Avdt 32 electromechanical or electronic. Electronic or electromechanical ouzo. External Power Supply - Battery Test

To protect against current leaks, differential current switches, or a residual current device (RCD) are used. In every new apartment, new house, this device becomes a necessary equipment.

However, devices with a fundamentally different internal design, which determines the reliability of the entire RCD, can be sold under the general name. The design can have a different arrangement of levers and control buttons, have standard or extended options for connecting buses and wires, but the design is of fundamental importance RCD trip unit... It can be electromechanical or electronic. Just how to immediately distinguish an electromechanical RCD from an electronic one? This issue needs to be covered in detail.

What is the difference between an electromechanical RCD and an electronic one

RCDs and difavtomats (these are RCDs and a circuit breaker in one case), according to their internal design, are divided into two types: electromechanical and electronic... This does not in any way affect the operating parameters and specifications. Many people immediately have a question: what is the difference between them? And there is a difference, and an important one: An electromechanical type RCD will work in any case if a leakage current appears in the damaged area, regardless of the voltage in the network or not... The main working module of an electromechanical RCD is a differential transformer (toroidal core with windings). If a leak occurs in the damaged area, then a voltage appears in the secondary winding of this transformer, which turns on the polarized relay, which in turn leads to the operation of the shutdown mechanism.

Electronic RCDs operate in the presence of current leakage in the damaged area and only in the presence of voltage in the network. That is, for full operation, an electronic type of residual current device needs an external power source. This is due to the fact that the main working module of electronic RCDs is an electronic board with an amplifier. And this board will not work without external power supply.

Where does the power source come from? There are no batteries or accumulators inside the RCD. And the voltage for powering the electronic board with the amplifier comes from the external network. There is a 220V network, and there is a current leakage - the RCD will work! If there is no voltage in the network, the protective device will not work.

So, for the operation of an electromechanical RCD, only a leakage of current is needed, for an electronic RCD, a leakage of current and voltage in the network is needed.

In the picture on the left - Hager RCD with an electromechanical release, on the right RCD with an electronic release.

How important is it that the protective device remains functional in the absence of voltage? I am sure that many users will answer something like this: if there is voltage in the network, the electronic RCD will work. If there is no voltage in the network, then why should he work at all, because there is no voltage in the network, which means that there is nowhere to take the leakage current. What do you know emergency situations, when in a house or apartment tension may disappear or, as the people say, “there is no light”? It could be an accident on the line coming to the house, it could be renovation work electrical services, or maybe another very common problem - the burnout of the neutral wire in the floor board. All equipment will be without signs of life, all signaling devices (signal lamps, if any) will indicate that there is no voltage in the network. However, the phase has not gone anywhere! The danger of electric shock remains. Imagine that in such a situation there was a damage to the insulation inside the washing machine, the phase hit the body. If at this moment you touch the body of the machine, a leak will occur and the RCD should work. But it is precisely electronic The RCD will not work, since only the "phase" without zero comes to its electronic board with the amplifier, there is no power supply, therefore the electronic board will not fix the resulting leakage current, the shutdown pulse will not be sent to the shutdown mechanism, and the RCD will not turn off. For a person, such a situation is extremely dangerous. Therefore, no matter how sad, when a leakage current appears in this situation electronic RCD will not work.

Another common problem is power surges. Of course, now many people install voltage relays for protection, but not everyone has them. What are voltage surges is a deviation from the nominal value. That is, instead of 220 Volts, 170 Volts or 260 Volts, or, even worse, 380 Volts may appear in your outlet. Increased voltage is dangerous for electronic equipment, which is what electronic RCDs and electronic differential automatic devices are actually equipped with. Power surges can damage the electronic board with the amplifier. Outwardly, everything will look safe and sound, but if a current leak occurs, the situation can become deplorable for a person - due to damaged electronic components, the RCD will not react to the leak.

You may not know that the internal filling of the protective device is out of order. Therefore, it is necessary to periodically check the operation of the RCD using the "TEST" button. Experts recommend performing this check at least once a month.

So, in the power supply network, various emergencies can arise in which electronic RCDs or diffautomatics can lose their protective functions. The above problems are not dangerous for electromechanical protective devices. since they do not require an external power supply to operate. Will there be voltage in the network or not, electromechanical RCD (RCBO) will work in any case if there is a current leak in the network.

How to distinguish an electromechanical RCD from an electronic

Outwardly, these two devices are very similar and many users, without hesitation, buy them indiscriminately in the store, without even knowing about the features. In order to understand which residual current device in front of you is electronic or electromechanical, you need to be able to distinguish between them. Do you think that only professionals can do it? But I assure you this is not so, there is nothing complicated here.

Pay attention to the diagram shown on the RCD case

The easiest and most reliable way is to study the circuit shown on the RCD case. An electrical circuit is applied to any protective device. Between the displayed diagrams on electromechanical RCD and electronic there are slight differences.

The diagram of an electro-mechanical RCD or a difavtomat displays a differential transformer (through which the phase and zero are "threaded"), the secondary winding of this transformer, as well as a polarized relay that is connected to the secondary winding. The polarized relay already acts directly on the trip mechanism. All this is shown in the diagram. You just need to understand what figure each of the above-described element is designated by. For example, an electromechanical RCD of the European manufacturer HAGER:

The differential transformer is marked in the form of a rectangle (sometimes it is an oval) around the phase and neutral wires. A turn of the secondary winding departs from it, which is connected to a polarized relay. In the diagram, a polarized relay is indicated as a rectangle or square. The relay is mechanically linked to the trip trigger.

The TEST button with its own resistance is also indicated here (the resistance allows you to create a leakage of 30mA, a safe threshold for human life). As you can see, there are no electronic boards and amplifiers in an electromechanical RCD. The design consists of one mechanic.

Now let's consider an electronic RCD. For example, an electronic difavtomat 16A, 220V, with a leakage current of 30 mA.

As you can see from the diagram, on the case of the electronic difavtomat almost everything is indicated as on the electromechanical protective device.

But, if you look closely, you can see that between the differential transformer and the polarized relay there is an additional element in the form of a rectangle with the letter "A", designation I>. This is the same electronic board with an amplifier. In addition, you can see that two wires "phase" and "zero" are suitable for this board (indicated in the figure in green below). This is exactly the external power source that is necessary for the full operation of this type of RCD. There will be no power supply, and the RCD will not work. Regardless of whether there is a leak or not.

So, for the operation of an electromechanical RCD, only a leakage of current is needed, for an electronic RCD, a leakage of current and voltage in the network is needed. We strongly recommend that you purchase an RCD or diffautomat of an electromechanical type.

Residual current devices (RCDs) are one of the most popular devices used by both construction corporations and private users. But how can you be sure of the right choice? Hope this article will make it easier for you to navigate the RCD market saturated with various models.

Residual current device. The basics

Residual current devices (RCDs) or, otherwise, differential protection devices, are designed to protect people from electric shock in the event of electrical faults or in contact with live parts of an electrical installation, as well as to prevent fires and fires caused by leakage currents and earth faults ... These functions are not inherent in conventional circuit breakers that only respond to overload or.

What is the reason for the fire-fighting demand for these devices?

According to statistics, the cause of about 40% of all fires occurring is “electrical wiring closure”.

In many cases, the general phrase “short circuiting of electrical wiring” is often covered by electrical leakage that occurs due to aging or damage to the insulation. In this case, the leakage current can reach 500mA. It has been experimentally established that when a leakage current of exactly this strength flows (and what is a half-ampere? Neither thermal nor electromagnetic release to a current of such strength simply does not react - if only for the reason that they are not intended for this) for a maximum of half an hour through wet sawdust, they spontaneously ignite. (And this applies not only to sawdust, but in general to any dust.)

And how do the differential protection devices protect you and me from electric shocks?

If a person touches a live part, a current will flow through his body, the value of which is the quotient of dividing the phase voltage (220 V) by the sum of the resistances of the wires, grounding and the human body itself: Ipers = Uph / (Rpr + Rz + Rp). In this case, the resistances of grounding and wiring in comparison with the resistance of the human body can be neglected, the latter can be taken equal to 1000 ohms. Consequently, the magnitude of the current about which in question, will be 0.22 A, or 220 mA.

From the normative and reference literature on labor protection and safety measures, it is known that the minimum current, the flow of which is already felt by the human body, is 5 mA. The next standardized value is the so-called non-release current, equal to 10 mA. When a current of such strength flows through the human body, spontaneous muscle contraction occurs. An electric current of 30 mA can already cause respiratory paralysis. Irreversible processes associated with bleeding and cardiac arrhythmia begin in the human body after a current of 50 mA flows through his body. A lethal outcome is possible when exposed to a current of 100 mA. Obviously, one should already be protected from a current equal to 10 mA.

So, the timely response of automation to a current of less than 500 mA protects the object from fire, and to a current of less than 10 mA - protects a person from the consequences of accidentally touching live parts.

It is also known that you can safely hold on to the current-carrying part, which is under a voltage of 220 V, for 0.17 s. If the live part is energized at 380 V, the safe touch time is reduced to 0.08 s.

The problem is that such a small current, and even in a negligibly short time, is not able to fix (and, of course, turn off) conventional protective devices.

Therefore, such a technical solution was born as a ferromagnetic core with three windings: - "current supply", "current lead", "control". The current corresponding to the phase voltage applied to the load and the current flowing from the load into the neutral conductor induce magnetic fluxes of opposite signs in the core. If there are no leaks in the load and in the protected section of the wiring, the total flow will be zero. Otherwise (touching, insulation damage, etc.), the sum of the two flows becomes nonzero.

The flux arising in the core induces an electromotive force in the control winding. A relay is connected to the control winding through a precision filtering device for all kinds of interference. Under the influence of the EMF arising in the control winding, the relay breaks the phase and zero circuits.

In many countries, the use of RCDs in electrical installations is regulated by norms and standards. So, for example, in Russian Federation- adopted in 1994-96. GOST R 50571.3-94, GOST R 50807-95, etc. According to GOST R 50669-94, the RCD is installed in mandatory in the power supply network of mobile buildings made of metal or with a metal frame for street trade and consumer services for the population. IN last years administration of large cities in accordance with state standards and the recommendations of Glavgosenergonadzor, decisions were made to equip the fund of residential and public buildings with these devices (in Moscow - Order of the Moscow Government No. 868-RP dated 20.05.94).

RCDs are different .... Three-phase and single-phase ...

But the division of the RCD into subclasses does not end there ...

Currently on Russian market there are 2 fundamentally different categories of RCDs.

1. Electromechanical (grid independent)

2. Electronic (network dependent)

Let's consider separately the principle of operation of each of the categories:

Electromechanical RCDs

The founders of RCDs are electromechanical. It is based on the principle of precision mechanics i.e. looking inside such an RCD, you will not see the comparators of operational amplifiers, logic and the like.

Consists of several main components:

1) The so-called zero-sequence current transformer, its purpose is to track the leakage current and transmit it with a certain Ktr to the secondary winding (I 2), I ut = I 2 * Ktr (a very idealized formula, but reflecting the essence of the process).

2) A sensitive magnetoelectric element (lockable, i.e. when triggered without external intervention, it cannot return to the initial state- latch) - plays the role of a threshold element.

3) Relay - provides tripping if the latch is triggered.

This type of RCD requires high precision mechanics for the sensitive magnetoelectric element. Currently, only a few global companies sell electromechanical RCDs. Their cost is much higher than the price of electronic RCDs.

Why is it that electromechanical RCDs have become widespread in most countries of the world? It's very simple - this type of RCD will work if a leakage current is detected at any voltage level in the network.

Why is this factor (independence from the mains voltage level) so important?

This is due to the fact that when using a workable (serviceable) electromechanical RCD, we guarantee in 100% of cases the relay is triggered and, accordingly, the power supply to the consumer is turned off.

In electronic RCDs, this parameter is also large, but not equal to 100% (as will be shown below, this is due to the fact that at a certain level of network voltage, the electronic RCD circuit will not work), and in our case, every percentage is possible human lives(whether it be a direct threat to human life when it touches the wires, or indirectly, in the event of a fire from burning out the insulation).

In most of the so-called "developed" countries, electromechanical RCDs are a standard and a device that is mandatory for widespread use. In our country, there are gradually shifts towards the mandatory use of RCDs, however, in most cases, the consumer is not given information about the type of RCDs, which entails the use of cheap electronic RCDs.

Electronic RCDs

Any construction market is flooded with such RCDs. The cost for electronic RCDs is in places lower than for electromechanical ones up to 10 times.

The disadvantage of such RCDs, as already mentioned above, is not a 100% guarantee, if the RCD is in good condition, to get it triggered as a result of the appearance of a leakage current. The advantage is cheapness and availability.

In principle, an electronic RCD is built in the same way as an electromechanical one (Fig. 1). The difference lies in the fact that the place of the sensitive magnetoelectric element is taken by the reference element (comparator, zener diode). For such a circuit to work, you will need a rectifier, a small filter, (possibly even a KREN). Because the zero-sequence current transformer is a step-down (tens of times), then a signal amplification circuit is also needed, which, in addition to the useful signal, will also amplify the interference (or the unbalance signal present at zero leakage current). From the above, it is obvious that the moment when the relay is triggered in this type of RCD is determined not only by the leakage current, but also by the mains voltage.

If you cannot afford an electromechanical RCD, then it is still worth taking an electronic RCD, because it works in most cases.

There are also cases when it makes no sense to buy an expensive electromechanical RCD. One of such cases is the use of a stabilizer or an uninterruptible power supply (UPS) when powering an apartment / house. In this case, it makes no sense to take an electromechanical RCD.

Immediately, I note that I am talking about the categories of RCDs, their pros and cons, and not about specific models. You can buy low-quality RCDs of both electromechanical and electronic types. When buying, ask for a certificate of conformity, because many electronic RCDs on our market are not certified.

Zero sequence current transformer (TTNP)

Usually it is a ferrite ring through which (inside) the phase and neutral wire pass, they play the role of the primary winding. The secondary winding is evenly wound over the surface of the ring.

Ideally:

Let the leakage current be zero. The current flowing through the phase wire creates an equal in magnitude to the magnetic field created by the current flowing through the neutral wire, and the opposite direction. Thus, the total clutch flux is zero and the current induced in the secondary winding is zero.

At the moment the leakage current flows in the wires (zero, phase), a current inequality appears, as a result of the occurrence of a clutch flow and induction of a current proportional to the leakage current to the secondary winding.

In practice, there is an unbalance current that flows through the secondary winding and is determined by the transformer used. The requirement for the TTNP is as follows: the unbalance current must be significantly less than the leakage current reduced to the secondary winding.

RCD selection

Let's say you have decided on the type of RCD (electromechanical, electronic). But what to choose from the huge list of products on offer?

You can select an RCD with sufficient accuracy using two parameters:

Rated current and leakage current (trip current).

The rated current is the maximum current that will flow through your phase conductor. It is easy to find this current by knowing the maximum power consumption. Just divide the worst case power consumption (maximum power at minimum Cos (?)) By the phase voltage. It makes no sense to put an RCD for a current greater than the rated current of the machine in front of the RCD. Ideally, with a margin, we take an RCD for a rated current equal to the rated current of the machine.

RCDs with rated currents of 10,16,25,40 (A) are often found.

Leakage current (actuation current) is usually 10mA if an RCD is installed in an apartment / house to protect human life, and 100-300mA at an enterprise to prevent fires, if the wires are burnt.

There are other RCD parameters, but they are specific and not interesting to ordinary consumers.

Conclusion

This article covered the basics of understanding the principles of RCDs, as well as methods for constructing various types of residual current devices. Both electromechanical and electronic RCDs, of course, have a right to exist because has its own expressive advantages and disadvantages.

RCD (residual current device)- This is an installation electrical product designed to turn off the supply of electricity to the wiring in the event of a current leak in the event of insulation failure in wires or electrical appliances.

An RCD, unlike a circuit breaker, is intended solely to protect a person from electric shock, prevent a fire from occurring and does not directly participate in the operation of electrical appliances. The RCD does not protect against a short circuit in the wiring and in the event of a person touching the phase and neutral wires.

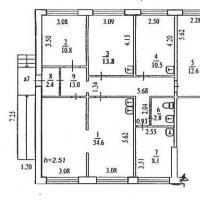

The photo shows a two-wire residual current device type VD1-63, designed to operate in a single-phase AC 220 V network and rated for a protection current of 30 mA. An RCD with such characteristics is suitable for installation at the input of almost any apartment wiring.

The assortment of installation products includes combined ones, in one case of which an RCD and a circuit breaker are built. Such a device is called a residual current circuit breaker with built-in overcurrent protection. The photo shows the appearance of the RCBO32 model, designed for a current of protection of electrical wiring 16 A and protection of a person at 30 mA. But such protection devices are not widely used due to their high cost.

In addition, in the event of a trip, it is difficult to find out whether the fault is a short circuit or a current leak.

How to choose an RCD

Choosing an RCD for apartment wiring or a house for a home electrician is not difficult. Any single-phase RCD is suitable, designed for an operating current equal to the protection current of the circuit breaker and a leakage current of 30 mA... A photograph of such an RCD is given at the beginning of the article.

What type of RCD is best for an apartment

electromechanical or electronic

RCDs are available in two designs - electromechanical and electronic. For the right choice, you need to compare their technical characteristics.

| Comparative table of characteristics of electromechanical and electronic RCD | ||

|---|---|---|

| Characteristic | Electromechanical RCD | Electronic RCD |

| Price | low | high |

| Design | complex | simple |

| Reliability | high | low |

| Accuracy of operating current | high | low |

| Efficiency in the event of a break in the neutral wire or when the mains voltage drops below the permissible | persists | does not work |

| Resistance to overvoltage surges in the network | high | low |

| dimensions | big | many times less |

As can be seen from the table, if there are no restrictions on overall dimensions you need to choose an electromechanical RCD. An electronic RCD is indispensable when installed on a separate electrical appliance, for example, in an electrical outlet or extension cord.

Main technical characteristics of RCD

Requirements for the technical characteristics of RCDs are established by GOST R 51326.1-99 (IEC 61008-1-96) "Automatic circuit breakers controlled by differential current for household and similar purposes without built-in overcurrent protection".

For those who want to make a more informed choice, I have brought all the main technical characteristics of the RCD into a table.

| Table of the main technical characteristics of the RCD | ||||

|---|---|---|---|---|

| Characteristic | Designation | The quantity | Note | |

| Working voltage | IN | 220, 380 | For a single-phase home network, an RCD is installed for a voltage of 220 V, for a three-phase network - for 380 V | |

| Number of phases | 1, 3 | Indicated in the passport | ||

| Leakage current of operation, I∆n | mA | 5 | In the PUE there are no instructions for installation, but can be found in the recommendations for the use of electrical appliances, for example, underfloor heating | |

| 10 | Designed to connect sockets installed in bathrooms, kitchens, children's rooms and appliances installed on the ground | |||

| 30 | Versatile, suitable for all home or apartment applications | |||

| 100, 300 | Used in industry, sometimes installed at the input of electrical wiring to housing to increase fire safety | |||

| Maximum load current, In | BUT | 6-125 | Must be equal to or greater than the current of the circuit breaker installed after the RCD | |

| Maximum switching current, Im | BUT | 500 | Must be 10 times the maximum load current | |

| Short circuit current, Inc | kA | 3-10 | The maximum current that the RCD can withstand for a short time in the event of a short circuit in the wiring | |

| Shutdown time | ms | The time after which, after exceeding the permissible leakage current, the RCD must disconnect the load | ||

| Inspection frequency | month | 1 | For a simple test, just press the RCD Test button. To diagnose the response time, a special device is required. | |

| Working temperature | ° C | minus 25 - +40 | Operating temperature at which the operation of the RCD is allowed | |

| Constructive execution | Electromechanical | More reliable, cheaper, but larger electronic RCDs | ||

| Electronic | Modern RCDs, expensive, small | |||

| Type according to the shape of the operating current | AS | Trips if sinusoidal leakage current rises slowly or abruptly | ||

| BUT | Trips if sinusoidal or pulsating DC leakage current rises slowly or abruptly | |||

| IN | Trips if sinusoidal, pulsating DC or DC leakage current rises slowly or abruptly | |||

| Installation method | Designed for mounting on a DIN rail in a shield | Designed for installation in electrical panels of apartments and houses | ||

| Built into a socket | Installed to protect a separate electrical appliance or in the case of old electrical wiring to prevent false alarms from natural leakage currents | |||

| In the form of an adapter plugged into an outlet | ||||

| Extension Mount | Installed on the power cord of an electrical appliance | |||

On the front side of the residual current device, the markings with the main technical characteristics... The decoding of the alphanumeric designation is shown in the drawing.

When choosing an RCD, the main thing to pay attention to is voltage, operating current and leakage current. The rest of the parameters are of secondary importance.

Wiring diagram for connecting an RCD in the dashboard

The residual current device in the panel of the quarter wiring is connected immediately after the meter to the gap between the neutral and phase wires going to the circuit breakers.

The wires coming from the meter are connected on top of the RCD. The phase wire L is to the left contact, and zero N to the right contact. The wires going to the machines are connected to the lower terminals in the same sequence. The yellow-green grounding conductor is laid bypassing the RCD.

The device and principle of operation of the RCD

When the RCD is in the on state (the lever is lifted up), the supply voltage is supplied through it to the circuit breakers in the wiring. If the consumer of electricity is turned on, then current flows through the neutral and phase wires.

In an RCD, wires pass through a differential ring transformer, and when current flows through them, a magnetic field is excited in its magnetic circuit. If there is no leakage, then the currents in the phase and neutral wires are equal and flow in opposite directions. Therefore, the magnetic fields they create have the opposite polarity and are mutually annihilated. In this case, according to Kirchhoff's law, EMF does not arise in the additional winding of the transformer, regardless of the current flowing through it into the load.

The principle of operation of an electromechanical RCD

In the event that, due to a violation of the insulation of a household electrical appliance, a current greater than through the phase wire flows through the phase wire, a magnetic field appears in the magnetic circuit of the transformer. If the difference in currents exceeds I∆n, then an EMF of sufficient magnitude is induced in the additional winding for the RCD to trip and turn off the power supply to the wiring.

In an electromechanical RCD, an electromagnet is connected to the additional winding of the transformer, the solenoid of which is mechanically connected to the release mechanism. When a given EMF occurs in the winding, the solenoid is pulled in and thereby, acting on the release mechanism, opens the contacts. The power supply to the wiring stops.

The principle of operation of an electronic RCD

By appearance a standard electronic RCD does not differ from an electromechanical one and can only be distinguished by marking or a diagram on the case. The principle of operation of both types of RCDs is the same and the difference lies in the measuring device. In electronic, instead of an electromagnet, electronic circuit in the form of a threshold comparator with an amplifier and a relay.

If the difference in currents I∆n flowing through the phase and neutral wires is exceeded, voltage is supplied from the amplifier to the relay. It is triggered and the RCD stops supplying voltage to the wiring.

Fastening the RCD in the shield on a DIN rail

In a wall panel or boxes, RCDs, like other installation electrical devices, are mounted on a DIN rail, it is also often called a mounting rail. It is a 35 mm wide metal plate bent in such a way that its longitudinal edges are raised. According to GOST R IEC 60715-2003 “Low-voltage distribution and control equipment. Installation and fastening on rails electrical apparatus in low-voltage complete distribution and control devices " denoted by T35.

This method of fastening does not require additional fasteners and allows you to quickly both install the RCD and remove it for prevention, check or replacement. The photo shows an old-style DIN rail when they were an aluminum alloy profile.

DIN rails are installed horizontally in the panel. On the back side of the RCD there are two clamps - stationary (in the photo on the left) and spring-loaded movable (on the right). Thus, in order to install the RCD on the rail, you need to put the upper fixed latch over the edge of the DIN rail, and then press the lower part against it. The movable latch will sink into the RCD case and come out of it when the RCD is pressed against the DIN rail by the entire plane.

To remove the RCD from the DIN rail, it is enough to insert the end of the flat screwdriver blade located below the outgoing conductor into the eye of the movable retainer and push it down. The latch will disengage, and the lower part of the RCD will freely move away from the DIN rail.

The connected RCD is under phase voltage and must be de-energized before dismantling.

How to properly connect the wires to the RCD

The uninterrupted operation of all electrical wiring is determined not only the right choice cross-section of wire and electrical appliances, but also the reliability of their connection to each other. Despite the simplicity of this operation, mistakes are often made, which subsequently leads to burning of the contacts and failure of the RCD.

The main feature of electromechanical devices is operation regardless of whether there is voltage in the network or not.

The leakage current will be quite enough for the equipment to work, at this time a current arises in the secondary winding of the transformer, which is the reason for the activation of the relay, and, accordingly, the trigger.

In order for the electronic RCD to work, one cannot do without voltage, due to completely different principles of operation.

Inside them there is an amplifier and a board for it, which is triggered by the presence of even a small current in the secondary winding. The board increases the available current and transmits a pulse strong enough to activate the relay.

That is why in the design of such RCDs there is a smaller transformer.

Electromechanical units have a simple, but at the same time more reliable design, so they break less often during operation. But to disable electronic device possible with a small impulse in the network.

In this case, it will be necessary to change the microcircuit or semiconductors. Despite this, the great popularity of electronic RCDs is due to their lower cost.

Moreover, modern developments have made it possible to equip such equipment with additional protection against voltage surges. As soon as the jump occurs, it will disconnect itself.

There are several other ways to distinguish between these two types of RCDs.

The hardest part is to look at the diagram inside. If this is an electromechanical device, then its diagram will show a differential type transformer, in which the second winding is connected directly to the relay.

The relay can be shown schematically in the form of a square, sometimes a rectangle. The connection with the mains supplying the node should not be shown schematically.

If we consider a schematic representation of an electric type RCD, then the board on it will be shown as a triangle. The diagram shows the lines from the power supply.

A simple battery can be used to distinguish one device from another. We turn on the equipment and connect its poles with two wires to it.

Thus, we provoke a current surge, as a result of which, if it is an electromechanical RCD, then the relay will turn off. Accordingly, if the shutdown did not occur, then we have an electronic version.

If you do not have a battery handy, find a medium-sized permanent magnet and hold it near the body of the equipment in question. Wherein a prerequisite is the ON state of the unit. Run the magnet along the side and front panel. If the relay does not work in front of you electronic equipment, and if it does work - electromechanical.

Write comments, additions to the article, maybe I missed something. Take a look at, I will be glad if you find something else useful on mine.

Residual current devices are of two types according to the principle of internal design. These are electromechanical and electronic. This also applies to difavtomats, since RCDs are their part of... The different principle of the internal design of these devices does not affect their operating parameters. However, there are nuances in which one type of RCD regularly performs its functions, while another type cannot do this, which can lead to disastrous consequences. Therefore, even before buying, you need to know how to distinguish between them.

There are three available ways how to distinguish an electromechanical RCD from an electronic one. This is according to the wiring diagram, which is shown on the body of the device, using a conventional battery and using a permanent magnet. Let's take a closer look at each method below.

1. Using the wiring diagram, which is shown on the body of the device.

I believe that this is the easiest way to distinguish between them, since this does not require any additional elements and tools. The main thing here is to remember the differences in the schemes and that's it.

If you pick up any RCD or difavtomat, then on its case you will definitely find a schematic diagram of their internal structure. In fact, there are two types of schemes. This is one type for the electromechanical type and the second type for the electronic type. Although each type of scheme has slight differences, they are not so significant.

In a nutshell: An electromechanical RCD or difavtomat consists of a differential transformer and a polarized relay. If a leakage current occurs in the controlled circuit, then it generates a current in the secondary winding of the differential transformer. This differential current triggers the relay, which acts on the trigger, causing the device to trip.

So on the diagram we need to find a differential transformer and a polarized relay. The first is designated as an oval around the phase and neutral conductors, and the relay is designated as a square or rectangle. Relays with a transformer are connected by means of a secondary winding, which is shown as a solid line. The dotted line indicates the mechanical link to the trigger. Also, the diagram often depicts the "Test" button, but it is not on the difavtomat shown in the photo.

In the photo below, I have signed the necessary elements on the diagram.

Electronic RCDs and difavtomats have a slightly different wiring diagram on their case. From the name it can be understood that the operation of such devices is controlled by an electronic board.

In a nutshell: If a leakage current occurs in the monitored circuit, it strikes the current in the secondary winding of the differential transformer. This differential current is captured by the electronic board, amplifies it and creates a pulse from which the relay is triggered. The relay is already acting on the trigger, thereby disabling the device.

Electronic elements are much more compact and therefore such RCDs and difavtomats are often smaller. There are commercially available electronic single-module protective devices, i.e. the size of a single-pole circuit breaker.

Here, in the diagram, we need to find, in addition to the differential transformer and the relay, an electronic amplifier board. It is designated as a triangle. Also, not a single board operates without power, therefore, there are additional lines for its power supply on the diagram. In the photo below, I signed all the necessary elements.

As a result, we get:

- If the diagram shows an oval above the neutral and phase conductors (differential transformer) and a square (relay) connected by a solid line, then you have an electromechanical RCD or a difavtomat.

- If the diagram shows an oval above the neutral and phase conductors (differential transformer) and a square (relay) connected by a solid line through a triangle (amplifier board), to which two power lines are connected, then you have an electronic RCD or a difavtomat.

2. The second way to distinguish an electromechanical RCD from an electronic one is with the help of a battery.

Although this option is reliable, I find it more difficult, since you need to have a charged battery, two wires and a screwdriver with you. Also in the store, I think you will not be given a device in your hands so that you connect something to it and experiment. Many more protective devices are sold in a sealed package (box), which will not be allowed to be opened in the store either.

However, this method has the right to life and I will tell you about it. For example, in the photo, I use an RCBO from Schneider Electric.

Everything is simple here. It is necessary to screw one wire from above to one, for example, to the zero pole. Screw the second wire to the lower zero pole. Then cock the control handle, i.e. turn on the RCD or difavtomat. Now the other ends of the wires must be closed to any charged battery. If the device shuts down, then it is electromechanical. If it does not turn off, then turn the battery over (reverse its polarity) and try to short the wires again. If the device turns off, then it is definitely electromechanical.

Why do electromechanical RCDs and difavtomats operate on batteries? Because the battery starts to discharge through the closed pole, i.e. a current appears in one pole, which in turn affects the differential current in the secondary winding of the transformer. It is enough to trigger a polarized relay.

If the device does not turn off, then it means that it is electronic. Why does this type of RCD not turn off? Because for the amplifier board to work, power is needed, which is not there. Consequently, the amplifier does not impulse a relay that has no effect on the trigger.

This operation can be carried out at any pole and at zero and phase. The electromechanical protective device will trip in any case.

3. The third way to distinguish an electromechanical RCD from an electronic one is with the help of a permanent magnet.

There is nothing complicated here either. You just need to find somewhere a medium-sized permanent magnet (1 / 4-1 / 3 of the RCD).

The sequence of actions is as follows:

- we pick up an RCD or a difavtomat;

- cocking the lever, i.e. turn it on;

- drive the magnet in a circular motion near the front and side of the device.

If during such movements the device turns off, then it means it is electromechanical, and if not, then it is electronic. This method is not one hundred percent, since the strength of your magnet may not be enough for the appearance of a differential current.

So we analyzed all three available ways of how to determine the types of RCDs and difavtomats.

Have you ever used such options to distinguish an electromechanical RCD from an electronic one?

Let's smile:

"Let there be light!" - Said the electrician and crawled for the matches.

What you need to open a hookah lounge, and how to do it correctly

What you need to open a hookah lounge, and how to do it correctly How to start a business and choose donut equipment

How to start a business and choose donut equipment Opening a company in Montenegro Open a company in Montenegro

Opening a company in Montenegro Open a company in Montenegro The carpentry shop as a business

The carpentry shop as a business How to choose a business direction?

How to choose a business direction? Sample business plan of a dental office

Sample business plan of a dental office Five best business ideas that brought millions What business to open so as not to go bankrupt

Five best business ideas that brought millions What business to open so as not to go bankrupt