Product life cycle processes. QMS: Input and output data for design and development Document input data for product design

7.3.1 General guidelines

Top management should ensure that the organization has identified, implemented and maintains the necessary design and development processes to effectively and efficiently respond to the needs and expectations of its customers and other interested parties.

In the design and development of products or processes, management needs to ensure that the organization is not only able to consider its core activities and functions, but all factors that contribute to the performance of products and processes that meet the expectations of customers and other interested parties. For example, an organization should consider product lifecycle, health and safety, testability, suitability, ease of use, reliability, durability, ergonomics, environment, product disposal, and certain risks.

Management is also responsible for taking steps to identify and reduce potential risk to users of the organization's products and processes. Risks should be assessed to assess the likelihood of their occurrence and the consequences of likely failures or deficiencies in products or processes. The results of the assessment should be used to identify and implement preventive actions in order to reduce the identified risks. Examples of design and development risk assessments include:

Analysis of the causes and consequences of project failures;

- analysis of the fault tree;

- reliability forecast;

- dependency diagrams;

- classification methods;

- modeling methods.

7.3 Design and development7.3.1 Design and development planning The organization shall plan and control the design and development of the product. During design and development planning, the organization should establish:

The organization must manage communications different groups engaged in design and development in order to ensure effective communication and clear allocation of responsibilities. Exit planning should be updated, as appropriate, as design and development advances. |

7.3.2 Design and development inputs and outputs

The organization needs to define process inputs that influence product design and development and contribute to effective and efficient effective work process to meet the needs and expectations of customers and other interested parties. These external needs and expectations, combined with the organization's internal needs, should be suitable for translation into input requirements for the design and development processes.

Examples are:

a) external inputs such as:

The needs and expectations of consumers or the market;

- the needs and expectations of other interested parties;

- Contribution of suppliers;

- user input, aimed at creating a stable project and development;

- changes to relevant legal and regulatory requirements;

- international or national standards;

- industrial codes of good practice;b) internal inputs such as:

Policy and goals;

- the needs and expectations of people in the organization, including those who receive the outputs from the processes;

- technological developments;

- requirements for the competence of designers and developers;

- feedback on past experience;

- records and data on existing processes and products;

- outputs from other processes;c) inputs defining those characteristics of processes or products that are critical to their safety, proper operation and maintenance, such as data on:

Work, installation and application;

- storage, handling and delivery;

- physical parameters and external environment;

- requirements for the disposal of products.

Product-related inputs can be essential and are based on an assessment of the needs and expectations of end users as well as direct customers. These inputs need to be formulated so that products can be effectively and efficiently verified and validated.

The output includes information that allows verification and validation against the planned requirements. Examples of design and development output include:

Data confirming the comparison of process inputs with process outputs;

- product specifications, including acceptance criteria;

- process specifications;

- specifications for materials;

- test specifications;

- requirements for training;

- information about the user and the consumer;

- procurement requirements;

- protocols of verification of compliance with technical conditions.

Design and development outputs should be reviewed against inputs to provide objective evidence that the outputs effectively and efficiently meet the process and product requirements.

ISO 9001: 2000. Quality management systems. Requirements 7.3.2 Inputs for design and developmentInput data related to product requirements should be defined and records maintained. This data should include:

These inputs should be reviewed for adequacy. Requirements must be complete, unambiguous and consistent. 7.3.3 Design and development outputsDesign and development outputs should be presented in a form that allows verification against the design and development input requirements and should be approved prior to release. Design and development outputs should:

|

7.3.3 Design and development review

Top management needs to ensure that appropriate people are assigned to manage and conduct a systematic review to establish the achievement of design and development objectives.

Such analyzes can be carried out at selected points in the design and development process, and also after its completion.

The objects of such analyzes are:

Adequacy of inputs for completing design and development assignments;

- progress of the planned design and development process;

- compliance with the objectives of verification and validation;

- assessment of potential risks or causes of failure when using the product;

- data life cycle product characteristics;

- change management and their consequences during design and development;

- identification and correction of problems;

- opportunities to improve the design and development process;

- the potential impact of the product on the environment.

At appropriate stages in the organization, reviews of the design and development outputs and processes should also be performed to meet the needs and expectations of customers and those of the organization receiving the process outputs. Attention must also be paid to the needs and expectations of other stakeholders.

Examples of activities to verify the outputs of the design and development process are:

Comparisons of input requirements versus process output;

- the use of comparative methods, such as alternative calculations in design and development;

- assessment in relation to analogs;

- verification, simulation and testing to verify compliance with specific input requirements;

- assessment of lessons learned from past experience, such as inconsistencies and deficiencies in the process.

Validation of the outputs of the design and development processes is essential for their successful acquisition and use by customers, suppliers, employees of the organization, and other interested parties.

Party participation allows actual users to rate outputs through means such as:

Validation of technical design prior to construction, installation or application;

- validation of software outputs prior to installation or use;

- validation of services prior to their widespread introduction.

Partial validation of design and development outputs may be required to provide confidence in their future use.

During verification and validation, sufficient data should be collected to enable analysis of design and development methods and decisions made. Method analysis includes:

Improvement of processes and products;

- output data on applicability;

- the adequacy of the process and analysis records;

- failure research activities;

- future needs of the design and development process.

ISO 9001: 2000. Quality management systems. Requirements 7.3.4 Design and development reviewAt appropriate stages, a systematic design and development review should be carried out in accordance with planned activities in order to:

The participants in this analysis should include representatives of the departments related to the analyzed design and development stage (s). Records of the analysis results and all necessary actions should be maintained. 7.3.5 Design and development verificationVerification should be carried out in accordance with planned arrangements to ensure that the design and development output meets the design and development input requirements. Records of the results of verification and all necessary actions should be maintained. 7.3.6 Design and development validationDesign and development validation should be carried out in accordance with planned arrangements to ensure that the resulting product is capable of meeting the requirements for the specified application or intended use, where known. Where practicable, validation should be completed prior to delivery or sale of the product. Records of the results of validation and all necessary actions shall be maintained. 7.3.7 Control of design and development changesDesign and development changes must be identified and records maintained. Changes should be reviewed, verified and approved, if appropriate, and approved prior to implementation. The analysis of design and development changes shall include an assessment of the impact of the changes on the component parts and the delivered product. Records of the results of the review of changes and any necessary actions shall be maintained. |

Input data related to product requirements shall be defined and records maintained (4.2.4).

Input data must include:

a) functional and performance requirements;

b) relevant legislation and other mandatory requirements;

c) where possible, information taken from previous similar projects;

d) other requirements important to design and development.

The input data should be analyzed for sufficiency. Requirements must be complete, unambiguous and consistent.

Design and development output

The design and development outputs should be presented in a form suitable for verification against the design and development input requirements, and should be formally approved prior to their subsequent use.

Design and development outputs should:

a) meet the design and development input requirements;

b) provide relevant information on procurement, production and services;

d) determine the characteristics of the product that are essential for its safe and correct use.

NOTE Information for production and service can include details of the preservation of the product.

Analysis of the project and development

At appropriate stages, a systematic design and development review shall be carried out in accordance with planned activities (7.3.1) in order to:

a) evaluating the ability of the design and development results to meet requirements;

b) identify any problems and propose necessary actions.

The participants in this analysis should include representatives of the departments related to the analyzed design and development stage (s). Records of the results of analysis and all necessary actions shall be maintained (see 4.2.4).

Project and development verification

Verification should be carried out in accordance with planned arrangements (7.3.1) to ensure that the design and development outputs meet the input requirements. Records of the results of verification and all necessary actions shall be maintained (see 4.2.4).

Project and development validation

Design and development validation should be performed in accordance with planned arrangements (7.3.1) to ensure that the resulting product meets the requirements for the specified or intended use, if known. Where practicable, validation should be completed prior to delivery or use of the product. Records of the results of validation and any required actions shall be maintained (see 4.2.4).

Project and development change management

Design and development changes must be identified and records maintained. Changes should be reviewed, verified and validated as appropriate, and approved prior to implementation. The analysis of design and development changes should include an assessment of the impact of the changes on the component parts and products already delivered. Records of the results of the review of changes and any necessary actions shall be maintained (see 4.2.4).

Procurement

Procurement process

The organization shall ensure that purchased products meet specified purchasing requirements. The type and degree of control applied to the supplier and purchased product should depend on its impact on subsequent stages of the product life cycle or finished product.

The organization shall evaluate and select suppliers based on their ability to supply product in accordance with the organization's requirements. Criteria for selection, evaluation and re-evaluation should be developed. Records of the results of the assessment and any necessary actions resulting from the assessment shall be maintained (4.2.4).

Purchasing information

The purchasing information should describe the products ordered, including, where applicable, requirements:

a) formal approval of products, procedures, processes and equipment;

b) personnel qualifications;

c) the quality management system.

The organization shall ensure that specified purchasing requirements are sufficient prior to communicating them to the supplier.

Inputs should be identified in order to provide a basis for formulating requirements that are used to verify and validate outputs. Input data can be external or internal.

In order to ensure that the needs and expectations of all interested parties for a process and / or service, process or system are met, design and / or development inputs must be accurate and complete. The resolution of ambiguous or conflicting inputs should be done with the involvement of external and internal influences.

External inputs can include customer or market needs and expectations, stakeholder specifications, contract requirements, regulatory requirements, international or national standards, and industry codes.

Internal inputs can include policies, standards and specifications, qualification requirements, documentation and data for existing products and / or services, and outputs from other processes.

In the case of designing and / or developing software or services, inputs from end-user requirements (as well as direct customer requirements) can be particularly important. Such inputs should be formulated in such a way that they can be effectively monitored during subsequent verification and validation. Such inputs should be formulated in such a way that they can be effectively monitored during subsequent verification and validation.

Input data can also arise during the design phase in the course of activities that are not even fully appreciated. Also, the input data should be subject to evaluation by subsequent reviews and verification and validation activities.

Other inputs identify those design and / or development characteristics that are critical to the safety and proper functioning of a product and / or service, or identify processes such as operations, storage, handling, operation, and placement requirements.

Typical examples of development activities include:

modified materials,

modified product components,

new technologies for the provision of services,

market analysis results.

Inputs that are critical to a product and / or service or to a process must be identified in order to assign appropriate responsibilities and resources.

|

ISO 9001: 2000 - Quality management systems - Requirements 7.3.2 Inputs for design and development. Requirements for a product and / or service should be defined and recorded (see 5.6.7). These requirements should include: fulfillment requirements from the customer or the market; applicable regulatory and legal requirements; applicable environmental requirements requirements arising from previous similar projects; any other requirements essential for design and development. These inputs should be reviewed for adequacy or inconsistency with the requirements to be met. |

7.3.1 Design and development planning

TSU management plans and manages design and development in accordance with the procedures "Preparation educational process"OP 01.02," Providing educational and methodological support "PP 01.03.

When assessing the potential, the components of the education system are considered, which have a quantitative characteristic:

Personnel composition;

Material and technical base;

Information base;

Scientific and methodological support;

Financial resources;

Management of the system and its individual elements.

At Tyumen State University, the design and development of the following documents is usually carried out:

4. Taking into account the strategic and medium-term development plan of Tyumen State University.

The development of new cycles of disciplines and the adjustment of the existing ones is ensured by the implementation of the following tasks:

1. Course design. Determination of learning outcomes.

2. Self-analysis of teaching staff and building their own system of pedagogical activity.

3. Certification and technology of self-examination of the university.

Design and development planning is carried out on the basis of the schedule contained in the System of program activities for academic year... The work schedule is divided into stages of work, each of which is detailed into separate tasks.

The work schedule establishes the stages of verification, revision and approval of documentation, stages of verification and validation, division of responsibility and authority in the field of design and development between the participants in the work.

The head of a specific work analyzes the terms of reference and determines the composition of the design and development performers (including with the involvement of third-party specialists).

Development and design is carried out by Tyumen State University independently or with the involvement of third-party organizations and / or specialists.

The procedure for monitoring the quality of scientific and educational-methodical literature consists of an analysis of the results of the activities of the following structural units:

CIT - organization and support of the electronic environment of the university;

IBC - use (acquisition, delivery) of educational, methodological and scientific literature;

Publishing house - publishing educational-methodical and scientific literature;

Faculties and departments - creation and preparation for publication of scientific and educational literature.

Terms of reference for co-executors are developed by the responsible executor with the participation, if necessary, of the involved organizations and / or specialists. The content of the technical assignment is determined by Tyumen State University. The terms of reference are approved by the rector.

The agreement (contract) with the co-contractor is coordinated by the following persons (in the order of obtaining visas):

· Co-executor;

· Head of the structural unit;

· Chief Accountant;

· Quality management representative;

· Rector and / or Vice-rector.

Input data related to the requirements of the educational process at Tyumen State University include:

1. Requirements for educational and organizational documentation;

2. Requirements for information and teaching and methodological support;

3. Requirements for teaching staff, administrative and managerial and educational support personnel;

4. Requirements for material and technical equipment;

5. Requirements for the level of training of applicants;

6. Information from the strategic and medium-term development plan of Tyumen State University.

7.3.3 Design and development outputs

Design and development outputs are:

Educational programs;

Teaching aids;

Dictionaries.

For all design and development, the output must:

· Meet the design and development input requirements;

· Provide relevant information on procurement, production and services;

· To define characteristics of the results of design and development, essential for their safe and correct use.

The completeness of the design and development documentation is determined by the terms of reference. Typically, a set of documents includes a paper version and an electronic version on CD-ROM.

Responsible for the preparation of documents is the responsible executor.

Copies of the developed design and development documentation and their electronic versions are kept by the responsible contractor with subsequent transfer to the archive.

The responsible executor keeps records of the documentation in accordance with the list of documentation specified in the work schedule. Records fixing the accounting of the developed documentation are reflected in the periodic reports on the work done.

Output data of organizational and methodological work:

§ prepared methodological developments,

§ compiled educational and methodological complexes of disciplines,

§ settlement system teaching load,

§ schedule of exams,

§ organization of the office work system,

§ drawing up plans for departments,

§ preparation of the department for self-certification and accreditation.

7.3.4 Design and development review

In the design and development process, a systematic analysis is carried out to establish compliance with the requirements for the design and development results, that is, the development quality is analyzed (clauses 3.1.1, 3.8.7 GOST R ISO 9000 - 2001).

Tyumen State University uses a multi-level system for analyzing the quality of design and development, which provides for the analysis at the appropriate stages of design and development in accordance with the planned activities. The analysis system includes the following sequential procedures:

· internal analysis carried out by Tyumen State University in the process of preparing preliminary and final versions of design and development documents;

· Internal analysis carried out by Tyumen State University in the process of finalizing (correcting) the documentation on the remarks and / or suggestions of the Consumer;

· External analysis by state examination bodies (if necessary);

· External analysis carried out by the Consumer.

The design and development analysis system applies to preliminary and final versions of documentation. The acceptance system includes design and development review activities at various levels.

The number of levels of analysis depends on the design and development environment and may vary.

I level of analysis

The responsible executor analyzes and accepts design and development work in accordance with the terms of reference from the staff of Tyumen State University.

If the responsible executor has any comments on the submitted documentation, staff members finalize the documentation in a working order.

Confirmation of the analysis and acceptance of works is the signature of the responsible executor.

II level of analysis

The responsible executor of work under the agreement (contract), together with the staff of Tyumen State University, carry out the analysis of documentation and acceptance of work in accordance with the terms of reference from subcontractors.

Confirmation of the analysis carried out is the endorsement by the responsible executor of work under the agreement (contract) of the acceptance certificate of work from subcontractors.

III level of analysis

The responsible executor of work in accordance with the terms of reference carries out the analysis and acceptance of work for individual sections of the documentation from the involved specialists.

If the responsible executor has any comments on the submitted documentation, the involved employees finalize the documentation in working order.

Confirmation of the analysis carried out is the endorsement by the responsible executor of the acceptance certificate of work from subcontractors.

IV level of analysis

Analysis with the involvement of third-party organizations and / or specialists. The decision to engage third-party organizations and / or specialists for the analysis is made by the Quality Management Representative.

Confirmation of the analysis is the endorsement by the responsible executor of work under the agreement (contract) of the acceptance certificate of work with third-party organizations and / or specialists involved for analysis.

V level of analysis

Analysis by the Consumer.

If there are any comments in such an analysis on the submitted documentation, the employees modify the documentation in a working order.

The confirmation of the analysis is the signature of the acceptance certificate of the work by the Consumer.

Materials for the analysis of the project and development are stored in the development department and / or at the responsible executor of the work for 3 years.

7.3.5 Design and development verification

Verification is carried out in accordance with planned activities to ensure that the design and development outputs meet the input requirements. The activity to confirm the fulfillment of the established requirements is carried out in accordance with the planned activities (clause 7.3.1). The following verification steps are provided for various design and development options:

Responsible executor;

A specially appointed employee;

With normative control.

A note about the verification is the signature of the relevant contractor in the places provided for this (on the documents being developed, in the act, etc.). Records of verification results and all required actions are maintained.

7.3.6 Design and development validation

Validation activities are carried out in accordance with the planned activities (clause 7.3.1). The following validation steps are provided for various design and development options:

Head of the department;

Dean or head of the institute;

Vice-rector;

Quality Management Representative;

Rector.

The mark of the validation is the signature of the relevant contractor in the places provided for this (on the documents being developed, in the act, etc.).

In the provided cases, validation is carried out by the Consumer and / or third parties.

7.3.7 Control of design and development changes

Changes to the developed documentation can occur:

· When errors are detected;

· When improving the developed documentation;

· When the requirements of the Consumers change.

Changes to the developed documentation can be carried out at any stage of the work.

The texts of changes are developed by the initiator of the change in accordance with the accepted procedure for development and approval. Changes to the developed documentation are made by specialists who perform or have performed the relevant work, under the supervision of a responsible specialist (the form of notification of the change is given in the annex to procedure 01.04.02 / PP 01.04 "Management of Documents and Records").

Changes made to the developed documentation are analyzed from the point of view of their impact on other developed project documentation, verified, validated and agreed in the same manner as the developed documentation (clauses 7.3.3 - 7.3.6 of the Quality Manual ).

The seized documentation is stored for 3 years.

Design and Development Input

Input data related to product requirements shall be defined and records maintained (4.2.4). This data should include:

a) functional and performance requirements;

b) applicable statutory and regulatory requirements;

c) where appropriate, information drawn from previous similar projects;

d) other requirements important to design and development. These inputs should be reviewed for adequacy. Requirements must be complete, unambiguous and consistent.

Design and development output

Design and development outputs should be presented in a form that allows verification against the design and development input requirements and should be approved prior to release.

Design and development outputs should:

a) meet the design and development input requirements;

b) provide relevant information on procurement, production and services;

d) determine the characteristics of the product that are essential for its safe and correct use.

History of work in the field of quality in Russia.

Speaking about the advanced experience in the field of quality management, one cannot but recall the domestic practice of quality improvement.

What quality improvement concepts existed in our country?

1. BIP concept(Defect-free Manufacturing of Products) This system was based on the mechanism of activating participants production process, stimulating them to identify and eliminate not product defects, but their causes. After re-presentation of the product, the worker was deprived of the bonus.

2. CANARSPI concept(Quality, Reliability, Resource from First Products) Was introduced at the Gorky Aviation Plant. Recognized as the best in the country, the system was based on the following principles:

Versatility (the possibility of using in other industries)

· complex provision product quality

Conducting research aimed at improving the quality of products and developing the experimental design services of the enterprise

Organization of a comprehensive accounting of the quality of products

Focusing on the quality of products at the stage of their development

Involvement of consumers in the improvement of products

1. NORM concept In the mid-1960s. at the Yaroslavl Motor Plant Avtodiesel, the NORM system was introduced, in which one of the most important technical parameters- resource before the first major overhaul. Particular attention was paid to the development of design and technology that ensure an increase in the technical level and quality of the engine. In the NORM system, the main elements of the Saratov and Gorky systems of quality management of manufactured products were used and developed.

2. KSUKP concept(Integrated product quality management system)

In the first half of the 1970s. As a result of a joint research and production experiment of the enterprises of the Lviv region, the All-Union Research Institute of Standardization of the USSR State Standard for Standardization and the Scientific and Production Association "Sistema", a comprehensive product quality management system was developed and tested.

The main goal of the system was to ensure high and sustainable growth rates of the quality of products manufactured by the enterprise due to:

· Creation and development of new high-quality types of products;

Timely putting into production new products;

· Removal from production of obsolete products;

· Improving the quality indicators of manufactured products by improving and modernizing them.

What was the specificity of the Russian experience in quality management?

The specificity of quality management in Russia was that efficient systems quality management was created at the enterprises of the military-industrial complex (MIC). It was in the military-industrial complex that methods of quality assurance at the stages of research and design of new products, statistical quality control using control charts, and special standards were widespread. In the depths of the military-industrial complex, KSUKP ( complex systems product quality management, including automated).

QMS: Management of nonconforming products.

Methodology for managing nonconforming products.

1) we determine the products included in the scope of the QMS, 2) we determine what the corresponding products are, 3) we determine which control mechanisms are applicable to which products (it can be in the form of a table), 4) we describe in detail these mechanisms as applied to specific products: who is responsible for what, what powers they have, what they do.

While the products are with us.

What can we do to ensure product conformity when nonconformity is found?

The first is obvious: fix it. those. in terms of ISO 9000, perform the correction. But this is not always possible.

Then the second is to assess how much the nonconformity prevents the intended use of the product and, if appropriate, allow the deviation. If possible, the permission to reject is also requested from the consumer, whether he agrees. The customer, having analyzed which functions will be missing, may consider this quite acceptable and give permission.

If neither the first nor the second is possible, then the third option remains: to change the initial application or to refuse to use the product altogether.

Obviously, the procedure for managing nonconforming products cannot be fully developed if

the product itself is not defined, the quality of which is managed within the framework of the QMS

it is not defined what the conforming product is, because it is tantamount to not defining the nonconforming product.

From listening experience: if I cannot understand from the quality manual which specific products are included in the scope of the QMS, then I may not even look at the procedure for managing nonconforming products, guaranteeing in advance that it is formal.

Control mechanisms in each of the three cases:

Change products (correction)

Specify the method for identifying the nonconforming product and who is responsible for this identification,

specify who is responsible for preventing the release and delivery of identified nonconforming product and his authority,

indicate the person responsible for the correction,

establish a re-control procedure and a person responsible for its implementation,

establish the form in which a record of the nature of the non-compliance and the decision on correction is made.

Change requirements

indicate the authorization to grant the waiver and his authority, and establish a procedure for such authorization, including the identification of the person authorized by the consumer to authorize the waiver,

establish the form in which the record of the nature of the nonconformity and the permission for deviation is made.

Change application

Establish who is responsible and authorized to prevent the initial use of nonconforming products by the customer, as well as a procedure for such prevention,

Establish the form in which the nature of the nonconformity and the actions taken to prevent initial use are recorded.

Consumer products.

Obviously, in this situation, none of the mechanisms described above is applicable: the products have gone out of our control. All that we can in this case is to take actions that reduce the negative consequences or the risk of such consequences for the consumer. As an example, here you can cite everyone famous companies on the recall of cars.

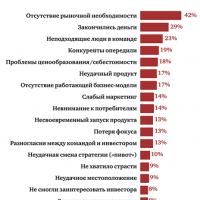

What you need to open a hookah lounge, and how to do it correctly

What you need to open a hookah lounge, and how to do it correctly How to start a business and choose donut equipment

How to start a business and choose donut equipment Opening a company in Montenegro Open a company in Montenegro

Opening a company in Montenegro Open a company in Montenegro The carpentry shop as a business

The carpentry shop as a business How to choose a business direction?

How to choose a business direction? Sample business plan of a dental office

Sample business plan of a dental office Five best business ideas that brought millions What business to open so as not to go bankrupt

Five best business ideas that brought millions What business to open so as not to go bankrupt