Occupational safety training programs by occupation. Labor protection training program for chief engineer Engineer's blog rf training program

Approved by: Director of Labor Protection LLC _____________ Directors D.D. December 12, 2012 M.P. TRAINING PROGRAM AND EXAMINATION TICKETS IN LABOR PROTECTION FOR HIGHER HAZARD PROFESSION: INSTALLER FOR INSTALLATION OF STEEL AND REINFORCED CONCRETE STRUCTURES Localization of www.blog-engineer.rf By the decree of the Ministry of Labor of Russia and the Ministry of Education of Russia dated 13.01.03 No. 1/29, the employer (or a person authorized by him) is obliged to organize, within a month after hiring, training in safe methods and techniques for performing work for all persons applying for work, as well as persons transferred to other work. Occupational safety training is carried out in the preparation of workers in working professions, retraining and training them in other working professions. The employer (or a person authorized by him) provides training for persons hired to work with harmful and (or) dangerous conditions work, safe methods and techniques for performing work with an internship at the workplace and passing an exam, and in the process labor activity- conducting periodic training on labor protection and testing knowledge of labor protection requirements. Workers of blue-collar professions who have entered the specified jobs for the first time, or who have a break in their profession (type of work) for more than a year, are trained and tested for knowledge of labor protection requirements within the first month after being assigned to these jobs. Since the work of an installer in the installation of steel and reinforced concrete structures is associated with hazardous working conditions, he must undergo training and testing of knowledge on labor protection. Periodic testing of knowledge is carried out at least once a year within the scope of this training program. The training program is developed based on the current normative documents regulating the labor safety of an installer for the installation of steel and reinforced concrete structures, his qualification characteristics in accordance with the Unified tariff and qualification reference book of work and professions of workers, as well as an analysis of the working conditions and safety of an installer for the installation of steel and reinforced concrete structures. The time allotted for the study of labor protection issues is determined depending on the volume of the studied material, as well as the complexity and danger of the work performed. The training includes the development of theoretical knowledge and practical skills of safe work in the profession. The training program consists of three sections: - legal issues of labor protection; - organization and management of labor protection; - safety. The first two sections are common to all occupations of workers and serve to study the general organizational and legal principles of labor protection. The section "Occupational Safety" is special and is designed to study the methods of occupational safety for the profession. The formation of the topic of special issues is based on the tariff and qualification characteristics of the profession, measures to ensure labor safety, analysis of the causes of accidents at work and morbidity among installers for the installation of steel and reinforced concrete structures. The program contains a list of regulatory legal acts containing labor protection requirements for the profession of an assembler for the installation of steel and reinforced concrete structures. 2. CHARACTERISTIC OF THE INSTALLER'S WORKS ON INSTALLATION OF STEEL AND REINFORCED CONCRETE STRUCTURES Execution of works during the installation of steel and reinforced concrete structures. Hooking steel, concrete and reinforced concrete structures with inventory slings for mounting loops, brackets, hooks, etc. Performing work on a hand winch. Cleaning surfaces for insulation. Punching holes and grooves in concrete and reinforced concrete structures. Driving the threads of bolts and nuts. Installing and removing bolts. Fastening the mounting bolt connections. Spreading with kerosene and chalk welds when checking their density. Caulking, pouring and pointing seams and joints in precast concrete structures. Sealing the ends of beams, grooves, nests, potholes and holes with bricks or concrete. Straightening of shaped steel on manual screw presses. Thermal insulation of concrete and reinforced concrete structures. Sheeting of steel and concrete structures. Thermal insulation of external joints with mineral and synthetic materials. Sealing joints with special sealants, applying them with a brush or spatula, using pneumatic tools. Preparation of sealants. Fastening parts on concrete and reinforced concrete surfaces using a construction and assembly gun. Anti-corrosion painting of parts. Application of epoxy glue to reinforced concrete structures. Should know: methods and techniques for installing steel and reinforced concrete structures. Rules for the transportation and storage of structures and products. Methods for slinging mounted structures. Methods of connections and fastening of structural elements. Ways of paving during the installation of structures. Properties and brands of concrete mixes. Rules for the preparation of surfaces for insulation. Basic requirements for the quality of mounted structures. Rules for the operation of construction and assembly guns. Rules for working with electrified and pneumatic tools. Methods and techniques for applying epoxy glue to reinforced concrete structures. Methods and techniques for assembling and installing rigging and lifting equipment and devices during the assembly and installation of structures. Rules, norms and instructions for labor protection and fire safety... Rules for the use of primary fire extinguishing equipment. First aid methods in case of accidents. Internal labor regulations of the organization. 3. THEMATIC PLAN OF TRAINING ON LABOR PROTECTION OF INSTALLER ON INSTALLATION OF STEEL AND REINFORCED CONCRETE STRUCTURES No. of the topic Topic Time of study of the topic, hour1. General issues labor protection 0.52. Labor protection legislation 2.03. Normative documents on labor protection 0.54. Organization and management of labor protection 0.55. Training of workers in labor protection requirements 0.56. and reinforced concrete structures 2.08. Safety requirements for tools, fixtures, equipment 2.09. Safety requirements when performing work on the installation of steel and reinforced concrete structures 8.010. Safety requirements when working at height 1.011. Means individual protection 1,012. Methods of rendering first aid to victims in case of accidents 1.0 Total: 20.0 4. TRAINING PROGRAM ON LABOR PROTECTION OF INSTALLER ON INSTALLATION OF STEEL AND REINFORCED CONCRETE STRUCTURES Topic 1. General issues of labor protection Definition of terms "Labor protection", "Working conditions", "Harmful (hazardous) production factor", "Safe working conditions", "Workplace", "Individual and collective protective equipment for workers", " Production activity". Main directions public policy in the field of labor protection. Labor safety as component production activities. Topic 2. Legislation on labor protection Labor Code Russian Federation... Obligations of the employer to ensure safe conditions and labor protection. Obligations of the employee in the field of labor protection. Collective agreement. Content of the collective agreement. Financing of measures to improve labor conditions and safety. Labor contract. Content employment contract... The term of the employment contract. The employee's right to work that meets the requirements of safety and hygiene. Mandatory preliminary and periodic medical examinations(surveys). Providing employees with personal protective equipment. The procedure for the issuance of milk or other equivalent food products to workers. Working hours and rest time. Duration working week, daily work (shift), start and end time of work, break time, number of shifts per day, alternation of workers and non-working days... Shift work. Overtime work and its limitation. Types of rest time. Rest and meal breaks. Duration of weekly uninterrupted rest. Annual paid vacations and their duration. Annual additional paid leave. Features of labor regulation of employees under the age of 18. Work in which the employment of persons under the age of 18 is prohibited. Features of labor regulation of women, persons with family responsibilities. Jobs that restrict the use of women's labor. Topic 3. Normative documents on labor protection Occupational safety standards system (SSBT). Enterprise safety standards. Rules, norms, typical instructions and other regulations on labor protection. Labor protection instructions binding on employees. Topic 4. Organization and management of labor protection State management of labor protection. Bodies of state supervision and control of compliance labor legislation... Labor protection service in the organization. Committee (commission) on labor protection. Topic 5. Training workers in labor protection requirements Training and testing the knowledge of workers in labor protection. Conducting briefings on labor protection: introductory, primary at the workplace, repeated, unscheduled, targeted. Training of persons entering work with harmful and (or) hazardous working conditions, safe methods and techniques for performing work with an internship at the workplace and passing exams. Periodic training in labor protection and testing of knowledge of labor protection requirements during the period of work. Topic 6. Industrial accidents Industrial accidents subject to investigation and record. Obligations of the employer in the event of an industrial accident. The procedure for investigating an accident at work. Registration of materials for the investigation of an industrial accident. Topic 7. Characteristics of the working conditions of an installer for the installation of steel and reinforced concrete structures. Types of work performed by the installer. Typical causes of accidents and occupational diseases when installing steel and reinforced concrete structures. Dangerous and harmful production factors influencing the installer during work. Unfavorable and dangerous effects of harmful and hazardous production factors on the human body. Topic 8. Safety requirements for tools, fixtures, equipment Safety requirements for technological equipment and tools. The procedure for checking their serviceability. Security requirements for access and passage systems on workplace(stairs, ladders, bridges). Requirements for hinged mounting sites. Safety requirements for hand-held locksmith tools. Safety requirements for wrenches and other tools. Safety requirements for hand-held impact tools. Safety rules when working with the tool. Prevention of injury when using hand-held locksmith tools. Safety requirements for sharpening hand tools. Rules for the safe use of hand-held power tools. Faults preventing the use of a hand-held power tool. Electrical safety requirements when working with a hand-held power tool. Classification of the power tool according to the degree of protection. Electrical safety group, which gives the right to use hand-held power tools. Topic 9. Safety requirements when performing work on the installation of steel and reinforced concrete structures Actions of the installer before starting work. Restrictions for getting started. Safety violations that prevent the installer from proceeding installation works ... Safety measures in preparation for installation work. Requirements for the organization of the workplace and approaches to the workplace. Inspection of the elements of building structures intended for installation. Precautions when positioning the tool in the workplace. Safety requirements when performing installation work. The installer's actions before installing the structure in the design position. Safety requirements for slinging structures. Rules for the exchange of conventional signals between the crane operator and the slinger. Features of the use of braces of a hemp or nylon rope during the installation of structures. Safety measures when lifting and feeding and guiding the structure to be installed to the installation site. Duties of the installer when installing elements of building structures in the design position. Precautions when pointing the structure to the installation site. Safety requirements for the final alignment of center and geometric axes. Safety measures when installing the structure in the design position and securing. Requirements for ensuring the stability and immobility of the assembled structure under the influence of assembly and wind loads. Safety requirements for unstitching structural elements installed in the design position. Safety requirements for punching furrows, holes and openings in stone and concrete structures. Safety requirements when using a construction and assembly gun. Allowable norms for manual movement of goods. Topic 10. Safety requirements for work at height. Definition of the concepts "Work at height", "Climbing work". Devices used for the work of installers at height. Rules for using a safety harness and a safety rope. Safety measures when using ladders and stepladders. Rules for fencing a hazardous area when working at height. Topic 11. Personal protective equipment Norms of free distribution of overalls, safety footwear and other personal protective equipment from the effects of hazardous and harmful production factors for the installer for the installation of steel and reinforced concrete structures. Rules for the use of personal protective equipment. Care rules and frequency of replacement of personal protective equipment. The procedure for replacing overalls, footwear and other personal protective equipment that have become unusable before the due date. The use of personal eye protection when punching furrows, holes and openings in stone and concrete structures. Topic 12. Methods of rendering first aid to victims in case of accidents Actions of the installer in case of an accident. First aid methods for bleeding, wounds, fractures, dislocations, bruises and sprains. First aid methods for eye contact with particulate matter First aid kit for first aid in case of accidents. RECOMMENDED REFERENCES 1. Labor Code of the Russian Federation of December 30, 2001 No. 197-FZ (as amended on July 24, 25, 2002, June 30, 2003, April 27, August 22, December 29, 2004, May 9 2005, 30 June, 18, 30 December 2006, 20 April, 21 July, 1, 18 October, 1 December 2007, 28 February, 22, 23 July, 25, 30 December 2008, 7 May , July 17, November 10, 25, 2009, July 27, December 23, 29, 2010, June 17, July 1, 18, 19, November 7, 21, 22, 2011). 2. The procedure for training in labor protection and testing the knowledge of labor protection requirements for employees of organizations, approved by the decree of the Ministry of Labor of Russia and the Ministry of Education of the Russian Federation of 13.01.03 No. 1/29. 3.GOST 12.0.003-74 * SSBT. Dangerous and harmful production factors. Classification. 4.GOST 12.0.004-90 SSBT. Organization of occupational safety training. General Provisions... 5. Regulation on the features of investigation of accidents at work in selected industries and organizations, approved by the decree of the Ministry of Labor of Russia from 24.10.02 No. 73. 6. SNiP 12-03-2001. Labor safety in construction. Part 1. General requirements. 7. SNiP 12-04-2002. Labor safety in construction. Part 2. Construction production. 8. SP 12-135-2003 Labor safety in construction. Industry standard instructions on labor protection. 9. Safety requirements for work with hand tools (collection of regulatory documents). - M .: NITs "Normative-Inform", 2004. 10. Intersectoral rules for labor protection when working at height (POT RM-012-2000). 11. Resolution of April 25, 2012 N 390 "On the fire regime". 12. Cross-sectoral rules for the provision of workers with special clothing, special footwear and other personal protective equipment, approved by order of the Ministry of Health and social development Of the Russian Federation dated June 1, 2009 No. 290n (as amended on January 27, 2010). 13. Lists of harmful and (or) hazardous production factors and work during which preliminary and periodic medical examinations (examinations) are carried out, and the procedure for conducting these examinations (examinations), approved by the Ministry of Health and Social Development of the Russian Federation No. 302n dated April 12, 2011. 14. Interdisciplinary instruction on first aid for industrial accidents. - M .: Publishing house NTs ENAS, 2007. 5. EXAMINATION TICKETS TO CHECK THE KNOWLEDGE OF LABOR PROTECTION OF THE INSTALLER FOR INSTALLATION OF STEEL AND REINFORCED CONCRETE CONSTRUCTIONS Ticket No. 1 1. Procedure for issuing personal protective equipment from exposure to hazardous and harmful production factors? 2. First aid to the victim in case of an accident? 3. What are the safety requirements for installing the structures to be installed in the design position? 4. Safety rules when working with hand-held locksmith tools? 5. What are the main causes of injury during the installation of steel and reinforced concrete structures? Ticket number 2 1. Labor protection issues in the Labor Code of the Russian Federation? 2. What should the installer do in the event of an industrial accident? 3. Safety requirements for slinging structures? 4. Safety measures when performing installation work at height? 5. Work safety when punching holes and grooves in concrete and reinforced concrete structures? Ticket number 3 1. Procedure for replacing overalls and footwear that have become unusable before the due date of wearing? 2. Safety measures in preparation for installation work? 3. Ensuring safety when using a construction and assembly gun? 4. What are the safety measures when driving the threads of bolts and nuts? 5. What should the installer do in the event of a fire in the work area? Ticket number 4 1. Types and procedure for passing instructions on labor protection? 2. Obligations of the employer for labor protection? 3. What should the installer do in an emergency? 4. The procedure for performing work on the admission side? 5. What protective equipment is used when punching holes? Ticket number 5 1. Features of work on weekends and holidays? 2. The collective agreement and its content? 3. How to protect a person from electric shock? 4. Safety requirements when working at height? 5. Ensuring stability and immobility of the mounted structure when exposed to wind loads? Ticket number 6 1. Mandatory preliminary and periodic medical examinations? 2. Grounds for termination of an employment agreement (contract) in the Labor Code of the Russian Federation? 3. What are the safety requirements when moving the fitter around the enterprise? 4. Precautions for loosening structural members installed in the design position? 5. What are the safety measures for drilling and hole punching? Ticket number 7 1. How often the installer undergoes repeated briefings on labor protection at the workplace? 2. Benefits provided to workers employed in jobs with hazardous working conditions? 3. Safety requirements when installing dowels? 4. Safety requirements for caulking, pouring and pointing seams and joints in prefabricated reinforced concrete structures? 5. Frequency of testing safety belts? Ticket number 8 1. Types of liability for violation of labor protection requirements? 2. Procedure for issuing workwear, footwear and other personal protective equipment to an installer? 3. The procedure for passing mandatory periodic medical examinations? 4. What should the installer do in the event of an accident? 5. What are the safety requirements when working with a hand-held power tool? Ticket number 9 1. Grounds for termination of an employment agreement (contract) in the Labor Code of the Russian Federation? 2. Targeted instruction on labor protection? 3. Safety requirements for slinging structures? 4. What are the acceptable norms for manual movement of weights for men? 5. Safety rules for fastening structures and equipment with a construction and assembly gun? Ticket number 10 1. Unscheduled instruction on labor protection? 2. The concept of "Labor protection" in the Labor Code of the Russian Federation? 3. What are the safety requirements for working with hand-held portable power tools? 4. What are the safety requirements for the organization of the installer's workplace? 5. What are the safety requirements for bricking or cementing the ends of beams, grooves, nests and holes? Ticket number 11 1. Criminal liability for violation of labor protection requirements? 2. Dangerous and harmful production factors that can have an adverse effect on the installer during work? 3. Safety requirements for the installation of structures at a height? 4. What are the safety measures when working with an impact tool? 5. What should the installer do before starting work? Ticket number 12 1. The procedure for registration of accidents at work? 2. Annual additional paid leave for workers employed in jobs with hazardous working conditions? 3. Safety measures in preparation for work on the installation of steel and reinforced concrete structures? 4. Safety requirements for thermal insulation of external joints with mineral and synthetic materials? 5. Methods of rendering first aid to victims with closed fractures of limb bones? Ticket number 13 1. Duties of the installer to ensure labor protection at his workplace? 2. Working hours and working hours of the installer? 3. Safety measures when using hemp or nylon rope guy wires when assembling structures? 4. Eye protection used when punching holes? 5. What should the installer do in an emergency? Ticket number 14 1. What is the installer's actions in the event of an accident at work? 2. Restrictions on limit overtime work? 3. Labor safety when sealing joints with special sealants? 4. Safety measures when lifting, feeding and guiding the structure to be installed to the installation site? 5. Personal hygiene rules at the end of work? Ticket number 15 1. The concept of "labor protection" in the Labor Code of the Russian Federation? 2. What are the duties of the installer for the storage and care of overalls, footwear and other personal protective equipment? 3. Rules for the exchange of conventional signals during the installation of structures? 4. What are the safety measures when working with an impact tool? 5. Safety requirements for anti-corrosion treatment of structures? 18

Having made a decision on choosing the profession of an occupational safety engineer, you need to know that the range of his activities is extremely wide. In its practical work he will be responsible for an important area - labor protection. The occupant of this position must clearly understand the OSH training program for an OSH engineer.

When the enterprise employs more than fifty workers, then an OT service should function on it. Its leadership is usually entrusted to an occupational safety engineer, or a chief of service, to whom the engineer will report.

The production hierarchy is that the chief accountant is the right hand of any manager. The occupational safety engineer is considered left-handed, which speaks of the extreme importance of labor protection. In terms of importance, these two positions are equally important.

Occupational safety engineers are trained by special training centers that provide training services for labor protection requirements, or health and safety centers. Such institutions must be licensed to educational activities.

Labor protection is a clearly planned and approved by regulatory legal acts system that combines a variety of labor protection measures. All of them are aimed at one and only goal - the preservation of human life, his ability to work and health.

If there is no industrial injuries at the enterprise, then this is the highest mark. professional activity engineer, an indicator of his effective training. This also testifies to the properly organized training of all personnel in OT requirements.

Occupational safety engineer, in the performance of his duties, must carry out:

... Organization and control over the exact implementation of labor protection legislation;

... Development of action plans that are aimed at improving health and safety conditions;

... Establishing the causes of accidents at production sites;

... Development of various OSH instructions;

... Conducting briefings for personnel;

... Drawing up applications for individual means protection, overalls, special food:

... Control of the timely passage of medical examinations by employees;

... Participation in labor protection measures at the enterprise and beyond.

As you can see, the O&M engineer has plenty of responsibilities. Their implementation is possible on condition of full mastery of the knowledge that is covered by the curriculum for training this category of specialists. This requires training in special educational institutions, which have the right to carry out labor protection training for workers of different professions.

One of these organizations is the training and consulting center "Development", on the website of which you are now if you are reading these explanations. We are licensed to conduct training

See the most complete list of OSH training programs posted on the TechDoc.ru website. The site contains more than 100 curricula occupational safety training in various professions. To go to the site and familiarize yourself with the list of programs, click on the button below:

How to use the list of programs?

Go to the website to select an occupational health and safety training program. To search for the desired program, press Ctrl + F and enter the name of the profession. If you haven't found the program you need, you can visually view the list by scrolling down the page. After choosing an OSH training program, you can download it. To do this, click on the name of the file with the .zip extension, which is located to the right of the "File name" field. The file will start downloading.

What is a typical OSH training program for?

The head of any organization should not forget that in addition to his main task of "making money", he is also obliged to take care of his employees in terms of ensuring labor safety. One of the conditions for compliance with labor safety is periodic training of employees of the organization who are related to the field of labor protection, as well as employees of the enterprise as a whole. According to the legislation of the Russian Federation, the head of the organization is responsible for the training of his employees.

A generic OSH training program is needed by plant managers and OSH professionals to deliver OSH training within an organization.

Who should be trained in OSH programs?

A complete list of persons who should be trained is given in.

1. Individual entrepreneurs, heads of organizations and their deputies for labor protection, deputy chief engineers for labor protection, managers, specialists, engineers and technical workers who organize, manage and carry out work at workplaces, as well as control and technical supervision of the work, teaching staff educational institutions who teach disciplines on labor protection, managers of industrial practice of students in the field of labor protection, specialists of federal, executive and local authorities in the field of labor protection, members of commissions for testing knowledge of labor protection requirements.

The above mentioned persons undergo training in specialized training centers when hiring, and then once every three years. The occupational safety training program is designed for 40 hours, so the training takes place quite quickly in 1-2 days. The cost of such training is minimal.

2 ... Heads of the security service, specialists of the labor protection service, persons who are entrusted with the duties of organizing labor protection work in the company.

These persons, in addition to the training specified in paragraph 1, improve their qualifications once every five years in training centers. The OSH program is usually 72 hours long, and the cost of such training is 2-3 times higher than training in a 40-hour program.

3. Specialists in labor protection without appropriate specialized education in labor protection pass. Go through the training once. It is designed for 250 - 600 hours, and is a full-fledged training with a diploma in the specialty of labor protection.

4. The workers of the enterprise are trained within the organization. Occupational health and safety training is provided by persons appointed by the employer, including an occupational health and safety specialist. The training uses standard training programs on occupational safety and health by profession.

Where to get training in OSH programs?

Categories of students in labor protection. Training at the training center and organization of training at the enterprise. Formation of a permanent commission for the verification of knowledge (PDK). Check of knowledge. Occupational safety specialist training. Professional standard requirements.

Training in labor protection is regulated by the Resolution of the Ministry of Labor of the Russian Federation and the Ministry of Education of the Russian Federation of January 13, 2003 N 1/29 "On Approval of the Procedure for Training in Labor Protection and Testing the Knowledge of Labor Protection Requirements of Employees of Organizations." Popularly referred to as "Order 1/29".

There is GOST 12.0.004-2015 Occupational Safety Standards System (SSBT). Organization of occupational safety training. General Provisions. From March 1, 2017, it replaced GOST 12.0.004-90.

Of course, you can apply this GOST, but you must definitely use your head. Because if you take a stupidly written document (which it undoubtedly is) and just apply it “head-on”, you get the impression that you don’t understand at all what labor protection is.

Categories of trainees in labor storage

All employees must be trained in labor protection. But we are obliged to train some in a specialized training center, while others can be trained at the enterprise and their knowledge can be tested by our commission.

Be sure to undergo training at the training center:

- Head of the organization;

- Occupational safety specialists (SOT qualified as a safety engineer (specialist) technological processes and production or labor protection with continuous work experience in the field of labor protection for at least five years, within a year after joining the job may not undergo training in labor protection and testing of knowledge of labor protection requirements);

- Immediate supervisors of work (the same who should conduct briefings at the workplace);

- Members of labor protection committees (commissions), incl. members of commissions for testing knowledge of labor protection requirements in the organization;

- Authorized (trusted) persons for labor protection trade unions and other representative bodies authorized by employees.

Managers and specialists of organizations undergo training and regular testing of knowledge of labor protection requirements at least once every three years.

Training centers that provide training in labor protection, in addition to a license for educational activities, must have accreditation from the Ministry of Labor, which gives them the right to conduct such training.

Today, in different training centers, you can find programs designed for a different number of hours. It is important to know that the only difference between the 72-hour program and the 40-hour program is a more in-depth study of the material. All other stories about mandatory requirements for selected categories it's only desire training centers sell your services more expensively.

Training in the organization

All other employees (not related to the above categories) can be trained in their organization.

To test the knowledge of labor protection requirements of employees in organizations, by order of the employer, a commission is created to test knowledge of labor protection requirements, consisting of at least three people who have undergone training in labor protection and tested knowledge of labor protection requirements in the prescribed manner.

The commissions include the heads of organizations and their structural divisions, specialists from labor protection services, chief specialists (technologist, mechanic, power engineer, etc.). Representatives of an elected trade union body representing the interests of employees of this organization, including authorized (trusted) persons for labor protection of trade unions, may take part in the work of the commission. (It is not recommended to include in the permanent commission a specialist who is entrusted with training employees).

During the first month after hiring, the employee is obliged to undergo occupational safety training.

Employee training is carried out according to training programs that the company develops on the basis of approved sample programs.

The procedure for conducting training is determined by the relevant regulation.

Upon completion of the training, the commission must take an exam from the employee, according to the tickets approved by the director.

The commission draws up the result of the knowledge test with a protocol

An employee who has not passed the knowledge test of labor protection requirements is obliged to re-test his knowledge no later than one month. If he did not pass the check and the second time the question of the employee's suitability for the position is raised.

Extraordinary knowledge test

An extraordinary test of knowledge of the labor protection requirements of employees of organizations, regardless of the period of the previous test, is carried out:

- when introducing new or introducing amendments and additions to existing legislative and other normative legal acts containing labor protection requirements. At the same time, only knowledge of these legislative and regulatory legal acts is tested;

- when commissioning new equipment and changes in technological processes that require additional knowledge of workers' labor protection. In this case, the knowledge of labor protection requirements associated with the relevant changes is checked;

- when appointing or transferring employees to another job, if new duties require additional knowledge of labor protection (before they begin to perform their official duties);

- at the request of officials of the federal labor inspectorate, other bodies of state supervision and control, as well as federal executive bodies and executive bodies of the constituent entities of the Russian Federation in the field of labor protection, bodies local government, as well as the employer (or a person authorized by him) in the establishment of violations of labor protection requirements and insufficient knowledge of labor safety and labor protection requirements;

- after accidents and accidents that have occurred, as well as in the event of repeated violations by employees of the organization of the requirements of regulatory legal acts on labor protection;

- with a break in this position for more than one year.

Occupational safety specialist training. Professional standard requirements

In accordance with the Federal Law of 02.05.2015 No. 122-FZ "On Amendments to the Labor Code of the Russian Federation and Articles 11 and 73 Federal law“On education in the Russian Federation” the concept of “professional standard” has changed (Article 195.1 of the Labor Code of the Russian Federation).

According to article 195.3, employers are obliged to apply professional standards in terms of establishing requirements for the qualifications that an employee needs to perform his labor function, if these requirements are established by regulatory legal acts of the Russian Federation.

The position of a labor protection specialist has an established professional standard. (Order of the Ministry of Labor of Russia dated 04.08.2014 N 524n "On the approval of the professional standard" Specialist in the field of labor protection ").

An employee is appointed to the position of COT, either already having the appropriate education, or having undergone professional retraining in the amount of at least 250 hours.

In accordance with the Procedure for the organization and implementation of educational activities for additional professional programs, approved by order of the Ministry of Education and Science of the Russian Federation of July 1, 2013 N 499, the minimum permissible period for the development of programs professional retraining cannot be less than 250 hours. (Be careful, some of the modern training centers have shorter training programs).

A feature of the professional retraining program, in contrast to the second higher education is the exclusion of basic disciplines and the development of exclusively purely professional competencies.

Scenario "March 8" junior group

Scenario "March 8" junior group Scenario of a game program for junior schoolchildren

Scenario of a game program for junior schoolchildren Flowers from Zhostovo: painting on metal

Flowers from Zhostovo: painting on metal Why does the router not distribute the Internet via WiFi and how to fix it?

Why does the router not distribute the Internet via WiFi and how to fix it? SAP program what is it

SAP program what is it Electronic money and payment systems

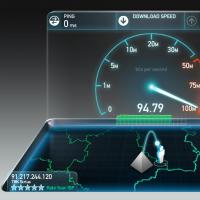

Electronic money and payment systems What is internet speed and how to check it online

What is internet speed and how to check it online