filling factor of the volume, the capacity of any equipment for storing materials and products (cells, racks, stacks, etc.) is determined by the formula:

where Vob is the geometric volume of the corresponding equipment, m3; - specific gravity material or product, t / m3; b - volume filling factor (packing density).

Knowing the amount of material to be stored, the required amount of equipment (cells, racks, stacks) n is determined by the formula:

Knowing in the plan dimensions the accepted equipment and the required amount, determine the useful area of the warehouse for storing this type of material:

fpol = l * b * n = fob * n (m2), (8.5)

l is the length of the corresponding storage equipment, m;

b - width, m.

By calculating the usable storage area in this way certain types or groups of materials and products and summing it up, we get the total usable area of the warehouse.

Determination of the area occupied by the acceptance and release sites. In warehouses with a large volume of work, acceptance and release sites are arranged separately, and with a small amount of work - together.

Required area of the acceptance site:

where is the annual receipt of goods, t; (s1 is the load per 1 m2 of area, t (taken approximately 0.25 of the average load per 1 m2 of usable area s in the warehouse, or about 0.25-0.5 t / m2; k is the coefficient of unevenness of the receipt of material at the warehouse ( 1.2-1.5); t is the number of days the material has been at the acceptance site (up to 2 days).

The size of the release site is determined in the same way.

Determination of the service area. Warehouse office area is calculated depending on the number of employees. With a warehouse staff of up to three employees, the office area is taken at 5 m2 for each person; from 3 to 5 - 4 m2, with more than 5 employees - 3.25 m2 each.

Determination of the auxiliary area. The dimensions of the aisles and driveways in the warehouse are determined depending on the size of the stored materials, the size of the cargo turnover, lifting vehicles. For this purpose, use the formula:

A = 2 * B + 3 * C,

where A is the width of the passage, cm;

B is the width of the vehicle;

C - the width of the gaps between vehicles and between them and the racks on both sides of the driveway (taken 15-20 cm).

In absolute terms, the width of the main passages (passages) is taken from 1.5 to 4.5 m. The width of the side passages (passages) is from 0.7 to 1.5 m.

The height of the warehouse from the floor level to the tightening of the trusses or rafters is usually taken from 3.5 to 5.5 m.In cases where the warehouse is equipped with an overhead crane, its height is calculated and can reach 8 m.

With approximate calculations, the total area of warehouses Ftotal can be determined depending on the usable area fpol through the utilization factor according to the formula:

b) Storage of products:

Warehousing of products is necessary due to the existing fluctuations in the cycles of production, transportation and consumption. Warehouses of various types can be created at the beginning, middle and end of transport cargo flows or production processes for temporary storage of goods and timely supply of production with materials in the required quantities. Temporary storage (accumulation) of products is due to the nature of production and transport. It allows you to overcome the temporal, spatial, quantitative and qualitative discrepancies between the availability and demand for materials in the process of production and consumption. In addition to cargo storage operations, the warehouse also performs intra-warehouse transport, loading, unloading, sorting, picking and intermediate reloading operations, as well as some technological operations etc. Therefore, warehouses should be considered not just as devices for storing goods, but as transport and warehouse complexes in which the processes of moving goods play important role... The operation of these complexes is dynamic, stochastic in nature due to the uneven transportation of goods.

It should be borne in mind that warehouses contribute to the transformation of cargo flows by changing the parameters of received and issued consignments in terms of size, composition, physical characteristics of incoming goods, time of dispatch of transport consignments, etc.

Warehouse - buildings, structures, devices designed for receiving and storing various material values, preparing them for production consumption and uninterrupted supply to consumers.

Problem 4

The RIM company is a large trade and intermediary company that sells household and electronic appliances. In connection with entering new markets and increasing sales, the company plans to acquire a warehouse in Moscow. Calculate the area of storage areas, taking into account that the storage area will be divided into two sections: section A - rack storage of goods of the "small household appliances" group, section B - stacked storage of goods of the "large household appliances" group.

Table 5.2

Initial data for the problem

|

Average daily receipt of goods at the warehouse | |

|

Loading factor for 1 m 2 | |

|

The coefficient of uneven receipt of goods at the warehouse | |

|

The number of days the goods were in the acceptance area | |

|

Annual volume of shipment of products | |

|

Coefficient of uneven shipment of products from the warehouse | |

|

The number of days the goods have been in the picking area | |

|

Rack width | |

|

Rack depth | |

|

Number of racks | |

|

Loader width | |

|

The width of the gaps between vehicles and between them and racks on both sides of the driveway | |

|

Stack length | |

|

Stack width | |

|

Number of stacks | |

|

The width of the gaps between vehicles and between them and stacks on both sides of the driveway | |

|

Office space |

Solution

S floor - usable area, i.e. the area occupied by directly stored resources (racks, stacks, bins, bins and other devices for storing these resources);

Setc - the area occupied by the acceptance and release sites;

S sl - office space (occupied by office and other office premises);

S O b - the area occupied by stationary handling and other equipment (hoists, conveyors, etc.);

S vp - auxiliary area, i.e. the area occupied by driveways and aisles.

1. Let's calculate the area of the unloading and receiving area.

q cf - the average daily flow of resources to the warehouse, t;

σ 1, - load per 1 m 2 of usable area in the warehouse, depending on the type of storage of resources, t / m 2;

K is the coefficient of unevenness of the flow of resources to the warehouse (with rational loading of the warehouse K = 1.2, ..., 1.5);

t - the number of days of finding resources at the acceptance site (up to 2 days)

2. Let's calculate the useful area. In this example, the useful area will be space for shelving small household appliances and places for stacking large household appliances, i.e.

S st , S pcs - the area occupied, respectively, for one rack, one stack;

N st , N pcs - the number of racks and stacks, respectively.

3. Let's calculate the auxiliary area according to the following formula

S vpst - the area occupied by driveways and aisles between the rack, m 2.

S vspsht - the area occupied by driveways and aisles between the piles, m 2.

The auxiliary warehouse area includes the area occupied by aisles and driveways. The dimensions of the aisles and driveways in the warehouse are determined depending on the size of the resources stored in the warehouse, the size of the cargo turnover, the type of lifting and transport mechanisms applicable to the movement of resources. The main aisles where the main vehicles move should be checked for the possibility of free turning in them of industrial trucks (carts, forklifts, etc.). If necessary, they should also be calculated for the oncoming movement of mechanisms. For this or use the formula

l- rack width, m; NS - number of racks, pcs;

BUT- passage width, m.

IN- vehicle width, m;

C - the width of the gap between vehicles, between them and the racks (stacks) on both sides of the passage (taken equal to 15-20 cm).

Similarly, the area occupied by driveways and aisles between the stacks (S pcs) is found.

3. Let's calculate the area of the picking and shipment area. The areas of the picking and shipping areas in the warehouse are combined, therefore:

q send - the average daily volume of cargo dispatch from the warehouse, t;

K - coefficient of unevenness of dispatch of goods from the warehouse (with rational loading of the warehouse K = 1.2, ..., 1.5);

t - the number of days of finding resources in the dispatching expedition (up to 2 days)

Thus, the total area of the warehouse will be equal.

Material assets, capitalized by the accounting department, must be stored somewhere until they are needed for the production of products. The storage location is called a warehouse. Warehouses can be of different shapes and be constructed from different materials, occupy different areas (volumes). The size of the warehouse depends, on the one hand, the possibility of placing the received material resources, on the other, the costs of its construction, depreciation (or rent) and maintenance.

The total warehouse area is conventionally divided into four parts:

1) useful area directly occupied by stored material resources;

2) the acceptance area where the acceptance and release sites are located;

3) service area for warehouse management services;

4) auxiliary area occupied by driveways and walkways. The useful area of the warehouse is determined in two ways.

The first method is to calculate the load per 1 m 2 of floor area (f floor)

In this case, the formula is used

f floor = W obsh: σ (9.2)

where Z total - total amount stock material resource;

a - load per 1 m 2 of floor area, and the value of σ has different values depending on the purpose of the warehouse and the type of stored material stocks (Table 9.1).

Table 9.1

The value of a for various warehouses

The second method is the use of the volume filling factor (q ABOUT) - The capacity of any equipment for storing materials (cells, racks) is determined by the formula

q OB = V OB γ β, (9.3)

where V ABOUT is the geometric volume of the corresponding equipment;

γ is the specific weight of the material resource;

β - volume filling factor (packing density).

Knowing the amount of material stock to be stored (Z total), you can determine the required amount of equipment (cells, racks, etc.) (and) by the formula

n = 3 TOTAL: q OB (9.4)

Then the useful area of the warehouse (f floor) is calculated by the formula

f floor = dsh n. (9.5)

where d is the length of the corresponding equipment for storing material resources;

w is the width of the equipment.

The area for acceptance and release sites (f pr) is calculated by the formula

f pr = (Q pos kt): (360σ 1), (9.6)

where Q p oc is the annual flow of material resources;

k is the coefficient of unevenness of the receipt of material

resource to the warehouse (varies from 1.2 to 1.5);

t is the number of days the material resource has been at the acceptance site;

σ 1 - load per 1 m 2 of area (taken as 0.25 of the average load per 1 m 2 of usable area about the warehouse).

The next calculation is the service area of the warehouse. It is determined depending on the number of employees. With a warehouse staff of up to three employees, the area of office premises is assumed to be 5 m 2 for each person; with a staff of three - five people - 4 m 2 each; with a staff of more than five people - 3.25 m 2 each.

After that, the auxiliary area is calculated. It is formed by driveways for lifting vehicles and walkways for workers. The placement of driveways and aisles is outlined in the figure with the warehouse layout. The width of the passages (W) for two vehicles is determined by the formula

W = 2V + ЗС, (9.7)

where B is the width of the vehicle;

C - the width of the gaps between vehicles and between them and the racks on both sides of the passage.

By setting the length and width of aisles and aisles, you can calculate the total auxiliary area.

The sum of the four components will give the total area of the warehouse for storing material resources.

TRAINING TASK

Problem 1... The warehouse worked for 18 days for a month (30 days).

Determine the percentage of cargo that went through the acceptance expedition if the goods arrived evenly during the month both on workdays and on weekends?

When the cargo arrives at non-working days(in our case, 30 days -18 days = 12 days), he gets into the acceptance expedition.

Therefore, it will pass through it in a month (12 days: 30 days) x 100% = 40% of the goods.

Problem 2... There are coordinates of stores (in kilometers) and data on their turnover (G i).

Coordinates of stores in accordance with their numbers (X, Y): № 1 (15,40); No. 2 (50.40); No. 3 (30.55); No. 4 (50.10); No. 5 (80.45); No. 6 (85, 35); No. 7 (70, 20); No. 8 (90, 25).

The turnover of stores in accordance with their numbers (tons per month): 35, 60, 20.45, 60.10, 55.10.

The location of the stores in the coordinate grid is shown in Fig. one.

Determine the location for the distribution warehouse by determining the center of gravity of the cargo flows.

Solution. Find the coordinates distribution center:

(km).

(km).

So, the coordinates of the distribution center are (57; 33). The location of the distribution center is shown in Fig. 2.

Self-solve task

Problem 1... To ensure the production of products, the enterprise needs to have 1000 tons of sand in stock. A warehouse is needed to store sand.

Using the method of determining the load per 1 m 2, calculate the total area of the warehouse if the following values are known:

■ the value of the permissible load per 1 m 2 of the floor is 2 t / m 2;

■ the coefficient of unevenness of the supply of sand to the warehouse is 1.5;

■ sand is on the acceptance site for 2 days;

■ 4 people work in the warehouse;

■ vehicle width is 3 m;

■ the width of the gaps is 50 cm.

Problem 2... The amount of simultaneously stored raw materials is 1830 tons, the staff is 6 people, the width of the loader is 1.5 m, the length of each of the two aisles will be 30 m, racks are installed between the aisles. The width of the gap between the racks and the vehicles is 1 m, between each rack, the walls of the warehouse and the aisles there are passageways 1.5 m wide and 30 m long.

Determine the useful, service and auxiliary area of the finished product warehouse if the load on 1 m 2 of floor area is 2.2.

Tests

1. A warehouse is ...

2. Which of the factors, more than others, proves the need for storage facilities:

a) the existence of stocks of raw materials, materials, finished products;

b) temporal, spatial, quantitative and qualitative discrepancies between the availability and demand for materials in the process of production and consumption;

d) lack of demand for manufactured products?

3. Which of the listed functions is the main one for the warehouse:

a) preparation of materials for production consumption;

b) temporary placement and storage of material resources;

c) prevention of damage and theft of material values?

4. Which of the following factors affect the choice of a physical distribution channel for products:

a) location of storage facilities, method of shipment of products, method of transportation of products;

b) market conditions, warehouse construction costs, transportation costs;

c) the number of intermediaries, distribution patterns, type of goods.

5. By what criteria are the warehouses of enterprises classified:

a) according to the purpose, type and nature of the stored materials;

b) by type of construction, location, scale of action and fire resistance;

c) are both answers correct?

6. What are the areas of the total warehouse area:

a) useful, acceptance, service and auxiliary;

b) vacation, acceptance, auxiliary, useful, driveway and walkway area;

c) are all answers correct?

7. In which answer is the useful area correctly determined, if: the value of the established storage capacity is 240 tons, the load per 1 m 2 of floor area is 0.6 tons:

8. What is the useful area of the warehouse, if the length of the equipment for storing material stocks is 3 m, the width is 2 m, the number of the same type of equipment is 4 units:

d) suggest your answer?

9. What is the size of the receiving area, if the annual consumption of the material resource is 72,000 tons, the coefficient of unevenness of the cargo arrival at the warehouse is 1.2, the number of days the material is at the receiving site is 2, the load per 1 m2 of floor area is 0.24 tons:

SECTION CONCLUSIONS

Warehousing of products is due to the nature of production and transport. It allows you to overcome the temporal, spatial, quantitative and qualitative discrepancies between the availability and demand for materials in the process of production and consumption.

The warehouses carry out transport, loading, unloading, sorting, picking and intermediate reloading operations, as well as some technological operations. The main tasks solved in the field of warehousing are choosing the location of the warehouse, organizing warehouse operations and determining the area of the warehouse.

SERVICE IN LOGISTICS

© 2015-2019 site

All rights belong to their authors. This site does not claim authorship, but provides free use.

Date the page was created: 2016-04-02

What you need to open a hookah lounge, and how to do it correctly

What you need to open a hookah lounge, and how to do it correctly How to start a business and choose donut equipment

How to start a business and choose donut equipment Opening a company in Montenegro Open a company in Montenegro

Opening a company in Montenegro Open a company in Montenegro The carpentry shop as a business

The carpentry shop as a business How to choose a business direction?

How to choose a business direction? Sample business plan of a dental office

Sample business plan of a dental office Five best business ideas that brought millions What business to open so as not to go bankrupt

Five best business ideas that brought millions What business to open so as not to go bankrupt